Aerospace 3D Printing Materials Market by Material Type (Plastic, Metal, Others), Printing Technology (DMLS, FDM, CLIP, SLA, SLS), Platform (Aircraft, UAVs, Spacecraft), Application (Prototyping, Tooling, Functional Parts), End Product (Engine Components, Structural Components, Others), and Region - Global Forecast to 2027

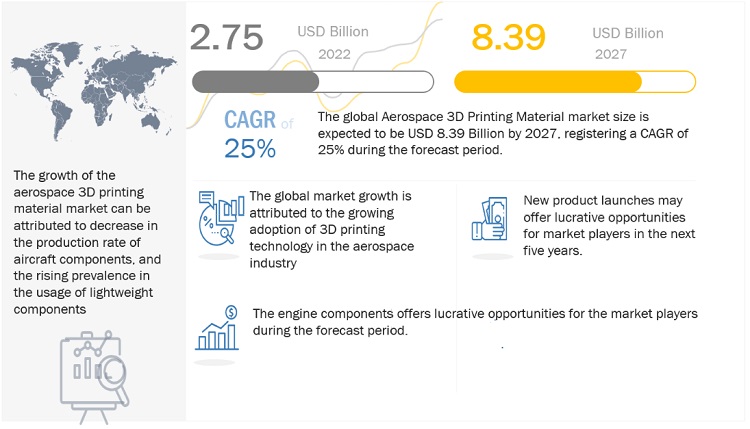

The aerospace 3D printing materials market is projected to reach USD 8.39 billion by 2027, at a CAGR of 25% from USD 2.75 billion in 2022. Demand for lightweight, cost-effective aircraft, as well as the need for rapid manufacturing of complex parts are expected to drive the aerospace 3D printing materials market forward.

Attractive Opportunities in the Aerospace 3D Printing Materials Market

To know about the assumptions considered for the study, Request for Free Sample Report

Market Dynamics

Driver: Increased demand for lightweight and long-lasting aerospace components

The increase in jet fuel prices, as well as the implementation of stringent government regulations on the carbon footprint generated by the aviation industry, have enabled aircraft manufacturers to investigate ways to improve fuel efficiency. The airline industry is expected to achieve net-zero carbon emissions by 2050, according to IATA. The primary approach used by aircraft manufacturers to improve fuel efficiency and achieve the designated goal is to reduce an aircraft's net weight and optimize the engine. The use of additive manufacturing allows aircraft manufacturers to reap the benefits of design optimization and significant weight reduction. Complex assemblies can be disassembled into single components using 3D printing technologies, reducing the operation's complexity and net weight.

Restraints: Inadequate regulatory infrastructure

Although additive manufacturing technology was introduced in 1987, it was not commercially accepted due to several operational limitations. With advancements in additive manufacturing technology, it has gained traction in industries such as aviation, space, and defense. The rapid adoption of this technology has created a regulatory gap in its scope of operations. Companies in the aviation, space, and defense industries are developing novel alloys that can be used in the additive manufacturing process. Though these alloys have improved properties, there was no proper regulatory framework catering to additive manufacturing operations. To address these growing concerns, several Standards Developing Organizations (SDOs) including the American Society for Testing Materials (ASTM), the International Organization for Standardization (ISO), and other European Standardization Organizations such as CEN (European Committee for Standardization) and CENELEC (European Committee for Electrotechnical Standardization) have begun developing a framework to bridge the gap. These bodies' regular technology transfer sessions, exhibitions, and safety awareness seminars, organized in collaboration with major industry players, are among the first steps toward establishing a concrete regulatory framework.

Opportunities: Advanced 3D printing technologies that require less production time are being developed.

When compared to 3D printing, traditional processes for manufacturing aerospace components take longer. The advancement of new 3D printing technologies allows for the faster production of parts and components that would otherwise take months or years to manufacture, reducing their production time. CLIP (Continuous Liquid Interface Production) is one of the recent 3D printing technologies used for manufacturing parts and objects through continuous production. It eliminates layer by layer processes, unlike other 3D printing technologies, such as SLA and SLS. Another technology is DMLS, which uses powdered metals instead of powdered thermoplastics for creating metal components. These technologies can develop products at a rate hundred times faster than other 3D printing technologies.

Challenges: High volume production of aerospace components is slower as compared to traditional manufacturing

In the traditional manufacturing of aerospace components, increasing production volume results in lower manufacturing costs while maintaining production speed. However, as the production scale increases in 3D printing technology, the manufacturing costs rise, making the technology more suitable for low production volumes. The costs of running and procuring 3D printing machines, as well as the raw materials used in 3D printing, are higher than in conventional manufacturing. This factor is a barrier to the expansion of the aerospace 3D printing market, but it can be overcome by lowering the costs of raw materials used in 3D printing.

