TABLE OF CONTENTS

1 INTRODUCTION (Page No. - 52)

1.1 STUDY OBJECTIVES

1.2 MARKET DEFINITION

1.3 INCLUSIONS AND EXCLUSIONS

1.4 STUDY SCOPE

FIGURE 1 MARKETS COVERED

1.4.1 REGIONAL SCOPE

1.4.2 YEARS CONSIDERED

1.5 CURRENCY AND PRICING

1.6 LIMITATIONS

1.7 STAKEHOLDERS

1.8 SUMMARY OF CHANGES

1.9 RECESSION ANALYSIS

2 RESEARCH METHODOLOGY (Page No. - 59)

2.1 RESEARCH DATA

FIGURE 2 INDUSTRIAL ROBOTICS MARKET: RESEARCH DESIGN

2.1.1 SECONDARY DATA

2.1.1.1 Major secondary sources

2.1.1.2 Key data from secondary sources

2.1.2 PRIMARY DATA

2.1.2.1 Key data from primary sources

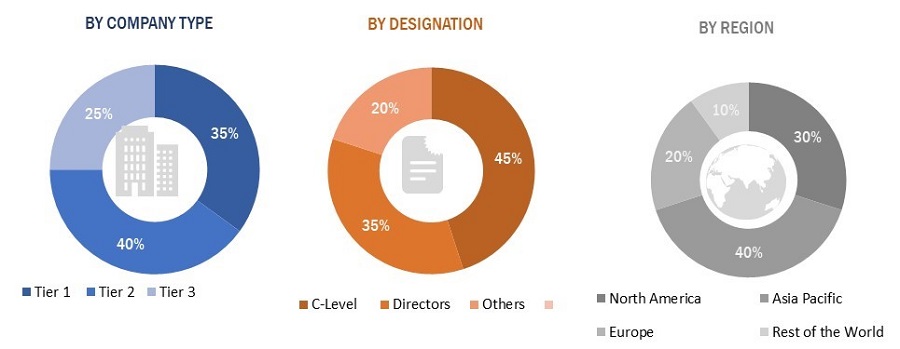

2.1.2.2 Breakdown of primaries

2.1.3 SECONDARY AND PRIMARY RESEARCH

2.1.3.1 Key industry insights

2.2 MARKET SIZE ESTIMATION

FIGURE 3 RESEARCH FLOW OF MARKET SIZE ESTIMATION

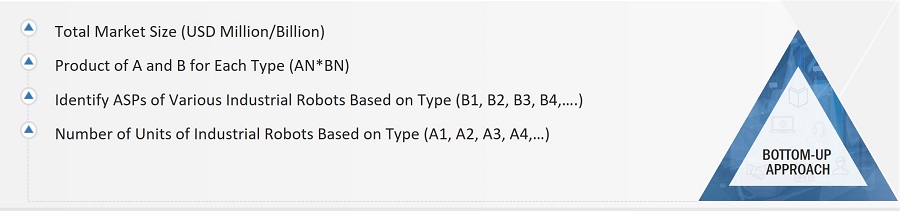

2.2.1 BOTTOM-UP APPROACH

FIGURE 4 MARKET SIZE ESTIMATION METHODOLOGY: APPROACH 1–DEMAND-SIDE: DEMAND FOR INDUSTRIAL ROBOTS IN US

FIGURE 5 INDUSTRIAL ROBOTS MARKET: BOTTOM-UP APPROACH

2.2.1.1 Capturing market share using bottom-up approach (demand side)

2.2.2 TOP-DOWN APPROACH

FIGURE 6 MARKET SIZE ESTIMATION METHODOLOGY: APPROACH 2 (SUPPLY-SIDE): REVENUE GENERATED FROM PRODUCTS IN INDUSTRIAL ROBOTS MARKET (EXCLUDING PRICES OF PERIPHERALS, SOFTWARE, AND SYSTEM ENGINEERING)

FIGURE 7 INDUSTRIAL ROBOTS MARKET: TOP-DOWN APPROACH

2.2.2.1 Capturing market share using top-down analysis (supply side)

2.3 MARKET BREAKDOWN AND DATA TRIANGULATION

FIGURE 8 DATA TRIANGULATION

2.4 RESEARCH ASSUMPTIONS

2.4.1 ASSUMPTIONS

2.5 IMPACT OF RECESSION

TABLE 1 RISK ASSESSMENT: INDUSTRIAL ROBOTS MARKET

2.6 RISK ASSESSMENT

2.7 RESEARCH LIMITATIONS

3 EXECUTIVE SUMMARY (Page No. - 74)

3.1 INDUSTRIAL ROBOTS MARKET: RECESSION IMPACT

FIGURE 9 RECESSION IMPACT: GDP GROWTH PROJECTION TILL 2023 FOR MAJOR ECONOMIES

FIGURE 10 RECESSION IMPACT ON INDUSTRIAL ROBOTS MARKET, 2019–2028 (USD MILLION)

FIGURE 11 IN TERMS OF VOLUME, ARTICULATED ROBOTS TO DOMINATE TRADITIONAL INDUSTRIAL ROBOTS MARKET DURING FORECAST PERIOD

FIGURE 12 MARKET FOR 16.01–60.00 KG SEGMENT TO RECORD HIGHEST CAGR DURING FORECAST PERIOD

FIGURE 13 TRADITIONAL INDUSTRIAL ROBOTICS MARKET FOR SOFTWARE & PROGRAMMING EXPECTED TO DISPLAY SIGNIFICANT GROWTH RATE DURING FORECAST PERIOD

