Top 3D Printing Companies Shaping the Landscape: The Future of the 3D Printing Industry

The 3D printing industry has undergone significant growth over the past few years. With advancements in technology and an increasing demand for customized and on-demand products, the sector shows no signs of slowing down. This article highlights the top players in the 3D printing industry, their contributions, and the future potential of this rapidly evolving field.

As the 3D printing industry continues to grow, the demand for 3D-printed products is increasing. According to the latest 3D printing statistics, the market is expected to reach $34.5 billion by 2028, growing at a CAGR of 18.1% from 2023 to 2028.

Leading 3D Printing Companies

There is a myriad of 3D printing companies contributing to this growth. However, these are the trailblazers that are shaping the future of this industry:

1. Stratasys: A Pioneer in the 3D Printing Space

Stratasys, a U.S.-based company, is a leading player in the 3D printing industry. The company prides itself on its rich history, tracing its roots back to the early stages of 3D printing technology.

1.1. Overview and Key Features

Stratasys has been at the forefront of the 3D printing revolution since 1989. Its technology has found applications in various sectors, including aerospace, healthcare, and consumer products. The company offers solutions for both small-scale and large-scale production, catering to a wide range of customers.

1.2. Financial Performance

Despite facing some difficulties, Stratasys has managed to maintain a relatively stable financial performance. As of December 2022, the company reported a revenue of $659.2 million with a market cap of $818.8 million.

1.3. Future Prospects

Stratasys continues to invest in research and development, promising even more innovative solutions for the future. Despite the challenges posed by production times, the company's dedication to improving its technology is evident.

2. 3D Systems: Innovating Since the Dawn of 3D Printing

3D Systems, another U.S.-based company, has been a significant player in the 3D printing industry since its inception in 1989. The company has been instrumental in developing new technologies that have shaped the industry.

2.1. Overview and Key Features

3D Systems boasts a wide range of products, from small desktop printers to commercial ones. The company's technology includes stereolithography, selective laser sintering, multi-jet printing, and more.

2.2. Financial Performance

Despite some financial challenges, 3D Systems remains a key player in the market with a revenue of $556.2 million and a market cap of $1.2 billion as of December 2022.

2.3. Future Prospects

3D Systems continues to innovate, promising more advanced and precise 3D printing technologies. The company's diverse range of services and products demonstrates its commitment to meeting the varying needs of its customers.

3. Materialise: Bridging the Gap with Software Solutions

Materialise, a Belgium-based company, has been providing 3D printing solutions and related software for three decades.

3.1. Overview and Key Features

Materialise offers platforms to facilitate the development of 3D printing applications in industries such as healthcare, automotive, aerospace, and art and design. The company started with anatomical models in dental and hearing aid products and has since expanded into other sectors.

3.2. Financial Performance

As of December 2022, Materialise reported a revenue of $245.2 million. Despite a slight dip in its total return, the company maintains a healthy market cap of $562.3 million.

3.3. Future Prospects

Materialise continues to play a significant role in the industry by providing software solutions that help other companies and individuals unlock the full potential of 3D printing.

4. GE: Utilizing 3D Printing in Manufacturing

General Electric (GE) is a global digital industrial company that has adopted 3D printing in its manufacturing process.

4.1. Overview and Key Features

The GE Additive team specializes in hardware, software, and consulting services for 3D-printed metal parts. Utilizing direct metal laser melting and electron beam melting processes, the company builds custom part solutions for various industries.

4.2. Financial Performance

While specific financial data for GE's additive manufacturing division is not available, the company's overall commitment to 3D printing technology demonstrates its belief in the industry's potential.

4.3. Future Prospects

With its dedicated additive manufacturing team, GE continues to explore and expand the applications of 3D printing in various sectors, including orthopedic implants, aircrafts, and automobiles.

5. Protolabs: Speeding Up the Manufacturing Process

Protolabs, based in the U.S., has revolutionized the manufacturing process by introducing a quick-turnaround prototyping company.

