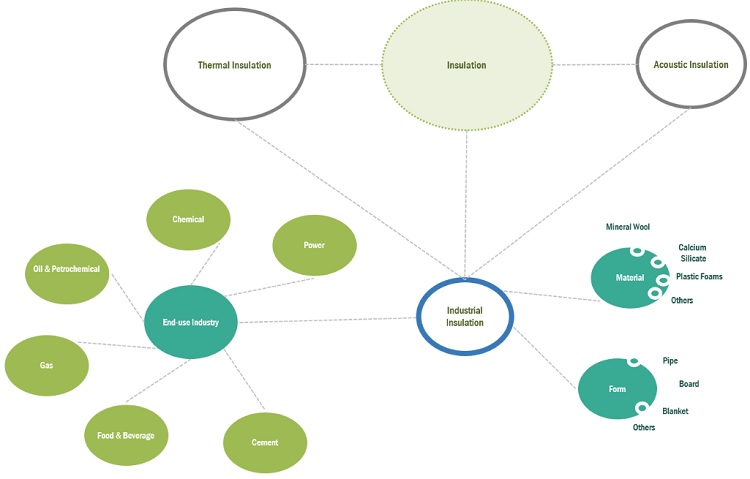

Industrial Insulation Market by Form (Pipe, Blanket, Board), Material (Mineral wool, Calcium silicate, Plastic foams), End-use (Power, Oil & Petrochemical, Gas, Chemical, Cement, Food & Beverage), and Region - Global Forecast to 2027

Updated on : August 28, 2025

Industrial Insulation Market

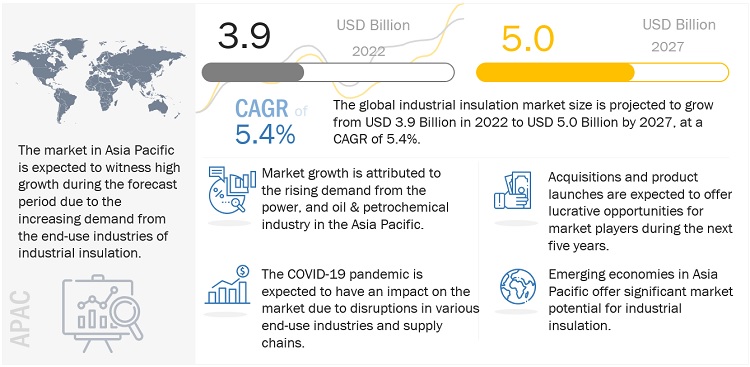

The global industrial insulation market was valued at USD 3.9 billion in 2022 and is projected to reach USD 5.0 billion by 2027, growing at 5.4% cagr from 2022 to 2027. Increasing power and energy requirements in emerging as well as developed economies, growing industrialization across developing economies, and regulations mandating the use of insulation for energy conservation are driving its market.

Global Industrial Insulation Market Trends

To know about the assumptions considered for the study, Request for Free Sample Report

COVID-19 impact

During the COVID-19 pandemic, every country in the world entered some form of lockdown and this has had a considerable impact on the world’s manufacturing industry. The disruptions in the production and supply chain have had a negative impact on the industrial insulation market.

The industrial insulation market is significantly concentrated in the Asia Pacific and leading the market in terms of value. Given that Asia Pacific countries such as China, Japan, and India have become virus hotspots in the early outbreak of the COVID-19 pandemic, most of their manufacturing hubs remained under lockdowns to restrict the spread of the virus. Hence, the region underwent an intensive social distancing campaign, further affecting its manufacturing industries.

The COVID-19 pandemic spread through Asia Pacific countries such as China. As a result, Asia Pacific countries including China, Japan, India, and others, were sealed to contain the spread of the virus. As a cascading effect of Chinese factories being forced into lockdown, there were supply chain disruptions in manufacturing industries, with exports to the country decreasing by almost 50% in 2020.

Industrial Insulation Market Dynamics

Driver: Growing industrialization across developing economies

Increased urbanization, growing per capita income, and rising population will drive infrastructural spending in emerging economies such as China, India, Malaysia, and Vietnam. By 2040, the infrastructure spending as a percentage of GDP in China, Indonesia, Australia, India, Japan, South Korea, Russia, Brazil, and Saudi Arabia is projected to be about 5.1%, 4.1%, 3.6%, 3.6%, 3.2%, 2.9%, 2.8%, 2.7%, and 2.3%, respectively, according to the Global Infrastructure Hub. Growing urbanization and industrialization has led to an increase in the construction and industrial activities in many regions around the world. As insulation is used in these sectors, the demand is estimated to increase at a rapid pace. The benefits attached to insulation bring considerable growth opportunities for the industrial insulation market. Insulation guards equipment in extreme high and low temperature. Furthermore, it decreases the risk of accidents and prevents moisture condensation. These factors serve as growth boosters for the industrial insulation market.

Restraint: Fluctuating raw material prices

Fluctuation in raw material prices of plastic foams is a major restraint in the growth of the industrial insulation market. Plastic foams are derivatives of fossil fuels. These foams, including polyurethane foams, and polystyrene foams, are crude oil-based products and, thus, fluctuations in pricing and availability of crude oil are major limitations in their production and use. Volatility in the supply and demand of crude oil hampers the production of these materials. The availability of crude oil-based products, such as polymers and elastomers, depends on the import and production scenario of various countries. Owing to these fluctuations in crude oil prices, the prices of raw materials for industrial insulation have also been affected. Manufacturers need to cope with these fluctuations in raw material costs, which reduce their profit margins. This scenario has compelled market players to enhance the efficiency and productivity of their operations to sustain growth.

Opportunity: Growing adoption of industrial automation technology

Industrial automation has grown rapidly due to the increased adoption of cutting-edge technologies like machine learning (ML), the internet of things (IoT), and artificial intelligence (AI). Over the years, the desire for automation in the food and beverage industry has been driven by several advantages, including improved traceability, increased efficiency, and high adaptability. Modern manufacturing sectors are experiencing growth in the use of automation technology since it is a successful method for reducing production costs. Apart from electrical insulation, automation experts are also concerned with thermal insulation because it enables machine performance, such as faster operation and longer service life. The use of automation in electric and electrical components is likely to increase, which will increase the need for industrial insulation to keep them thermally insulated.