FIGURE 14 HANDLING APPLICATIONS TO HOLD LARGEST SHARE OF INDUSTRIAL ROBOTS MARKET IN 2023

FIGURE 15 MARKET FOR FOOD & BEVERAGES INDUSTRY TO RECORD HIGHEST CAGR DURING FORECAST PERIOD

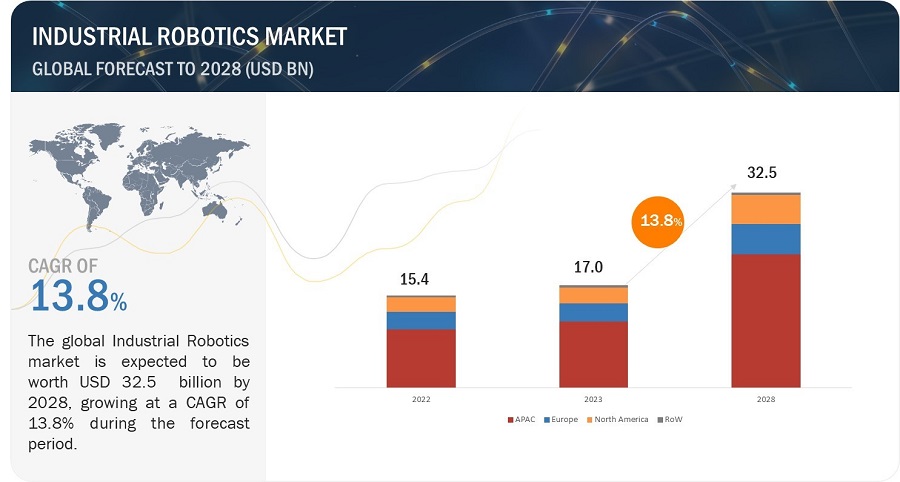

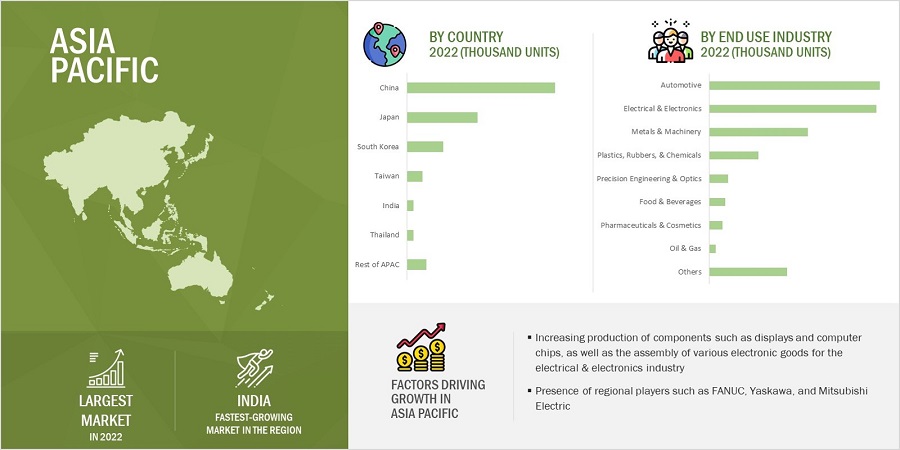

FIGURE 16 ASIA PACIFIC ACCOUNTED FOR LARGEST MARKET SHARE IN 2022

4 PREMIUM INSIGHTS (Page No. - 81)

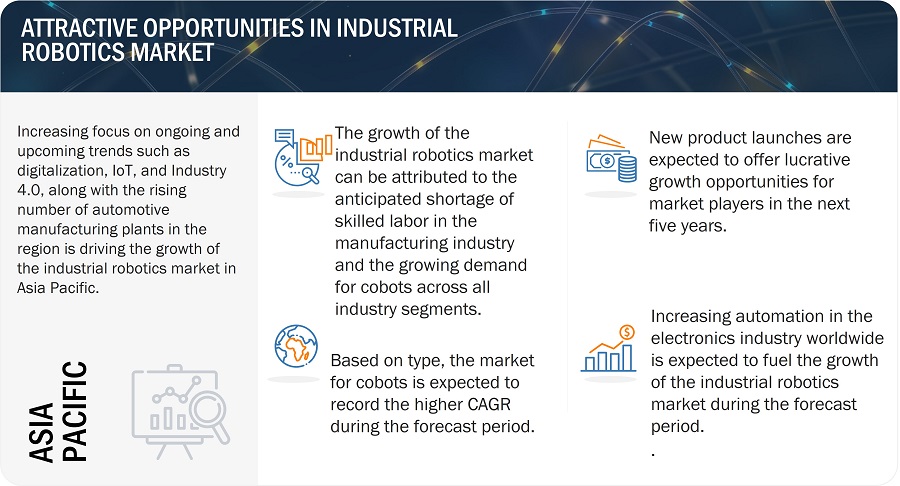

4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN INDUSTRIAL ROBOTS MARKET

FIGURE 17 ANTICIPATED SHORTAGE OF SKILLED LABOR IN MANUFACTURING INDUSTRY TO FUEL MARKET GROWTH

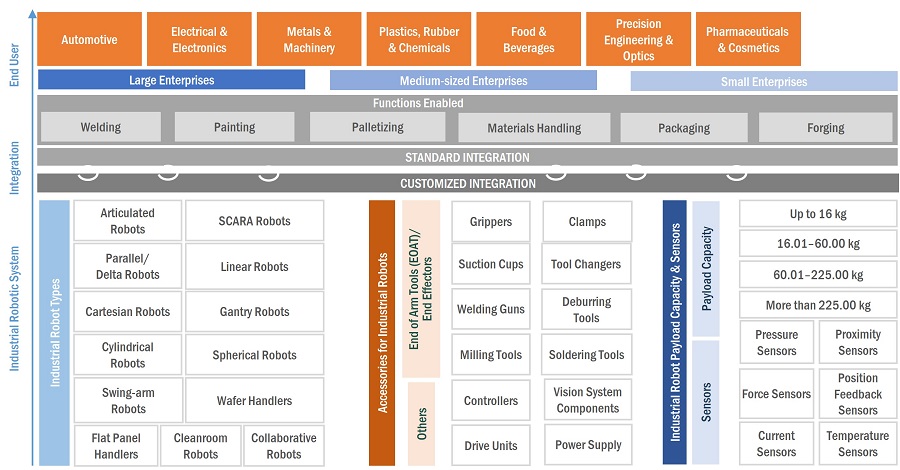

4.2 INDUSTRIAL ROBOTS MARKET, BY TYPE

FIGURE 18 TRADITIONAL ROBOTS TO HOLD LARGER SHARE OF MARKET IN 2023

4.3 INDUSTRIAL ROBOTS MARKET, BY PAYLOAD

FIGURE 19 UPTO 16.00 KG TO ACCOUNT FOR LARGEST SHARE OF INDUSTRIAL ROBOTS MARKET IN 2023

4.4 INDUSTRIAL ROBOTICS MARKET, BY COMPONENT

FIGURE 20 INDUSTRIAL ROBOTS TO LEAD MARKET OF TRADITIONAL INDUSTRIAL ROBOTICS MARKET IN 2023

4.5 INDUSTRIAL ROBOTS MARKET, BY APPLICATION

FIGURE 21 HANDLING APPLICATION TO SECURE LARGEST MARKET SHARE IN 2023

4.6 INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY

FIGURE 22 AUTOMOTIVE INDUSTRY TO CLAIM LARGEST SHARES OF INDUSTRIAL ROBOTS MARKET IN 2023

4.7 TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY COUNTRY

FIGURE 23 CHINA TO HOLD LARGEST SHARE OF GLOBAL INDUSTRIAL ROBOTS MARKET IN 2022

5 MARKET OVERVIEW (Page No. - 85)

5.1 INTRODUCTION

5.2 MARKET DYNAMICS

FIGURE 24 INDUSTRIAL ROBOTICS MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

5.2.1 DRIVERS

5.2.1.1 Rising demand for collaborative robots across industries

FIGURE 25 INCREASED ADOPTION OF COLLABORATIVE ROBOTS EXPECTED DURING FORECAST PERIOD

5.2.1.2 Anticipated shortage of skilled labor in manufacturing industries

5.2.1.3 Growing adoption of Industry 4.0

5.2.1.4 Rising demand for automation in manufacturing and logistics

5.2.1.5 AI and digital automation to enhance capabilities of industrial robots

FIGURE 26 DRIVERS FOR INDUSTRIAL ROBOTICS MARKET AND THEIR IMPACT

5.2.2 RESTRAINTS

5.2.2.1 High cost of deployment for SMEs

5.2.2.2 Complexity and integration difficulties

FIGURE 27 RESTRAINTS FOR INDUSTRIAL ROBOTICS MARKET AND THEIR IMPACT

5.2.3 OPPORTUNITIES

5.2.3.1 Increasing automation in electronics industry

5.2.3.2 Emergence of Industry 5.0

FIGURE 28 OPPORTUNITIES FOR INDUSTRIAL ROBOTICS MARKET AND THEIR IMPACT

5.2.4 CHALLENGES

5.2.4.1 Safety concerns related to industrial robotics systems

5.2.4.2 Workforce skills and interoperability

FIGURE 29 CHALLENGES FOR INDUSTRIAL ROBOTICS MARKET AND THEIR IMPACT

5.3 VALUE CHAIN ANALYSIS

FIGURE 30 VALUE CHAIN ANALYSIS: MAJOR VALUE ADDED TO INDUSTRIAL ROBOTICS MARKET

5.3.1 SUPPLY CHAIN PARTICIPANTS

5.3.1.1 OEMs

TABLE 2 INDUSTRIAL ROBOT OEMS

5.3.1.2 Suppliers

5.3.1.3 Robot integrators

5.3.1.4 Distributors

5.3.1.5 IT/Big data companies

5.3.1.6 Research centers

5.4 MARKET MAP

FIGURE 31 INDUSTRIAL ROBOTICS ECOSYSTEM

TABLE 3 INDUSTRIAL ROBOTICS MARKET: ECOSYSTEM ANALYSIS

5.5 PRICING ANALYSIS

5.5.1 AVERAGE SELLING PRICE OF VARIOUS INDUSTRIAL ROBOTS

TABLE 4 AVERAGE SELLING PRICE OF VARIOUS INDUSTRIAL ROBOTS, BY PAYLOAD CAPACITY

FIGURE 32 AVERAGE SELLING PRICE OF KEY PLAYERS, BY PRODUCT

TABLE 5 AVERAGE SELLING PRICE OF KEY PLAYERS, BY PRODUCT (USD)

