Global Chemical Industry Outlook 2025

Updated on : October 07, 2025

Chemical Industry Outlook 2025

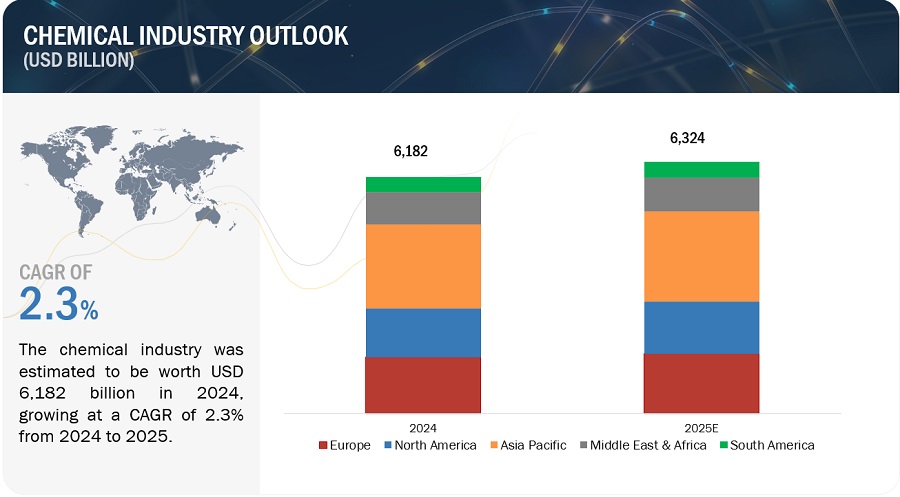

The global chemical industry size was valued at USD 6,182 billion in 2024 and is projected to reach USD 6,324 billion by 2025, growing at 2.3% cagr from 2024 to 2025. In 2024, the global industry grew at a modest pace, recovering from pandemic-induced economic realignments and the pursuit of sustainability. Growth was facilitated by the accelerated demand for energy transition materials such as battery chemicals, lightweight materials, and renewable feedstocks, in conjunction with stable demand from the automotive, construction, and electronics industries. The industry will have to catch up fast from 2025 since, by then, government policies and incentives prescribing clean energy, circular economy concepts, and sustainable manufacturing will have become well-entrenched. Asia Pacific will continue to be the market leader, with rising levels to maintain about a 5.0% increase in China’s chemical production, fueled by policy-led demand chiefly from construction and automotive industries. Europe is experiencing a slow recovery while maintaining low production levels and majorly being dependent on imports. Despite all the uncertainty in the world economy, there is still growth because the speed toward sustainability solutions, as well as a specialty chemical approach, is still pushing that growth.

ATTRACTIVE OPPORTUNITIES IN GLOBAL CHEMICAL INDUSTRY

To know about the assumptions considered for the study, Request for Free Sample Report

MARKET DYNAMICS

Driver: Shift toward specialty chemicals

The shift toward specialty chemicals is one of the key growth drivers for the global chemical industry. This is due to the increasing demand for customized high-performance solutions in sectors such as automotive, electronics, construction, agriculture, pharmaceuticals, and personal care. Specialty chemicals are not like regular chemicals, which are manufactured in huge quantities for general use. Instead, they are manufactured to fulfill specific needs. In the electronics and automotive industries, for instance, specialty chemicals are instrumental in the development of newer, high-tech products, such as lightweight materials and parts for electric vehicles and superior coatings, among others. Many pharmaceutical and personal care companies employ specialty chemicals in the production of medicines, skincare products, and hygiene products. For agriculture, specialty fertilizers and crop protection are the starting point for the improvement of farming and increased yields. As companies seek to produce alternative and sustainable solutions through innovation, the growth is further enhanced, for example, for biodegradable products, bio-based chemicals, and friendly manufacturing processes. Specialty chemicals have become more efficient and more environment-friendly as research has advanced and more investments are made. With a quest for higher-value products, specialty chemicals will continue to grow and be important in the chemical industry.

Restraint: Supply chain disruptions

Supply chain disruptions are one of the major restraints for the global chemical industry in terms of production, delivery schedules, and overall efficiency. The chemical industry depends on highly complex supply chains to get raw materials, transport products, and deliver finished goods to customers. However, the political tensions around the world would probably lead to shortages, delays, and a hike in prices. For instance, various trade wars may bring a rise in tariffs, sanctions, and locked shipping routes, disturbing the supply chain of essential commodities. Higher and costlier fuel prices and environmental restrictions imposed on shipping add more costs to companies, which leads to lower profit margins. Other logistical issues, such as crowded ports and worker shortages, also cause delays in transportation; hence, manufacturers cannot meet the demand for that period. The diversification risks also increase due to dependence on one region or supplier; therefore, any interruption in one region affects all areas. Reducing the risks requires chemical companies to make more resilient supply chains through new suppliers, production near home, and real-time monitoring of digital tools for supply chains. Again, these solutions take some time and investment, thus posing a long-term problem in this regard.