5.1. Overview and Key Features

Since its foundation in 1999, Protolabs has grown to include more than 100 printers capable of printing materials ranging from metal to plastic. The company's primary business services include injection molding, sheet metal fabrication, and 3D printing.

5.2. Financial Performance

As of December 2022, Protolabs reported a revenue of $496.4 million, with a net income of $23.5 million. The company's market cap stands at $722.1 million.

5.3. Future Prospects

Protolabs continues to innovate, bridging the gap between the prototyping phase and small-batch testing, thereby speeding up the overall manufacturing process.

6. Desktop Metal: Bringing Metal 3D Printing to the Desk

Desktop Metal, founded in 2015, designs and manufactures 3D printing systems, offering solutions for various industries.

6.1. Overview and Key Features

Desktop Metal's technology pairs 3D printing systems with performance-driven materials, applications, and technologies. The company's printers are used in various sectors, including automotive, consumer goods, machine design, and manufacturing tooling.

6.2. Financial Performance

Despite some financial challenges, Desktop Metal reported a revenue of $205.1 million with a market cap of $495.4 million as of December 2022.

6.3. Future Prospects

With its commitment to providing high-speed and reliable 3D printing solutions, Desktop Metal is poised to make significant strides in the industry.

7. HP: Expanding Beyond PCs

Known for its computers and related hardware, HP has also ventured into the 3D printing space.

7.1. Overview and Key Features

HP offers personal 3D printers, 3D-printing software, services, and varied materials. Its Jet Fusion printer series are multi-material compatible and scalable to manufacturing needs.

7.2. Financial Performance

While specific financial data for HP's 3D printing division is not available, the company's investment in the technology indicates a belief in its potential.

7.3. Future Prospects

HP continues to innovate in the 3D printing space, providing solutions for industries ranging from aerospace to consumer goods and electronics.

8. Carbon: Reinventing the Fusing Process

Carbon, a California-based 3D printing company, has developed a unique fusing process that enhances the finish and strength of 3D-printed products.

8.1. Overview and Key Features

Carbon's Digital Light Synthesis smooths away the "seams" often produced by 3D printing, resulting in a seamless finish and a stronger product.

8.2. Financial Performance

Specific financial data for Carbon is not publicly available. However, the company's innovative technology makes it a noteworthy player in the industry.

8.3. Future Prospects

Carbon continues to innovate, focusing on improving the quality and strength of 3D-printed products.

9. Formlabs: Offering Precision in 3D Printing

Formlabs, based in Massachusetts, produces a range of 3D printers, from desktop to industrial formats.

9.1. Overview and Key Features

Formlabs' printers, such as the Form 3+ and Form 3L, use laser light and a flexible tank of resin to print quickly and precisely. The printers can create features as narrow as one thousandth of an inch.

9.2. Financial Performance

Specific financial data for Formlabs is not publicly available. However, its innovative technology and wide range of applications make it a significant player in the industry.

9.3. Future Prospects

Formlabs continues to innovate, providing precise and quick 3D printing solutions for various applications, including footwear and medical devices.

10. Xometry: Simplifying Prototyping

Xometry, a Maryland-based company, began as a tool to simplify the prototyping process.

10.1. Overview and Key Features

Xometry's software provides access to six different types of 3D printers on demand and at instantly-quoted rates. This model has attracted high-profile clients, such as BMW, which relies on Xometry for custom trim, logos, and other unique touches.

10.2. Financial Performance

Specific financial data for Xometry is not publicly available. However, the company's significant client base indicates a healthy business model.

10.3. Future Prospects

Xometry continues to simplify the prototyping process, providing on-demand access to various 3D printers and materials.

11. CELLINK: Pioneering Bioprinting

CELLINK, based in Massachusetts, focuses on "bioprinting" – the 3D printing of bone, cartilage, and potentially functioning human organs.