5.5.2 AVERAGE SELLING PRICE TREND, BY PAYLOAD CAPACITY

FIGURE 33 INDUSTRIAL ROBOTS MARKET: AVERAGE PRICE BASED ON PAYLOAD CAPACITY

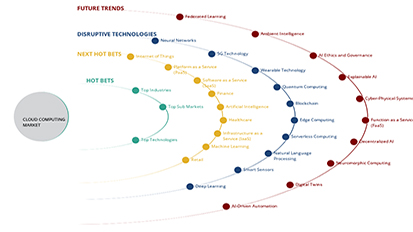

5.6 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

5.6.1 REVENUE SHIFT & NEW REVENUE POCKETS FOR INDUSTRIAL ROBOTICS PROVIDERS

FIGURE 34 REVENUE SHIFT FOR INDUSTRIAL ROBOTICS MARKET

5.7 TECHNOLOGY ANALYSIS

5.7.1 KEY TECHNOLOGY TRENDS

5.7.1.1 Integration of industrial robots and vision systems

5.7.2 COMPLEMENTARY TECHNOLOGIES

5.7.2.1 Penetration of Industrial Internet of Things and AI in industrial manufacturing

5.7.2.2 Adoption of safety sensors in industrial robotics

5.7.3 ADJACENT TECHNOLOGIES

5.7.3.1 Introduction of 5G into industrial manufacturing

5.8 PORTER’S FIVE FORCES ANALYSIS

TABLE 6 INDUSTRIAL ROBOTICS MARKET: PORTER’S FIVE FORCES ANALYSIS

FIGURE 35 INDUSTRIAL ROBOTICS MARKET: PORTER’S FIVE FORCES ANALYSIS

5.8.1 INTENSITY OF COMPETITIVE RIVALRY

5.8.2 BARGAINING POWER OF SUPPLIERS

5.8.3 BARGAINING POWER OF BUYERS

5.8.4 THREAT OF SUBSTITUTES

5.8.5 THREAT OF NEW ENTRANTS

5.9 KEY STAKEHOLDERS & BUYING CRITERIA

5.9.1 KEY STAKEHOLDERS IN BUYING PROCESS

FIGURE 36 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END USE INDUSTRIES

TABLE 7 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END USE INDUSTRIES

5.9.2 BUYING CRITERIA

FIGURE 37 KEY BUYING CRITERIA FOR TOP THREE END USE INDUSTRIES

TABLE 8 KEY BUYING CRITERIA FOR TOP THREE END USE INDUSTRIES

5.10 CASE STUDY ANALYSIS

TABLE 9 USE OF HRC SAFETY SOLUTION ENHANCES PRODUCTIVITY

TABLE 10 ROBOTIC INTEGRATION PROJECT REDUCES TIME TO MARKET

TABLE 11 UTILIZING DRIVERLESS ROBOTS ENHANCES EFFICIENCY AND MEET MARKET DEMAND IN COMPONENT DISTRIBUTION

TABLE 12 AUTOMATION OF QUALITY TESTING PROCESS IN GLASS LABORATORY WITH COLLABORATIVE ROBOTICS

TABLE 13 ROBOTIC PAD INSERTER REVOLUTIONIZES PRODUCE PACKAGING EFFICIENCY

TABLE 14 EMERSON PROFESSIONAL TOOLS AG OPTS FOR COLLABORATIVE ROBOT THAT MEETS THEIR REQUIREMENTS

TABLE 15 ROBOTICS TECHNOLOGY FACILITATES BULK PALLETIZING

5.11 TRADE ANALYSIS AND TARIFF ANALYSIS

5.11.1 TRADE ANALYSIS

5.11.1.1 Trade data for HS code 847950

FIGURE 38 IMPORT DATA, BY COUNTRY, 2018−2022 (USD MILLION)

FIGURE 39 EXPORT DATA, BY COUNTRY, 2018−2022 (USD MILLION)

5.11.2 TARIFF ANALYSIS

TABLE 16 TARIFF FOR INDUSTRIAL ROBOTS EXPORTED BY US, 2022

TABLE 17 TARIFF FOR INDUSTRIAL ROBOTS EXPORTED BY CHINA, 2022

TABLE 18 TARIFF FOR INDUSTRIAL ROBOTS EXPORTED BY GERMANY, 2022

5.12 PATENT ANALYSIS

FIGURE 40 COMPANIES WITH HIGHEST NUMBER OF PATENT APPLICATIONS IN LAST 10 YEARS

TABLE 19 TOP 20 PATENT OWNERS IN LAST 10 YEARS

FIGURE 41 NUMBER OF PATENTS GRANTED PER YEAR, 2012−2023

5.12.1 MAJOR PATENTS

TABLE 20 MAJOR PATENTS IN INDUSTRIAL ROBOTICS MARKET

5.13 KEY CONFERENCES AND EVENTS, 2023–2024

TABLE 21 INDUSTRIAL ROBOTICS MARKET: CONFERENCES AND EVENTS

5.14 REGULATORY LANDSCAPE

5.14.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS RELATED TO INDUSTRIAL ROBOTICS

TABLE 22 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 23 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 24 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 25 ROW: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

5.14.2 STANDARDS AND REGULATIONS RELATED TO INDUSTRIAL ROBOTICS

TABLE 26 INTERNATIONAL: SAFETY STANDARDS FOR INDUSTRIAL ROBOTICS MARKET

TABLE 27 NORTH AMERICA: SAFETY STANDARDS FOR INDUSTRIAL ROBOTICS MARKET

TABLE 28 EUROPE: SAFETY STANDARDS FOR INDUSTRIAL ROBOTICS MARKET

TABLE 29 ASIA PACIFIC: SAFETY STANDARDS FOR INDUSTRIAL ROBOTICS MARKET

TABLE 30 ROW: SAFETY STANDARDS FOR INDUSTRIAL ROBOTICS MARKET

6 REFURBISHMENT OF INDUSTRIAL ROBOTS (QUALITATIVE) (Page No. - 139)

6.1 INTRODUCTION

6.2 KEY PARAMETERS

6.2.1 CYCLE TIME

6.2.2 PERFORMANCE & ACCURACY

6.2.3 WEAR & TEAR

6.3 REFURBISHMENT TRENDS FOR VARIOUS INDUSTRIAL ROBOTS

6.4 TOP FIVE INDUSTRIES ADOPTING REFURBISHED ROBOTS

6.4.1 AUTOMOTIVE

6.4.2 METALS & MACHINERY

6.4.3 ELECTRICAL & ELECTRONICS

6.4.4 SMALL WORKSHOPS

6.4.5 FOOD & BEVERAGES

6.4.6 PHARMACEUTICALS & HEALTHCARE

6.4.7 LOGISTICS & WAREHOUSING

6.5 KEY PRACTICES OF INDUSTRIAL ROBOT OEMS

6.5.1 FOCUS ON NEW ROBOTS

6.5.2 POST-SALES SERVICE

6.5.3 RESEARCH & DEVELOPMENT

6.5.4 CUSTOMIZATION & FLEXIBILITY

6.5.5 INTEGRATION & CONNECTIVITY

6.5.6 SAFETY STANDARDS AND COMPLIANCE

6.5.7 USE CASE: JACOBS DOUWE EGBERTS ENHANCES PERFORMANCE WITH ABB IRB640 REFURBISHED ROBOT

6.5.8 USE CASE: OSSID MACHINERY BOOSTS RELIABILITY PERFORMANCE WITH AND MITSUBISHI ELECTRIC AUTOMATION PORTFOLIO

7 INDUSTRIAL ROBOTICS MARKET, BY TYPE (Page No. - 148)

7.1 INTRODUCTION

FIGURE 42 COLLABORATIVE ROBOTS TO RECORD HIGHER CAGR DURING FORECAST PERIOD

TABLE 31 INDUSTRIAL ROBOTS MARKET, BY TYPE, 2019–2022 (USD MILLION)

TABLE 32 INDUSTRIAL ROBOTS MARKET, BY TYPE, 2023–2028 (USD MILLION)

TABLE 33 INDUSTRIAL ROBOTS MARKET, BY TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 34 INDUSTRIAL ROBOTS MARKET, BY TYPE, 2023–2028 (THOUSAND UNITS)

7.2 TRADITIONAL ROBOTS

7.2.1 INCREASING ADOPTION OF ARTICULATED ROBOTS TO FUEL MARKET GROWTH

FIGURE 43 ARTICULATED ROBOTS TO REGISTER LARGEST SHIPMENT IN 2023

TABLE 35 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY TYPE, 2019–2022 (USD MILLION)

TABLE 36 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY TYPE, 2023–2028 (USD MILLION)

TABLE 37 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 38 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY TYPE, 2023–2028 (THOUSAND UNITS)

TABLE 39 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY TYPE, 2019–2022 (USD MILLION)

TABLE 40 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY TYPE, 2023–2028 (USD MILLION)

7.2.2 ARTICULATED ROBOTS

7.2.2.1 Increased flexibility and performance of complex movements to boost demand

FIGURE 44 REPRESENTATION OF 6-AXIS ARTICULATED ROBOT

TABLE 41 ARTICULATED ROBOTS: SUMMARY

FIGURE 45 PHARMACEUTICALS & COSMETICS INDUSTRY TO DISPLAY HIGHEST CAGR DURING FORECAST PERIOD

TABLE 42 ARTICULATED ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 43 ARTICULATED ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 44 ARTICULATED ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (THOUSAND UNITS)

TABLE 45 ARTICULATED ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (THOUSAND UNITS)

TABLE 46 ARTICULATED ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 47 ARTICULATED ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 48 ARTICULATED ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 49 ARTICULATED ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