“Fused Deposition Modeling (FDM) was the largest 3D printing technology aerospace 3D printing materials market in 2021, in terms of value”

The Fusion Deposition Modeling (FDM) segment is expected to dominate the aerospace 3D printing market in terms of printing technology. The ability of this technology to produce complex shapes with varying textures, thickness, and color is one of the main factors driving the segment's overall growth.

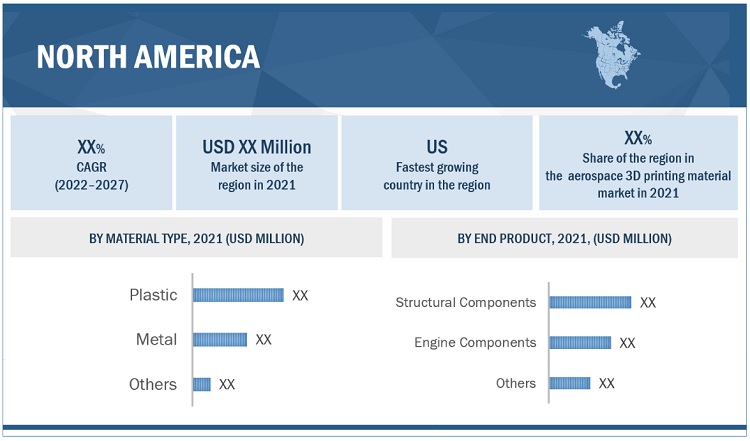

“North America was the largest market for aerospace 3D printing materials in 2021, in terms of value.”

North America is the largest region in the aerospace 3D printing materials market and is driven by the increasing adoption of 3D printing technology for the production of complex, lightweight 3D components Furthermore, aircraft component and aircraft manufacturers are shifting to 3D printing technology to produce low-volume parts, fueling the growth of the aerospace 3D printing market.

To know about the assumptions considered for the study, download the pdf brochure

Key Market Players

The key players in this market 3D systems Corporation (US), Stratasys, Inc. (Israel), Materialise N.V (Belgium), EOS GmbH (Germany), and Ultimaker B.V. (Netherlands). Continuous developments in the market—including new product launches, mergers & acquisitions, agreements, and expansions—are expected to help the market grow. Leading manufacturers of aerospace 3D printing materials market have opted for new product launches to sustain their market position.

Scope of the Report

|

Report Metric |

Details |

|

Years considered for the study |

2018-2027 |

|

Base Year |

2021 |

|

Forecast period |

2022–2027 |

|

Units considered |

Volume (Kilotons); Value (USD Billion) |

|

Segments |

Material Type, Printing Technology, Platform, Application, End Product, and Region |

|

Regions |

Asia Pacific, North America, Europe, Middle East & Africa, and South America |

|

Companies |

The key players in this market 3D systems Corporation (US), Stratasys, Inc. (Israel), Materialise N.V (Belgium), EOS GmbH (Germany), Ultimaker B.V. (Netherlands) |

This report categorizes the global aerospace 3d printing materials market based on material type, printing technology, platform, application, end product, and region.

On the basis of material type, the aerospace 3d printing materials market has been segmented as follows:

- Plastic

- Metal

- Others

On the basis of printing technology, the aerospace 3d printing materials market has been segmented as follows:

- Direct Metal Laser Sintering (DMLS)

- Fused Deposition Modeling (FDM)

- Continuous Liquid Interface Production (CLIP)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

On the basis of platform, the aerospace 3d printing materials market has been segmented as follows:

- Aircraft

- UAVs

- Spacecraft

On the basis of application, the aerospace 3d printing materials market has been segmented as follows:

- Prototyping

- Tooling

- Functional Parts

On the basis of end product, the aerospace 3d printing materials market has been segmented as follows:

- Engine Components

- Structural Components

- Others

On the basis of region, the aerospace 3d printing materials market has been segmented as follows:

- Asia Pacific

- Europe

- North America

- Middle East & Africa

- South America

Frequently Asked Questions (FAQ):

What is the expected growth rate of aerospace 3D printing materials market?

The forecast period for aerospace 3D printing materials market in this study is 2022-2027. The aerospace 3D printing materials market is projected to grow at CAGR of 25%, in terms of value, during the forecast period.

Who are the major key player in aerospace 3D printing materials market?

3D systems Corporation (US), Stratasys, Inc. (Israel), Materialise N.V (Belgium), EOS GmbH (Germany), Ultimaker B.V. (Netherlands)

Which is the largest region in the aerospace 3D printing materials market?