11.1. Overview and Key Features

CELLINK's patent-pending universal bioink is a soup of stem cells and alginate derived from brown seaweed. This substance is used in more than 700 labs worldwide. The company also makes 3D printers, software, and specialty inks designed for specific types of tissue.

11.2. Financial Performance

Specific financial data for CELLINK is not publicly available. However, the company's pioneering work in bioprinting makes it a significant player in the industry.

11.3. Future Prospects

CELLINK continues to innovate in the field of bioprinting, aiming to revolutionize healthcare with its 3D-printed tissues and organs.

12. Markforged: Accelerating Prototype Manufacturing

Markforged, based in Massachusetts, provides industrial 3D printers that can print hardier substances, including nylon, carbon fiber, and even metal.

12.1. Overview and Key Features

Markforged's industrial printers are integrated into factories worldwide. These printers have helped transform supply chains by accelerating prototype and replacement part manufacturing.

12.2. Financial Performance

Specific financial data for Markforged is not publicly available. However, the company's innovative technology and wide range of applications make it a significant player in the industry.

12.3. Future Prospects

Markforged continues to innovate, focusing on providing hardier materials for 3D printing and accelerating the manufacturing process.

3D Printing Industry Growth

The 3D printing industry growth is projected to skyrocket in the coming years. The increasing adoption of the technology in industries such as healthcare, automotive, and aerospace is a major driver of this growth.

3D Printing Trends

Several 3D printing trends are shaping the future of the industry:

1. Increased Use of Metal Materials

Although plastic remains the most common material used in 3D printing, the use of metal materials is on the rise. Metal 3D printing offers the advantages of high strength, durability, and heat resistance.

2. Development of New Materials

Companies in the 3D printing industry are continually developing new materials to enhance the capabilities of 3D printers. These include flexible materials, high-performance thermoplastics, and even edible materials for food printing.

3. Bioprinting

The use of 3D printing in the medical field is set to revolutionize healthcare. Bioprinting, the process of creating cell patterns using 3D printing technology, could potentially be used to print tissues and organs in the future.

3D Printing News

Recent Advancements in 3D Printing Technology

One of the key advancements in 3D printing technology is the development of faster and more efficient printers. Traditional 3D printers were known for their slow speeds, but with the introduction of new printing techniques and improved hardware, printing times have been significantly reduced. This has allowed for larger and more complex objects to be printed in a shorter amount of time, making 3D printing a viable option for mass production.

Another significant advancement in 3D printing technology is the development of new materials. In the early days of 3D printing, plastic was the primary material used. However, researchers and engineers have since developed a wide range of materials that can be used for 3D printing, including metals, ceramics, and even food. These new materials have expanded the possibilities of 3D printing, allowing for the creation of more durable and functional objects.

In addition to faster printers and new materials, advancements have also been made in the precision and accuracy of 3D printing. This has been achieved through the development of more sophisticated software and improved control systems. These advancements have made it possible to create highly detailed and intricate objects with a level of precision that was once unimaginable.

Applications of 3D Printing in Various Industries

The applications of 3D printing are vast and diverse, with almost every industry finding innovative ways to incorporate this technology into their processes. Let's explore some of the most exciting applications of 3D printing in various industries.

