Aluminum Foam Market by Type (Open-Cell, Closed-Cell), Application (Anti-Intrusion Bars, Heat Exchangers, Sound Absorbers, Filters), End-Use Industry (Automotive, Construction & Infrastructure, Industrial), and Region - Global Forecast to 2027

Updated on : March 19, 2024

Aluminum Foam Market

The global aluminum foam market was valued at USD 43 million in 2022 and is projected to reach USD 55 million by 2027, growing at 4.8% cagr from 2022 to 2027. Significant growth in the market is observed because of the increase in the demand for aluminum foam from various end-use industries such as automotive and construction & infrastructure and industrial. Aluminum foam offers a huge range of advantages, such as cost-benefit, low weight, and good thermal conductivity, resulting in its increasing adoption in different applications.

Attractive Opportunities in the Aluminum Foam Market

To know about the assumptions considered for the study, Request for Free Sample Report

Aluminum Foam Market Dynamics

Drivers: Superior properties of aluminum foams

Aluminum foams are widely used for sound and energy absorption applications. They possess various properties, such as high stiffness, low specific weight, high compression strength, high porosity, and low thermal conductivity. The cellular structure of aluminum foams depends on the manufacturing process, which impacts the foam's properties. Aluminum foams are widely used in various applications, such as heat exchangers, anti-intrusion bars, sound absorbers, and energy absorbers. They can withstand a high amount of mechanical energy when they are deformed. This makes them a good material for usage in energy absorbers. Aluminum foams also possess higher collapse strength than polymer-based foams. The damping capacity of aluminum foams is generally 5–10 times more than the aluminum from which the foam is made. Foams that are manufactured from nonflammable aluminum remain nonflammability even after processing.

Restraints: Difficulty in bonding, welding, and soldering aluminum foams

Experts in the aluminum foam market are still widening their knowledge regarding the interrelationship between structure and morphology. The cellular structure of aluminum foams creates a problem with their cutting and bonding. In glue-bonded aluminum foams, glued joined areas turn out to be stronger than the other part of the foam. This leads to a different rate of thermal expansion, low thermal stability at elevated temperatures, and different electrical and thermal conductivity. Furthermore, welding aluminum foam is technically difficult. This is because of the non-uniform fusion of the thin-walled skeletal structure of the aluminum foam and its varying pore size. Its irregular pore shape makes it difficult to solder. Properties such as low melting point, large shrinkage, high thermal conductivity, and expansion further make the aluminum foam soldering process difficult.

Opportunities: Increasing usage of aluminum foams in the automotive industry

For many years, reducing the weight of vehicles and increasing safety have been the major concerns for the automotive industry. Aluminum foams are an emerging class of materials with attractive properties. These materials are lightweight and have very high stiffness due to their porous structure. They offer significant potential for the reduction of vehicle weight. Aluminum foams can absorb high amounts of energy, making them suitable for shock absorption. The usage of aluminum foams also reduces automotive vehicles' weight, leading to better fuel efficiency. Aluminum foams are gaining high acceptance in the automotive industry. It is used in various structural automotive parts such as anti-intrusion bars, front bumpers, and crash boxes. Inferno, a Mexico-based company, has manufactured a hypercar using aluminum foams. The aluminum foam can stretch a hundred times its original length without affecting its intrinsic properties. Audi, Bentley, and Ferrari have also used aluminum foams in their automotive structural parts. Federal Motor Vehicle Safety Standards conducted a test for measuring the impact of head injury on A-pillars in automobiles. The result showed double the head injury coefficient (HIC) value.

Challenges: Development needed to control pore size and shape of end products

The history of aluminum foams dates to the 1940s. Many patents were developed between the 1950s and 1970s, and various foaming processes were proposed. There are no solid reading materials available for those patents. Most of the R&D activities for aluminum foams have been carried out on an empirical basis, without in-depth knowledge of the underlying mechanism of the foaming process. Further development is required to understand the reason for the critical cell wall thickness of aluminum foams. Research is carried out to control aluminum foams' pore size and shape. However, further R&D activities are needed to reduce aluminum foams' production and processing costs.

The automotive end-use industry is expected to witness highest CAGR between 2022 and 2027

Aluminum foam is finding increasing applications in the automotive industry due to the growing demand for high-performance and lightweight aluminum foam. With the growth in the automotive industry the demand for aluminum foam is also growing. Aluminum foam is used in Anti-intrusion bars and crash guards in light weight electric and hybrid cars for ensuring passengers safety due to its high energy absorbing tendency.

The anti-intrusion bars application segment accounted for a significant share in the overall aluminum foam market in 2021.

The anti-intrusion bars application leads the aluminum foam market, in terms of value due to the high demand for aluminum foam coming from automotive end-use industry. Anti-intrusion bars play an important role in absorbing the kinetic energy of the colliding vehicles. Anti-intrusion bars are generally used in ground vehicles and passenger cars to ensure passengers protection from side impacts. Side impacts are particularly dangerous as these impacts are very close to the passenger. Aluminum foam offers high energy absorption property, which makes it a favored material for usage in anti-intrusion bars in automotive industry.