North America is the largest region in the aerospace 3D printing materials market due to the the presence of experienced professionals in 3D aerospace printing and highly integrated aircraft manufacturing facilities. .

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Table of Content

1 Introduction

1.1 Objectives of the Study

1.2 Market Definition

1.3 Market Scope

1.3.1 Markets Covered

1.3.2 Years Considered in the Report

1.4 Currency

1.5 Limitations

1.6 Stakeholders

2 Research Methodology

2.1 Market Share Estimation

2.1.1 Secondary Data

2.1.1.1 Key Data from Secondary Sources

2.1.2 Primary Data

2.1.2.1 Key Data from Primary Sources

2.1.2.2 Key Industry Insights

2.2 Market Size Estimation

2.2.1 Bottom-Up Approach

2.2.2 Top-Down Approach

2.3 Market Breakdown & Data Triangulation

2.4 Research Assumptions

3 Executive Summary

4 Premium Insights

4.1 Significant Opportunities in Aerospace 3D Printing Materials Market, 2022–2027

4.2 Aerospace 3D Printing Materials Market, By Material Type

4.3 Aerospace 3D Printing Materials Market, By Printing Technology

4.4 Aerospace 3D Printing Materials Market, By Platform

4.5 Aerospace 3D Printing Materials Market, By Application

4.6 Aerospace 3D Printing Materials Market, By End Product

4.7 Aerospace 3D Printing Materials Market, By Country

5 Market Overview

5.1 Introduction

5.2 Market Segmentation

5.2.1 Aerospace 3D Printing Materials Market, By Material Type

5.2.2 Aerospace 3D Printing Materials Market, By Printing Technology

5.2.3 Aerospace 3D Printing Materials Market, By Platform

5.2.4 Aerospace 3D Printing Materials Market, By Application

5.2.5 Aerospace 3D Printing Materials Market, By End Product

5.3 Market Dynamics

5.3.1 Drivers

5.3.2 Restraints

5.3.3 Opportunities

5.4.4 Challenges

5.4 Porter's Five Forces Analysis

5.4.1 Bargaining Power of Suppliers

5.4.2 Bargaining Power of Buyers

5.4.3 Threat of New Entrants

5.4.4 Threat of Substitutes

5.4.5 Degree of Competition

5.5 Supply Chain Analysis

5.6 Ecosystem: Aerospace 3D Printing Materials Market

5.7 Value Chain Analysis

5.8 Technology Analysis

5.9 Pricing Analysis

5.10 Trends and Disruptions Impacting Customers

6 Aerospace 3D Printing Materials Market, By Material Type

6.1 Plastic

6.2 Metal

6.3 Others

7 Aerospace 3D Printing Materials Market, By Printing Technology

7.1 Direct Metal Laser Sintering (DMLS)

7.2 Fused Deposition Modeling (FDM)

7.3 Continuous Liquid Interface Production (CLIP)

7.4 Stereolithography (SLA)

7.5 Selective Laser Sintering (SLS)

8 Aerospace 3D Printing Materials Market, By Platform

8.1 Aircraft

8.2 UAVs

8.3 Spacecraft

9 Aerospace 3D Printing Materials Market, By Application

9.1 Prototyping

9.2 Tooling

9.3 Functional Parts

10 Aerospace 3D Printing Materials Market, By End Product

10.1 Engine Components

10.2 Structural Components

10.3 Others

11 Aerospace 3D Printing Materials Market, By Region

11.1 Introduction

11.2 North America

11.2.1 Aerospace 3D Printing Materials Market Size in North America, By Material Type

11.2.2 Aerospace 3D Printing Materials Market Size in North America, By Country

11.2.2.1 Canada

11.2.2.1.1 Aerospace 3D Printing Materials Market Size in Canada, By Material Type

11.2.2.2 U.S.

11.2.2.2.1 Aerospace 3D Printing Materials Market Size in U.S., By Material Type

11.2.2.3 Mexico

11.2.2.3.1 Aerospace 3D Printing Materials Market Size in Mexico, By Material Type

11.3 Europe

11.3.1 Aerospace 3D Printing Materials Market Size in Europe, By Material Type

11.3.2 Aerospace 3D Printing Materials Market Size in Europe, By Country

11.3.2.1 Germany

11.3.2.1.1 Aerospace 3D Printing Materials Market Size in Germany, By Material Type