TABLE 50 ARTICULATED ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022(THOUSAND UNITS)

TABLE 51 ARTICULATED ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 52 ARTICULATED ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 53 ARTICULATED ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

7.2.3 SCARA ROBOTS

7.2.3.1 High-speed capabilities to drive demand

FIGURE 46 REPRESENTATION OF 4-AXIS SCARA ROBOT

TABLE 54 SCARA ROBOTS: SUMMARY

FIGURE 47 SCARA ROBOTS HOLD FOR MAJOR SHARE IN HANDLING APPLICATIONS DURING FORECAST PERIOD

TABLE 55 SCARA ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 56 SCARA ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 57 SCARA ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (THOUSAND UNITS)

TABLE 58 SCARA ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (THOUSAND UNITS)

TABLE 59 SCARA ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 60 SCARA ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 61 SCARA ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 62 SCARA ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

TABLE 63 SCARA ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 64 SCARA ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 65 SCARA ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 66 SCARA ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

7.2.4 PARALLEL ROBOTS

7.2.4.1 Improved accuracy and super dynamic performance to augment market size

FIGURE 48 REPRESENTATION OF PARALLEL ROBOT

TABLE 67 PARALLEL ROBOTS: SUMMARY

FIGURE 49 PRECISION ENGINEERING & OPTICS INDUSTRY TO RECORD HIGHEST CAGR DURING FORECAST PERIOD

TABLE 68 PARALLEL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 69 PARALLEL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 70 PARALLEL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (THOUSAND UNITS)

TABLE 71 PARALLEL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (THOUSAND UNITS)

TABLE 72 PARALLEL ROBOTS: INDUSTRIAL ROBOTICS MARKET FOR PARALLEL ROBOTS, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 73 PARALLEL ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 74 PARALLEL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 75 PARALLEL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

TABLE 76 PARALLEL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 77 PARALLEL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 78 PARALLEL ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 79 PARALLEL ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

7.2.5 CARTESIAN ROBOTS

7.2.5.1 Simple movements and ease of programmability to augment market size

FIGURE 50 REPRESENTATION OF CARTESIAN ROBOT

TABLE 80 CARTESIAN ROBOTS: SUMMARY

FIGURE 51 PROCESSING APPLICATION TO WITNESS HIGHEST CAGR DURING FORECAST PERIOD

TABLE 81 CARTESIAN ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 82 CARTESIAN ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 83 CARTESIAN ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (THOUSAND UNITS)

TABLE 84 CARTESIAN ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (THOUSAND UNITS)

TABLE 85 INDUSTRIAL ROBOTICS MARKET FOR CARTESIAN ROBOTS, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 86 INDUSTRIAL ROBOTICS MARKET FOR CARTESIAN ROBOTS, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 87 CARTESIAN ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 88 CARTESIAN ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

TABLE 89 CARTESIAN ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 90 CARTESIAN ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 91 CARTESIAN ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 92 CARTESIAN ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

7.2.6 CYLINDRICAL ROBOTS

7.2.6.1 Compatibility with various automation technologies to drive market

TABLE 93 CYLINDRICAL ROBOTS: SUMMARY

FIGURE 52 HANDLING APPLICATION TO WITNESS MAJOR SHARE IN CYLINDRICAL ROBOTS MARKET

TABLE 94 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 95 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 96 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (THOUSAND UNITS)

TABLE 97 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (THOUSAND UNITS)

TABLE 98 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 99 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 100 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 101 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

TABLE 102 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 103 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 104 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 105 CYLINDRICAL ROBOTS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

7.2.7 OTHERS

7.2.7.1 Spherical robots

7.2.7.1.1 Ability to navigate challenging terrains to drive demand

TABLE 106 SPHERICAL ROBOTS: SUMMARY

7.2.7.2 Swing-arm robots

7.2.7.2.1 Ongoing development in sensing AI to drive market

TABLE 107 SWING-ARM ROBOTS: SUMMARY

FIGURE 53 OTHER ROBOTS TO BE PRIMARILY ADOPTED FOR HANDLING APPLICATIONS DURING FORECAST PERIOD

TABLE 108 OTHERS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 109 OTHERS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 110 OTHERS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (THOUSAND UNITS)

TABLE 111 OTHERS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (THOUSAND UNITS)

TABLE 112 OTHERS: INDUSTRIAL ROBOTICS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 113 OTHERS: INDUSTRIAL ROBOTICS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 114 OTHERS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 115 OTHERS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

TABLE 116 OTHERS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 117 OTHERS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 118 OTHERS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 119 OTHERS: INDUSTRIAL ROBOTICS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

7.3 COLLABORATIVE ROBOTS

7.3.1 EASE OF USE AND LOW-COST DEPLOYMENT TO DRIVE MARKET

TABLE 120 COLLABORATIVE INDUSTRIAL ROBOTS: SUMMARY

TABLE 121 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY VALUE AND VOLUME, 2019–2022

TABLE 122 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY VALUE AND VOLUME, 2023–2028

8 INDUSTRIAL ROBOTS MARKET, BY PAYLOAD (Page No. - 205)

8.1 INTRODUCTION

FIGURE 54 INDUSTRIAL ROBOTS WITH PAYLOAD RANGE OF 16.01 KG–60.00 KG TO WITNESS HIGHEST GROWTH RATE DURING FORECAST PERIOD

TABLE 123 INDUSTRIAL ROBOTS MARKET, BY PAYLOAD, 2019–2022 (USD MILLION)

TABLE 124 INDUSTRIAL ROBOTS MARKET, BY PAYLOAD, 2023–2028 (USD MILLION)

TABLE 125 INDUSTRIAL ROBOTS MARKET, BY PAYLOAD, 2019–2022 (THOUSAND UNITS)

TABLE 126 INDUSTRIAL ROBOTS MARKET, BY PAYLOAD, 2023–2028 (THOUSAND UNITS)

8.2 UP TO 16.00 KG

8.2.1 HIGH ACCURACY AND FLEXIBILITY TO STRENGTHEN MARKET

TABLE 127 TYPES OF INDUSTRIAL ROBOTS WITH UP TO 16. OO KG PAYLOAD CAPACITY

8.3 16.01–60.00 KG

8.3.1 AUTOMOTIVE INDUSTRY TO OFFER LUCRATIVE OPPORTUNITIES

TABLE 128 TYPES OF INDUSTRIAL ROBOTS WITH 16.01–60.00 KG PAYLOAD CAPACITY

8.4 60.01–225.00 KG

8.4.1 ENSURED SAFETY IN INDUSTRIES WITH HEAVY AND CUMBERSOME MATERIALS TO BOOST DEMAND

TABLE 129 TYPES OF INDUSTRIAL ROBOTS WITH 60.01–225.00 KG PAYLOAD CAPACITY

8.5 MORE THAN 225.00 KG

8.5.1 REDUCED RISK OF HUMAN INJURY AND IMPROVED PRODUCTIVITY TO AUGMENT MARKET SIZE

TABLE 130 TYPES OF INDUSTRIAL ROBOTS WITH MORE THAN 225.00 KG PAYLOAD CAPACITY

9 INDUSTRIAL ROBOTICS MARKET, BY COMPONENT (Page No. - 213)

9.1 INTRODUCTION

FIGURE 55 SOFTWARE & PROGRAMMING TO WITNESS HIGHEST GROWTH RATE DURING FORECAST PERIOD

TABLE 131 TRADITIONAL INDUSTRIAL ROBOTICS MARKET, BY COMPONENT, 2019–2022 (USD BILLION)

TABLE 132 TRADITIONAL INDUSTRIAL ROBOTICS MARKET, BY COMPONENT, 2023–2028 (USD BILLION)

