Automatic Tube Cleaning System Market Size, Share & Trends by Type (Automatic Ball Tube Cleaning System, Automatic Brush Tube Cleaning System), Industry (Power Generation, Oil & Gas, Commercial Spaces, and Hospitality), Application and Region - Global Forecast to 2028

Updated on : October 22, 2024

Automatic Tube Cleaning System Market Size & Share

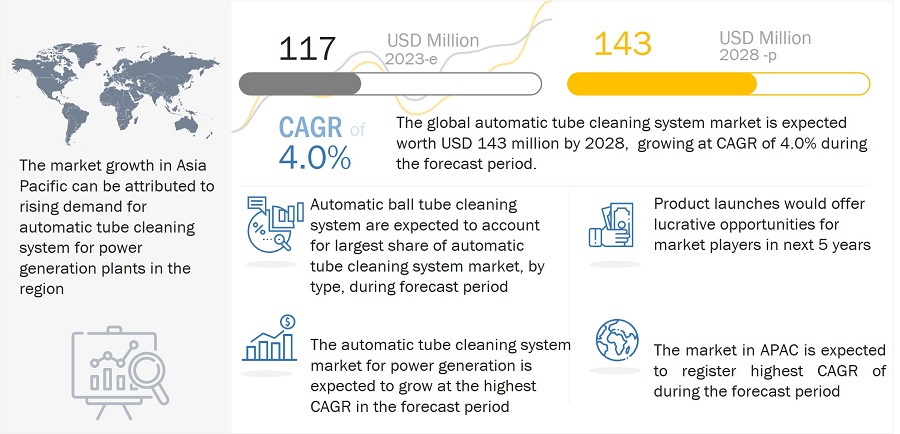

The global Automatic Tube Cleaning System Market size is estimated to be USD 117 million in 2023 and is projected to reach USD 143 billion by 2028, at a CAGR of 4.0% from 2023 to 2028

Increasing maintenance-related requirements for regular cleaning of cold storage components, such as pumps, filters, and tubes, is driving the demand for the automatic tube cleaning system industry in the forecast period.

Automatic Tube Cleaning System Market Forecast to 2028

To know about the assumptions considered for the study, Request for Free Sample Report

Automatic Tube Cleaning System Market Trends & Dynamics

DRIVERS: Rising investments in refrigerated warehouses and cold storages

Increasing demand for online grocery shopping and frozen food has encouraged e-commerce companies to invest in refrigerated warehouses and cold storages. Many perishable eatable items need to be stored for a brief period until it gets sold by e-commerce companies. Hence, companies are installing cold storage systems in their warehouses. This helps companies to optimize the supply chain of perishable items and reduce the wastage of their products. Food processing industries are rapidly adopting more efficient cold storage facilities by investing in developing and introducing more advanced technologies. With the adoption of cold storages, their maintenance-related work would also increase. Regularly cleaning the components of cold storages, such as pumps, filters, and tubes is necessary to maintain these cold storages. Therefore, there will be an increase in demand for automatic tube cleaning systems in the forecast period.

RESTRAINT: Design-related faults and limitations in some automatic tube cleaning systems

A few automatic tube cleaning systems have design faults/limitations. Sometimes, the heated water leaving the condenser mixes with water re-entering the cold-water system, thereby reducing the efficiency of the chiller. Also, additional energy is needed for heat transfer.

Further, after the cleaning process, balls are collected in a ball trap, which includes a strainer or screen, allowing water to flow continuously but preventing balls from escaping downstream. Mechanically actuated clamshell-like screens were used in early designs of ball traps, which are used today as well. However, these designs are sometimes prone to mechanical failure leading to ball loss and decreased condenser efficiency. Design-related problems cause faults in tubes, which increase the energy consumption of the Heat Exchangers. These faults increase maintenance costs & downtime.

OPPORTUNITIES: Rise in desalination projects across the globe

Automatic tube cleaning systems are widely used in desalination plants to avoid fouling in water circuits that are present in desalination plants. In the extensive infrastructural setup of desalination plants, multiple tubes are used to carry water in each stage of desalination. The seawater consists of various dissolved chemicals and salts that must be removed. These salts may deposit inside the walls of the tube, which can cause fouling or corrosion. Due to increased water scarcity across the globe, many countries are focusing on the desalination of sea waters and investing in desalination plants. The Middle East had a shortage of potable water earlier; hence, desalination of the seawater was the only option left as the region did not have any fresh water source. Many countries in this region are installing desalination plants. Thus, the rising need to build seawater desalination plants is expected to increase the demand for automatic tube cleaning systems

CHALLENGES: Constant requirement to replace sponge balls in Automatic Tube Cleaning System

Balls used in automatic tube cleaning systems are made of soft natural sponge rubber. Typically, the lifespan of these balls is of 1,000 hours of chiller operation, but it depends on the roughness of the tube and the frequency at which these balls are sent through the pipe. As time passes, balls get denser and eventually lose their elasticity. Different types of balls are available in the market: standard, extended life, and abrasive. Standard variant balls are for general applications with different sizes and hardness scales. They can withstand the temperature of 140°Celsius. Extended life balls are standard balls with a thin, smooth skin coating. But because of their smoothness, extended-life balls have reduced cleaning efficiency. For harsh applications, abrasive balls are preferred; these are standard balls with a coating of abrasive materials. Either the balls are lost in the ball trap or strainer, or the efficiency at which tubes are cleaned is reduced. Hence, regular replacement of different variants of cleaning balls is needed, which creates challenges in installing the automatic tube cleaning system.

Automatic ball tube cleaning system is projected to witness the highest growth during forecast period.

