Triple Offset Butterfly Valve Market by Material (Stainless Steel, Cast Iron, Cryogenic, Alloy Based), Valve Size, Industry (Oil & Gas, Water & Wastewater Treatment, Energy & Power, Chemicals), and Region - Global Forecast to 2025-2035

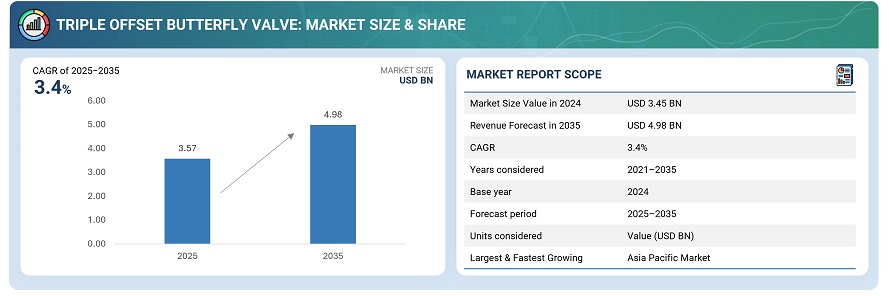

The global triple offset butterfly valve market was valued at USD 3.45 billion in 2024 and is estimated to reach USD 4.98 billion by 2035, at a CAGR of 3.4% between 2025 and 2035.

The global triple offset butterfly valve market is experiencing robust growth, driven by rising industrial automation, stringent safety regulations, and increasing demand for reliable flow control solutions across various industries, including oil & gas, energy & power, chemical processing, pharmaceuticals, water & wastewater, and petrochemicals. Triple offset valves are favored for their zero-leakage sealing, high-pressure tolerance, and long service life, making them indispensable for critical applications requiring precision flow regulation and enhanced operational safety. Technological advancements, including IoT-enabled valve monitoring, predictive maintenance, and the use of corrosion- and wear-resistant materials, are further improving efficiency, durability, and overall lifecycle performance. Accelerating infrastructure development and industrial expansion in the Asia Pacific, particularly in China and India, is boosting market demand. Key players are focusing on product innovation, compliance with international standards, and regional expansion to meet evolving safety, performance, and operational requirements globally.

Triple offset butterfly valves (TOBVs) are high-performance isolation devices designed to provide tight shut-off and reliable flow control in pipelines and process systems, preventing leakage, equipment damage, and operational downtime. They play a vital role in ensuring efficiency and safety across various industries, including oil & gas, chemical processing, power generation, and water treatment. TOBVs feature a unique three-offset design that enhances sealing performance, reduces wear, and ensures durability under extreme conditions. Recent developments highlight the focus on advanced performance and critical application readiness. In June 2024, Severn Valve (UK) launched the 8500 OCT series, incorporating Oblique Cone Technology (OCT) for superior sealing and precise control. Earlier, in January 2024, IMI Process Automation (UK) successfully tested an 84-inch TOBV for a propane dehydrogenation plant in Saudi Arabia, demonstrating reliability under high-pressure conditions. These valves are available in wafer, lug, and double-flanged designs, constructed from high-performance materials for reliable, long-lasting operation.

Market by Industry

Oil & Gas

The oil and gas industry is the largest segment in the Triple Offset Butterfly Valve market, driven by the sector's critical need for precise flow control, high-pressure resistance, and compliance with stringent safety and environmental regulations. Triple Offset Butterfly Valves are widely used in pipelines, compressors, storage tanks, and processing units to provide tight shut-off, reduce operational risks, and maintain system integrity under extreme conditions. Their robust design, featuring a metal-to-metal seal and long service life, makes them suitable for safely controlling the flow of hydrocarbons in demanding applications. The use of Internet of Things (IoT)- enabled monitoring and predictive maintenance is increasingly being adopted to enhance operational safety, efficiency, and reliability across upstream, midstream, and downstream processes.