Industrial Insulation Market Ecosystem

Source: Secondary Research and MarketsandMarkets Analysis

Pipe is the fastest-growing form in the industrial insulation market during the forecast period.

Pipe is the most widely used form of insulation material. Pipe insulation reduces energy loss to a great extent, thereby controlling energy prices. It is used as a system to move liquid, gas, or fine particles from one point to another. In power plants, pipes are used to carry superheated steam, feedwater, discharge fluid, and other substances. In the petrochemical industry, the transport of fluid is carried out with the help of pipes. Providing proper insulation to pipes is therefore a necessary function in most heavy industries, such as power, petrochemical, and oil & gas. Similarly, in cold insulation, they prevent moisture formation and collection on the surface of the piping system due to the condensation of cold surfaces.

Mineral wool is the fastest-growing material in the industrial insulation market during the forecast period.

Mineral wool is a fibrous, versatile material produced from rock materials or minerals including slag or ceramics, that can effectively address heat and acoustic insulation requirements in many applications. The effective use of rock wool & mineral wool insulation on walls and ceilings provides enhanced and full sound insulation in a particular room. The market is growing at a rapid pace in the Asia Pacific, mainly in China and Japan, owing to the presence of diversified end-use industries and government initiatives to boost these industries, which are the major consumers of mineral wool.

Power is the fastest-growing end-use industry during the forecast period.

Power is the largest end-use industry for industrial insulation. Industrial insulation is a key component of any of these plants. It helps the steam generating boilers keep their temperatures at certain levels. These facilities contain miles and miles of mechanical piping which move materials from point A to point B. These pipes require insulation to maintain temperatures along the electricity generating process. Insulation helps to maintain a certain temperature along the electricity generation process.

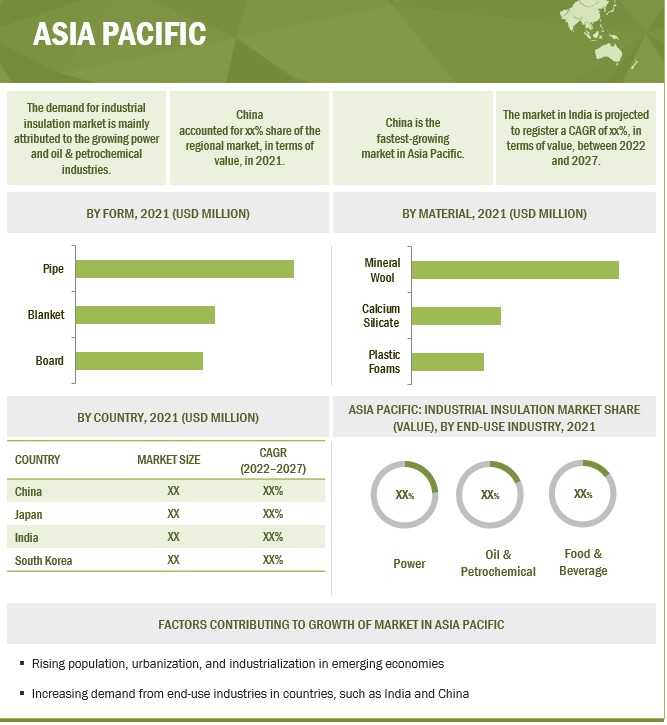

Asia Pacific is the fastest-growing region in the industrial insulation market during the forecast period

Rising population, increasing electrification, growth in disposable income, rapid industrialization, and increased urbanization are driving the Asia Pacific industrial insulation market. Increasing use of oil & petrochemical, gas for power, growing population, and rising demand for petrochemicals are responsible for the high growth of the market in this segment. The Asia Pacific region is dependent upon public-private partnerships for regional development. Many Southeast Asian countries have been making efforts to invest significantly in infrastructure. All these factors contribute to the growth of the industrial insulation market.

Source: Secondary Research, Primary Interviews, and MarketsandMarkets Analysis

To know about the assumptions considered for the study, download the pdf brochure

Industrial Insulation Market Players

Major players operating in the global industrial insulation include Owens Corning (US), Saint-Gobain ISOVER (Germany), ROCKWOOL (Denmark), Knauf Insulation (US), Armacell (Luxembourg), Insulcon BV (Netherlands), Kingspan Group (Ireland), Johns Manville (US), Nichias Corporation (Japan), and Promat (ETEX) (Belgium) among many others.

Industrial Insulation Market Report Scope

|

Report Metric |

Details |

|

Market Size Value in 2022 |

USD 3.9 billion |

|

Revenue Forecast in 2027 |

USD 5.0 billion |

|

CAGR |

5.4% |

|

Years considered for the study |

2020-2027 |

|

Base year |

2021 |

|

Forecast period |

2022-2027 |

|

Units considered |

Value (USD Billion) |

|

Segments |

By form, By material, By end-use industry, and By Region |

|

Regions |

North America, Asia Pacific, Western Europe, Eastern & Central Europe, South America, and the Middle East & Africa |

|

Companies |

Owens Corning (US), Saint-Gobain ISOVER (Germany), ROCKWOOL (Denmark), Knauf Insulation (US), Armacell (Luxembourg), Insulcon BV (Netherlands), Kingspan Group (Ireland), Johns Manville (US), Nichias Corporation (Japan), and Promat (ETEX) (Belgium). Total 25 major players covered |

This research report categorizes the industrial insulation market is segmented by form, material, end-use industry, and region.

Industrial Insulation Market based on form:

- Pipe

- Blanket

- Board

- Others

Industrial Insulation Market based on material:

- Mineral wool

- Calcium silicate

- Plastic foams

- Others

Industrial Insulation Market based on end-use industry:

- Power

- Oil & petrochemical

- Gas

- Chemical

- Cement

- Food & beverage

- Others

Industrial Insulation Market based on the region:

- Asia Pacific

- Western Europe

- Eastern & Central Europe

- North America

- Middle East & Africa

- South America

Recent Developments

- In August 2022, Owens Corning announced the acquisition of Natural Polymers, LLC, a manufacturer of spray polyurethane foam insulation for building and construction applications, based in Cortland, Illinois.

- In July 2022, the acquisition of IZOLIR extends Armacell's footprint in Europe, enabling to reach more customer segments in new geographies. Furthermore, by expanding new capacities and adding new products to its existing portfolio, the company is entering the energy-efficient and fast-growing pre-insulated pipe market.