To know about the assumptions considered for the study, download the pdf brochure

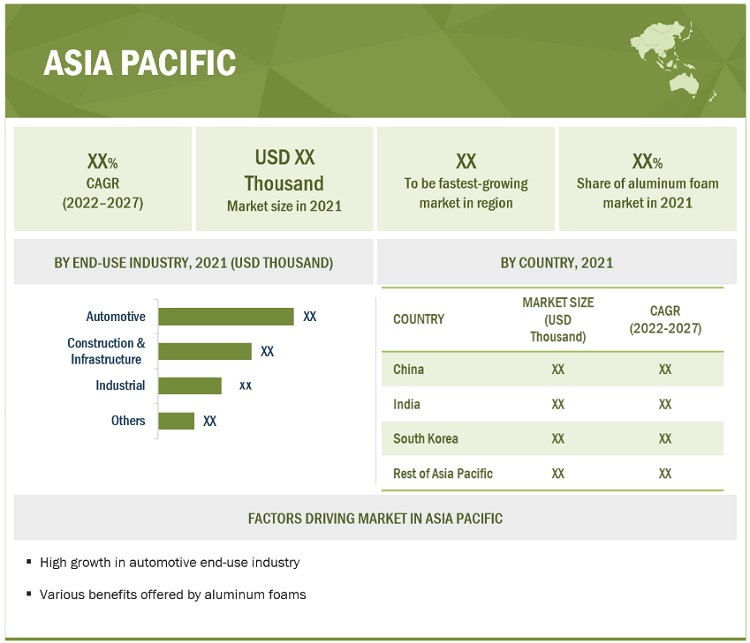

Asia Pacific is expected to lead the aluminum foam market during the forecast period.

Asia Pacific is the largest and projected to be the fastest-growing aluminum foam market. The automotive and construction industry is the major consumer of aluminum foam in the region. Due to the presence of a large number of manufacturers, it is the most important market for aluminum foam. The growth of aluminum foam is attributed to the high demand coming from the automotive and construction end-use industry. China, India, and South Korea are the major countries in the aluminum foam market in Asia Pacific region.

Increasing importance of aluminum foam in construction industry

The growing demand for lightweight structural materials in construction applications such as cladding, panels, ceilings, display platforms, and wallboards is a huge opportunity for aluminum foam manufacturers. Aluminum foams are generally used as sandwich structures in the construction sector. Features such as optimal fire, weather, and chemical resistance of aluminum foam coupled with the emerging international building codes that have challenged the construction market to be design-oriented with sustainability and energy-efficient solutions are creating an excellent opportunity for aluminum foam manufacturers.

Aluminum Foam Market Players

Some of the key players in the aluminum foam market are ERG Aerospace Corporation (US), CYMAT Technologies Ltd. (Canada), Alantum Corporation (South Korea), Liaoning Rontec Advanced Material Technology Co., Ltd. (China), Shanxi Putai Aluminum Foam Manufacturing Co., Ltd. (China), Mayser GmbH & Co. KG (Germany), Aluminum King Co., Ltd (China), and Pohltec Metalfoam GmbH (Germany).

Aluminum Foam Market Report Scope

|

Report Metric |

Details |

|

Market Size Value in 2022 |

USD 43 Million |

|

Revenue Forecast in 2027 |

USD 55 Million |

|

CAGR |

4.8% |

|

Years considered for the study |

2020–2027 |

|

Base year |

2021 |

|

Forecast period |

2022–2027 |

|

Units considered |

Value (USD thousand), Volume (ton) |

|

Segments |

Type, Application, End-use Industry, and Region |

|

Regions |

Asia Pacific, North America, Europe, Latin America, and Middle East & Africa |

|

Companies |

ERG Aerospace Corporation (US), CYMAT Technologies Ltd. (Canada), Alantum (South Korea), Liaoning Rontec Advanced Material Technology Co., Ltd. (China), Shanxi Putai Aluminum Foam Manufacturing Co., Ltd. (China), Mayser GmbH & Co. KG (Germany), Aluminum King Co., Ltd (China), and Pohltec Metalfoam GmbH (Germany) |

This research report categorizes the aluminum foam market based on type, application, end-use industry, and region.

Aluminum Foam Market by Type:

- Open-cell aluminum foam

- Closed-cell aluminum foam

Aluminum Foam Market by Application:

- Anti-intrusion Bars

- Heat Exchangers

- Sound Insulation

- Filters

- Others (Railway Buffer, Medical Implants)

Aluminum Foam Market by End-use industry:

- Automotive

- Construction & infrastructure

- Industrial

- Others (Aerospace, Defense, Medical)

Aluminum Foam Market by Region:

- Asia Pacific

- North America

- Europe

- Latin America

- Middle East & Africa

Recent Developments

- In April 2022, CYMAT Technologies has announced Expansion & Technological Advancements. The company is planning to expand plant output capacity to approx. USD 75 million on a staged basis and to deploy automation and new technology to improve cost structure.