Energy & Power

The energy and power industry is expected to emerge as one of the fastest-growing application areas for Triple Offset Butterfly Valves, driven by increasing investments in power generation, renewable energy projects, and modernization of thermal and nuclear power plants. Triple Offset Butterfly Valves are extensively used in steam, water, and gas pipelines, turbines, and pressure control systems to ensure tight shut-off, prevent leakage, and maintain reliable flow regulation under high-pressure and high-temperature conditions. Their metal-to-metal sealing design and robust construction provide excellent durability, corrosion resistance, and minimal maintenance requirements, making them ideal for continuous operation in demanding environments. Furthermore, the valves contribute to operational efficiency by reducing energy loss, ensuring precise flow control, and supporting compliance with safety and environmental standards across large-scale power generation and distribution facilities.

Chemicals

The chemical industry is one of the major application areas for Triple Offset Butterfly Valves, driven by the need for precise flow control, high-pressure resistance, and safe handling of corrosive and hazardous fluids. These valves are extensively used in pipelines, reactors, storage tanks, and process units to provide tight shut-off, prevent leakage, and maintain system integrity under extreme temperature and pressure conditions. The metal-to-metal sealing mechanism and robust construction ensure long-term durability, corrosion resistance, and minimal maintenance, making them suitable for continuous operations in demanding chemical processing environments. Additionally, Triple Offset Butterfly Valves contribute to operational efficiency by enabling accurate flow regulation, reducing downtime, and supporting compliance with stringent safety and environmental standards across large-scale chemical plants.

Market by Material

Stainless Steel

Stainless steel is a dominant material segment in the Triple Offset Butterfly Valve market, valued for its strength, corrosion resistance, and durability in demanding industrial environments. Stainless steel Triple Offset Butterfly Valves are engineered to operate reliably under high-pressure and high-temperature conditions, making them suitable for applications in oil & gas, energy & power, chemical processing, water and wastewater treatment, and other heavy industries. They offer seamless integration with pipelines, pressure vessels, and process systems, ensuring precise flow control, tight shut-off, and compliance with safety and operational standards. With features such as metal-to-metal sealing, high corrosion resistance, and long service life, stainless steel Triple Offset Butterfly Valves provide dependable and efficient solutions for critical industrial operations.

Carbon Steel

Carbon steel is one of the major material segments in the Triple Offset Butterfly Valve market, valued for its strength, durability, and cost-effectiveness in industrial valve applications. Carbon steel triple offset valves are engineered to perform reliably under high-pressure and moderate-to-high temperature conditions, making them suitable for industrial pipelines, pressure vessels, and process systems in oil and gas, energy and power, chemical processing, and other heavy industries. These industrial valves provide precise flow control, tight shut-off, and operational safety, ensuring minimal leakage and long-term reliability. Currently, carbon steel butterfly valves hold a significant market share due to their robust construction, corrosion resistance, and long service life. Looking ahead, demand for carbon steel flow control valves is expected to grow steadily, driven by expanding industrial infrastructure, rising investments in oil and gas, power generation, and chemical processing projects, as well as the increasing need for high-performance, reliable valves across both emerging and mature markets.

Market by Geography

The Asia Pacific region is the largest and fastest-growing market for Triple Offset Butterfly Valves, driven by increasing investments in infrastructure, energy, and industrial projects across China, India, and Southeast Asia. These valves are widely used in oil and gas pipelines, power generation facilities, chemical processing plants, and water treatment systems, providing tight shut-off, precise flow control, and reliable performance under high-pressure and high-temperature conditions. The growth in renewable energy projects, expansion of industrial facilities, and modernization of processing plants are further fueling demand for industrial valves that offer durability, corrosion resistance, and long service life. Leading manufacturers are focusing on product innovation, high-performance materials, and compliance with international standards to meet the region’s increasing requirements for safe and efficient flow control solutions.