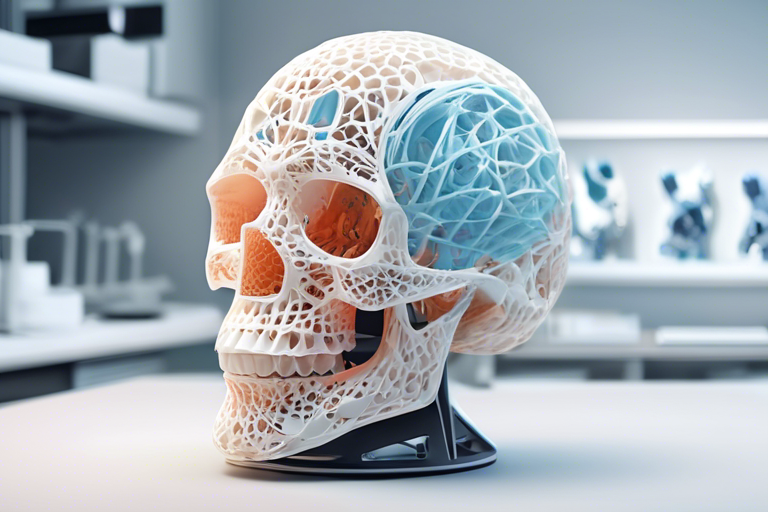

In the healthcare industry, 3D printing has proven to be a game-changer. It has enabled the creation of custom medical devices, such as prosthetics and implants, that are tailored to the individual patient's needs. This not only improves patient outcomes but also reduces costs and eliminates the need for traditional manufacturing processes that can be time-consuming and expensive. Additionally, 3D printing has been used to create models of organs and tissues for surgical planning and medical training purposes.

In the aerospace industry, 3D printing has revolutionized the manufacturing process. Traditionally, aerospace components were manufactured using subtractive methods, where excess material was removed from a larger block. However, 3D printing allows for the creation of complex geometries and lightweight structures that are impossible to achieve with traditional manufacturing methods. This has led to significant improvements in aircraft performance and fuel efficiency.

The automotive industry has also embraced 3D printing, particularly in the prototyping stage. 3D printing allows for the rapid production of prototypes, enabling manufacturers to test and refine designs before committing to expensive tooling and production processes. This not only speeds up the development process but also reduces costs and improves overall design quality.

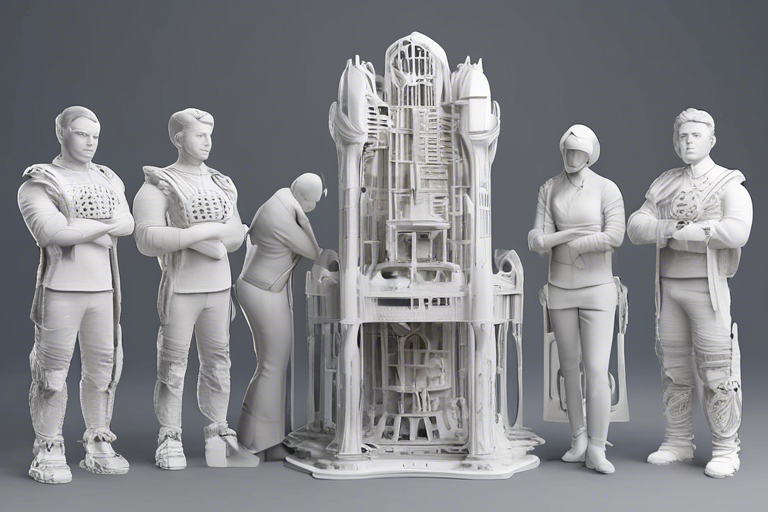

In the architecture industry, 3D printing has opened up new possibilities in design and construction. It has been used to create intricate architectural models, allowing architects and clients to visualize and refine their designs. Additionally, 3D printing has been utilized in the construction of small-scale structures, such as houses and pavilions, showcasing the potential for large-scale 3D printed buildings in the future.

These are just a few examples of how 3D printing is being used in various industries. From healthcare to aerospace, automotive to architecture, 3D printing is transforming the way we design, manufacture, and innovate.

80% of the Forbes Global 2000 B2B companies rely on MarketsandMarkets to identify growth opportunities in emerging technologies and use cases that will have a positive revenue impact.