- In July 2017, ERG Aerospace Corporation opened a facility for manufacturing operations at Sparks, Nevada, in the US. The company invested USD 2.1 million in the plant. The location of the plant offers logistic advantages and low-cost labor. This expansion has helped the company to increase its geographical presence.

- In December 2017, the company Mayser GmbH & Co. KG invested in a new factory in Michigan, US, to meet the growing demand in the automotive sector. The factory also develops aluminum foam products for non-automotive field, products for safety, and foam technology. This expansion has led to the growth of the aluminum foam market in the North American region.

- In December 2017, CYMAT announced a joint-venture with Alucoil SA (Spain) for producing aluminum composite panels with metallurgically-bonded aluminum foam cores. This joint venture resulted in increasing the geographical presence of the company.

Frequently Asked Questions (FAQ):

What are the factors influencing the growth of the aluminum foam market?

The properties of aluminum foam, increasing environmental awareness, and its upcoming new applications.

Which is the largest country-level market for aluminum foam?

China is the largest aluminum foam market due to high demand from automotive industry.

What are the factors contributing to the final price of aluminum foam?

Raw material plays a vital role in the costs. The cost of these materials contributes largely to the final pricing of aluminum foam.

What are the challenges in the aluminum foam market?

Development of low-cost production technology is the major challenge in the aluminum foam market, along with the percentage of getting a desired product. .

Which type of aluminum foam holds the largest market share?

Open-cell aluminum foam holds the largest share.

How is the aluminum foam market aligned?

The market is growing at a significant pace. It is a potential market and many manufacturers are planning business strategies to expand their business.

Who are the major manufacturers?

ERG Aerospace Corporation (US), CYMAT Technologies Ltd. (Canada), Alantum Corporation (South Korea), Liaoning Rontec Advanced Material Technology Co., Ltd. (China), and Shanxi Putai Aluminum Foam Manufacturing Co., Ltd. (China)

What are the major applications for aluminum foam?

The major applications for aluminum foam are anti-intrusion bars, sound absorbers, heat exchangers, filters and many more. .

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

- 5.1 INTRODUCTION

-

5.2 MARKET DYNAMICSDRIVERS- Superior properties of aluminum foams- Increasing usage of aluminum foams in applications such as heat exchangers and anti-intrusion barsRESTRAINTS- Difficulty in bonding, welding, and soldering aluminum foams- High cost of aluminum foam compared with substitutesOPPORTUNITIES- Increasing usage of aluminum foams in the automotive industry- Increasing demand for lightweight structural materials in construction industryCHALLENGES- Development needed to control pore size and shape of end products- Developing cost-efficient manufacturing methods

-

5.3 PORTER’S FIVE FORCES ANALYSISTHREAT OF NEW ENTRANTSTHREAT OF SUBSTITUTESBARGAINING POWER OF SUPPLIERSBARGAINING POWER OF BUYERSINTENSITY OF COMPETITIVE RIVALRY

- 5.4 SUPPLY CHAIN ANALYSIS

-

5.5 PRICING ANALYSISAVERAGE SELLING PRICES FOR END-USE INDUSTRIES, BY KEY PLAYERS

- 5.6 AVERAGE SELLING PRICE

-

5.7 KEY STAKEHOLDERS AND BUYING CRITERIAKEY STAKEHOLDERS IN BUYING PROCESSBUYING CRITERIA

- 5.8 TECHNOLOGY ANALYSIS

- 5.9 KEY CONFERENCES AND EVENTS, 2022–2023

-

5.10 GLOBAL REGULATORY FRAMEWORK AND ITS IMPACT ON ALUMINUM FOAM MARKETREGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