For tube cleaning, the ball tube cleaning system is very commonly used technique. Elastomeric balls, having a slightly larger size than the diameter of the tube, are periodically injected into heat exchanger tubes with the help of an injection pump, thereby distributing the sponge balls in several tubes. The ball tube cleaning system that was introduced was primarily used for applications in the power generation industry. The ball tube cleaning system has been proven effective in increasing heat transfer efficiency for large-scale condensers used in power plants. Advances in ball tube cleaning system technology have resulted in more effective and reliable systems with enhanced scalability.

Power Generation sector to be the fastest growing segment in automatic tube cleaning system market during forecast period.

With the help of water, the power generation industry produces a significant amount of electricity. It is an essential element in the industry’s processes, such as steam generation and cooling condenser. In the power plant, water-based cooling systems necessarily suffer from the fouling of heat exchanger surfaces. This leads to a reduction in efficiency, which, in turn, increases energy use, emission of CO2 & NOx, and operating costs. Fouling affects the condenser's overall efficiency and increases the energy consumed in power plants, which is likely to impact the overall revenue of the power plants. Hence, automatic tube cleaning systems are installed to enable power plants to generate electricity at maximum efficiency by removing fouling automatically and continuously.

Automatic Tube Cleaning System Market Regional Analysis

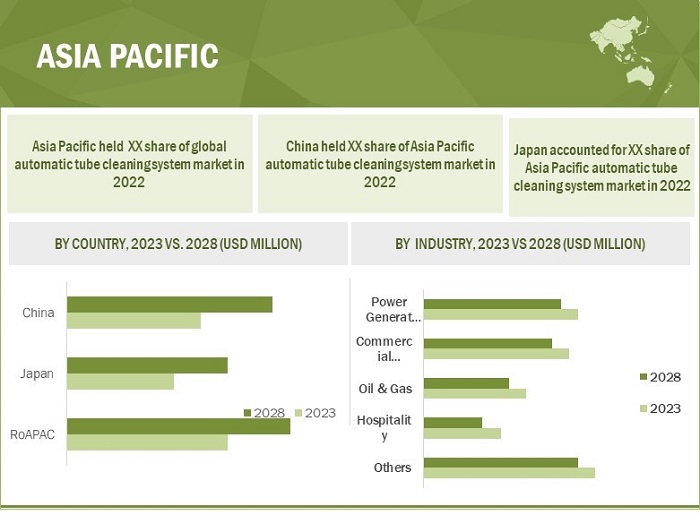

Asia Pacific to grow at highest CAGR during forecast period

China and India are among the major countries in APAC. These countries, being global manufacturing hubs, hold immense potential for the automatic tube cleaning system market growth. They are also among the fast-growing economies in the world. These countries include a large part of the world's population. To fulfill the electricity demand by the people in these countries, power generation through renewable energy is adopted. With China and India's growing adoption of renewable energy, the market for automatic tube cleaning systems in these power stations is anticipated to increase in the forecast period

Automatic Tube Cleaning System Market by Region

To know about the assumptions considered for the study, download the pdf brochure

Automatic Tube Cleaning System Companies : Key Market Players

The automatic tube cleaning system companies is dominated by a few globally established players such as

- Taprogge Gmbh (Germany)

- BEAUDREY (France),

- Westech Engineering,

- LLC (US), Ovivo (Canada), and

- Balltech Energy Ltd. (Israel).

Automatic Tube Cleaning System Market Report Scope

|

Report Metric |

Details |

|

Estimated Market Size |

USD 117 million in 2023 |

|

Projected Market Size |

USD 143 billion by 2028 |

|

Growth Rate |

CAGR of 4.0% |

|

Market Size Available for Years |

2019–2028 |

|

Base Year |

2022 |

|

Forecast Period |

2023–2028 |

|

Units |

Value (USD Million) |

|

Segments Covered |

Type and Industry |

|

Geographic Regions Covered |

North America, Europe, Asia Pacific, and RoW |

|

Companies Covered |

Major Players: Taprogge Gmbh (Germany) BEAUDREY (France), WesTech Engineering, LLC (U.S.), Ovivo (Canada), Balltech Energy Ltd.(Israel), Nijhuis Saur Industries (Netherland), Conco Service LLC (U.S.), Hydroball Technics Holdings PTE Ltd. (Singapore), WSA Engineered System (U.S.), Watco Group (Singapore), Thermax Ltd (India), Innovas Technologies LLC. (U.S.), Ecomax Solutions Pvt Ltd (India), NLB Corporation (U.S.), and CET Enviro Pvt Ltd (India) |

Automatic Tube Cleaning System Market Highlights

This research report segments the automatic tube cleaning system market based on tool type, mode of operation, application and region.

|

Aspect |

Details |

|

By Type: |

|

|

By Application |

|

|

By Region: |

|

Recent Developments in automatic tube cleaning system industry

- In October 2022, Innovas Technologies launched an improved Helios Automatic Tube Cleaning System that eliminates fouling in water-cooled chiller plants. The Helios Automatic Tube Cleaning System represents Innovas Technologies LLC’s latest efforts to pioneer a new type of solution designed to improve energy efficiency.

Frequently Asked Questions (FAQ):

What is the total CAGR expected to be recorded for the automatic tube cleaning system market during 2023–2028?

The global automatic tube cleaning system market is expected to record a CAGR of 4.0% from 2023–2028.

What are the driving factors for the automatic tube cleaning system market?

Improving operational efficiency of HVAC systems due to automatic tube cleaning system installation and rising investments in refrigerated warehouses and cold storages.

Which are the significant players operating in the automatic tube cleaning system market?

Taprogge Gmbh (Germany) BEAUDREY (France), Westech Engineering, LLC (US), Ovivo (Canada), and Balltech Energy Ltd. (Israel) are some of the major companies operating in the automatic tube cleaning system market.

Which region will lead the automatic tube cleaning system market in the future?