- In September 2022, Armacell, a global leader in energy efficiency, announced the launch of ArmaGel HTL, a unique, non-combustible aerogel blanket specifically engineered for industrial applications where non-combustibility, thermal performance, and corrosion under insulation mitigation are essential.

- In July 2021, ROCKWOOL North America began 460,000 sq. ft. of commercial production of stone wool insulation products at a US manufacturing facility, located in Jefferson County, West Virginia.

Frequently Asked Questions (FAQ):

What is the current size of the global industrial insulation market?

The global industrial insulation market is estimated to be USD 3.9 billion in 2022 and is projected to reach USD 5.0 billion by 2027, at a CAGR of 5.4%

What are the factors influencing the growth of the industrial insulation market?

The growth of this market can be attributed to the rising demand for industrial insulation in the power and oil & petrochemical industries.

What is the biggest restraint for industrial insulation?

The fluctuating raw material prices is restraining the growth of the market.

Who are the major manufacturers?

Major manufacturers include Owens Corning, Saint-Gobain ISOVER, ROCKWOOL, Knauf Insulation, Armacell, Insulcon BV, Kingspan Group, Johns Manville, Nichias Corporation, and Promat (ETEX) among many others.

What is the impact of COVID-19 on the overall industrial insulation market?

Industrial insulation is used in various end use industries including power, oil & petrochemical, chemical, gas, cement, food & beverage, and others. Due to the ongoing pandemic, these industries have been severely affected throughout the world. Manpower shortage, logistical restrictions, material unavailability, and other restrictions have slowed the growth of the industry in a considerable manner.

What will be the growth prospects of the industrial insulation market?

Increased infrastructural spending in emerging economies is expected to offer significant growth opportunities to manufacturers of the industrial insulation market. .

To speak to our analyst for a discussion on the above findings, click Speak to Analyst

TABLE OF CONTENTS

1 INTRODUCTION (Page No. - 25)

1.1 STUDY OBJECTIVES

1.2 MARKET DEFINITION

1.2.1 INCLUSIONS AND EXCLUSIONS

1.3 MARKET SCOPE

FIGURE 1 INDUSTRIAL INSULATION: MARKET SEGMENTATION

1.3.1 YEARS CONSIDERED

1.3.2 REGIONAL SCOPE

1.4 CURRENCY CONSIDERED

1.5 UNIT CONSIDERED

1.6 STAKEHOLDERS

1.7 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY (Page No. - 29)