-

5.11 ECOSYSTEM/MARKET MAP

- 5.12 VALUE CHAIN ANALYSIS

-

5.13 TRADE ANALYSIS: KEY MARKET FOR IMPORT/EXPORTCHINAUSGERMANYINDIA

- 5.14 CASE STUDY ANALYSIS

- 5.15 TRENDS IMPACTING CUSTOMER BUSINESS

-

5.16 PATENT ANALYSISMETHODOLOGYLIST OF PATENTS

- 6.1 INTRODUCTION

-

6.2 OPEN-CELL ALUMINUM FOAMHIGH DEMAND FOR SOUND ABSORBERS TO DRIVE MARKET

-

6.3 CLOSED-CELL ALUMINUM FOAMCLOSED-CELL ALUMINUM FOAM TO REGISTER HIGHEST GROWTH

- 7.1 INTRODUCTION

-

7.2 ANTI-INTRUSION BARSANTI-INTRUSION BAR APPLICATION TO LEAD DEMAND FOR ALUMINUM FOAM

-

7.3 HEAT EXCHANGERSDEMAND FOR ALUMINUM FOAMS TO INCREASE DUE TO HIGH POROSITY

-

7.4 SOUND ABSORBERSDEMAND FOR SOUND INSULATION TO INCREASE WITH INCREASING NOISE POLLUTION

-

7.5 FILTERSHIGH POROSITY TO CREATE DEMAND FOR ALUMINUM FOAMS

-

7.6 OTHERSRAILWAY BUFFERSMEDICAL IMPLANTS

- 8.1 INTRODUCTION

-

8.2 AUTOMOTIVE INDUSTRYHIGH DEMAND FOR ANTI-INTRUSION BARS TO DRIVE MARKET

-

8.3 CONSTRUCTION & INFRASTRUCTUREEXCELLENT SOUND-ABSORBING CAPABILITY OF ALUMINUM FOAMS TO INCREASE DEMAND

-

8.4 INDUSTRIALEXTENSIVE USE OF HEAT EXCHANGERS TO BOOST DEMAND

-

8.5 OTHER END-USE INDUSTRIESAEROSPACEDEFENSEMEDICAL

- 9.1 INTRODUCTION

-

9.2 ASIA PACIFICBY COUNTRYBY TYPEBY APPLICATIONBY END-USE INDUSTRYCHINA- Automotive industry to drive marketSOUTH KOREA- High demand in construction industry to drive marketINDIA- Growing end-use industries to support market growthREST OF ASIA PACIFIC- By type- By end-use industry

-

9.3 NORTH AMERICABY COUNTRYBY TYPEBY APPLICATIONBY END-USE INDUSTRYUS- High demand from automotive manufacturers to drive marketCANADA- Automotive to be fastest-growing segment

-

9.4 EUROPEBY COUNTRYBY TYPEBY APPLICATIONBY END-USE INDUSTRYGERMANY- Huge demand from automotive sector to drive marketFRANCE- Construction sector to lead market for aluminum foamsAUSTRIA- Automotive industry to create opportunities in marketNETHERLANDS- Demand for aluminum foams to increase at faster paceREST OF EUROPE- By type- By end-use industry

-

9.5 MIDDLE EAST & AFRICABY COUNTRYBY TYPEBY APPLICATIONBY END-USE INDUSTRYUAE- Open-cell aluminum foam to lead market due to demand from construction sectorSAUDI ARABIA- Automotive to be fastest-growing end-use industryQATAR- Qatar to be rapidly growing economy in Middle East & AfricaREST OF MIDDLE EAST & AFRICA- By type- By end-use industry

-

9.6 LATIN AMERICABY COUNTRYBY TYPEBY APPLICATIONBY END-USE INDUSTRYBRAZIL- Brazil to be the largest market for aluminum foam in Latin AmericaMEXICO- Rapidly growing end-use industries to drive marketREST OF LATIN AMERICA- By type- By end-use industry

- 10.1 INTRODUCTION

- 10.2 MARKET SHARE ANALYSIS

- 10.3 MARKET RANKING

- 10.4 REVENUE ANALYSIS OF TOP FIVE PLAYERS IN ALUMINUM FOAM MARKET IN 2021

-

10.5 COMPANY EVALUATION MATRIXSTRENGTH OF PRODUCT PORTFOLIOBUSINESS STRATEGY EXCELLENCE

-

10.6 COMPANY EVALUATION QUADRANT (TIER 1)STARSPERVASIVE COMPANIESPARTICIPANTSEMERGING LEADERS

- 10.7 COMPETITIVE BENCHMARKING OF KEY STARTUP/SMES

-

10.8 STARTUP/SMALL AND MEDIUM-SIZED ENTERPRISES (SME) EVALUATION MATRIXPROGRESSIVE COMPANIESRESPONSIVE COMPANIESDYNAMIC COMPANIESSTARTING BLOCKS

- 10.9 COMPETITIVE SCENARIO AND TRENDS

-

11.1 KEY PLAYERSERG AEROSPACE CORPORATION- Business overview- Products offered- Recent developments- MnM viewCYMAT TECHNOLOGIES LTD.- Business overview- Products offered- Recent developments- MnM viewALANTUM CORPORATION- Business overview- Products offered- MnM viewLIAONING RONTEC ADVANCED MATERIAL TECHNOLOGY CO., LTD.- Business overview- Products offered- MnM viewAMERICAN ELEMENTS- Business overview- Products offered- MnM viewMAYSER GMBH & CO. KG- Business overview- Products offered- Recent developments- MnM viewALUMINUM KING CO., LTD.- Business overview- Products offered- MnM viewPOHLTEC METALFOAM GMBH- Business overview- Products offered- MnM viewSHANGHAI WINFAY NEW MATERIAL CO., LTD.- Business overview- Products offered- MnM viewSHANXI PUTAI ALUMINUM FOAM MANUFACTURING CO., LTD.- Business overview- Products offered- MnM viewVIM TECHNOLOGY LTD- Business overview- Products offered- MnM viewCHINA BEIHAI BUILDING MATERIAL GROUP- Business overview- Products offered- MnM view

-

11.2 OTHER PLAYERSHAVEL METAL FOAMALUINVENTFOAMTECH NORTH AMERICAEXXENTIS LTDRECEMAT BVVERSARIEN TECHNOLOGIESNANOSHEL LLCECOCONTACT (AMC ETEC)FRAUNHOFER INSTITUTE FOR MACHINE TOOLS AND FORMING TECHNOLOGY IWEALCARBONCOMPOSITE MATERIALS, LTD. (ALUPOR LLC)