Asia Pacific is expected to lead the automatic tube cleaning system market during the forecast period.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

- 5.1 INTRODUCTION

-

5.2 MARKET DYNAMICSDRIVERS- Improving operational efficiency of HVAC systems due to automatic tube cleaning system installationRESTRAINTS- Design-related faults and limitations in some automatic tube cleaning systemsOPPORTUNITIES- Rise in desalination projects worldwideCHALLENGES- Constant requirement to replace sponge balls in automatic tube cleaning systems- Low awareness about benefits of automatic tube cleaning systems

- 5.3 VALUE CHAIN ANALYSIS

-

5.4 ECOSYSTEM ANALYSIS

-

5.5 PRICING ANALYSISAVERAGE SELLING PRICE OF COMPONENTS PROVIDED BY MARKET PLAYERS, BY TYPE

-

5.6 TRENDS/DISRUPTIONS IMPACTING CUSTOMERS’ BUSINESSES

-

5.7 TECHNOLOGY ANALYSISSHELL AND TUBE EXCHANGER TECHNOLOGYSPIRAL HEAT EXCHANGER TECHNOLOGYREMOTE MONITORINGINTERNET OF THINGS

-

5.8 PORTER’S FIVE FORCES ANALYSISTHREAT OF NEW ENTRANTSTHREAT OF SUBSTITUTESBARGAINING POWER OF SUPPLIERSBARGAINING POWER OF BUYERSINTENSITY OF COMPETITIVE RIVALRY

-

5.9 KEY STAKEHOLDERS AND BUYING CRITERIAKEY STAKEHOLDERS IN BUYING PROCESSBUYING CRITERIA

-

5.10 CASE STUDYUSE CASE 1: A PARTNERSHIP STORY—ICICI BANKUSE CASE 2: SUCCESS STORY WITH RENAISSANCE HOTEL (MUMBAI, INDIA)USE CASE 3: DOMINION POWER CASE STUDYUSE CASE 4: XCEL ENERGY CASE STUDY

- 5.11 TRADE ANALYSIS

-

5.12 PATENTS ANALYSISLIST OF MAJOR PATENTS

- 5.13 KEY CONFERENCES AND EVENTS IN 2022–2023

-

5.14 REGULATIONS AND STANDARDSREGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONSSTANDARDS

- 6.1 INTRODUCTION

-

6.2 AUTOMATIC BALL TUBE CLEANING SYSTEMINCREASE IN DEMAND FROM POWER GENERATION INDUSTRY

-

6.3 AUTOMATIC BRUSH TUBE CLEANING SYSTEMGROWING ADOPTION OF BRUSHES FOR CONDENSER TUBE CLEANING

- 7.1 INTRODUCTION

-

7.2 BOILERSINCREASING USE OF BOILERS IN MANUFACTURING INDUSTRY

-

7.3 CHILLERSINCREASE IN DEMAND FOR CHILLERS IN HOTELS AND RESTAURANTS

-

7.4 COOLING TOWERSCOOLING TOWERS PROVIDE COST-EFFECTIVE AND ENERGY-EFFICIENT OPERATION OF SYSTEMS IN NEED OF COOLING

- 7.5 OTHER APPLICATIONS

- 8.1 INTRODUCTION

-

8.2 POWER GENERATIONGROWING ADOPTION OF COOLING SYSTEMS DUE TO INCREASING PRODUCTION OF ELECTRICITY

-

8.3 OIL & GASRAPID ADOPTION OF HEAT EXCHANGERS AND SHELL AND TUBE CONDENSERS BY OIL & GAS INDUSTRY

-

8.4 COMMERCIAL SPACESINCREASING DEMAND FOR COOLING UNITS IN COMMERCIAL SPACES

-

8.5 HOSPITALITYINCREASE IN TOURISM ACTIVITIES WORLDWIDE

- 8.6 OTHER INDUSTRIES

- 9.1 INTRODUCTION

-

9.2 NORTH AMERICAUS- Increasing oil production expected to drive growthCANADA- Increasing demand for electricity to drive growthMEXICO- Increasing reliance on nuclear power to support growth

-

9.3 EUROPEGERMANY- Growing hospitality industry to propel growthFRANCE- Increasing demand for nuclear power to drive growthREST OF EUROPE

-

9.4 ASIA PACIFICCHINA- Growing adoption of renewable energy to drive growthJAPAN- Growing installation of coal-fired power plants to support growthREST OF ASIA PACIFIC

-

9.5 REST OF THE WORLDMIDDLE EAST & AFRICA- Increasing number of desalination plants to drive growthSOUTH AMERICA- Increase in oil production through refineries to propel growth

- 10.1 INTRODUCTION

- 10.2 REVENUE ANALYSIS OF TOP 5 COMPANIES

- 10.3 MARKET SHARE ANALYSIS OF TOP PLAYERS, 2022

-

10.4 COMPETITIVE EVALUATION QUADRANT, 2022STARSEMERGING LEADERSPERVASIVE PLAYERSPARTICIPANTS

-

10.5 SMALL AND MEDIUM-SIZED ENTERPRISES (SME) EVALUATION QUADRANT, 2022PROGRESSIVE COMPANIESRESPONSIVE COMPANIESDYNAMIC COMPANIESSTARTING BLOCKS

- 10.6 AUTOMATIC TUBE CLEANING SYSTEM MARKET: COMPANY FOOTPRINT

-

10.7 COMPETITIVE BENCHMARKINGAUTOMATIC TUBE CLEANING SYSTEM MARKET: DETAILED LIST OF KEY START-UPS/SMESAUTOMATIC TUBE CLEANING SYSTEM MARKET: COMPETITIVE BENCHMARKING OF KEY START-UPS/SMES, BY TYPEAUTOMATIC TUBE CLEANING SYSTEM MARKET: COMPETITIVE BENCHMARKING OF KEY START-UPS/SMES, BY INDUSTRYAUTOMATIC TUBE CLEANING SYSTEM MARKET: COMPETITIVE BENCHMARKING OF KEY START-UPS/SMES, BY REGION