11.3.2.2 France

11.3.2.2.1 Aerospace 3D Printing Materials Market Size in France, By Material Type

11.3.2.3 UK

11.3.2.3.1 Aerospace 3D Printing Materials Market Size in UK, By Material Type

11.3.2.4 Italy

11.3.2.4.1 Aerospace 3D Printing Materials Market Size in Italy, By Material Type

11.3.2.5 Rest of Europe

11.3.2.5.1 Aerospace 3D Printing Materials Market Size in Rest of Europe, By Material Type

11.4 Asia-Pacific

11.4.1 Aerospace 3D Printing Materials Market Size in Asia-Pacific, By Material Type

11.4.2 Aerospace 3D Printing Materials Market Size in Asia-Pacific, By Country

11.4.2.1 China

11.4.2.1.1 Aerospace 3D Printing Materials Market Size in China, By Material Type

11.4.2.2 Japan

11.4.4.2.1 Aerospace 3D Printing Materials Market Size in Japan, By Material Type

11.4.2.3 India

11.4.2.3.1 Aerospace 3D Printing Materials Market Size in India, By Material Type

11.4.2.4 South Korea

11.4.2.4.1 Aerospace 3D Printing Materials Market Size in South Korea, By Material Type

11.4.2.5 Rest of Asia Pacific

11.4.2.5.1 Aerospace 3D Printing Materials Market Size in Rest of Asia Pacific, By Material Type

11.5 South America

11.5.1 Aerospace 3D Printing Materials Market Size in South America, By Material Type

11.5.2 Aerospace 3D Printing Materials Market Size in South America, By Country

11.5.2.1 Brazil

11.5.2.1.1 Aerospace 3D Printing Materials Market Size in Brazil, By Material Type

11.5.2.2 Argentina

11.5.2.2.1 Aerospace 3D Printing Materials Market Size in Argentina, By Material Type

11.5.2.3 Rest of South America

11.5.2.3.1 Aerospace 3D Printing Materials Market Size in South America, By Material Type

11.6 Middle East & Africa

11.6.1 Aerospace 3D Printing Materials Market Size in Middle East & Africa, By Material Type

11.6.2 Aerospace 3D Printing Materials Market Size in Middle East & Africa, By Country

11.5.2.1 Saudi Arabia

11.5.2.1.1 Aerospace 3D Printing Materials Market Size in Saudi Arabia, By Material Type

11.5.2.2 South Africa

11.5.2.2.1 Aerospace 3D Printing Materials Market Size in South Africa, By Material Type

11.5.2.3 Rest of Middle East & Africa

11.5.2.3.1 Aerospace 3D Printing Materials Market Size in Rest of Middle East & Africa, By Material Type

12 Competitive Landscape

12.1 Introduction

12.2 Market Share Analysis

12.3 Market Ranking

12.4 Market Evaluation Framework

12.4.1 Product Launches and Developments

12.4.2 Expansions

12.4.3 Contracts and Agreements

12.4.4 Mergers & Acquisitions

12.5 Revenue Analysis of Top Market Players

12.6 Company Evaluation Matrix

12.4.1 Star

12.4.2 Emerging Leaders

12.4.3 Pervasive

12.4.4 Participants

13 Company Profiles

* (Business Overview, Products Mix, Recent Developments, SWOT Analysis, MnM view)

13.1 3D Systems Corporation

13.2 Stratasys, Inc.

13.3 Materialise NV

13.4 EOS GmbH

13.5 Ultimaker B.V.

13.6 EnvisionTec GmbH

13.7 EXONE

13.8 General Electric

13.9 Covestro AG

13.10 Sandvik AB

13.11 Other Companies

*Details Might Not Be Captured in Case of Unlisted Companies.

Note: This is the tentative list, we will provide you the company profiles of major companies in this market.

14 Appendix

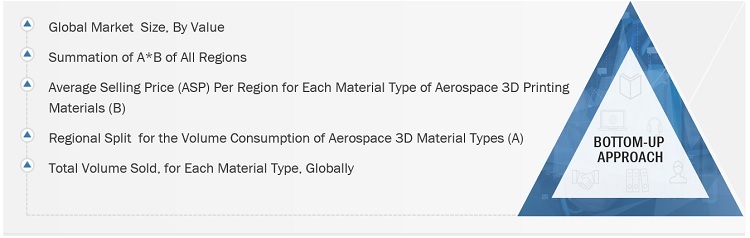

The study involved four major activities to estimate the size of aerospace 3d printing materials market. Exhaustive secondary research was done to collect information on the market, the peer market, and the parent market. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain through primary research. Both top-down and bottom-up approaches were employed to estimate the complete market size. Thereafter, the market breakdown and data triangulation procedures were used to estimate the market size of the segments and subsegments.