9.2 INDUSTRIAL ROBOTS

9.2.1 PHARMACEUTICAL AND FOOD AND BEVERAGE SECTORS TO GENERATE SIGNIFICANT DEMAND

9.3 ROBOT ACCESSORIES

9.3.1 GROWING INVESTMENT IN RESEARCH AND DEVELOPMENT TO DRIVE MARKET

9.3.2 END EFFECTORS

9.3.2.1 Growth in welding and painting applications to boost demand

9.3.2.2 Welding guns

9.3.2.2.1 Suitable for high-volume production applications

9.3.2.3 Grippers

9.3.2.3.1 Growing need to handle sensitive objects cautiously to boost demand

9.3.2.3.2 Mechanical

9.3.2.3.2.1 Cost-effective nature to drive market

9.3.2.3.3 Electric

9.3.2.3.3.1 Programmability and seamless integration with other robotic systems to boost demand

9.3.2.3.4 Magnetic

9.3.2.3.4.1 Capability to function during blackout to drive market

TABLE 133 COMPARISON OF MECHANICAL, ELECTRIC, AND MAGNETIC GRIPPERS

9.3.2.4 Tool changers

9.3.2.4.1 Increasing need to use robotic tool changers for multiple functioning of robot arms

9.3.2.5 Clamps

9.3.2.5.1 Space-saving benefits and enhanced safety to strengthen market

9.3.2.6 Suction cup

9.3.2.6.1 Inexpensive and versatility to benefit market growth

9.3.2.7 Others

9.3.2.7.1 Deburring tools

9.3.2.7.2 Milling tools

9.3.2.7.3 Soldering tools

9.3.2.7.4 Painting tools

9.3.2.7.5 Screwdrivers

9.3.3 CONTROLLERS

9.3.3.1 Ease of programming and minimizing compatibility issues to drive demand

9.3.4 DRIVE UNITS

9.3.4.1 Ability to enhance capacity of robot to boost demand

9.3.4.2 Hydraulic drive

9.3.4.2.1 Ability of being used around highly explosive materials to boost demand

9.3.4.3 Electric drives

9.3.4.3.1 Low maintenance requirements to augment market size

9.3.4.4 Pneumatic drives

9.3.4.4.1 Ease of installation to benefit market

9.3.5 VISION SYSTEMS

9.3.5.1 Reduced human involvement and operational benefits to strengthen market

9.3.6 SENSORS

9.3.6.1 Incorporation of sensors in industrial robots to gather information about environment to strengthen market

9.3.7 POWER SUPPLY

9.3.7.1 Incorporation of safety features like voltage regulation to drive market

9.3.8 OTHERS

9.4 ADDITIONAL HARDWARE

9.4.1 SAFETY FENCING

9.4.1.1 Addresses safety concerns by machine perimeter guarding, among others

9.4.2 FIXTURES

9.4.2.1 Enhanced flexibility in manufacturing to expand segment growth

9.4.3 CONVEYORS

9.4.3.1 High efficiency in manufacturing processes to augment market size

9.5 SYSTEM ENGINEERING

9.5.1 FACILITATES INSTALLATION OF ROBOTIC SYSTEM IN INDUSTRIAL ENVIRONMENT

9.6 SOFTWARE & PROGRAMMING

9.6.1 EASE OF MAINTENANCE AND OPERATIONS OF INDUSTRIAL ROBOTS TO BOOST DEMAND

10 INDUSTRIAL ROBOTS MARKET, BY APPLICATION (Page No. - 229)

10.1 INTRODUCTION

FIGURE 56 HANDLING APPLICATION TO HOLD LARGEST SHARE OF INDUSTRIAL ROBOTS MARKET IN 2028

TABLE 134 INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 135 INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

TABLE 136 INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (THOUSAND UNITS)

TABLE 137 INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (THOUSAND UNITS)

TABLE 138 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (USD MILLION)

TABLE 139 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (USD MILLION)

FIGURE 57 HANDLING APPLICATION TO HOLD LARGEST SIZE IN TRADITIONAL INDUSTRIAL ROBOTS MARKET IN 2028

TABLE 140 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (THOUSAND UNITS)

TABLE 141 TRADITIONAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (THOUSAND UNITS)

FIGURE 58 HANDLING APPLICATION TO HOLD LARGEST SIZE OF COLLABORATIVE INDUSTRIAL ROBOTS MARKET IN 2028

TABLE 142 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION 2019–2022 (USD MILLION)

TABLE 143 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION 2023–2028 (USD MILLION)

TABLE 144 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2019–2022 (THOUSAND UNITS)

TABLE 145 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY APPLICATION, 2023–2028 (THOUSAND UNITS)

10.2 HANDLING

10.2.1 INCREASING DEMAND FOR PALLETIZING ROBOTS IN MATERIAL HANDLING APPLICATIONS

TABLE 146 COMPANIES OFFERING INDUSTRIAL ROBOTS FOR HANDLING APPLICATION

TABLE 147 HANDLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 148 HANDLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 149 HANDLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 150 HANDLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

TABLE 151 HANDLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 152 HANDLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 153 HANDLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 154 HANDLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

10.2.2 PICK & PLACE

10.2.2.1 Increasing demand in electronics and food & beverages sectors to benefit market

10.2.3 MATERIAL HANDLING

10.2.3.1 Increased productivity in manufacturing and logistics to drive market

10.2.4 PACKAGING & PALLETIZING

10.2.4.1 Integration of advanced sensors and grippers in packaging and palletizing robots to boost operation

10.3 ASSEMBLING & DISASSEMBLING

10.3.1 INCREASING DEMAND FOR ROBOTS OFFERING SPEED AND PRECISION TO BOOST DEMAND

TABLE 155 COMPANIES OFFERING INDUSTRIAL ROBOTS FOR ASSEMBLING & DISASSEMBLING APPLICATION

TABLE 156 ASSEMBLING & DISASSEMBLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 157 ASSEMBLING & DISASSEMBLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 158 ASSEMBLING & DISASSEMBLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 159 ASSEMBLING & DISASSEMBLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

TABLE 160 ASSEMBLING & DISASSEMBLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 161 ASSEMBLING & DISASSEMBLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 162 ASSEMBLING & DISASSEMBLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 163 ASSEMBLING & DISASSEMBLING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

10.4 WELDING & SOLDERING

10.4.1 RISING DEMAND FOR ROBOTS WITH HOLLOW WRISTS TO DRIVE MARKET

TABLE 164 COMPANIES OFFERING INDUSTRIAL ROBOTS FOR WELDING & SOLDERING APPLICATION

TABLE 165 WELDING & SOLDERING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 166 WELDING & SOLDERING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 167 WELDING & SOLDERING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 168 WELDING & SOLDERING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

TABLE 169 WELDING & SOLDERING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 170 WELDING & SOLDERING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 171 WELDING & SOLDIERING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 172 WELDING & SOLDIERING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

10.5 DISPENSING

10.5.1 INCREASING DEMAND IN PHARMACEUTICAL AND COSMETIC INDUSTRIES TO DELIVER HIGH PRECISION

TABLE 173 COMPANIES OFFERING INDUSTRIAL ROBOTS FOR DISPENSING APPLICATION

10.5.2 GLUING

10.5.2.1 Increasing demand for highly precise adhesive dispensers from automotive and electronics industries to boost market

10.5.3 PAINTING

10.5.3.1 Need for explosion- and contamination-proof robots to drive market

10.5.4 FOOD DISPENSING

10.5.4.1 Technological advances to result in rising demand for robots in food processing

TABLE 174 DISPENSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 175 DISPENSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 176 DISPENSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 177 DISPENSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

TABLE 178 DISPENSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 179 DISPENSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 180 DISPENSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 181 DISPENSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

10.6 PROCESSING

10.6.1 FOOD AND BEVERAGE INDUSTRY TO OFFER LUCRATIVE OPPORTUNITIES

TABLE 182 COMPANIES OFFERING INDUSTRIAL ROBOTS FOR PROCESSING APPLICATION

10.6.2 GRINDING AND POLISHING

10.6.2.1 Time and cost savings while machining complex designs to boost demand

10.6.3 MILLING

10.6.3.1 High degree of freedom due to multi-axis robot arms to boost demand

10.6.4 CUTTING

10.6.4.1 Automotive industry to generate significant demand

TABLE 183 PROCESSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 184 PROCESSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 185 PROCESSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 186 PROCESSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

TABLE 187 PROCESSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 188 PROCESSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 189 PROCESSING APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 190 INDUSTRIAL ROBOTS MARKET FOR PROCESSING APPLICATION, BY TRADITIONAL ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

10.7 CLEANROOM

10.7.1 INCREASING USE IN PHARMACEUTICALS, ELECTRONICS, AND SEMICONDUCTOR MANUFACTURING

TABLE 191 CLEANROOM APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 192 CLEANROOM APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 193 CLEANROOM APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 194 CLEANROOM APPLICATION: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

TABLE 195 CLEANROOM APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 196 CLEANROOM APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 197 CLEANROOM APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 198 CLEANROOM APPLICATION: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

10.8 OTHERS

TABLE 199 COMPANIES OFFERING INDUSTRIAL ROBOTS FOR OTHER APPLICATIONS

10.8.1 INSPECTION & QUALITY TESTING

10.8.1.1 Automotive sector to offer lucrative opportunities

10.8.2 DIE-CASTING & MOLDING

10.8.2.1 Improved worker safety by minimizing exposure to hazardous materials to boost demand

TABLE 200 OTHER APPLICATIONS: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (USD MILLION)