-

10.8 COMPETITIVE SITUATIONS AND TRENDSPRODUCT LAUNCHES

-

11.1 KEY PLAYERSTAPROGGE GMBH- Business overview- Products offered- MnM viewBEAUDREY- Business overview- Products offered- MnM viewWSA ENGINEERED SYSTEMS- Business overview- Products offered- MnM viewWESTECH ENGINEERING, LLC- Business overview- Products offeredOVIVO- Business overview- Products offeredBALLTECH ENERGY LTD.- Business overview- Products offeredNIJHUIS SAUR INDUSTRIES- Business overview- Products offeredCONCO SERVICES LLC- Business overview- Products offeredHYDROBALL TECHNICS HOLDINGS PTE LTD.- Business overview- Products offeredTHERMAX LIMITED- Business overview- Products offeredWATCO GROUP- Business overview- Products offeredINNOVAS TECHNOLOGIES, LLC.- Business overview- Products offered- Recent developmentsECOMAX SOLUTIONS PVT. LTD.- Business overview- Products offeredNLB CORPORATION- Business overview- Products offeredCET ENVIRO PVT. LTD.- Business overview- Products offered

-

11.2 OTHER KEY PLAYERSWTR ENGINEERINGENERGEONYKK ENGINEERING GROUPVULCAN INDUSTRIESSUNJIN ENVIRONMENT CO., LTD.POWER WISE CONVEYOR CO., LTD.JIANGSU YLD WATER PROCESSING EQUIPMENT CO. LTD.DYYNARO TECHNOLOGIESACMV PTE. LTD.WATER TECHNOLOGY OF PENSACOLA INC. (ATB SYSTEM)

- 12.1 INTRODUCTION

- 12.2 LIMITATIONS

-

12.3 INDUSTRIAL REFRIGERATION MARKET, BY COMPONENTINTRODUCTION

-

12.4 COMPRESSORSRECIPROCATING COMPRESSORS- Advantages such as low cost and high efficiency of reciprocating compressors to accelerate market growth- Semi-hermetic type- Hermetic type- Open typeSCREW COMPRESSORS- Characteristics such as higher capacity output, larger compression ratios, and smoother control to deliver energy savings to propel growth of screw compressors- Single-screw compressors- Twin-screw compressors

-

12.5 CONDENSERSAIR-COOLED CONDENSERS- Air-cooled condensers offer easy installation and low/less water consumptionWATER-COOLED CONDENSERS- Benefits such as higher efficiency and smaller space requirement to propel market growthEVAPORATIVE CONDENSERS- Evaporative condensers to continue to dominate industrial refrigeration condenser market during forecast period

-

12.6 EVAPORATORSAPAC TO GROW AT HIGHEST CAGR FOR EVAPORATORS DURING FORECAST PERIODBY COOLING TYPE- Air-cooled evaporatorsBY DESIGN TYPE- Bare tube evaporators- Plate type evaporators- Finned evaporators- Shell and tube-type evaporators

-

12.7 CONTROLSCONTROL SYSTEMS HELP REMOTELY MONITOR INDUSTRIAL REFRIGERATION SYSTEMS, THEREBY LOWERING OPERATING & MAINTENANCE COSTSCOMPRESSOR CONTROLSCONDENSER CONTROLSEVAPORATOR CONTROLS

-

12.8 VESSELS, PUMPS, VALVES, AND AUXILIARY EQUIPMENTREFRIGERATED WAREHOUSE & FOOD PROCESSING INDUSTRY TO CREATE NEW MARKET OPPORTUNITIES FOR VESSELS, PUMPS, VALVES, AND AUXILIARY EQUIPMENT

- 13.1 INSIGHTS OF INDUSTRY EXPERTS

- 13.2 DISCUSSION GUIDE

- 13.3 KNOWLEDGESTORE: MARKETSANDMARKETS’ SUBSCRIPTION PORTAL

- 13.4 CUSTOMIZATION OPTIONS

- 13.5 RELATED REPORTS

- 13.6 AUTHOR DETAILS

- TABLE 1 LIMITATIONS AND ASSOCIATED RISKS

- TABLE 2 COMPANIES AND THEIR ROLE IN AUTOMATIC TUBE CLEANING SYSTEM MARKET ECOSYSTEM

- TABLE 3 AVERAGE SELLING PRICE OF COMPONENTS PROVIDED BY KEY PLAYERS, BY TYPE (USD)

- TABLE 4 PORTER’S FIVE FORCES ANALYSIS

- TABLE 5 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END USERS

- TABLE 6 KEY BUYING CRITERIA FOR TOP 3 END USERS

- TABLE 7 TOP PATENT OWNERS IN LAST 10 YEARS (US)

- TABLE 8 AUTOMATIC TUBE CLEANING SYSTEM MARKET: DETAILED LIST OF CONFERENCES AND EVENTS

- TABLE 9 NORTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 10 EUROPE: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 11 ASIA PACIFIC: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 12 REST OF THE WORLD: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 13 GLOBAL STANDARDS FOR AUTOMATIC TUBE CLEANING SYSTEMS

- TABLE 14 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 15 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 16 AUTOMATIC BALL TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2019–2022 (USD MILLION)

- TABLE 17 AUTOMATIC BALL TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2023–2028 (USD MILLION)

- TABLE 18 AUTOMATIC BALL TUBE CLEANING SYSTEM MARKET, BY REGION, 2019–2022 (USD MILLION)

- TABLE 19 AUTOMATIC BALL TUBE CLEANING SYSTEM MARKET, BY REGION, 2023–2028 (USD MILLION)

- TABLE 20 AUTOMATIC BALL TUBE CLEANING SYSTEM MARKET IN ROW, BY REGION, 2019–2022 (USD MILLION)

- TABLE 21 AUTOMATIC BALL TUBE CLEANING SYSTEM MARKET IN ROW, BY REGION, 2023–2028 (USD MILLION)