Market Dynamics

Driver: Rising Demand for High-Performance Flow Control

The increasing need for reliable and efficient flow control valves is a primary driver for the Triple Offset Butterfly Valve market. Industries such as oil & gas, energy & power, chemical processing, and water & wastewater treatment rely on valves that provide tight shut-off, precise flow regulation, and long-term durability, particularly under high-pressure and high-temperature conditions. Triple offset butterfly valves are preferred for critical applications due to their metal-to-metal sealing design, which minimizes leakage, reduces maintenance requirements, and ensures continuous operation. The robust construction, corrosion-resistant materials, and high performance of these industrial valves make them ideal for managing complex flow systems safely and efficiently. As industries increasingly demand high-performance valves that support operational reliability and safety, the adoption of triple offset butterfly valves continues to rise across key industrial sectors.

Restraint: High Initial Cost and Design Complexity

The higher initial cost of triple offset butterfly valves compared to conventional butterfly valves is a key restraint in the market. These valves require precision engineering, advanced materials, and specialized manufacturing processes, which increase procurement and installation expenses. Smaller facilities or cost-sensitive industrial projects may find the upfront investment challenging despite long-term durability and low maintenance benefits. Additionally, the complex design requires skilled personnel for proper installation, operation, and maintenance, which can further increase operational costs. Ensuring the proper alignment and seating of industrial valves in high-pressure systems is crucial to prevent leakage or failure. These cost and complexity factors can limit adoption in certain regions or industries where budget constraints outweigh performance considerations.

Opportunity: Industrial Expansion in Emerging Markets

The growth of energy, chemical, water & wastewater treatment, as well as industrial infrastructure in emerging markets, offers significant opportunities for triple offset butterfly valves. Expanding pipelines, processing plants, power generation facilities, and water distribution systems require industrial valves that provide tight shut-off, leak-free operation, and long-term reliability. Manufacturers can capitalize on this demand by offering high-performance valves made from corrosion-resistant materials, featuring precise flow control, and meeting international safety standards. Emerging markets increasingly recognize the operational and safety benefits of triple offset valves, driving higher adoption rates. Customizable valve solutions, local support, and maintenance services further enhance market opportunities, enabling manufacturers to expand their presence and capitalize on the growing demand for reliable and durable flow control solutions across various industrial applications.

Challenge: Maintaining Performance in Extreme Conditions

Ensuring consistent performance of triple offset butterfly valves under extreme pressure, high temperature, and corrosive environments is a key challenge. These valves are deployed in critical applications such as oil and gas pipelines, chemical reactors, power plants, and water treatment systems, where flow control and tight shut-off are essential for operational safety and efficiency. Maintaining seal integrity, preventing leakage, and ensuring long-term durability require precise material selection, high-quality manufacturing, and stringent testing. Any lapses can result in operational inefficiencies, maintenance issues, or safety risks. Adhering to regulatory standards and maintaining industrial valve performance in demanding conditions remains a continuous challenge for manufacturers and end-users aiming for reliable and safe flow control across critical industrial systems.

Future Outlook

Between 2025 and 2035, the Triple Offset Butterfly Valve market is expected to experience significant growth as industries increasingly require reliable and high-performance industrial valves for critical flow control applications in oil and gas, energy and power, chemical processing, and water treatment sectors. Advancements in triple offset valve design, precision-engineered metal-to-metal sealing, and corrosion- and wear-resistant materials will enhance durability, ensure tight shut-off, and improve operational efficiency in high-pressure and high-temperature systems. The expansion of energy infrastructure, industrial plants, and water distribution networks will further drive the adoption of these high-performance flow control valves. As the market evolves, triple offset butterfly valves will play a pivotal role in minimizing leakage, reducing maintenance requirements, optimizing flow regulation, and ensuring safe and efficient operation of critical industrial processes worldwide.