TABLE 201 OTHER APPLICATIONS: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 202 OTHER APPLICATIONS: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 203 OTHER APPLICATIONS: INDUSTRIAL ROBOTS MARKET, BY ROBOT TYPE, 2023–2028 (THOUSAND UNITS)

TABLE 204 OTHER APPLICATIONS: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOTS TYPE, 2019–2022 (USD MILLION)

TABLE 205 OTHER APPLICATIONS: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOT TYPE, 2023–2028 (USD MILLION)

TABLE 206 OTHER APPLICATIONS: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOTS TYPE, 2019–2022 (THOUSAND UNITS)

TABLE 207 OTHER APPLICATIONS: INDUSTRIAL ROBOTS MARKET, BY TRADITIONAL ROBOTS TYPE, 2023–2028 (THOUSAND UNITS)

11 INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY (Page No. - 267)

11.1 INTRODUCTION

FIGURE 59 AUTOMOTIVE INDUSTRY TO ACCOUNT FOR LARGEST SIZE OF INDUSTRIAL ROBOTS MARKET DURING FORECAST PERIOD

TABLE 208 INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 209 INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

TABLE 210 INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 211 INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

FIGURE 60 AUTOMOTIVE TO ACCOUNT FOR LARGEST MARKET SIZE OF TRADITIONAL INDUSTRIAL ROBOTS MARKET DURING FORECAST PERIOD

TABLE 212 TRADITIONAL INDUSTRIAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 213 TRADITIONAL INDUSTRIAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

TABLE 214 TRADITIONAL INDUSTRIAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 215 TRADITIONAL INDUSTRIAL ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

FIGURE 61 ELECTRICAL & ELECTRONICS INDUSTRY TO RECORD HIGHEST CAGR IN COLLABORATIVE ROBOTS MARKET DURING FORECAST PERIOD

TABLE 216 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (USD MILLION)

TABLE 217 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (USD MILLION)

TABLE 218 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 219 COLLABORATIVE ROBOTS: INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

11.2 AUTOMOTIVE

11.2.1 INCREASING NEED FOR CONSISTENCY AND REPEATABILITY TO DRIVE MARKET

FIGURE 62 AUTOMOTIVE INDUSTRY IN ASIA PACIFIC TO MAINTAIN LARGEST SHARE DURING FORECAST PERIOD

TABLE 220 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 221 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 222 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN NORTH AMERICA, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 223 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN NORTH AMERICA , BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 224 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN EUROPE, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 225 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN EUROPE, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 226 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ASIA PACIFIC, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 227 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 228 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ROW, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 229 AUTOMOTIVE INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ROW, BY REGION, 2023–2028 (THOUSAND UNITS)

11.3 ELECTRICAL & ELECTRONICS

11.3.1 EXTENSIVE USE OF SCARA ROBOTS FOR HANDLING APPLICATIONS TO DRIVE MARKET

FIGURE 63 IN TERMS OF VOLUME, MARKET FOR ELECTRICAL & ELECTRONICS INDUSTRY IN ASIA PACIFIC TO RECORD HIGHEST CAGR DURING FORECAST PERIOD

TABLE 230 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR ELECTRICAL & ELECTRONICS INDUSTRY, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 231 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR ELECTRICAL & ELECTRONICS INDUSTRY, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 232 ELECTRICAL & ELECTRONICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN NORTH AMERICA, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 233 ELECTRICAL & ELECTRONICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN NORTH AMERICA, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 234 ELECTRICAL & ELECTRONICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN EUROPE, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 235 ELECTRICAL & ELECTRONICS: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN EUROPE, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 236 ELECTRICAL & ELECTRONICS: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ASIA PACIFIC, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 237 ELECTRICAL & ELECTRONICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 238 ELECTRICAL & ELECTRONICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ROW, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 239 ELECTRICAL & ELECTRONICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ROW, BY REGION, 2023–2028 (THOUSAND UNITS)

11.4 METALS & MACHINERY

11.4.1 INCREASING DEMAND FOR COST-EFFECTIVE PRODUCTION COMPONENTS TO BENEFIT MARKET

FIGURE 64 MARKET FOR METALS & MACHINERY INDUSTRY IN ASIA PACIFIC TO RECORD HIGHEST CAGR DURING FORECAST PERIOD

TABLE 240 TRADITIONAL INDUSTRIAL ROBOTS MARKET, FOR METALS & MACHINERY INDUSTRY BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 241 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR METALS & MACHINERY INDUSTRY, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 242 METALS & MACHINERY INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 243 METALS & MACHINERY INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 244 METALS & MACHINERY INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 245 METALS & MACHINERY INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 246 METALS & MACHINERY INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 247 METALS & MACHINERY INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 248 METALS & MACHINERY INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 249 METALS & MACHINERY INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2023–2028 (THOUSAND UNITS)

11.5 PLASTICS, RUBBER & CHEMICALS

11.5.1 RISING USE OF ROBOTIC MOLDING AND HANDLING FOR VARIOUS PURPOSES TO STRENGTHEN MARKET

FIGURE 65 PLASTICS, RUBBER & CHEMICALS INDUSTRY IN ASIA PACIFIC TO MAINTAIN LARGEST MARKET SHARE DURING FORECAST PERIOD

TABLE 250 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 251 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 252 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 253 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 254 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 255 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 256 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR PLASTICS, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 257 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 258 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 259 PLASTICS, RUBBER & CHEMICALS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2023–2028 (THOUSAND UNITS)

11.6 FOOD & BEVERAGES

11.6.1 GROWING REQUIREMENT FOR FOOD-GRADE AND WATER-RESISTANT ROBOTS

FIGURE 66 ASIA PACIFIC TO BE FASTEST-GROWING REGION IN TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY DURING FORECAST PERIOD

TABLE 260 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 261 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 262 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY IN NORTH AMERICA, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 263 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY IN NORTH AMERICA, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 264 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY IN EUROPE, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 265 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY IN EUROPE, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 266 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY IN ASIA PACIFIC, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 267 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 268 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY IN ROW, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 269 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR FOOD & BEVERAGES INDUSTRY IN ROW, BY REGION, 2023–2028 (THOUSAND UNITS)

11.7 PRECISION ENGINEERING & OPTICS

11.7.1 RISING USE OF ROBOTS FOR BUFFING AND POLISHING TASKS

FIGURE 67 MARKET FOR PRECISION ENGINEERING & OPTICS INDUSTRY IN ASIA PACIFIC TO RECORD HIGHEST CAGR DURING FORECAST PERIOD

TABLE 270 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR PRECISION ENGINEERING & OPTICS INDUSTRY, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 271 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR PRECISION ENGINEERING & OPTICS INDUSTRY, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 272 PRECISION ENGINEERING & OPTICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 273 PRECISION ENGINEERING & OPTICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 274 PRECISION ENGINEERING & OPTICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 275 PRECISION ENGINEERING & OPTICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 276 PRECISION ENGINEERING & OPTICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 277 PRECISION ENGINEERING & OPTICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 278 PRECISION ENGINEERING & OPTICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 279 PRECISION ENGINEERING & OPTICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2023–2028 (THOUSAND UNITS)

11.8 PHARMACEUTICALS & COSMETICS

11.8.1 USE OF ROBOTS IN HOSPITALS AND RESEARCH LABORATORIES FOR HANDLING AND DISPENSING APPLICATIONS TO DRIVE MARKET

FIGURE 68 PHARMACEUTICALS & COSMETICS INDUSTRY IN ASIA PACIFIC TO CLAIM LARGEST SHARE DURING FORECAST PERIOD

TABLE 280 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 281 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 282 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 283 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 284 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 285 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 286 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 287 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 288 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 289 PHARMACEUTICALS & COSMETICS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2023–2028 (THOUSAND UNITS)

11.9 OIL & GAS

11.9.1 IMPROVED OIL AND GAS SAFETY, PRODUCTIVITY, AND QUALITY TO DRIVE MARKET

FIGURE 69 OIL & GAS INDUSTRY IN ASIA PACIFIC TO SECURE LARGEST SHARE DURING FORECAST PERIOD

TABLE 290 OIL & GAS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 291 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR OIL & GAS INDUSTRIES, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 292 OIL & GAS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 293 OIL & GAS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 294 OIL & GAS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 295 OIL & GAS INDUSTRIES: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 296 OIL & GAS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 297 OIL & GAS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 298 OIL & GAS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 299 OIL & GAS INDUSTRY: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2023–2028 (THOUSAND UNITS)