- Food Packaging Market Size Set for Strong Growth Through 2030 Amid Rising Demand for Convenience Foods

- Fertilizers Industry Set to Grow at 4.1% CAGR Through 2030

- Leading Automated Guided Vehicle Companies 2024: An In-depth Analysis

- CHARGED UP: SHIFT TO E-MOBILITY AND THE EVOLUTION OF TRANSPORTATION

- Global Automotive Market: Predictions For 2024

Impact of 3D Printing on Manufacturing Processes

The impact of 3D printing on manufacturing processes cannot be overstated. This disruptive technology has the potential to revolutionize the way we produce goods, offering numerous advantages over traditional manufacturing methods.

One of the key advantages of 3D printing is the ability to create complex geometries and intricate designs that would be impossible to achieve with traditional manufacturing methods. This opens up new possibilities in product design, allowing for the creation of highly customized and personalized products. Additionally, 3D printing eliminates the need for expensive tooling and molds, reducing upfront costs and enabling small-scale production runs.

Another significant impact of 3D printing on manufacturing processes is the reduction in material waste. Traditional manufacturing methods often result in significant material waste, as excess material is removed from a larger block. However, 3D printing is an additive process, where material is added layer by layer, minimizing waste and optimizing material usage. This not only reduces costs but also has positive environmental implications.

Future Trends and Possibilities in 3D Printing

The future of 3D printing is bright, with numerous trends and possibilities on the horizon. As technology continues to advance and new innovations emerge, we can expect to see exciting developments in the field of 3D printing.

One of the key trends in 3D printing is the use of multi-material printing. Currently, most 3D printers are limited to printing with a single material at a time. However, researchers are working on developing printers that can print with multiple materials simultaneously, opening up new possibilities for creating objects with unique properties and functionalities.

Another trend in 3D printing is the development of bioprinting, which involves using living cells to create 3D printed organs and tissues. This has the potential to revolutionize the field of medicine, offering new solutions for organ transplantation and regenerative medicine. While still in the early stages of development, bioprinting holds great promise for the future.

Additionally, advancements in 3D scanning technology are expected to play a significant role in the future of 3D printing. 3D scanning allows for the creation of digital models of real-world objects, which can then be 3D printed. This opens up new possibilities for replicating and recreating existing objects, as well as for reverse engineering and design optimization.

Furthermore, the development of 3D printing networks and marketplaces is likely to drive the adoption of 3D printing on a larger scale. These platforms connect designers, manufacturers, and consumers, making it easier to access 3D printing services and collaborate on projects. This democratization of 3D printing has the potential to transform the way we create and consume goods.

As we look to the future, it is clear that 3D printing will continue to evolve and disrupt industries. From multi-material printing to bioprinting, 3D scanning to 3D printing networks, the possibilities are endless. The only limit is our imagination.

Notable 3D Printing Projects and Success Stories

Across the globe, there have been numerous notable 3D printing projects and success stories that highlight the potential of this groundbreaking technology. Let's take a look at some of the most impressive and inspiring examples.

In the healthcare industry, 3D printing has been used to create custom prosthetics for individuals in need. One notable project is the e-NABLE community, a global network of volunteers who use 3D printing to create prosthetic hands for children. These prosthetics are low-cost, lightweight, and fully functional, transforming the lives of those who receive them.

In the aerospace industry, Airbus has been exploring the use of 3D printing for aircraft components. They successfully printed a titanium bracket for the Airbus A350 XWB aircraft, reducing its weight by 45% compared to the traditionally manufactured version. This not only improves fuel efficiency but also reduces manufacturing costs.

The automotive industry has also seen impressive 3D printing projects. Local Motors, a US-based car manufacturer, created the world's first 3D printed car, the Strati. This fully functional electric vehicle was printed using a large-scale 3D printer and showcased the potential for 3D printing in the automotive industry.

In the field of architecture, the MX3D Bridge project in Amsterdam is a prime example of the possibilities of 3D printing. The project involves the creation of a 3D printed stainless steel pedestrian bridge, using robots to print the structure layer by layer. This innovative project showcases the potential for large-scale 3D printed structures.