Key Market Players

Top Triple offset Butterfly Valve companies Emerson Electric Co. (US),.IMI plc (UK),. Flowserve Corporation (US), Bray International (US), and Curtiss-Wright Corporation (US).

Key Questions addressed in this report:

- What is the current market size of the triple offset butterfly valve market, and how is it expected to grow between 2025 and 2035?

- What are the global trends driving demand in the triple offset butterfly valve market?

- Which regions are leading in the adoption of triple offset butterfly valves, and which regions show the fastest growth?

- What are the key industries driving the demand for industrial valves such as triple offset butterfly valves?

- 5.1 PORTER'S FIVE FORCES ANALYSIS

- 5.2 MACROECONOMIC INDICATORS

- 5.3 SUPPLY CHAIN ANALYSIS

- 5.4 VALUE CHAIN ANALYSIS

- 5.5 ECOSYSTEM ANALYSIS

- 5.6 PRICING ANALYSIS

- 5.7 TRADE ANALYSIS

- 5.8 KEY CONFERENCES AND EVENTS (2025-2026)

- 5.9 TRENDS/DISRUPTIONS IMPACTING CUSTOMERS’ BUSINESS

- 5.10 INVESTMENT AND FUNDING SCENARIO

- 5.11 CASE STUDY ANALYSIS

-

5.12 IMPACT OF 2025 US TARIFFINTRODUCTIONKEY TARIFF RATESPRICE IMPACT ANALYSISIMPACT ON COUNTRIES/REGIONIMPACT ON END-USE INDUSTRIES

- 6.1 KEY EMERGING TECHNOLOGIES

- 6.2 COMPLEMENTARY TECHNOLOGIES

- 6.3 TECHNOLOGY/PRODUCT ROADMAP

- 6.4 PATENT ANALYSIS

- 6.5 IMPACT OF AI/GEN AI

-

7.1 REGIONAL REGULATIONS AND COMPLIANCEREGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONSINDUSTRY STANDARDS

- 8.1 DECISION-MAKING PROCESS

- 8.2 BUYER STAKEHOLDERS AND BUYING EVALUATION CRITERIA

- 8.3 ADOPTION BARRIERS & INTERNAL CHALLENGES

- 8.4 UNMET NEEDS FROM VARIOUS END-USE INDUSTRIES

- 9.1 INTRODUCTION

- 9.2 UP TO 10”

- 9.3 10”-25”

- 9.4 25”-50”

- 9.5 >50”

- 10.1 INTRODUCTION

- 10.2 STAINLESS STEEL

- 10.3 CARBON STEEL

- 10.4 ALLOY-BASED

-

10.5 OTHERSBRASSBRONZECAST IRONCRYOGENIC

- 11.1 INTRODUCTION

- 11.2 OIL & GAS

- 11.3 WATER & WASTEWATER TREATMENT

- 11.4 ENERGY & POWER

- 11.5 PHARMACEUTICALS & HEALTHCARE

- 11.6 FOOD & BEVERAGES

- 11.7 CHEMICALS

- 11.8 BUILDING & CONSTRUCTION

- 11.9 PULP & PAPER

- 11.10 METALS & MINING

- 11.11 OTHERS

- 12.1 INTRODUCTION

-

12.2 NORTH AMERICAUSCANADAMEXICO

-

12.3 EUROPEUKGERMANYFRANCEITALYREST OF EUROPE

-

12.4 ASIA PACIFICCHINAJAPANINDIASOUTH KOREAREST OF ASIA PACIFIC

-

12.5 ROWMIDDLE EASTAFRICASOUTH AMERICA

- 13.1 OVERVIEW

- 13.2 KEY PLAYER STRATEGIES/RIGHT TO WIN

- 13.3 REVENUE ANALYSIS

- 13.4 MARKET SHARE ANALYSIS

- 13.5 BRAND/PRODUCT COMPARISON

-

13.6 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024STARSEMERGING LEADERSPERVASIVE PLAYERSPARTICIPANTSCOMPANY FOOTPRINT: KEY PLAYERS, 2024