- TABLE 22 AUTOMATIC BRUSH TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2019–2022 (USD MILLION)

- TABLE 23 AUTOMATIC BRUSH TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2023–2028 (USD MILLION)

- TABLE 24 AUTOMATIC BRUSH TUBE CLEANING SYSTEM MARKET, BY REGION, 2019–2022 (USD MILLION)

- TABLE 25 AUTOMATIC BRUSH TUBE CLEANING SYSTEM MARKET, BY REGION, 2023–2028 (USD MILLION)

- TABLE 26 AUTOMATIC BRUSH TUBE CLEANING SYSTEM MARKET IN ROW, BY REGION, 2019–2022 (USD MILLION)

- TABLE 27 AUTOMATIC BRUSH TUBE CLEANING SYSTEM MARKET IN ROW, BY REGION, 2023–2028 (USD MILLION)

- TABLE 28 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2019–2022 (USD MILLION)

- TABLE 29 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2023–2028 (USD MILLION)

- TABLE 30 POWER GENERATION: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 31 POWER GENERATION: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 32 POWER GENERATION: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2019–2022 (USD MILLION)

- TABLE 33 POWER GENERATION: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2023–2028 (USD MILLION)

- TABLE 34 OIL & GAS: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 35 OIL & GAS: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 36 OIL & GAS: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2019–2022 (USD MILLION)

- TABLE 37 OIL & GAS: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2023–2028 (USD MILLION)

- TABLE 38 COMMERCIAL SPACES: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 39 COMMERCIAL SPACES: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 40 COMMERCIAL SPACES: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2019–2022 (USD MILLION)

- TABLE 41 COMMERCIAL SPACES: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2023–2028 (USD MILLION)

- TABLE 42 HOSPITALITY: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 43 HOSPITALITY: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 44 HOSPITALITY: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2019–2022 (USD MILLION)

- TABLE 45 HOSPITALITY: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2023–2028 (USD MILLION)

- TABLE 46 OTHER INDUSTRIES: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 47 OTHER INDUSTRIES: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 48 OTHER INDUSTRIES: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2019–2022 (USD MILLION)

- TABLE 49 OTHER INDUSTRIES: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2023–2028 (USD MILLION)

- TABLE 50 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2019–2022 (USD MILLION)

- TABLE 51 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2023–2028 (USD MILLION)

- TABLE 52 NORTH AMERICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY COUNTRY, 2019–2022 (USD MILLION)

- TABLE 53 NORTH AMERICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY COUNTRY, 2023–2028 (USD MILLION)

- TABLE 54 NORTH AMERICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 55 NORTH AMERICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 56 NORTH AMERICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2019–2022 (USD MILLION)

- TABLE 57 NORTH AMERICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2023–2028 (USD MILLION)

- TABLE 58 US: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 59 US: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 60 CANADA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 61 CANADA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 62 MEXICO: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 63 MEXICO: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 64 EUROPE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY COUNTRY, 2019–2022 (USD MILLION)

- TABLE 65 EUROPE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY COUNTRY, 2023–2028 (USD MILLION)

- TABLE 66 EUROPE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 67 EUROPE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 68 EUROPE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2019–2022 (USD MILLION)

- TABLE 69 EUROPE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2023–2028 (USD MILLION)

- TABLE 70 GERMANY: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 71 GERMANY: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 72 FRANCE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 73 FRANCE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 74 REST OF EUROPE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 75 REST OF EUROPE: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 76 ASIA PACIFIC: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY COUNTRY, 2019–2022 (USD MILLION)

- TABLE 77 ASIA PACIFIC: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY COUNTRY, 2023–2028 (USD MILLION)

- TABLE 78 ASIA PACIFIC: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 79 ASIA PACIFIC: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 80 ASIA PACIFIC: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2019–2022 (USD MILLION)

- TABLE 81 ASIA PACIFIC: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2023–2028 (USD MILLION)

- TABLE 82 CHINA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 83 CHINA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 84 JAPAN: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 85 JAPAN: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 86 REST OF ASIA PACIFIC: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 87 REST OF ASIA PACIFIC: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 88 ROW: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2019–2022 (USD MILLION)

- TABLE 89 ROW: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY REGION, 2023–2028 (USD MILLION)

- TABLE 90 ROW: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2023 (USD MILLION)

- TABLE 91 ROW: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 92 ROW: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2019–2022 (USD MILLION)

- TABLE 93 ROW: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2023–2028 (USD MILLION)

- TABLE 94 MIDDLE EAST & AFRICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 95 MIDDLE EAST & AFRICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 96 SOUTH AMERICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2019–2022 (USD MILLION)

- TABLE 97 SOUTH AMERICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- TABLE 98 KEY DEVELOPMENTS IN AUTOMATIC TUBE CLEANING SYSTEM MARKET (2021–2022)

- TABLE 99 AUTOMATIC TUBE CLEANING SYSTEM MARKET: DEGREE OF COMPETITION

- TABLE 100 AUTOMATIC TUBE CLEANING SYSTEM TYPE FOOTPRINT OF COMPANIES

- TABLE 101 INDUSTRY FOOTPRINT OF COMPANIES

- TABLE 102 REGIONAL FOOTPRINT OF COMPANIES

- TABLE 103 OVERALL FOOTPRINT OF COMPANIES

- TABLE 104 KEY START-UPS/SMES

- TABLE 105 COMPETITIVE BENCHMARKING OF KEY START-UPS/SMES, BY TYPE

- TABLE 106 COMPETITIVE BENCHMARKING OF KEY START-UPS/SMES, BY INDUSTRY

- TABLE 107 COMPETITIVE BENCHMARKING OF KEY START-UPS/SMES, BY REGION

- TABLE 108 AUTOMATIC TUBE CLEANING SYSTEM MARKET: PRODUCT LAUNCHES, JANUARY 2021–NOVEMBER 2022

- TABLE 109 TAPROGGE GMBH: BUSINESS OVERVIEW

- TABLE 110 TAPROGGE GMBH: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 111 BEAUDREY: BUSINESS OVERVIEW

- TABLE 112 BEAUDREY: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 113 WSA ENGINEERED SYSTEMS: BUSINESS OVERVIEW

- TABLE 114 WSA ENGINEERED SYSTEMS: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 115 WESTECH ENGINEERING, LLC: BUSINESS OVERVIEW