- 12.1 DISCUSSION GUIDE

- 12.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 12.3 CUSTOMIZATION OPTIONS

- 12.4 RELATED REPORTS

- 12.5 AUTHOR DETAILS

- TABLE 1 ALUMINUM FOAM MARKET: PORTER’S FIVE FORCES ANALYSIS

- TABLE 2 ALUMINUM FOAM MARKET: SUPPLY CHAIN

- TABLE 3 AVERAGE SELLING PRICES OF ALUMINUM FOAM, BY REGION

- TABLE 4 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE APPLICATIONS

- TABLE 5 KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

- TABLE 6 ALUMINUM FOAM MARKET: DETAILED LIST OF CONFERENCES AND EVENTS

- TABLE 7 NORTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 8 EUROPE: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 9 ASIA PACIFIC: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 10 LIST OF PATENTS

- TABLE 11 ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 12 ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 13 OPEN-CELL ALUMINUM FOAM MARKET, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 14 OPEN-CELL ALUMINUM FOAM MARKET, BY REGION, 2020–2027 (TON)

- TABLE 15 CLOSED-CELL ALUMINUM FOAM MARKET, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 16 CLOSED-CELL ALUMINUM FOAM MARKET, BY REGION, 2020–2027 (TON)

- TABLE 17 ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (USD THOUSAND)

- TABLE 18 ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (TON)

- TABLE 19 ALUMINUM FOAM MARKET IN ANTI-INTRUSION BARS APPLICATION, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 20 ALUMINUM FOAM MARKET IN ANTI-INTRUSION BARS APPLICATION, BY REGION, 2020–2027 (TON)

- TABLE 21 ALUMINUM FOAM MARKET IN HEAT EXCHANGERS APPLICATION, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 22 ALUMINUM FOAM MARKET IN HEAT EXCHANGERS APPLICATION, BY REGION, 2020–2027 (TON)

- TABLE 23 ALUMINUM FOAM MARKET IN SOUND ABSORBER APPLICATION, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 24 ALUMINUM FOAM MARKET IN SOUND INSULATION APPLICATION, BY REGION, 2020–2027 (TON)

- TABLE 25 ALUMINUM FOAM MARKET IN FILTER APPLICATION, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 26 ALUMINUM FOAM MARKET IN FILTER APPLICATION, BY REGION, 2020–2027 (TON)

- TABLE 27 ALUMINUM FOAM MARKET IN OTHER APPLICATIONS, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 28 ALUMINUM FOAM MARKET IN OTHER APPLICATIONS, BY REGION, 2020–2027 (TON)

- TABLE 29 ALUMINUM FOAM MARKET SIZE, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 30 ALUMINUM FOAM MARKET SIZE, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 31 ALUMINUM FOAM MARKET SIZE IN AUTOMOTIVE END-USE INDUSTRY, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 32 ALUMINUM FOAM MARKET SIZE IN AUTOMOTIVE END-USE INDUSTRY, BY REGION, 2020–2027 (TON)

- TABLE 33 ALUMINUM FOAM MARKET SIZE IN CONSTRUCTION & INFRASTRUCTURE END-USE INDUSTRY, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 34 ALUMINUM FOAM MARKET SIZE IN CONSTRUCTION & INFRASTRUCTURE END-USE INDUSTRY, BY REGION, 2020–2027 (TON)

- TABLE 35 ALUMINUM FOAM MARKET SIZE IN INDUSTRIAL END-USE INDUSTRY, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 36 ALUMINUM FOAM MARKET SIZE IN INDUSTRIAL END-USE INDUSTRY, BY REGION, 2020–2027 (TON)

- TABLE 37 ALUMINUM FOAM MARKET SIZE IN OTHER END-USE INDUSTRIES, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 38 ALUMINUM FOAM MARKET SIZE IN OTHER END-USE INDUSTRIES, BY REGION, 2020–2027 (TON)

- TABLE 39 ALUMINUM FOAM MARKET, BY REGION, 2020–2027 (USD THOUSAND)

- TABLE 40 ALUMINUM FOAM MARKET, BY REGION, 2020–2027 (TON)

- TABLE 41 ASIA PACIFIC: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (USD THOUSAND)

- TABLE 42 ASIA PACIFIC: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (TON)

- TABLE 43 ASIA PACIFIC: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 44 ASIA PACIFIC: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 45 ASIA PACIFIC: ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (USD THOUSAND)

- TABLE 46 ASIA PACIFIC: ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (TON)

- TABLE 47 ASIA PACIFIC: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 48 ASIA PACIFIC: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 49 CHINA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 50 CHINA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 51 CHINA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 52 CHINA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 53 SOUTH KOREA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 54 SOUTH KOREA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 55 SOUTH KOREA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 56 SOUTH KOREA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 57 INDIA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 58 INDIA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 59 INDIA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 60 INDIA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 61 REST OF ASIA PACIFIC: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 62 REST OF ASIA PACIFIC: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 63 REST OF ASIA PACIFIC: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 64 REST OF ASIA PACIFIC: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 65 NORTH AMERICA: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (USD THOUSAND)

- TABLE 66 NORTH AMERICA: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (TON)