-

13.7 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024PROGRESSIVE COMPANIESRESPONSIVE COMPANIESDYNAMIC COMPANIESSTARTING BLOCKSCOMPETITIVE BENCHMARKING STARTUPS/SMES, 2024- Detailed List of Key Startups/SMEs- Competitive Benchmarking of Key Startups/SMEs

- 13.8 COMPANY VALUATION AND FINANCIAL METRICS

-

13.9 COMPETITIVE SCENARIOPRODUCT LAUNCHESDEALSEXPANSIONS

-

14.1 KEY PLAYERSEMERSON ELECTRIC CO.FLOWSERVE CORPORATIONCURTISS-WRIGHT CORPORATIONIMI PLCCRANEVELANTRILLIUM FLOW TECHNOLOGIESBRAY INTERNATIONALBAKER HUGHESKSB SVERIGE AB

- 14.2 OTHER PLAYERS

-

15.1 RESEARCH DATAPRIMARY DATASECONDARY DATA

- 15.2 MARKET SIZE ESTIMATION

- 15.3 MARKET FORECAST APPROACH

- 15.4 DATA TRIANGULATION

- 15.5 FACTOR ANALYSIS

- 15.6 RESEARCH ASSUMPTION

- 15.7 RESEARCH LIMITATION AND RISK ASSESSMENT

- 16.1 DISCUSSION GUIDE

- 16.2 KNOWLEDGE STORE: MARKETSANDMARKETS’ SUBSCRIPTION PORTAL

- 16.3 CUSTOMIZATION OPTIONS

- 16.4 RELATED REPORTS

- 16.5 AUTHOR DETAILS

TABLE 1 Triple Offset Butterfly Valve Market, by size (USD Million)

|

Size |

2023 |

2025 |

2027 |

2029 |

2031 |

2033 |

2035 |

CAGR (2025–2035) |

|

Up to 10” |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

10”-25” |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

25”-50” |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

>50” |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Total |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

TABLE 2 Triple Offset Butterfly Valve Market, By material (USD Million)

|

Material |

2023 |

2025 |

2027 |

2029 |

2031 |

2033 |

2035 |

CAGR (2025–2035) |

|

Stainless Steel |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Carbon Steel |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Alloy-Based |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Others |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Total |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

TABLE 3 Triple Offset Butterfly Valve MARKET by Industry (USD Million)

|

Industry |

2023 |

2025 |

2027 |

2029 |

2031 |

2033 |

2035 |

CAGR (2025–2035) |

|

Oil & Gas |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Water & Wastewater Treatment |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Energy & Power |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Pharmaceuticals & Healthcare |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Food & Beverages |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Chemicals |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Building & Construction |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Pulp & Paper |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Metals & Mining |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Others |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Total |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

TABLE 4 Triple Offset Butterfly Valve Market, By Region (USD Million)

|

Region |

2023 |

2025 |

2027 |

2029 |

2031 |

2033 |

2035 |

CAGR (2025–2035) |

|

North America |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Europe |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Asia Pacific |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

RoW |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

|

Total |

XX |

XX |

XX |

XX |

XX |

XX |

XX |

XX% |

The study involved four major activities for estimating the size of the triple offset butterfly valve market. Exhaustive secondary research was done to collect information on the market, including its peer markets. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain through primary research. Both top-down and bottom-up approaches were employed to estimate the complete market size. After that, market breakdown and data triangulation were used to estimate the market size of segments and subsegments.

Secondary Research

In the secondary research process, various secondary sources have been referred to for identifying and collecting information important for this study. Secondary sources include corporate filings (such as annual reports, press releases, investor presentations, and financial statements); trade, business, and professional associations; white papers, valves-based marketing-related journals, certified publications, and articles from recognized authors; gold and silver standard websites; directories; and databases.