Opportunity: Sustainability and green chemistry

Sustainability and green chemistry is a major opportunity for the chemical industry. The growing environmental concerns, stringent regulations, and increasing demand for environmentally friendly products are expected to offer growth opportunities for market players. This allows chemical companies to find opportunities to develop and manufacture sustainable alternatives to existing chemicals. This leads to the production of bio-based chemicals from renewable resources, including plants, and the development of processes that also decrease carbon emissions and wastes.

One of the main drivers for circular economy innovation is recycling technologies with the use of chemicals, wherein chemicals can be reused, repurposed, and recycled to minimize the environmental impact. These include advanced chemical recycling of plastics that can also help in reducing plastic waste while creating value from materials disposed of. Companies that embrace green chemistry practices can achieve a competitive advantage by resonating with the environmentally conscious consumer and working toward more global sustainability goals. Additional benefits of sustainability include avoiding costs over time through efficiency in energy usage, diminished waste disposal, and minimal resource usage. As it becomes increasingly ingrained into business strategies, the potential for the chemical industry’s growth and innovation is being driven not just by statutory compliance but by sustainability aspects.

Challenge: Stringent environmental regulations

Stringent environmental regulations are one of the biggest challenges that the global chemical industry faces. Governments worldwide have been imposing stricter laws to counter climate change, pollution, and sustainability, all of which directly affect chemical manufacturers. Such regulations often oblige companies to use cleaner technologies, reduce their greenhouse gas emissions, and restrict the use of harmful substances in their products and in the production process. For example, the REACH law of the European Union requires companies to invest heavily in research and development for the chemicals they offer, ensuring that their products pass the safety and environmental criteria. This ranges from improving waste management techniques to a reduction in hazardous material levels and greener alternatives for chemical formulations. Although these regulations are essential for the protection of the environment, they increase the cost of operations because a company may have to upgrade facilities, adopt new processes, or switch to raw materials that are more expensive to procure but meet sustainability requirements. Failure to comply with such regulations leads to fines, legal penalties, or even the shutdown of manufacturing plants. There will be difficulties in complying with differing regional environmental regulations that create additional complexity in managing the operations of a global enterprise. The regulations, however, present an opportunity for chemical companies to innovate and take leadership positions in the development of eco-friendly products and processes to take sustainability positions within the industry.

GREEN ENERGY

Green energy is expected to transform the chemical industry by changing the shape of production processes. Chemical companies are adopting practices to reduce carbon emissions and are increasingly depending on renewable sources of energy such as solar, wind, and bioenergy to power their production. This will help chemical companies meet stricter environmental regulations and support the industry in changing its practices to greener alternatives. By using clean energy sources, chemical manufacturers are saving themselves from dependency on fossil fuels, which leads to decreased greenhouse gas emissions and fewer expenses in the long term during operations. Green energy will also spur the growth of bio-based chemicals and renewable feedstocks that provide sustainable alternatives to petrochemical products. This change to green energy requires heavy investment in infrastructure and technology, but it also provides new growth opportunities as more people seek sustainable and environmentally friendly chemical products. The industry will also gain competitive and market-edge advantages.

3D PRINTING

By 2025, 3D printing will revolutionize the chemical industry by making production more efficient and custom-made. It lets them create complex chemical products from the digital design level into such products as catalysts, parts for special equipment, and even packaging material directly. It saves materials and costs in production, as well as increases the speed of development cycles. In particular, 3D printing will upgrade the ability to design and produce tailor-made formulations, especially for chemical companies to create certain products with specific properties suited to industries such as the pharmaceutical, automotive, or electronics sectors. Some of the many benefits of 3D printing include reduced timespans in prototyping, leading to the rise of innovation and agility to react to market demands. 3D printing also provides local production opportunities that reduce supply chain dependencies and increase sustainability by reducing emissions from transport. As the technology eventually matures, 3D printing could, therefore, add even more flexibility to the chemical sector in terms of production, overall cost reduction, and increased ability to meet rising market demand for sustainable high-performance materials.