2.1 RESEARCH DATA

FIGURE 2 INDUSTRIAL INSULATION MARKET: RESEARCH DESIGN

2.1.1 SECONDARY DATA

2.1.1.1 List of major secondary sources

2.1.1.2 Key data from secondary sources

2.1.2 PRIMARY DATA

2.1.2.1 Key data from primary sources

2.1.3 PRIMARY INTERVIEWS

2.1.3.1 Demand and supply sides

2.1.3.2 Key industry insights

2.1.3.3 Breakdown of primary interviews

2.2 MARKET SIZE ESTIMATION

FIGURE 3 MARKET SIZE ESTIMATION APPROACH

2.2.1 TOP-DOWN APPROACH

2.2.1.1 Approach for arriving at market size using top-down approach

FIGURE 4 TOP-DOWN APPROACH

2.2.2 BOTTOM-UP APPROACH

2.2.2.1 Approach for arriving at market size using bottom-up approach

FIGURE 5 BOTTOM-UP APPROACH

2.3 DATA TRIANGULATION

FIGURE 6 INDUSTRIAL INSULATION MARKET: DATA TRIANGULATION

2.3.1 MARKET ANALYSIS THROUGH PRIMARY INTERVIEWS

2.4 FACTOR ANALYSIS

2.5 ASSUMPTIONS

2.6 LIMITATIONS & RISKS

3 EXECUTIVE SUMMARY (Page No. - 39)

FIGURE 7 PIPE SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

FIGURE 8 MINERAL WOOL TO LEAD MARKET DURING FORECAST PERIOD

FIGURE 9 POWER SEGMENT ACCOUNTED FOR LARGEST SHARE OF INDUSTRIAL INSULATION MARKET

FIGURE 10 ASIA PACIFIC ACCOUNTED FOR LARGEST MARKET SHARE IN 2021

4 PREMIUM INSIGHTS (Page No. - 43)

4.1 EMERGING ECONOMIES TO WITNESS HIGH GROWTH IN INDUSTRIAL INSULATION MARKET

FIGURE 11 ASIA PACIFIC TO OFFER ATTRACTIVE OPPORTUNITIES IN INDUSTRIAL INSULATION MARKET DURING FORECAST PERIOD

4.2 INDUSTRIAL INSULATION MARKET, BY FORM

FIGURE 12 PIPE SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

4.3 INDUSTRIAL INSULATION MARKET, BY MATERIAL

FIGURE 13 MINERAL WOOL SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

4.4 INDUSTRIAL INSULATION MARKET, BY END-USE INDUSTRY

FIGURE 14 POWER INDUSTRY TO LEAD MARKET BY 2027

4.5 INDUSTRIAL INSULATION MARKET, BY COUNTRY

FIGURE 15 MARKET IN CHINA TO GROW AT HIGHEST CAGR

5 MARKET OVERVIEW (Page No. - 46)

5.1 INTRODUCTION

5.2 MARKET DYNAMICS

FIGURE 16 DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES IN INDUSTRIAL INSULATION MARKET

5.2.1 DRIVERS

5.2.1.1 Increasing power and energy requirements in emerging as well as developed economies

5.2.1.2 Growing industrialization across developing economies

5.2.1.3 Regulations mandating use of insulation for energy conservation

5.2.2 RESTRAINTS

5.2.2.1 Fluctuating raw material prices

FIGURE 17 YEARLY GRAPH OF CRUDE OIL PRICES

5.2.2.2 Increased cost of insulation materials

5.2.3 OPPORTUNITIES

5.2.3.1 Increased infrastructural spending in emerging economies

5.2.3.2 Growing adoption of industrial automation technology

5.2.3.3 Emerging opportunities for bio-based insulation material

5.2.3.4 Increasing demand for high-temperature insulation materials

5.2.4 CHALLENGES

5.2.4.1 High cost of installation and requirement of skilled workforce

5.3 PORTER’S FIVE FORCES ANALYSIS

FIGURE 18 INDUSTRIAL INSULATION MARKET: PORTER’S FIVE FORCES ANALYSIS

5.3.1 THREAT OF SUBSTITUTES

5.3.2 BARGAINING POWER OF SUPPLIERS

5.3.3 THREAT OF NEW ENTRANTS

5.3.4 BARGAINING POWER OF BUYERS

5.3.5 INTENSITY OF COMPETITIVE RIVALRY

TABLE 1 INDUSTRIAL INSULATION: PORTER’S FIVE FORCES ANALYSIS

5.4 PATENT ANALYSIS

5.4.1 METHODOLOGY

5.4.2 DOCUMENT TYPE

FIGURE 19 GRANTED PATENTS

FIGURE 20 NUMBER OF PATENTS PUBLISHED IN LAST 10 YEARS

5.4.3 INSIGHTS

FIGURE 21 TOP JURISDICTION – BY DOCUMENT

5.4.4 TOP 10 COMPANIES/APPLICANTS

FIGURE 22 TOP 10 PATENT APPLICANTS

TABLE 2 PATENTS BY JOHNS MANVILLE

TABLE 3 PATENTS BY SAINT-GOBAIN ISOVER

TABLE 4 PATENTS BY AIRLITE PLASTICS CO

TABLE 5 TOP 10 PATENT OWNERS (US) IN LAST 10 YEARS

5.5 IMPACT OF COVID-19 ON INDUSTRIAL INSULATION MARKET

5.5.1 COVID-19

5.5.2 IMPACT ON END-USE INDUSTRIES

5.6 TARIFF AND REGULATORY LANDSCAPE

5.6.1 ASTM C1696-20

5.6.2 ASTM C547

5.6.3 ISO 13787:2003(E)

5.6.4 US

5.6.5 EUROPE

5.6.6 OTHERS

5.6.7 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 6 NORTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 7 EUROPE: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 8 REST OF THE WORLD: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

5.7 TECHNOLOGY ANALYSIS

5.7.1 NEW TECHNOLOGIES – INDUSTRIAL INSULATION

5.8 VALUE CHAIN ANALYSIS

FIGURE 23 VALUE CHAIN ANALYSIS

5.8.1 RAW MATERIAL SUPPLIERS

5.8.2 MANUFACTURERS

5.8.3 DISTRIBUTORS

5.8.4 END USERS

TABLE 9 INDUSTRIAL INSULATION: VALUE CHAIN STAKEHOLDERS

5.9 ECOSYSTEM MAPPING

FIGURE 24 INDUSTRIAL INSULATION ECOSYSTEM

5.10 RAW MATERIAL ANALYSIS

5.10.1 MINERAL WOOL

5.10.2 CALCIUM SILICATE

5.10.3 PLASTIC FOAMS

5.11 TRADE ANALYSIS

5.11.1 IMPORT TRADE ANALYSIS

TABLE 10 REGION-WISE IMPORT TRADE (IN USD THOUSAND)

FIGURE 25 REGION-WISE IMPORT TRADE (IN USD THOUSAND)

5.11.2 EXPORT TRADE ANALYSIS

TABLE 11 REGION-WISE EXPORT TRADE (IN USD THOUSAND)

FIGURE 26 REGION-WISE EXPORT TRADE (IN USD THOUSAND)

TABLE 12 MAJOR IMPORT PARTNERS – INDUSTRIAL INSULATION

5.12 MACROECONOMIC INDICATORS

5.12.1 GDP TRENDS AND FORECASTS

TABLE 13 PROJECTED REAL GDP GROWTH (ANNUAL PERCENT CHANGE) OF KEY COUNTRIES, 2018–2025

5.12.2 TRENDS IN POWER INDUSTRY

TABLE 14 ELECTRICITY GENERATION STATISTICS, BY COUNTRY, 2019–2020 (TWH)

5.12.3 OIL & GAS STATISTICS

TABLE 15 OIL PRODUCTION, BY COUNTRY, 2020–2021, THOUSAND BARRELS DAILY

5.13 TRENDS/DISRUPTIONS IMPACTING CUSTOMERS' BUSINESSES

FIGURE 27 TRENDS/DISRUPTIONS IMPACTING CUSTOMERS' BUSINESSES

5.14 KEY CONFERENCES & EVENTS IN 2022–2023

TABLE 16 INDUSTRIAL INSULATION MARKET: DETAILED LIST OF CONFERENCES & EVENTS

5.15 KEY FACTORS AFFECTING BUYING DECISION

5.15.1 QUALITY

5.15.2 SERVICE

FIGURE 28 SUPPLIER SELECTION CRITERION

5.16 CASE STUDY ANALYSIS

5.16.1 ROCKWOOL

5.16.2 OWENS CORNING

6 INDUSTRIAL INSULATION MARKET, BY FORM (Page No. - 77)

6.1 INTRODUCTION

FIGURE 29 PIPE TO BE FASTEST-GROWING FORM DURING FORECAST PERIOD

TABLE 17 INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2018–2021 (USD MILLION)

TABLE 18 INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2022–2027 (USD MILLION)

6.2 PIPE

6.2.1 LARGE NUMBER OF APPLICATION AREAS IN VARIOUS INDUSTRIES

TABLE 19 INDUSTRIAL INSULATION MARKET: DETAILED LIST OF COMPANIES BY FORM (PIPE)

6.3 BLANKET

6.3.1 LIGHTWEIGHT AND EASY TO HANDLE AND MANUFACTURE

TABLE 20 INDUSTRIAL INSULATION MARKET: DETAILED LIST OF COMPANIES BY FORM (BLANKET)

6.4 BOARD

6.4.1 GOOD THERMAL RESISTANCE AND REDUCTION IN HEAT CONDUCTION

TABLE 21 INDUSTRIAL INSULATION MARKET: DETAILED LIST OF COMPANIES BY FORM (BOARD)

6.5 OTHERS

7 INDUSTRIAL INSULATION MARKET, BY MATERIAL (Page No. - 83)

7.1 INTRODUCTION

FIGURE 30 MINERAL WOOL TO BE FASTEST-GROWING MATERIAL DURING FORECAST PERIOD

TABLE 22 INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 23 INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