- TABLE 67 NORTH AMERICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 68 NORTH AMERICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 69 NORTH AMERICA: ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (USD THOUSAND)

- TABLE 70 NORTH AMERICA: ALUMINUM FOAM MARKET, APPLICATION, 2020–2027 (TON)

- TABLE 71 NORTH AMERICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 72 NORTH AMERICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 73 US: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 74 US: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 75 US: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 76 US: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 77 CANADA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 78 CANADA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 79 CANADA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 80 CANADA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 81 EUROPE: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (USD THOUSAND)

- TABLE 82 EUROPE: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (TON)

- TABLE 83 EUROPE: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 84 EUROPE: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 85 EUROPE: ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (USD THOUSAND)

- TABLE 86 EUROPE: ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (TON)

- TABLE 87 EUROPE: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 88 EUROPE: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 89 GERMANY: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 90 GERMANY: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 91 GERMANY: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 92 GERMANY: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 93 FRANCE: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 94 FRANCE: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 95 FRANCE: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 96 FRANCE: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 97 AUSTRIA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 98 AUSTRIA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 99 AUSTRIA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 100 AUSTRIA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 101 NETHERLANDS: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 102 NETHERLANDS: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 103 NETHERLANDS: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 104 NETHERLANDS: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 105 REST OF EUROPE: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 106 REST OF EUROPE: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 107 REST OF EUROPE: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 108 REST OF EUROPE: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 109 MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (USD THOUSAND)

- TABLE 110 MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (TON)

- TABLE 111 MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 112 MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 113 MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (USD THOUSAND)

- TABLE 114 MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (TON)

- TABLE 115 MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 116 MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 117 UAE: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 118 UAE: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 119 UAE: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 120 UAE: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 121 SAUDI ARABIA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 122 SAUDI ARABIA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 123 SAUDI ARABIA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 124 SAUDI ARABIA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 125 QATAR: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 126 QATAR: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 127 QATAR: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 128 QATAR: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 129 REST OF MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 130 REST OF MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 131 REST OF MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 132 REST OF MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 133 LATIN AMERICA: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (USD THOUSAND)

- TABLE 134 LATIN AMERICA: ALUMINUM FOAM MARKET, BY COUNTRY, 2020–2027 (TON)

- TABLE 135 LATIN AMERICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 136 LATIN AMERICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 137 LATIN AMERICA: ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (USD THOUSAND)

- TABLE 138 LATIN AMERICA: ALUMINUM FOAM MARKET, BY APPLICATION, 2020–2027 (TON)

- TABLE 139 LATIN AMERICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 140 LATIN AMERICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 141 BRAZIL: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 142 BRAZIL: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 143 BRAZIL: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 144 BRAZIL: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 145 MEXICO: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 146 MEXICO: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 147 MEXICO: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 148 MEXICO: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 149 REST OF LATIN AMERICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (USD THOUSAND)

- TABLE 150 REST OF LATIN AMERICA: ALUMINUM FOAM MARKET, BY TYPE, 2020–2027 (TON)

- TABLE 151 REST OF LATIN AMERICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (USD THOUSAND)

- TABLE 152 REST OF LATIN AMERICA: ALUMINUM FOAM MARKET, BY END-USE INDUSTRY, 2020–2027 (TON)

- TABLE 153 DEGREE OF COMPETITION: ALUMINUM FOAM MARKET

- TABLE 154 COMPANY PRODUCT FOOTPRINT

- TABLE 155 COMPANY TYPE FOOTPRINT

- TABLE 156 COMPANY END-USE INDUSTRY FOOTPRINT

- TABLE 157 COMPANY REGION FOOTPRINT

- TABLE 158 ALUMINUM FOAM MARKET: DETAILED LIST OF KEY STARTUPS/SMES

- TABLE 159 ALUMINUM FOAM MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUP/SMES