11.1 OTHERS

FIGURE 70 OTHER INDUSTRIES IN ASIA PACIFIC TO SECURE LARGEST SHARE DURING FORECAST PERIOD

TABLE 300 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR OTHER INDUSTRIES, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 301 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR OTHER INDUSTRIES, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 302 OTHER INDUSTRIES: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 303 OTHER INDUSTRIES: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN NORTH AMERICA, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 304 OTHER INDUSTRIES: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 305 OTHER INDUSTRIES: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN EUROPE, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 306 TRADITIONAL INDUSTRIAL ROBOTS MARKET FOR OTHER INDUSTRIES IN ASIA PACIFIC, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 307 OTHER INDUSTRIES: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 308 OTHER INDUSTRIES: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 309 OTHER INDUSTRIES: TRADITIONAL INDUSTRIAL ROBOTS MARKET, IN ROW, BY REGION, 2023–2028 (THOUSAND UNITS)

12 INDUSTRIAL ROBOTS MARKET, BY REGION (Page No. - 325)

12.1 INTRODUCTION

FIGURE 71 INDUSTRIAL ROBOTS MARKET, BY REGION

TABLE 310 INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (USD MILLION)

TABLE 311 INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (USD MILLION)

TABLE 312 INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 313 INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 314 TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (USD MILLION)

TABLE 315 TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (USD MILLION)

TABLE 316 TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 317 TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 318 COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (USD MILLION)

TABLE 319 COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (USD MILLION)

TABLE 320 COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 321 COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (THOUSAND UNITS)

12.2 NORTH AMERICA

12.2.1 PROLIFERATION OF INDUSTRIAL ROBOTS AMONG REGIONAL AUTOMOTIVE MANUFACTURERS

FIGURE 72 NORTH AMERICA: INDUSTRIAL ROBOTS MARKET SNAPSHOT

FIGURE 73 US TO DOMINATE TRADITIONAL INDUSTRIAL ROBOTS MARKET IN NORTH AMERICA IN 2028

TABLE 322 NORTH AMERICA: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 323 NORTH AMERICA: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 324 NORTH AMERICA: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 325 NORTH AMERICA: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 326 NORTH AMERICA: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2019–2022 (USD MILLION)

TABLE 327 NORTH AMERICA: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2023–2028 (USD MILLION)

TABLE 328 NORTH AMERICA: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 329 NORTH AMERICA: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

12.2.2 IMPACT OF RECESSION ON INDUSTRIAL ROBOTS MARKET IN NORTH AMERICA

12.2.3 US

12.2.3.1 Increasing initiatives to automate business operations in manufacturing sector to drive market

12.2.4 CANADA

12.2.4.1 Increased foreign investments in industrial robots to drive market

12.2.5 MEXICO

12.2.5.1 Engagement in free trade agreements to boost market

12.3 EUROPE

12.3.1 RISING INDUSTRIALIZATION IN GERMANY, FRANCE, SPAIN, AND ITALY TO BOOST DEMAND FOR INDUSTRIAL ROBOTS

FIGURE 74 EUROPE: INDUSTRIAL ROBOTS MARKET SNAPSHOT

FIGURE 75 GERMANY TO DOMINATE TRADITIONAL INDUSTRIAL ROBOTS MARKET IN EUROPE IN 2028

TABLE 330 EUROPE: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 331 EUROPE: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 332 EUROPE: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 333 EUROPE: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY END USE INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 334 EUROPE: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2019–2022 (USD MILLION)

TABLE 335 EUROPE: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2023–2028 (USD MILLION)

TABLE 336 EUROPE: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 337 EUROPE: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

12.3.2 IMPACT OF RECESSION ON INDUSTRIAL ROBOTS MARKET IN EUROPE

12.3.3 GERMANY

12.3.3.1 Growth of automobile industry to drive demand for industrial robots

12.3.4 ITALY

12.3.4.1 Increasing initiatives from players to propel market

12.3.5 FRANCE

12.3.5.1 Rising adoption of electric and hybrid vehicles to drive demand for robots

12.3.6 SPAIN

12.3.6.1 Pharmaceuticals and automotive sectors to create significant demand for industrial robots

12.3.7 UK

12.3.7.1 Strong manufacturing industry to push demand for industrial robots

12.3.8 REST OF EUROPE

12.3.8.1 High labor cost expected to propel industrial robots market

12.4 ASIA PACIFIC

12.4.1 INCREASING GOVERNMENT INITIATIVES PRIORITIZING ADOPTION OF INDUSTRIAL ROBOTS TO DRIVE MARKET GROWTH

FIGURE 76 ASIA PACIFIC: INDUSTRIAL ROBOTS MARKET SNAPSHOT

FIGURE 77 CHINA TO DOMINATE TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ASIA PACIFIC IN 2028

TABLE 338 ASIA PACIFIC: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 339 ASIA PACIFIC: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

TABLE 340 ASIA PACIFIC: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 341 ASIA PACIFIC: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 342 ASIA PACIFIC: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2019–2022 (USD MILLION)

TABLE 343 ASIA PACIFIC: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2023–2028 (USD MILLION)

TABLE 344 ASIA PACIFIC: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY COUNTRY, 2019–2022 (THOUSAND UNITS)

TABLE 345 COLLABORATIVE INDUSTRIAL ROBOTS MARKET IN ASIA PACIFIC, BY COUNTRY, 2023–2028 (THOUSAND UNITS)

12.4.2 IMPACT OF RECESSION ON INDUSTRIAL ROBOTS MARKET IN ASIA PACIFIC

12.4.3 CHINA

12.4.3.1 Growth of automotive and electronics sectors to drive market

12.4.4 SOUTH KOREA

12.4.4.1 Electrical & electronics industry to offer lucrative opportunities

12.4.5 JAPAN

12.4.5.1 Rise in aging population to boost demand for industrial robots

12.4.6 TAIWAN

12.4.6.1 Favorable government policies to drive market

12.4.7 INDIA

12.4.7.1 Growing adoption of robots to benefit market

12.4.8 THAILAND

12.4.8.1 Thailand 4.0 initiative to benefit market

12.4.9 REST OF ASIA PACIFIC

12.5 ROW

FIGURE 78 ROW: INDUSTRIAL ROBOTS MARKET SNAPSHOT

FIGURE 79 MIDDLE EAST & AFRICA TO DOMINATE TRADITIONAL INDUSTRIAL ROBOTS MARKET IN ROW IN 2028

TABLE 346 ROW: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 347 ROW: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (THOUSAND UNITS)

TABLE 348 ROW: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY INDUSTRY, 2019–2022 (THOUSAND UNITS)

TABLE 349 ROW: TRADITIONAL INDUSTRIAL ROBOTS MARKET, BY INDUSTRY, 2023–2028 (THOUSAND UNITS)

TABLE 350 ROW: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (USD MILLION)

TABLE 351 ROW: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (USD MILLION)

TABLE 352 ROW: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY REGION, 2019–2022 (THOUSAND UNITS)

TABLE 353 ROW: COLLABORATIVE INDUSTRIAL ROBOTS MARKET, BY REGION, 2023–2028 (THOUSAND UNITS)