7.2 MINERAL WOOL

TABLE 24 HEAT RESISTANCE OF MINERAL WOOL

7.2.1 GLASS WOOL

7.2.1.1 Used in power and oil & petrochemical industries

7.2.2 STONE WOOL

7.2.2.1 Resilient to heat and fire

7.2.3 CERAMIC FIBER

7.2.3.1 Usage only in high-temperature industrial applications

7.3 CALCIUM SILICATE

7.4 PLASTIC FOAMS

7.4.1 PHENOLIC

7.4.1.1 Lightweight and low thermal conductivity

7.4.2 ELASTOMERIC

7.4.2.1 High flexibility and elasticity benefits

7.4.3 OTHERS

7.5 OTHERS

8 INDUSTRIAL INSULATION MARKET, BY END-USE INDUSTRY (Page No. - 89)

8.1 INTRODUCTION

FIGURE 31 POWER TO BE LARGEST END-USE INDUSTRY OF INDUSTRIAL INSULATION MARKET

TABLE 25 INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 26 INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

8.2 POWER

8.2.1 ECONOMIC GROWTH BY INDUSTRIALIZATION

8.3 CHEMICAL

8.3.1 INVESTMENTS IN CHEMICAL SECTOR TO SUPPORT GROWTH

8.4 OIL & PETROCHEMICAL

8.4.1 EXTENSIVE USAGE OF CALCIUM SILICATE AND MICROPOROUS INSULATION MATERIALS

8.5 GAS

8.5.1 INCREASING LNG TRADE IN EMERGING ECONOMIES

8.6 CEMENT

8.6.1 INCREASED GLOBAL SPENDING ON INFRASTRUCTURE

8.7 FOOD & BEVERAGE

8.7.1 PLASTIC FOAMS MAINLY USED FOR INSULATION

8.8 OTHERS

9 INDUSTRIAL INSULATION MARKET, BY REGION (Page No. - 95)

9.1 INTRODUCTION

FIGURE 32 INDUSTRIAL INSULATION MARKET IN CHINA TO REGISTER HIGHEST CAGR

TABLE 27 INDUSTRIAL INSULATION MARKET SIZE, BY REGION, 2018–2021 (USD MILLION)

TABLE 28 INDUSTRIAL INSULATION MARKET SIZE, BY REGION, 2022–2027 (USD MILLION)

9.2 NORTH AMERICA

FIGURE 33 NORTH AMERICA: INDUSTRIAL INSULATION MARKET SNAPSHOT

TABLE 29 NORTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 30 NORTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 31 NORTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2018–2021 (USD MILLION)

TABLE 32 NORTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2022–2027 (USD MILLION)

TABLE 33 NORTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 34 NORTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 35 NORTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 36 NORTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.2.1 US

9.2.1.1 High growth of major end-use industries

TABLE 37 US: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 38 US: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 39 US: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 40 US: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.2.2 CANADA

9.2.2.1 Diversified downstream sector

TABLE 41 CANADA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 42 CANADA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 43 CANADA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 44 CANADA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.2.3 MEXICO

9.2.3.1 Government initiatives for investments in power sector

TABLE 45 MEXICO: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 46 MEXICO: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 47 MEXICO: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 48 MEXICO: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.3 ASIA PACIFIC

FIGURE 34 ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SNAPSHOT

TABLE 49 ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 50 ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 51 ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2018–2021 (USD MILLION)

TABLE 52 ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2022–2027 (USD MILLION)

TABLE 53 ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 54 ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 55 ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 56 ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.3.1 CHINA

9.3.1.1 Huge industrial base

TABLE 57 CHINA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 58 CHINA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 59 CHINA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 60 CHINA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.3.2 JAPAN

9.3.2.1 Fossil fuel-based power generation

TABLE 61 JAPAN: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 62 JAPAN: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 63 JAPAN: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 64 JAPAN: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.3.3 SOUTH KOREA

9.3.3.1 Increasing investments across end-use industries

TABLE 65 SOUTH KOREA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 66 SOUTH KOREA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 67 SOUTH KOREA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 68 SOUTH KOREA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.3.4 INDIA

9.3.4.1 Government initiatives to build infrastructure

TABLE 69 INDIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 70 INDIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 71 INDIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 72 INDIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.3.5 INDONESIA

9.3.5.1 Investments in power and oil & gas industries

TABLE 73 INDONESIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 74 INDONESIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 75 INDONESIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 76 INDONESIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.3.6 VIETNAM

9.3.6.1 Investments across end-use industries

TABLE 77 VIETNAM: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 78 VIETNAM: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 79 VIETNAM: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 80 VIETNAM: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.3.7 REST OF ASIA PACIFIC

TABLE 81 REST OF ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 82 REST OF ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 83 REST OF ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 84 REST OF ASIA PACIFIC: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.4 WESTERN EUROPE

TABLE 85 WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 86 WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 87 WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2018–2021 (USD MILLION)

TABLE 88 WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2022–2027 (USD MILLION)

TABLE 89 WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 90 WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 91 WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 92 WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.4.1 GERMANY

9.4.1.1 Constant innovations in chemical and petrochemical industries

TABLE 93 GERMANY: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 94 GERMANY: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 95 GERMANY: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 96 GERMANY: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.4.2 FRANCE

9.4.2.1 Investments in construction industry and transition toward clean economy

TABLE 97 FRANCE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 98 FRANCE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 99 FRANCE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 100 FRANCE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.4.3 UK

9.4.3.1 Decarbonization activities to boost market

TABLE 101 UK: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 102 UK: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 103 UK: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 104 UK: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.4.4 ITALY

9.4.4.1 Transportation to be major consumer

TABLE 105 ITALY: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 106 ITALY: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 107 ITALY: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 108 ITALY: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.4.5 SPAIN

9.4.5.1 Growth in concentrated solar power generation

TABLE 109 SPAIN: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 110 SPAIN: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 111 SPAIN: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 112 SPAIN: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.4.6 REST OF WESTERN EUROPE

TABLE 113 REST OF WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 114 REST OF WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 115 REST OF WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 116 REST OF WESTERN EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.5 EASTERN & CENTRAL EUROPE

TABLE 117 EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 118 EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 119 EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2018–2021 (USD MILLION)

TABLE 120 EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2022–2027 (USD MILLION)