- TABLE 116 WESTECH ENGINEERING, LLC: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 117 OVIVO: BUSINESS OVERVIEW

- TABLE 118 OVIVO: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 119 BALLTECH ENERGY LTD.: BUSINESS OVERVIEW

- TABLE 120 BALLTECH ENERGY LTD.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 121 NIJHUIS SAUR INDUSTRIES: BUSINESS OVERVIEW

- TABLE 122 NIJHUIS SAUR INDUSTRIES: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 123 CONCO SERVICES LLC: BUSINESS OVERVIEW

- TABLE 124 CONCO SERVICES LLC: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 125 HYDROBALL TECHNICS HOLDINGS PTE LTD.: BUSINESS OVERVIEW

- TABLE 126 HYDROBALL TECHNICS HOLDINGS PTE LTD.: PRODUCTS/SOLUTIONS/ SERVICES OFFERED

- TABLE 127 THERMAX LIMITED: BUSINESS OVERVIEW

- TABLE 128 THERMAX LIMITED: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 129 WATCO GROUP: BUSINESS OVERVIEW

- TABLE 130 WATCO GROUP: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 131 INNOVAS TECHNOLOGIES, LLC.: BUSINESS OVERVIEW

- TABLE 132 INNOVAS TECHNOLOGIES, LLC.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 133 INNOVAS TECHNOLOGIES, LLC.: PRODUCT LAUNCHES AND DEVELOPMENTS

- TABLE 134 ECOMAX SOLUTIONS PVT. LTD.: BUSINESS OVERVIEW

- TABLE 135 ECOMAX SOLUTIONS PVT. LTD.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 136 NLB CORPORATION: BUSINESS OVERVIEW

- TABLE 137 NLB CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 138 CET ENVIRO PVT. LTD.: BUSINESS OVERVIEW

- TABLE 139 CET ENVIRO PVT. LTD.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 140 WTR ENGINEERING: COMPANY OVERVIEW

- TABLE 141 ENERGEO: COMPANY OVERVIEW

- TABLE 142 NYKK ENGINEERING GROUP: COMPANY OVERVIEW

- TABLE 143 VULCAN INDUSTRIES: COMPANY OVERVIEW

- TABLE 144 SUNJIN ENVIRONMENT CO., LTD.: COMPANY OVERVIEW

- TABLE 145 POWER WISE CONVEYOR CO., LTD.: COMPANY OVERVIEW

- TABLE 146 JIANGSU YLD WATER PROCESSING EQUIPMENT CO. LTD.: COMPANY OVERVIEW

- TABLE 147 DYYNARO TECHNOLOGIES: COMPANY OVERVIEW

- TABLE 148 ACMV PTE. LTD.: COMPANY OVERVIEW

- TABLE 149 WATER TECHNOLOGY OF PENSACOLA INC. (ATB SYSTEM): COMPANY OVERVIEW

- TABLE 150 INDUSTRIAL REFRIGERATION SYSTEM MARKET, BY COMPONENT, 2017–2020 (USD MILLION)

- TABLE 151 INDUSTRIAL REFRIGERATION SYSTEM MARKET, BY COMPONENT, 2021–2026 (USD MILLION)

- TABLE 152 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR COMPRESSORS, BY TYPE, 2017–2020 (USD MILLION)

- TABLE 153 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR COMPRESSORS, BY TYPE, 2021–2026 (USD MILLION)

- TABLE 154 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR COMPRESSORS, BY REGION, 2017–2020 (USD MILLION)

- TABLE 155 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR COMPRESSORS, BY REGION, 2021–2026 (USD MILLION)

- TABLE 156 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR COMPRESSORS, BY APPLICATION, 2017–2020 (USD MILLION)

- TABLE 157 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR COMPRESSORS, BY APPLICATION, 2021–2026 (USD MILLION)

- TABLE 158 INDUSTRIAL REFRIGERATION RECIPROCATING COMPRESSOR MARKET, BY TYPE, 2017–2020 (USD MILLION)

- TABLE 159 INDUSTRIAL REFRIGERATION RECIPROCATING COMPRESSOR MARKET, BY TYPE, 2021–2026 (USD MILLION)

- TABLE 160 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONDENSERS, BY TYPE, 2017–2020 (USD MILLION)

- TABLE 161 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONDENSERS, BY TYPE, 2021–2026 (USD MILLION)

- TABLE 162 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONDENSERS, BY REGION, 2017–2020 (USD MILLION)

- TABLE 163 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONDENSERS, BY REGION, 2021–2026 (USD MILLION)

- TABLE 164 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONDENSERS, BY APPLICATION, 2017–2020 (USD MILLION)

- TABLE 165 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONDENSERS, BY APPLICATION, 2021–2026 (USD MILLION)

- TABLE 166 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR EVAPORATORS, BY REGION, 2017–2020 (USD MILLION)

- TABLE 167 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR EVAPORATORS, BY REGION, 2021–2026 (USD MILLION)

- TABLE 168 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR EVAPORATORS, BY APPLICATION, 2017–2020 (USD MILLION)

- TABLE 169 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR EVAPORATORS, BY APPLICATION, 2021–2026 (USD MILLION)

- TABLE 170 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONTROLS, BY REGION, 2017–2020 (USD MILLION)

- TABLE 171 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONTROLS, BY REGION, 2021–2026 (USD MILLION)