Secondary Research

In the secondary research process, various secondary sources have been referred to for identifying and collecting information for this study. These secondary sources include annual reports, press releases, investor presentations of companies, white papers, certified publications, trade directories, certified publications, articles from recognized authors, gold standard and silver standard websites, and databases.

Secondary research has been used to obtain key information about the value chain of the industry, monetary chain of the market, the total pool of key players, market classification and segmentation according to industry trends to the bottom-most level, and regional markets. It was also used to obtain information about the key developments from a market-oriented perspective.

Primary Research

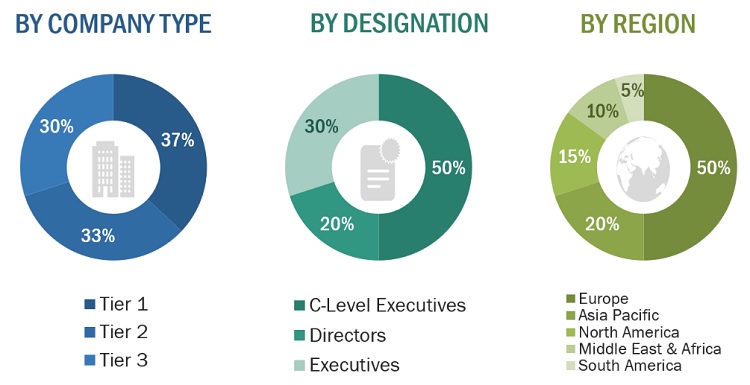

The aerospace 3d printing materials market comprises several stakeholders in the value chain, which include raw material suppliers, manufacturers, distributors, and end users. Various primary sources from the supply and demand sides of the aerospace 3d printing materials market have been interviewed to obtain qualitative and quantitative information.

The primary interviewees from the demand side include key opinion leaders in end-use sectors. The primary sources from the supply side include manufacturers, associations, and institutions involved in the aerospace 3d printing materials industry.

The breakdown of profiles of the primary interviewees is illustrated in the figure below:

Note: Tier 1, Tier 2, and Tier 3 companies are classified based on their market revenue in 2021 available in the public domain, product portfolios, and geographical presence.

Other designations include consultants and sales, marketing, and procurement managers.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

The top-down and bottom-up approaches have been used to estimate and validate the size of the aerospace 3d printing materials market.

- The key players in the industry have been identified through extensive secondary research.

- The supply chain of the industry has been determined through primary and secondary research.

- All percentage shares, splits, and breakdowns have been determined using secondary sources and verified through primary sources.

- All possible parameters that affect the markets covered in this research study have been accounted for, viewed in extensive detail, verified through primary research, and analyzed to obtain the final quantitative and qualitative data.

- The research includes the study of reports, reviews, and newsletters of the key market players, along with extensive interviews for opinions with leaders such as directors and marketing executives.

Aerospace 3D Printing Materials Market: Bottom-Up Approach 1

Source: MarketsandMarkets Analysis

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the total market size from the estimation process explained above, the overall market has been split into several segments and sub-segments. To complete the overall market engineering process and arrive at the exact statistics for all the segments and sub-segments, the data triangulation and market breakdown procedures have been employed, wherever applicable. The data has been triangulated by studying various factors and trends from both the demand and supply sides. Along with this, the market size has been validated by using both the top-down and bottom-up approaches and primary interviews. Hence, for every data segment, there have been three sources—top-down approach, bottom-up approach, and expert interviews. The data was assumed correct when the values arrived from the three sources matched.

Report Objectives

- To define, describe, and forecast the size of the aerospace 3d printing materials market, in terms of value and volume

- To provide detailed information regarding the major factors (drivers, opportunities, restraints, and challenges) influencing the growth of the market

- To estimate and forecast the market size based on material type, printing technology, platform, application, end product, and region

- To forecast the size of the market with respect to major regions, namely, Europe, North America, Asia Pacific, and Middle East & Africa, and South America along with their key countries

- To strategically analyze micromarkets with respect to individual growth trends, prospects, and their contribution to the overall market

- To analyze opportunities in the market for stakeholders and provide a competitive landscape of market leaders

- To track and analyze recent developments such as expansions, new product launches, partnerships & agreements, and acquisitions in the market

- To strategically profile key market players and comprehensively analyze their core competencies

Available Customizations

Along with the given market data, MarketsandMarkets offers customizations according to the company’s specific needs. The following customization options are available for the report:

- Regional Analysis

Further breakdown of a region with respect to a particular country or additional application

- Company Information

Detailed analysis and profiles of additional market players

Growth opportunities and latent adjacency in Aerospace 3D Printing Materials Market