TABLE 121 EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 122 EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 123 EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 124 EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.5.1 TURKEY

9.5.1.1 Urbanization and industrialization trends

TABLE 125 TURKEY: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 126 TURKEY: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 127 TURKEY: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 128 TURKEY: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.5.2 RUSSIA

9.5.2.1 Government plans to boost investments

TABLE 129 RUSSIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 130 RUSSIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 131 RUSSIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 132 RUSSIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.5.3 REST OF EASTERN & CENTRAL EUROPE

TABLE 133 REST OF EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 134 REST OF EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 135 REST OF EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 136 REST OF EASTERN & CENTRAL EUROPE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.6 MIDDLE EAST & AFRICA

TABLE 137 MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 138 MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 139 MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2018–2021 (USD MILLION)

TABLE 140 MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2022–2027 (USD MILLION)

TABLE 141 MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 142 MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 143 MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 144 MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.6.1 SAUDI ARABIA

9.6.1.1 Saudi Vision 2030 to contribute to significant rise in demand

TABLE 145 SAUDI ARABIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 146 SAUDI ARABIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 147 SAUDI ARABIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 148 SAUDI ARABIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.6.2 UAE

9.6.2.1 Expanding non-oil sectors

TABLE 149 UAE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 150 UAE: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 151 UAE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 152 UAE: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.6.3 EGYPT

9.6.3.1 Increasing investments in power generation

TABLE 153 EGYPT: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 154 EGYPT: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 155 EGYPT: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 156 EGYPT: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.6.4 SOUTH AFRICA

9.6.4.1 Developments in chemical and petrochemical sectors

TABLE 157 SOUTH AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 158 SOUTH AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 159 SOUTH AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 160 SOUTH AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.6.5 REST OF MIDDLE EAST & AFRICA

TABLE 161 REST OF MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 162 REST OF MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 163 REST OF MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 164 REST OF MIDDLE EAST & AFRICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.7 SOUTH AMERICA

TABLE 165 SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2018–2021 (USD MILLION)

TABLE 166 SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY COUNTRY, 2022–2027 (USD MILLION)

TABLE 167 SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2018–2021 (USD MILLION)

TABLE 168 SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY FORM, 2022–2027 (USD MILLION)

TABLE 169 SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 170 SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 171 SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 172 SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.7.1 BRAZIL

9.7.1.1 Growing investments across end-use industries

TABLE 173 BRAZIL: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 174 BRAZIL: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 175 BRAZIL: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 176 BRAZIL: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.7.2 ARGENTINA

9.7.2.1 Large shale deposits, investments in nuclear power plants, and growing chemical sector

TABLE 177 ARGENTINA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 178 ARGENTINA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 179 ARGENTINA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 180 ARGENTINA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.7.3 COLOMBIA

9.7.3.1 Increase in demand for chemicals and polymers

TABLE 181 COLOMBIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 182 COLOMBIA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 183 COLOMBIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 184 COLOMBIA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

9.7.4 REST OF SOUTH AMERICA

TABLE 185 REST OF SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2018–2021 (USD MILLION)

TABLE 186 REST OF SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY MATERIAL, 2022–2027 (USD MILLION)

TABLE 187 REST OF SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2018–2021 (USD MILLION)

TABLE 188 REST OF SOUTH AMERICA: INDUSTRIAL INSULATION MARKET SIZE, BY END-USE INDUSTRY, 2022–2027 (USD MILLION)

10 COMPETITIVE LANDSCAPE (Page No. - 183)

10.1 INTRODUCTION

10.2 STRATEGIES ADOPTED BY KEY PLAYERS

FIGURE 35 COMPANIES ADOPTED INVESTMENT & EXPANSION AND NEW PRODUCT LAUNCH AS KEY GROWTH STRATEGIES BETWEEN 2019 AND 2022

10.3 MARKET EVALUATION MATRIX

TABLE 189 MARKET EVALUATION MATRIX

10.4 REVENUE ANALYSIS OF TOP PLAYERS

TABLE 190 INDUSTRIAL INSULATION MARKET: REVENUE ANALYSIS (USD)

10.5 MARKET RANKING

FIGURE 36 MARKET RANKING OF KEY PLAYERS

10.5.1 OWENS CORNING

10.5.2 SAINT-GOBAIN

10.5.3 KNAUF INSULATION

10.5.4 ROCKWOOL

10.5.5 ARMACELL INTERNATIONAL

10.6 MARKET SHARE ANALYSIS

FIGURE 37 INDUSTRIAL INSULATION: MARKET SHARE ANALYSIS, 2021

TABLE 191 INDUSTRIAL INSULATION MARKET: DEGREE OF COMPETITION

10.7 COMPANY EVALUATION MATRIX (TIER 1)

10.7.1 STARS

10.7.2 EMERGING LEADERS

10.7.3 PERVASIVE PLAYERS

10.7.4 PARTICIPANTS

FIGURE 38 INDUSTRIAL INSULATION MARKET: COMPANY EVALUATION MATRIX FOR TIER 1 COMPANIES, 2021

10.8 STRENGTH OF PRODUCT PORTFOLIO

10.9 BUSINESS STRATEGY EXCELLENCE

10.10 COMPETITIVE BENCHMARKING

TABLE 192 INDUSTRIAL INSULATION MARKET: DETAILED LIST OF KEY START-UPS/SMES

TABLE 193 INDUSTRIAL INSULATION MARKET: COMPETITIVE BENCHMARKING OF START-UPS/SMES (FORM & END-USE INDUSTRY)

TABLE 194 INDUSTRIAL INSULATION MARKET: COMPETITIVE BENCHMARKING OF START-UPS/SMES (MATERIAL & REGION)