These are just a few examples of the many impressive 3D printing projects and success stories that have emerged in recent years. These projects highlight the limitless possibilities of 3D printing and the transformative impact it can have on industries and communities.

3D Printing in Healthcare and Medical Fields

3D printing has had a profound impact on the healthcare and medical fields, revolutionizing patient care, medical research, and education. Let's explore some of the key applications of 3D printing in healthcare.

One of the most significant applications of 3D printing in healthcare is in the creation of custom medical devices. 3D printing allows for the production of personalized prosthetics, orthotics, and implants that are tailored to each individual patient's needs. This improves patient outcomes and comfort, as well as reduces costs and manufacturing time.

In addition to custom medical devices, 3D printing has been used to create anatomical models for surgical planning and medical education. These models provide surgeons with a better understanding of complex anatomical structures and allow for more accurate preoperative planning. They also serve as valuable educational tools, helping medical students and trainees visualize and learn about the human body in a more hands-on and interactive way.

Another exciting application of 3D printing in healthcare is in the field of regenerative medicine. Researchers are exploring the use of 3D bioprinting to create living tissues and organs that can be used for transplantation. This has the potential to address the shortage of donor organs and eliminate the need for immunosuppressive drugs, as the organs would be created using the patient's own cells.

Furthermore, 3D printing has been used to create drug delivery systems that can release medication in a controlled and personalized manner. This allows for more precise dosing and targeted drug delivery, improving the efficacy and safety of treatments.

The possibilities of 3D printing in healthcare are vast and continue to expand as technology advances. From custom medical devices to anatomical models, regenerative medicine to personalized drug delivery systems, 3D printing is transforming the way we approach healthcare and improving patient outcomes.

3D Printing Materials and Their Properties

The choice of materials is a critical aspect of 3D printing, as it directly impacts the properties and performance of the printed objects. Let's explore some of the most commonly used 3D printing materials and their properties.

One of the most widely used materials in 3D printing is thermoplastics. Thermoplastics are a type of plastic that can be melted and solidified repeatedly without undergoing any significant chemical change. This makes them ideal for 3D printing, as they can be easily melted and extruded through the printer nozzle. Some common thermoplastics used in 3D printing include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol).

Another popular material in 3D printing is metal. Metal 3D printing involves the use of metal powders that are selectively melted and fused together using heat or lasers. This allows for the creation of complex metal parts with excellent mechanical properties. Common metals used in 3D printing include titanium, aluminum, stainless steel, and cobalt-chrome alloy.

In addition to plastics and metals, 3D printing can also be done with ceramics. Ceramic 3D printing involves the use of ceramic powders that are mixed with a binder and selectively deposited layer by layer. After printing, the object is fired in a kiln to remove the binder and sinter the ceramic particles, resulting in a fully dense ceramic object. Ceramic 3D printing is used in a wide range of applications, including dental crowns, custom implants, and even art pieces.

Furthermore, there are also specialty materials available for specific applications. For example, flexible filaments can be used to create objects with rubber-like properties, making them ideal for creating prototypes of flexible parts or wearable devices. Conductive filaments contain conductive additives and can be used to create objects with electrical conductivity, such as sensors or circuit boards.

The choice of materials in 3D printing depends on various factors, including the desired properties of the printed object, its intended application, and the capabilities of the 3D printer. With the continuous development of new materials, the possibilities of 3D printing are expanding, allowing for the creation of objects with increasingly diverse properties and functionalities.

In conclusion, the 3D printing industry is undergoing significant growth and development. Companies like Stratasys, 3D Systems, Materialise, GE, Protolabs, Desktop Metal, HP, Carbon, Formlabs, Xometry, CELLINK, and Markforged are at the forefront of this revolution, providing innovative solutions and contributing to the industry's growth. With advancements in technology and increasing demand for customized products, the future of the 3D printing industry looks promising.

For More Information Please Download PDF Brochure

Authored by Shweta Surender, MarketsandMarkets