Secondary research has been conducted to obtain key information about the industry’s supply chain, market’s monetary chain, the total pool of key players, and market segmentation according to industry trends to the bottom-most level, geographic markets, and key developments from both market and technology-oriented perspectives. The secondary data has been collected and analyzed to arrive at the overall market size, which has further been validated by primary research.

Primary Research

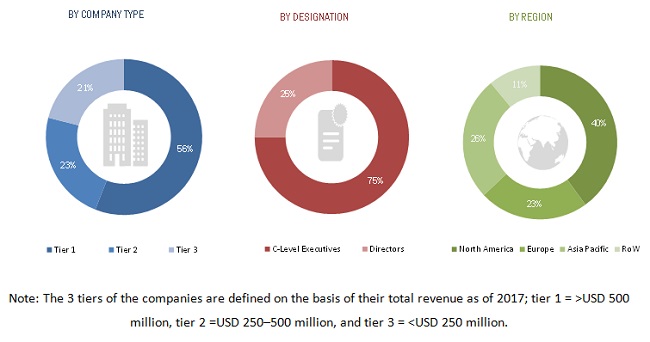

The triple offset butterfly valve market comprises several stakeholders, such raw material and component suppliers, original equipment manufacturers (OEMs), system integrators, distribution channels, and end users. The demand side of this market is characterized by the adoption and usage of triple offset butterfly valves in industries such as oil & gas, water & wastewater treatment, energy & power, food & beverages, metals & mining, chemicals, pharmaceuticals & healthcare, building & construction , pulp & paper, and others. Various primary sources from both the supply and demand sides of the market have been interviewed to obtain qualitative and quantitative information. The breakdown of primary respondents has been provided below.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

Both top-down and bottom-up approaches have been used to estimate and validate the total size of the triple offset butterfly valve market. These methods have also been used extensively to estimate the size of various subsegments in the market. The research methodology used to estimate the market size is as follows:

- Key industry players have been identified through extensive secondary research.

- The market size of industries, in terms of value, has been determined through primary and secondary research processes.

- All percentage shares, splits, and breakdowns have been determined using secondary sources and verified through primary sources.

Data Triangulation

After arriving at the overall market size—using the market size estimation processes as explained above—the market has been split into several segments and subsegments. To complete the overall market engineering process and arrive at the exact statistics of each market segment and subsegment, the data triangulation and market breakdown procedures have been employed, wherever applicable. The data has been triangulated by studying various factors and trends from both the demand and supply sides in the automotive & transportation, aerospace & defense, home & commercial, healthcare, energy & utilities, oil & gas, and other related industries.

Report Objectives

- To describe and forecast the triple offset butterfly valve market, by material, size, industry, and geography, in terms of value

- To describe and forecast the triple offset butterfly valve market for various segments with regard to 4 main regions—North America, Asia Pacific (APAC), Europe, Rest of the World (RoW), in terms of value

- To provide detailed information regarding drivers, restraints, opportunities, and challenges pertaining to the triple offset butterfly valve market

- To study a complete triple offset butterfly valve value chain and analyze current and future market trends

- To strategically analyze the micromarkets1 with respect to individual growth trends, prospects, and contributions to the overall triple offset butterfly valve market

- To analyze opportunities in the market for stakeholders by identifying high-growth segments in the triple offset butterfly valve market

- To strategically profile key players, along with detailing competitive landscape for market leaders

- To analyze strategic approaches such as product launches, acquisitions, mergers, collaborations, contracts, expansions, and partnerships in the triple offset butterfly valve market

Available Customizations

With the given market data, MarketsandMarkets offers customizations according to the companies’ specific needs. The following customization options are available for the report:

Company Information

- Detailed analysis and profiling of additional market players based on various blocks of the value chain

Growth opportunities and latent adjacency in Triple Offset Butterfly Valve Market