10.10.1 COMPANY FORM FOOTPRINT

TABLE 195 OVERALL FORM FOOTPRINT

10.10.2 COMPANY END-USE INDUSTRY FOOTPRINT

TABLE 196 OVERALL END-USE INDUSTRY FOOTPRINT

10.10.3 COMPANY MATERIAL FOOTPRINT

TABLE 197 OVERALL MATERIAL FOOTPRINT

10.10.4 COMPANY REGION FOOTPRINT

TABLE 198 OVERALL REGION FOOTPRINT

10.10.5 COMPANY FOOTPRINT

TABLE 199 OVERALL COMPANY FOOTPRINT

10.11 START-UPS AND SMALL AND MEDIUM-SIZED ENTERPRISES (SMES) EVALUATION MATRIX

10.11.1 STARTING BLOCKS

10.11.2 RESPONSIVE COMPANIES

10.11.3 PROGRESSIVE COMPANIES

10.11.4 DYNAMIC COMPANIES

FIGURE 39 INDUSTRIAL INSULATION MARKET: COMPANY EVALUATION MATRIX FOR SMES

10.11.5 STRENGTH OF PRODUCT PORTFOLIO (SMES)

10.11.6 BUSINESS STRATEGY EXCELLENCE (SMES)

10.12 COMPETITIVE SITUATION & TRENDS

10.12.1 PRODUCT LAUNCHES

TABLE 200 INDUSTRIAL INSULATION MARKET: PRODUCT LAUNCHES, 2019–2022

10.12.2 DEALS

TABLE 201 INDUSTRIAL INSULATION MARKET: DEALS, 2019–2022

10.12.3 OTHERS

TABLE 202 INDUSTRIAL INSULATION MARKET: OTHERS, 2019–2022

11 COMPANY PROFILES (Page No. - 210)

(Business overview, Products/Solutions offered, Recent developments & MnM View)*

11.1 KEY PLAYERS

11.1.1 OWENS CORNING

TABLE 203 OWENS CORNING: COMPANY OVERVIEW

FIGURE 40 OWENS CORNING: COMPANY SNAPSHOT

TABLE 204 OWENS CORNING: PRODUCT OFFERINGS

TABLE 205 OWENS CORNING: PRODUCT LAUNCHES

TABLE 206 OWENS CORNING: DEALS

11.1.2 SAINT-GOBAIN (ISOVER)

TABLE 207 SAINT-GOBAIN (ISOVER): COMPANY OVERVIEW

FIGURE 41 SAINT-GOBAIN (ISOVER): COMPANY SNAPSHOT

TABLE 208 SAINT-GOBAIN (ISOVER): PRODUCT OFFERINGS

TABLE 209 SAINT-GOBAIN: DEALS

TABLE 210 SAINT-GOBAIN: OTHER DEVELOPMENTS

11.1.3 ROCKWOOL

TABLE 211 ROCKWOOL: COMPANY OVERVIEW

FIGURE 42 ROCKWOOL: COMPANY SNAPSHOT

TABLE 212 ROCKWOOL: PRODUCT OFFERINGS

TABLE 213 ROCKWOOL: OTHER DEVELOPMENTS

11.1.4 KNAUF INSULATION

TABLE 214 KNAUF INSULATION: COMPANY OVERVIEW

TABLE 215 KNAUF INSULATION: PRODUCT OFFERINGS

TABLE 216 KNAUF INSULATION: PRODUCT LAUNCHES

TABLE 217 KNAUF INSULATION: OTHER DEVELOPMENTS

11.1.5 ARMACELL INTERNATIONAL SA

TABLE 218 ARMACELL: COMPANY OVERVIEW

FIGURE 43 ARMACELL: COMPANY SNAPSHOT

TABLE 219 ARMACELL: PRODUCT OFFERINGS

TABLE 220 ARMACELL: PRODUCT LAUNCHES

TABLE 221 ARMACELL: DEALS

TABLE 222 ARMACELL: OTHER DEVELOPMENTS

11.1.6 INSULCON BV

TABLE 223 INSULCON BV: COMPANY OVERVIEW

TABLE 224 INSULCON BV: PRODUCT OFFERINGS

11.1.7 KINGSPAN GROUP PLC

TABLE 225 KINGSPAN GROUP PLC: COMPANY OVERVIEW

FIGURE 44 KINGSPAN GROUP PLC: COMPANY SNAPSHOT

TABLE 226 KINGSPAN GROUP PLC: PRODUCT OFFERINGS

TABLE 227 KINGSPAN GROUP PLC: DEALS

TABLE 228 KINGSPAN GROUP PLC: OTHER DEVELOPMENTS

11.1.8 JOHNS MANVILLE

TABLE 229 JOHNS MANVILLE: COMPANY OVERVIEW

TABLE 230 JOHNS MANVILLE: PRODUCT OFFERINGS

TABLE 231 JOHNS MANVILLE: PRODUCT LAUNCHES

TABLE 232 JOHNS MANVILLE: DEALS

TABLE 233 JOHNS MANVILLE: OTHER DEVELOPMENTS

11.1.9 NICHIAS CORPORATION

TABLE 234 NICHIAS CORPORATION: COMPANY OVERVIEW

FIGURE 45 NICHIAS CORPORATION: COMPANY SNAPSHOT

TABLE 235 NICHIAS CORPORATION: PRODUCT OFFERINGS

11.1.10 PROMAT (ETEX)

TABLE 236 PROMAT (ETEX): COMPANY OVERVIEW

FIGURE 46 PROMAT (ETEX): COMPANY SNAPSHOT

TABLE 237 PROMAT (ETEX): PRODUCT OFFERINGS

*Details on Business overview, Products/Solutions offered, Recent developments & MnM View might not be captured in case of unlisted companies.