- TABLE 172 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONTROLS, BY APPLICATION, 2017–2020 (USD MILLION)

- TABLE 173 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR CONTROLS, BY APPLICATION, 2021–2026 (USD MILLION)

- TABLE 174 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR VESSELS, PUMPS, VALVES, & AUXILIARY EQUIPMENT, BY REGION, 2017–2020 (USD MILLION)

- TABLE 175 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR VESSELS, PUMPS, VALVES, & AUXILIARY EQUIPMENT, BY REGION, 2021–2026 (USD MILLION)

- TABLE 176 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR VESSELS, PUMPS, VALVES, & AUXILIARY EQUIPMENT, BY APPLICATION, 2017–2020 (USD MILLION)

- TABLE 177 INDUSTRIAL REFRIGERATION SYSTEM MARKET FOR VESSELS, PUMPS, VALVES, & AUXILIARY EQUIPMENT, BY APPLICATION, 2021–2026 (USD MILLION)

- FIGURE 1 AUTOMATIC TUBE CLEANING SYSTEM MARKET: RESEARCH DESIGN

- FIGURE 2 MARKET SIZE ESTIMATION METHODOLOGY (SUPPLY SIDE): REVENUE FROM AUTOMATIC TUBE CLEANING SYSTEM MARKET

- FIGURE 3 MARKET SIZE ESTIMATION METHODOLOGY: BOTTOM-UP APPROACH

- FIGURE 4 MARKET SIZE ESTIMATION METHODOLOGY: TOP-DOWN APPROACH

- FIGURE 5 MARKET BREAKDOWN AND DATA TRIANGULATION

- FIGURE 6 ASSUMPTIONS FOR RESEARCH STUDY

- FIGURE 7 AUTOMATIC BALL TUBE CLEANING SYSTEM SEGMENT TO DOMINATE MARKET FROM 2023 TO 2028

- FIGURE 8 POWER GENERATION INDUSTRY SEGMENT TO HOLD LARGEST MARKET SHARE FROM 2023 TO 2028

- FIGURE 9 AUTOMATIC TUBE CLEANING SYSTEM MARKET IN APAC TO GROW AT HIGHEST CAGR DURING FORECAST PERIOD (2023–2028)

- FIGURE 10 GDP GROWTH PROJECTIONS FOR MAJOR ECONOMIES TILL 2023

- FIGURE 11 IMPACT OF UPCOMING RECESSION ON GLOBAL AUTOMATIC TUBE CLEANING SYSTEM MARKET

- FIGURE 12 EXPANSION OF POWER GENERATION INDUSTRY TO CREATE LUCRATIVE OPPORTUNITIES FOR APAC AUTOMATIC TUBE CLEANING SYSTEM MARKET

- FIGURE 13 AUTOMATIC BALL TUBE CLEANING SYSTEM SEGMENT TO GROW AT HIGHER CAGR DURING FORECAST PERIOD

- FIGURE 14 POWER GENERATION INDUSTRY TO DOMINATE AUTOMATIC TUBE CLEANING SYSTEM MARKET DURING FORECAST PERIOD (2023–2028)

- FIGURE 15 ASIA PACIFIC TO HOLD LARGEST SHARE OF AUTOMATIC TUBE CLEANING SYSTEM MARKET DURING FORECAST PERIOD (2023–2028)

- FIGURE 16 US TO HOLD LARGEST SHARE OF AUTOMATIC TUBE CLEANING SYSTEM MARKET IN 2022

- FIGURE 17 AUTOMATIC TUBE CLEANING SYSTEM MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 18 DRIVERS FOR AUTOMATIC TUBE CLEANING SYSTEM MARKET AND THEIR IMPACT

- FIGURE 19 RESTRAINTS FOR AUTOMATIC TUBE CLEANING SYSTEM MARKET AND THEIR IMPACT

- FIGURE 20 OPPORTUNITIES FOR AUTOMATIC TUBE CLEANING SYSTEM MARKET AND THEIR IMPACT

- FIGURE 21 CHALLENGES FOR AUTOMATIC TUBE CLEANING SYSTEM MARKET AND THEIR IMPACT

- FIGURE 22 VALUE CHAIN ANALYSIS

- FIGURE 23 AUTOMATIC TUBE CLEANING SYSTEM MARKET: ECOSYSTEM

- FIGURE 24 AVERAGE SELLING PRICE OF COMPONENTS PROVIDED BY KEY PLAYERS, BY TYPE

- FIGURE 25 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END USERS

- FIGURE 26 KEY BUYING CRITERIA FOR TOP 3 END USERS

- FIGURE 27 IMPORTS DATA FOR PARTS OF REFRIGERATING OR FREEZING EQUIPMENT AND HEAT PUMPS, 2017–2021 (USD MILLION)

- FIGURE 28 EXPORTS DATA FOR PARTS OF REFRIGERATING OR FREEZING EQUIPMENT AND HEAT PUMPS, 2017–2021 (USD MILLION)

- FIGURE 29 NUMBER OF PATENTS GRANTED PER YEAR FROM 2012 TO 2021

- FIGURE 30 TOP 10 COMPANIES WITH HIGHEST NUMBER OF PATENT APPLICATIONS IN LAST 10 YEARS

- FIGURE 31 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE

- FIGURE 32 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY TYPE, 2023–2028 (USD MILLION)

- FIGURE 33 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY APPLICATION

- FIGURE 34 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY

- FIGURE 35 AUTOMATIC TUBE CLEANING SYSTEM MARKET, BY INDUSTRY, 2023–2028 (USD MILLION)

- FIGURE 36 SNAPSHOT OF GLOBAL ELECTRICITY GENERATION (2016–2021)

- FIGURE 37 AUTOMATIC TUBE CLEANING SYSTEM MARKET SEGMENTATION, BY REGION

- FIGURE 38 CHINA TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 39 ASIA PACIFIC TO DOMINATE GLOBAL MARKET DURING FORECAST PERIOD (2023–2028)