ARTIFICIAL INTELLIGENCE

By 2025, AI is supposed to reshape the chemical industry into being more efficient, innovative, and making decisions. Through machine learning and data analytics, chemical manufacturers can harness the power of AI technologies to raise the productivity and quality of products. With operational costs being reduced through the generation of less waste in different operations by AI analyzing a large volume of manufacturing data in real-time, this is achievable.

AI will also expedite research and development in the chemical industry, thus leading to the faster identification of new materials, chemicals, and formulations. With AI-driven simulations and modeling, the development of new products can be streamlined in terms of time-to-market, which can improve innovation. In addition, AI will improve supply chain management through enhanced demand forecasting, inventory control, and logistics, helping supply chains to be more responsive to the changes in the market. Overall, AI will make the chemical industry more agile, sustainable, and competitive.

MAJOR DISRUPTIONS IN CHEMICAL INDUSTRY IN 2025

- The chemical industry is expected to witness a few significant disruptions due to geopolitical, economic, and technological influences. Ongoing geopolitical tensions and trade restrictions will continue to affect the supply chains, resulting in delays in sourcing raw materials and, eventually, increased costs.

- Conflicts or trade wars may result in tariffs, sanctions, and the closure of essential trade routes, further destabilizing the sector. Fluctuations in energy prices will also affect production costs, especially for energy-intensive chemical manufacturing processes, as global energy transitions and regional policies reshape energy markets.

- Growing sustainability and more stringent environmental regulations will challenge the traditional ways of chemical manufacturing, thus forcing manufacturers to invest in green technologies and circular economy initiatives. Manufacturers will be forced to embrace bio-based feedstocks, carbon capture, and energy-efficient processes owing to stringent emissions standards and regulatory frameworks.

- Technological transformation through AI and automation will also disrupt the existing structure of the workforce, making it necessary for companies to upskill their employees to stay in the competition.

- Lastly, climate change and extreme weather conditions threaten production facilities, logistics, and infrastructure, which may create surprises in the form of production. This comes at a time when the demands of customers regarding sustainability and innovative products are changing, thus requiring chemical companies to adjust very quickly to remain resilient, competitive, and responsive to market uncertainties in 2025.

KEY MARKET PLAYERS

The top players in the chemical market are BASF SE (Germany), Dow Inc. (US), Saudi Basic Industries Corporation (SABIC) (Saudi Arabia), Exxon Mobil Corporation (US), Royal Dutch Shell (UK), DuPont (US), LyondellBasell Industries (Netherlands), Mitsubishi Chemical Group Corporation (Japan), INEOS (UK), Sumitomo Chemical Co., Ltd. (Japan), LG Chem (South Korea), Formosa Plastics Corporation (Taiwan), Bayer AG (Germany), Chevron Phillips Chemical Company LLC (US), Air Liquide (France), Akzo Nobel N.V. (Netherlands), Eastman Chemical Company (US), and Evonik Industries AG (Germany). Continuous developments in the market, including partnerships, mergers, acquisitions, agreements, and expansions, are expected to help the market grow. Leading chemical manufacturers have opted for investments and expansions to sustain their market position in 2024.

RECENT DEVELOPMENTS

- In November 2024, Air Liquide announced a renewable hydrogen production project at La Mède, choosing to offer support for the biorefinery of TotalEnergies under a long-term contract. The project includes the construction and operation of a hydrogen production unit that will have an annual capacity of 25,000 tons, with the production depending on recycled biogenic by-products in place of fossil hydrocarbons.

- In August 2024, Linde Engineering announced the building of the REFHYNE II hydrogen electrolysis facility, with electrolyzer stacks to be supplied by ITM Power. Expected to begin operations in 2027, the facility is designed to produce 44,000 kg of renewable hydrogen per day, thereby facilitating the decarbonization of operations and supporting the use of low-carbon fuels.

- In May 2024, Nel Hydrogen Electrolyzer concluded a technology licensing agreement with Reliance Industries Limited, giving RIL exclusive rights to Nel’s alkaline electrolyzers in India and the ability to manufacture globally for captive use.

- In April 2024, Sumitomo Metal Mining Co., Ltd. commenced the construction of two plants in Japan for the recycling of copper, nickel, cobalt, and lithium from discarded lithium-ion batteries (LIBs). The plants are located on the premises of the Toyo Smelter & Refinery, installed at Saijo City and Niihama Nickel Refinery at Niihama City, and are scheduled to be completed by June 2026.

- In April 2024, POSCO Future M and Honda Motor Co. established an agreement to jointly produce cathode materials for electric vehicle (EV) batteries in Canada and form a joint venture by the year’s end.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

Growth opportunities and latent adjacency in Global Chemical Indu