11.2 OTHER COMPANIES

11.2.1 AEROFOAM USA LLC

TABLE 238 AEROFOAM USA LLC: COMPANY OVERVIEW

11.2.2 BEIJING HOCREBOARD BUILDING MATERIAL LTD.

TABLE 239 BEIJING HOCREBOARD BUILDING MATERIAL LTD.: COMPANY OVERVIEW

11.2.3 BEIJING NEW BUILDING MATERIAL CO., LTD.

TABLE 240 BEIJING NEW BUILDING MATERIAL CO., LTD.: COMPANY OVERVIEW

11.2.4 CABOT CORPORATION

TABLE 241 CABOT CORPORATION: COMPANY OVERVIEW

11.2.5 GLASSROCK INSULATION COMPANY SAE

TABLE 242 GLASSROCK INSULATION COMPANY SAE: COMPANY OVERVIEW

11.2.6 L’ISOLANTE K-FLEX SPA

TABLE 243 L’ISOLANTE K-FLEX SPA: COMPANY OVERVIEW

11.2.7 NMC INTERNATIONAL SA

TABLE 244 NMC INTERNATIONAL SA: COMPANY OVERVIEW

11.2.8 PGF INSULATION

TABLE 245 PGF INSULATION: COMPANY OVERVIEW

11.2.9 TECRESA PROTECTION PASIVA S.L

TABLE 246 TECRESA PROTECTION PASIVA S.L: COMPANY OVERVIEW

11.2.10 TEMATI

TABLE 247 TEMATI: COMPANY OVERVIEW

11.2.11 UNIFRAX

TABLE 248 UNIFRAX: COMPANY OVERVIEW

11.2.12 UNION FOAM SPA

TABLE 249 UNION FOAM SPA: COMPANY OVERVIEW

11.2.13 VISIONARY INDUSTRIAL INSULATION

TABLE 250 VISIONARY INDUSTRIAL INSULATION: COMPANY OVERVIEW

11.2.14 ARABIAN FIBERGLASS INSULATION COMPANY LTD

TABLE 251 ARABIAN FIBERGLASS INSULATION COMPANY LTD: COMPANY OVERVIEW

11.2.15 ASPEN AEROGELS, INC.

TABLE 252 ASPEN AEROGELS: COMPANY OVERVIEW

12 APPENDIX (Page No. - 253)

12.1 DISCUSSION GUIDE

12.2 KNOWLEDGESTORE: MARKETSANDMARKETS’ SUBSCRIPTION PORTAL

12.3 AVAILABLE CUSTOMIZATIONS

12.4 RELATED REPORTS

12.5 AUTHOR DETAILS

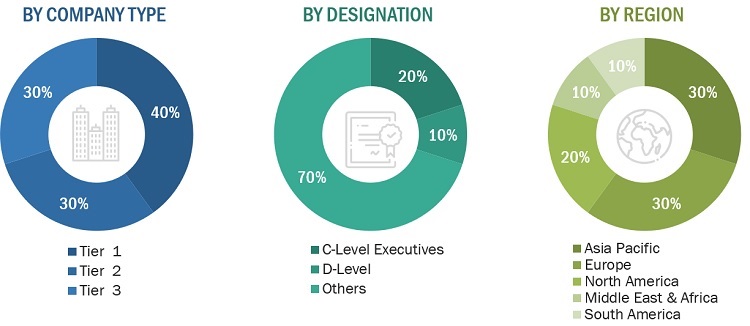

The study involved four major activities to estimate the current market size of industrial insulation. Exhaustive secondary research was done to collect information on the market, the peer market, and the parent market. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain through primary research. Both top-down and bottom-up approaches were employed to estimate the complete market size. Thereafter, market breakdown and data triangulation were used to estimate the market size of segments and sub-segments.

Secondary Research

In the secondary research process, various secondary sources such as Factiva, Zauba, Hoovers, and Bloomberg BusinessWeek were referred to for identifying and collecting information for this study. These secondary sources included annual reports, press releases & investor presentations of companies, white papers, certified publications, articles by recognized authors, regulations form agencies such as Association for the Development and Promotion of Electric Mobility, China Association of Automobile Manufacturers, European Automobile Manufacturers' Association (ACEA), and others.

Primary Research

Extensive primary research has been conducted after acquiring an understanding of the industrial insulation market scenario through secondary research. Several primary interviews have been conducted with market experts from both the demand- (industrial insulation manufacturers) and supply-side (end-product manufacturers, buyers, and distributors) players across six major regions, namely, North America, Western Europe, Eastern & Central Europe, Asia Pacific, Middle East & Africa, and South America. Approximately 70% and 30% of primary interviews have been conducted from the demand and supply side, respectively. Primary data has been collected through questionnaires, emails, and telephonic interviews. In the canvassing of primaries, various departments within organizations, such as sales, operations, and administration, were covered to provide a holistic viewpoint in our report. After interacting with industry experts, brief sessions were conducted with highly experienced independent consultants to reinforce the findings from our primaries. This, along with the in-house subject matter experts’ opinions, has led us to the findings as described in the remainder of this report

Following is the breakdown of primary respondents:

Notes: Companies are classified based on their revenue–Tier 1 = > USD 1 billion, Tier 2 = USD 500 million– USD 1 billion, and Tier 3 = < USD 500 million.

Other designations include sales representatives, production heads, and technicians.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

Both the top-down and bottom-up approaches were used to estimate and validate the total size of the industrial insulation market. These methods were also used extensively to estimate the size of various sub-segments in the market. The research methodology used to estimate the market size included the following:

- The key players in the industry and markets were identified through extensive secondary research.

- The industry’s supply chain and market size, in terms of value, were determined through primary and secondary research processes.

- All percentage shares, splits, and breakdowns were determined using secondary sources and verified through primary sources.

Global Industrial Insulation Market Size: Bottom-Up Approach

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the overall market size using the market size estimation processes as explained above, the market was split into several segments and sub-segments. In order to complete the overall market engineering process and arrive at the exact statistics of each market segment and subsegment, the data triangulation and market breakdown procedures were employed, wherever applicable. The data was triangulated by studying various factors and trends from both the demand and supply sides.

Report Objectives

- To analyze and forecast the industrial insulation market size, terms of value.

- To provide detailed information about the key factors (drivers, restraints, opportunities, and challenges) influencing the growth of the market

- To define, describe, and forecast the market by form, material, end-use industries, and region.

- To forecast the size of the market with respect to six regions, namely, Asia Pacific (APAC), Western Europe, Eastern & Central Europe, North America, South America, and the Middle East & Africa (MEA), along with their countries

- To strategically analyze micro markets with respect to individual growth trends, future prospects, and their contribution to the overall market

- To analyze the opportunities in the market for stakeholders and provide a competitive landscape for the market leaders

- To analyze competitive developments such as new product launch, merger & acquisition, and investment & expansion in the market

- To strategically profile the key players and comprehensively analyze their revenue and core competencies.

Available Customizations

MarketsandMarkets offers customizations according to the specific needs of the companies with the given market data.

The following customization options are available for the industrial insulation market report:

Product Analysis

- Product matrix, which provides a detailed comparison of the product portfolio of each company

Regional Analysis

- A further breakdown of the industrial insulation market, by segments

Company Information

- Detailed analysis and profiling of additional market players (up to five)

Generating Response ...

Generating Response ...

Growth opportunities and latent adjacency in Industrial Insulation Market