12.5.1 IMPACT OF RECESSION ON INDUSTRIAL ROBOTS MARKET IN ROW

12.5.2 MIDDLE EAST & AFRICA

12.5.2.1 Automation across industries expected to drive market

12.5.3 SOUTH AMERICA

12.5.3.1 Increasing use of robotics in various industries to fuel market growth

13 COMPETITIVE LANDSCAPE (Page No. - 367)

13.1 INTRODUCTION

13.2 KEY PLAYER STRATEGIES

TABLE 354 OVERVIEW OF STRATEGIES DEPLOYED BY KEY PLAYERS IN INDUSTRIAL ROBOTS MARKET

13.2.1 PRODUCT PORTFOLIO

13.2.2 REGIONAL FOCUS

13.2.3 MANUFACTURING FOOTPRINT

13.2.4 ORGANIC/INORGANIC GROWTH STRATEGIES

13.3 MARKET SHARE ANALYSIS, 2022

FIGURE 80 INDUSTRIAL ROBOTS MARKET SHARE ANALYSIS, 2022

TABLE 355 INDUSTRIAL ROBOTS MARKET: DEGREE OF COMPETITION

13.4 REVENUE ANALYSIS OF TOP PLAYERS IN INDUSTRIAL ROBOTS MARKET

FIGURE 81 5-YEAR REVENUE ANALYSIS OF TOP PLAYERS IN INDUSTRIAL ROBOTS MARKET

13.5 COMPANY EVALUATION MATRIX, 2022

13.5.1 STARS

13.5.2 PERVASIVE PLAYERS

13.5.3 EMERGING LEADERS

13.5.4 PARTICIPANTS

FIGURE 82 INDUSTRIAL ROBOTS MARKET: COMPANY EVALUATION MATRIX, 2022

13.6 START-UP/SME EVALUATION QUADRANT

13.6.1 PROGRESSIVE COMPANIES

13.6.2 RESPONSIVE COMPANIES

13.6.3 DYNAMIC COMPANIES

13.6.4 STARTING BLOCKS

FIGURE 83 INDUSTRIAL ROBOTS MARKET: START-UP/SME EVALUATION QUADRANT, 2022

13.7 COMPANY PRODUCT FOOTPRINT

TABLE 356 COMPANY PRODUCT FOOTPRINT

TABLE 357 TYPE OFFERING FOOTPRINT

TABLE 358 END-USER INDUSTRY FOOTPRINT

TABLE 359 REGIONAL FOOTPRINT

13.8 COMPETITIVE BENCHMARKING

TABLE 360 INDUSTRIAL ROBOTS MARKET: KEY START-UPS/SMES

TABLE 361 INDUSTRIAL ROBOTS MARKET: COMPETITIVE BENCHMARKING OF KEY START-UPS/SMES

13.9 COMPETITIVE SCENARIO AND TRENDS

13.9.1 PRODUCT LAUNCHES

TABLE 362 INDUSTRIAL ROBOTS MARKET: PRODUCT LAUNCHES, 2019–2023

13.9.2 DEALS

TABLE 363 INDUSTRIAL ROBOTS MARKET: DEALS, 2019–2023

13.9.3 OTHERS

TABLE 364 INDUSTRIAL ROBOTS MARKET: OTHERS, 2019–2023

14 COMPANY PROFILES (Page No. - 390)

(Business Overview, Products/Solutions/Services Offered, Recent Developments, and MnM View (Key strengths/Right to Win, Strategic Choices Made, and Weaknesses and Competitive Threats))*

14.1 KEY PLAYERS

14.1.1 ABB

TABLE 365 ABB: BUSINESS OVERVIEW

FIGURE 84 ABB: COMPANY SNAPSHOT

TABLE 366 ABB: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.1.2 YASKAWA ELECTRIC CORPORATION

TABLE 367 YASKAWA ELECTRIC CORPORATION: BUSINESS OVERVIEW

FIGURE 85 YASKAWA ELECTRIC CORPORATION: COMPANY SNAPSHOT

TABLE 368 YASKAWA ELECTRIC CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.1.3 FANUC CORPORATION

TABLE 369 FANUC CORPORATION: BUSINESS OVERVIEW

FIGURE 86 FANUC CORPORATION: COMPANY SNAPSHOT

TABLE 370 FANUC CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.1.4 KUKA AG

TABLE 371 KUKA AG: BUSINESS OVERVIEW

FIGURE 87 KUKA AG: COMPANY SNAPSHOT

TABLE 372 KUKA AG: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.1.5 MITSUBISHI ELECTRIC CORPORATION

TABLE 373 MITSUBISHI ELECTRIC CORPORATION: BUSINESS OVERVIEW

FIGURE 88 MITSUBISHI ELECTRIC CORPORATION: COMPANY SNAPSHOT

TABLE 374 MITSUBISHI ELECTRIC CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.1.6 KAWASAKI HEAVY INDUSTRIES, LTD.

TABLE 375 KAWASAKI HEAVY INDUSTRIES, LTD.: BUSINESS OVERVIEW

FIGURE 89 KAWASAKI HEAVY INDUSTRIES, LTD.: COMPANY SNAPSHOT

TABLE 376 KAWASAKI HEAVY INDUSTRIES, LTD.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.1.7 DENSO CORPORATION

TABLE 377 DENSO CORPORATION: BUSINESS OVERVIEW

FIGURE 90 DENSO CORPORATION: COMPANY SNAPSHOT

TABLE 378 DENSO CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.1.8 NACHI-FUJIKOSHI CORP.

TABLE 379 NACHI-FUJIKOSHI CORP.: BUSINESS OVERVIEW

FIGURE 91 NACHI-FUJIKOSHI CORP.: COMPANY SNAPSHOT

TABLE 380 NACHI-FUJIKOSHI CORP.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.1.9 SEIKO EPSON CORPORATION

TABLE 381 SEIKO EPSON: BUSINESS OVERVIEW

FIGURE 92 SEIKO EPSON: COMPANY SNAPSHOT

TABLE 382 SEIKO EPSON: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.1.10 DÜRR GROUP

TABLE 383 DÜRR GROUP: BUSINESS OVERVIEW

FIGURE 93 DÜRR GROUP: COMPANY SNAPSHOT

TABLE 384 DÜRR GROUP: PRODUCTS/SOLUTIONS/SERVICES OFFERED

14.2 OTHER PLAYERS

14.2.1 YAMAHA MOTOR CO., LTD.

14.2.2 ESTUN AUTOMATION CO., LTD.

14.2.3 SHIBAURA MACHINE CO. LTD.

14.2.4 DOVER CORPORATION

14.2.5 AUROTEK CORPORATION

14.2.6 HIRATA CORPORATION

14.2.7 RETHINK ROBOTICS

14.2.8 FRANKA EMIKA

14.2.9 TECHMAN ROBOT

14.2.10 BOSCH REXROTH AG

14.2.11 UNIVERSAL ROBOTS (TERADYNE)

14.2.12 OMRON ADEPT

14.2.13 STÄUBLI

14.2.14 COMAU

14.2.15 B+M SURFACE SYSTEMS

14.2.16 ICR SERVICES

14.2.17 IRS ROBOTICS

14.2.18 HD HYUNDAI ROBOTICS

14.2.19 SIASUN ROBOT AUTOMATION CO., LTD

14.2.20 ROBOTWORX

*Details on Business Overview, Products/Solutions/Services Offered, Recent Developments, and MnM View (Key strengths/Right to Win, Strategic Choices Made, and Weaknesses and Competitive Threats) might not be captured in case of unlisted companies.

15 APPENDIX (Page No. - 471)

15.1 DISCUSSION GUIDE

15.2 KNOWLEDGESTORE: MARKETSANDMARKETS’ SUBSCRIPTION PORTAL

15.3 CUSTOMIZATION OPTIONS

15.4 RELATED REPORTS

15.5 AUTHOR DETAILS

Generating Response ...

Generating Response ...

Growth opportunities and latent adjacency in Industrial Robotics Market

We need to know the industrial robots market size for electronics industry specifically.

Interested in a separate study on Philippines industrial robotics market (overall and by industry) and after-market of industrial robotics. Could you please quickly provide estimated fees and timeline for delivery?

I am currently pursuing MBA and require some market data on industrial Robots for the Oceania region (Australia and New Zealand). Can you help me with this?

We are interested in all Market type above and we would like to know more about Robotic molds appertain in Cast Industry.

Hello, I am interested in the warehousing, logistics and robotics.

Please let me know if this report include 1.Value chain analysis data 2.Total system cost analysis including materials cost and production cost and units/parts cost by each types of industry robots?

Hi, I'm interested in a sample or an overview of the report before purchase. I'm currently looking for forecasts and predictions in the different markets.

Specific interest is in Automotive robotics for different applications such as, dispensing, handling, welding, and fitting. Looking for market size of each application in this industry.

I am interested in information regarding Milking Robotics and future trends. Last time where I have purchased a report from you -finally the report did not answer my needs and expectations. Before purchasing any new report on milking robots - I would like to get insights on and from the report that will assure me I am getting what I really expecting to get. Can you please provide me this info?

Does your report have information on industrial robots and various end users of industrial robots?

Does your report have quantitate information on industrial robots and various end users of industrial robots?

I have purchased the report and need to understand what is driving the growth rates for the components of the industrial robots.

Would you have student version of the report, I am interested in a free version or a much reduced cost version as part of your corporate policy to support higher education?

I would like a free sample report to check weather this report fits with what I am looking for.

I'm doing a study to determine the size of robot market and how to define our strategy to address this market.

Does this report include information regarding the average unit price / cost for these robots and any unit cost data of their assembly components (gear drives, motors, sensors, structural elements, etc.)?

Is there any scope for new entrants in the market? If yes please provide me few start-ups in the market along with entry barriers in the market. Information on best practices in the market will also be well appreciated.

Can you provide me comparative qualitative and quantitate analysis of industrial robots? Make sure to provide unit shipments and ASP of industrial robots. Also provide me the top 10 vendors in the industrial robots market.

Interested in purchasing the complete "Industrial Robotics Market". Please suggest me the complete process and any discount offer available.