- TABLE 160 ALUMINUM FOAM MARKET: DEALS, 2017–2022

- TABLE 161 ALUMINUM FOAM MATERIAL: OTHERS, 2017–2022

- TABLE 162 ERG AEROSPACE CORPORATION: COMPANY OVERVIEW

- TABLE 163 CYMAT TECHNOLOGIES LTD.: COMPANY OVERVIEW

- TABLE 164 ALANTUM CORPORATION: COMPANY OVERVIEW

- TABLE 165 LIAONING RONTEC ADVANCED MATERIAL TECHNOLOGY MATERIAL CO., LTD.: COMPANY OVERVIEW

- TABLE 166 AMERICAN ELEMENTS: COMPANY OVERVIEW

- TABLE 167 MAYSER GMBH & CO. KG: COMPANY OVERVIEW

- TABLE 168 ALUMINUM KING CO. LTD.: COMPANY OVERVIEW

- TABLE 169 POHLTEC METALFOAM GMBH: COMPANY OVERVIEW

- TABLE 170 SHANGHAI WINFAY NEW MATERIAL CO. LTD.: COMPANY OVERVIEW

- TABLE 171 SHANXI PUTAI ALUMINUM FOAM MANUFACTURING CO., LTD.: COMPANY OVERVIEW

- TABLE 172 VIM TECHNOLOGY LTD.: COMPANY OVERVIEW

- TABLE 173 CHINA BEIHAI BUILDING MATERIAL GROUP: COMPANY OVERVIEW

- TABLE 174 HAVEL METAL FOAM: COMPANY OVERVIEW

- TABLE 175 ALUINVENT: COMPANY OVERVIEW

- TABLE 176 FOAMTECH NORTH AMERICA: COMPANY OVERVIEW

- TABLE 177 EXXENTIS LTD: COMPANY OVERVIEW

- TABLE 178 RECEMAT BV: COMPANY OVERVIEW

- TABLE 179 VERSARIEN TECHNOLOGIES: COMPANY OVERVIEW

- TABLE 180 NANOSHEL LLC: COMPANY OVERVIEW

- TABLE 181 ECOCONTACT (AMC ETEC): COMPANY OVERVIEW

- TABLE 182 FRAUNHOFER INSTITUTE FOR MACHINE TOOLS AND FORMING TECHNOLOGY IWU: COMPANY OVERVIEW

- TABLE 183 ALCARBON: COMPANY OVERVIEW

- TABLE 184 COMPOSITE MATERIALS, LTD. (ALUPOR LLC): COMPANY OVERVIEW

- FIGURE 1 ALUMINUM FOAM MARKET: RESEARCH DESIGN

- FIGURE 2 MARKET SIZE ESTIMATION METHODOLOGY: BOTTOM-UP APPROACH

- FIGURE 3 MARKET SIZE ESTIMATION METHODOLOGY: TOP-DOWN APPROACH

- FIGURE 4 ALUMINUM FOAM MARKET: DATA TRIANGULATION

- FIGURE 5 OPEN-CELL ALUMINUM FOAM REMAINS DOMINATING SEGMENT DURING FORECAST PERIOD

- FIGURE 6 AUTOMOTIVE TO BE FASTEST-GROWING END-USE INDUSTRY

- FIGURE 7 ANTI-INTRUSION BARS APPLICATION TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 8 ASIA PACIFIC DOMINATED ALUMINUM FOAM MARKET IN 2021

- FIGURE 9 HIGH DEMAND FROM AUTOMOTIVE END-USE INDUSTRY TO DRIVE MARKET

- FIGURE 10 ASIA PACIFIC ACCOUNTED FOR LARGEST MARKET SHARE

- FIGURE 11 AUTOMOTIVE END-USE INDUSTRY TO LEAD OVERALL ALUMINUM FOAM MARKET

- FIGURE 12 SOUND ABSORBERS APPLICATION ACCOUNTED FOR LARGEST SHARE OF ALUMINUM FOAM MARKET

- FIGURE 13 CHINA TO REGISTER HIGHEST CAGR IN ALUMINUM FOAM MARKET

- FIGURE 14 DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES IN ALUMINUM FOAM MARKET