- FIGURE 40 NORTH AMERICA: AUTOMATIC TUBE CLEANING SYSTEM MARKET SNAPSHOT

- FIGURE 41 EUROPE: AUTOMATIC TUBE CLEANING SYSTEM MARKET SNAPSHOT

- FIGURE 42 ASIA PACIFIC: AUTOMATIC TUBE CLEANING SYSTEM MARKET SNAPSHOT

- FIGURE 43 AUTOMATIC TUBE CLEANING SYSTEM MARKET IN ROW, BY REGION, 2023 VS. 2028 (USD MILLION)

- FIGURE 44 AUTOMATIC TUBE CLEANING SYSTEM MARKET: REVENUE ANALYSIS (2022)

- FIGURE 45 AUTOMATIC TUBE CLEANING SYSTEM MARKET: GLOBAL COMPANY EVALUATION QUADRANT, 2022

- FIGURE 46 AUTOMATIC TUBE CLEANING SYSTEM MARKET: GLOBAL SME EVALUATION QUADRANT, 2022

- FIGURE 47 THERMAX LIMITED: COMPANY SNAPSHOT

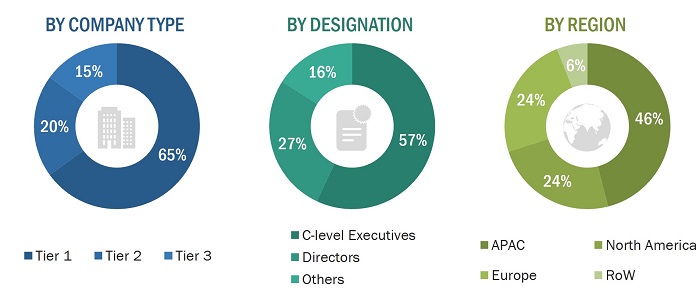

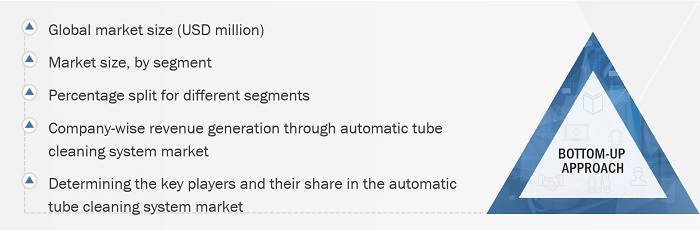

The study involved four major activities in estimating the current size of the automatic tube cleaning system market. Exhaustive secondary research has been done to collect information on the market, peer market, and parent market. To validate these findings, assumptions, and sizing with industry experts across the value chain through primary research has been the next step. Finally, both top-down and bottom-up approaches have been employed to estimate the complete market size. After that, market breakdown and data triangulation methods were used to estimate the market size of segments and subsegments.

Secondary Research

In the secondary research process, various secondary sources have been referred to identify and collect information relevant to this study. The secondary sources include annual reports, press releases, and investor presentations of companies; white papers, certified publications, and articles from recognized authors; directories; and databases. Secondary research has been mainly conducted to obtain key information about the industry’s supply chain, value chain of the market, total pool of key players, market classification and segmentation according to industry trends, geographic markets, and key developments from both market- and technology-oriented perspectives.

Primary Research

In the primary research process, various primary sources from both supply and demand sides have been interviewed to obtain the qualitative and quantitative information relevant to this report. Primary sources from the supply side include experts such as CEOs, VPs, marketing directors, technology and innovation directors, application developers, application users, and related executives from various key companies and organizations operating in the automatic tube cleaning system ecosystem. Following is the breakdown of primary respondents:

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

Both the top-down and bottom-up approaches have been used to estimate and validate the size of the overall automatic tube cleaning system market and the market based on segments. The research methodology used to estimate the market size has been given below:

- Major players operating in the automatic tube cleaning system market have been identified and considered for the report through extensive secondary research.

- The supply chain and market size of the automatic tube cleaning system market, both in terms of value and units, have been estimated/determined through secondary and primary research processes.

- All estimations and calculations, including percentage share, revenue mix, splits, and breakdowns have been determined through use of secondary sources which are further verified through primary sources.

Global Automatic Tube Cleaning System Market Size: Bottom-Up Approach

Data Triangulation

After arriving at the overall market size from the market size estimation process explained above, the total market has been split into several segments and subsegments. To complete the overall market engineering process and arrive at the exact statistics for all segments and subsegments, the data triangulation and market breakdown procedures have been employed, wherever applicable. The data has been triangulated by studying various factors and trends from both the demand and supply sides. Along with this, the market has been validated using both top-down and bottom-up approaches.

Report Objectives:

- To describe and forecast the automatic tube cleaning system market, in terms of value, based on type and industry

- To forecast the market size, in terms of value, for four main regions—North America, Europe, Asia Pacific (APAC), and the Rest of World (RoW)

- To provide detailed information regarding drivers, restraints, opportunities, and challenges influencing the market growth

- To provide a detailed overview of the value chain of the Automatic tube cleaning system ecosystem

- To strategically analyze micro markets with respect to individual growth trends, prospects, and contributions to the total market

- To analyze the opportunities in the market for stakeholders and details of the competitive landscape of the market

- To strategically profile the key players and comprehensively analyze their market position in terms of ranking and core competencies

- To analyze the major growth strategies implemented by key market players, such as contracts, agreements, acquisitions, product launches, expansions, and partnerships

Available Customizations:

Based on the given market data, MarketsandMarkets offers customizations in the reports according to the client’s specific requirements. The available customization options are as follows:

Company Information

- Detailed analysis and profiling of additional market players (up to 5)

Generating Response ...

Generating Response ...

Growth opportunities and latent adjacency in Automatic Tube Cleaning System Market