- FIGURE 15 PORTER’S FIVE FORCES ANALYSIS

- FIGURE 16 AVERAGE SELLING PRICES FOR TOP THREE END-USE INDUSTRIES (USD/KG), BY KEY PLAYERS

- FIGURE 17 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

- FIGURE 18 KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

- FIGURE 19 ECOSYSTEM: ALUMINUM FOAM MARKET

- FIGURE 20 VALUE CHAIN ANALYSIS: MAXIMUM VALUE ADDED DURING ALUMINUM FOAM RAW MATERIAL & MANUFACTURING PHASE

- FIGURE 21 OPEN-CELL ALUMINUM FOAM TO BE WIDELY USED TYPE

- FIGURE 22 ASIA PACIFIC TO DRIVE OPEN-CELL ALUMINUM FOAM MARKET

- FIGURE 23 ANTI-INTRUSION BARS SEGMENT TO ACCOUNT FOR LARGEST SHARE IN ALUMINUM FOAM MARKET

- FIGURE 24 ASIA PACIFIC TO REGISTER HIGHEST CAGR IN ANTI-INTRUSION BARS SEGMENT

- FIGURE 25 AUTOMOTIVE INDUSTRY TO LEAD ALUMINUM FOAM MARKET DURING FORECAST PERIOD

- FIGURE 26 ASIA PACIFIC TO DRIVE ALUMINUM FOAM MARKET IN AUTOMOTIVE INDUSTRY

- FIGURE 27 REGIONAL SNAPSHOT: CHINA TO REGISTER HIGHEST GROWTH RATE

- FIGURE 28 ASIA PACIFIC: ALUMINUM FOAM MARKET SNAPSHOT

- FIGURE 29 NORTH AMERICA: ALUMINUM FOAM MARKET SNAPSHOT

- FIGURE 30 EUROPE: ALUMINUM FOAM MARKET SNAPSHOT

- FIGURE 31 MIDDLE EAST & AFRICA: ALUMINUM FOAM MARKET SNAPSHOT

- FIGURE 32 LATIN AMERICA: ALUMINUM FOAM MARKET SNAPSHOT

- FIGURE 33 MARKET SHARE OF TOP COMPANIES IN ALUMINUM FOAM MARKET

- FIGURE 34 RANKING OF TOP FIVE PLAYERS IN ALUMINUM FOAM MARKET

- FIGURE 35 PRODUCT PORTFOLIO ANALYSIS OF TOP PLAYERS IN ALUMINUM FOAM MARKET

- FIGURE 36 BUSINESS STRATEGY EXCELLENCE OF TOP PLAYERS IN ALUMINUM FOAM MARKET

- FIGURE 37 ALUMINUM FOAM MARKET: COMPETITIVE LEADERSHIP MAPPING, 2021

- FIGURE 38 ALUMINUM FOAM MARKET: SMALL AND MEDIUM-SIZED ENTERPRISES MAPPING, 2021

- FIGURE 39 CYMAT TECHNOLOGIES LTD.: COMPANY SNAPSHOT

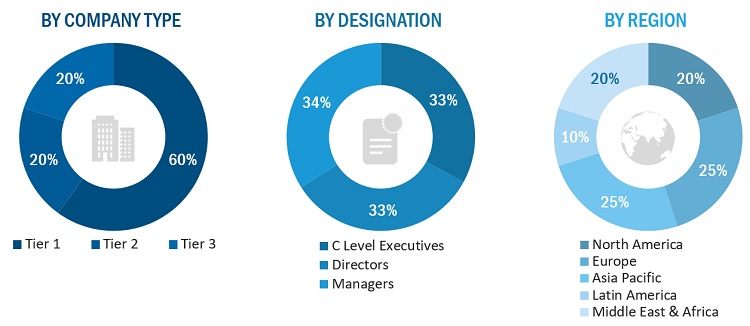

The study involved two major activities in estimating the current size of the aluminum foam market. Exhaustive secondary research was performed to collect information on the market, the peer market, and the parent market. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain through primary research. Both top-down and bottom-up approaches were employed to estimate the total market size. After that, market breakdown and data triangulation procedures were used to determine the extent of market segments and sub-segments.

Secondary Research

In the secondary research process, various secondary sources such as Hoovers, Bloomberg BusinessWeek, and Dun & Bradstreet were referred to for identifying and collecting information for this study. These secondary sources included annual reports, press releases & investor presentations of companies; white papers; certified publications; articles by recognized authors; gold standard & silver standard websites; regulatory bodies; trade directories; and databases.

Primary Research

The aluminum foam market comprises several stakeholders, such as raw material suppliers, processors, end-product manufacturers, and regulatory organizations in the supply chain. The demand side of this market is characterized by the development of various industry sectors such as building and infrastructure. Advancements in technology across diverse applications characterize the supply side. Various primary sources from both the supply and demand sides of the market were interviewed to obtain qualitative and quantitative information.

Following is the breakdown of primary interviews:

Others include sales, marketing, and product managers.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

Both the top-down and bottom-up approaches were used to estimate and validate the total aluminum foam market size. These methods were also used extensively to estimate the size of various subsegments in the market. The research methodology used to estimate the market size included the following:

- The key players in the industry and markets were identified through extensive secondary research.

- The industry’s supply chain and market size, in terms of value, were determined through primary and secondary research processes.

- All percentage shares, splits, and breakdowns were determined using secondary sources and verified through primary sources.

Data Triangulation

After arriving at the overall market size using the market size estimation process, as explained above, the market was split into several segments and subsegments. To complete the overall market engineering process and arrive at the exact statistics of each market segment and subsegment, the data triangulation and market breakdown procedures were employed, wherever applicable. The data was triangulated by studying various factors and trends from both the demand and supply sides in the building and infrastructure end-use sectors.

Objectives of the Report

- To define, describe, and forecast the market size of aluminum foam, in terms of value and volume

- To provide detailed information about the key factors (drivers, restraints, opportunities, and challenges) influencing the growth of the market

- To provide detailed information about the technological advancements influencing the growth of the market

- To forecast the market based on the type, application and end-use industry

- To define, describe, and forecast the market based on five regions, namely, North America, Europe, Asia Pacific, Latin America, and Middle East & Africa

- To strategically analyze micro-markets with respect to individual growth trends, prospects, and their contribution to the overall market

- To analyze the opportunities in the market for stakeholders and provide a competitive landscape for the market leaders

- To analyze recent developments such as expansions and joint ventures in the market

- To strategically profile the key players and comprehensively analyze their market share and core competencies

Available Customizations

With the given market data, MarketsandMarkets offers customizations according to the company’s specific needs.

The following customization options are available for the report:

Product Analysis

- Product matrix, which gives a detailed comparison of the product portfolio of each company

Regional Analysis

- Further breakdown of Rest of Europe aluminum foam market

- Further breakdown of Rest of Asia Pacific aluminum foam market

- Further breakdown of Rest of Middle East & Africa aluminum foam market

- Further breakdown of Rest of Latin America aluminum foam markets

Company Information

- Detailed analysis and profiling of additional market players (up to five)

Generating Response ...

Generating Response ...

Growth opportunities and latent adjacency in Aluminum Foam Market