Collaborative Robot Market Growth in the Japan

Japan’s cobot market is driving innovation by addressing labor shortages and enhancing productivity across industries

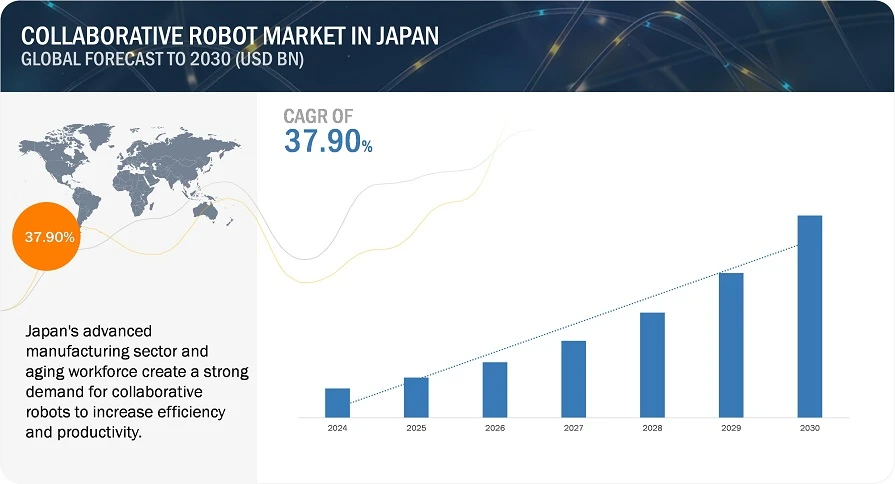

The market for collaborative robots in Japan is thriving. This is mainly due to an advanced manufacturing base, an aging workforce, and the changes in industrial needs. Japan is one of the largest robot manufacturers in the world and accounts for major portion of global production. Cobots are currently being implemented in various domains. For instance, automotive and electronics are the sectors that currently use cobots. The automotive industry, one of Japan’s major economic pillars, employs cobots in the assembly of electric and hybrid vehicles. For example, to make the assembling of engines less complex, Nissan has implemented Universal Robots cobots which eventually keep competitive workforce efficiency.

The Japanese leading robotics companies FANUC, YASKAWA, and DENSO are leading innovation in cobots. The CRX series of cobots for greater flexibility and ease in programming has been announced by FANUC for the SMEs and manufacturers working with high-mix low volume production. Cobots are taken up in a number of different sectors: the automotive and electronics sector. It is at the heart of Japan's economy, for instance assembling electric and hybrid vehicles for its automotive giant. Thus, Nissan utilizes Universal Robots cobots as a solution for reducing complexity in the engine assembly while maintaining the needed competitive efficiency of the production process. For example, YASKAWA teamed up with a European electronics company to assist the company in expanding its cobot application portfolio in precision electronics manufacturing.

Government policy is also significant in encouraging cobot adoption as the country is suffering labor shortages because of an aging population. The 2024 Problem, which emanates from new regulations limiting overtime truck driver hours, has increased automation to avoid logistical disruption. Kawasaki Heavy Industries has just released the duAro2 dual-arm cobot and has had immediate success in the food industry where companies like Delicious Cook & Co. are applying this to packaging. Government programs also exist to aid in the automation strategies with regard to these challenges, including incentives for industries such as logistics, manufacturing, and healthcare to embrace cobots.

There is growing concern toward Japan's cobot market amid innovation and automation, a thing which this market shall have to ensure is sustainable growth. Major key leaders FANUC, YASKAWA, and DENSO will bring this new look to this industry as the idea of adopting collaborative robots is finding a resolution toward workforce and efficiency issues. Factors like governmental support, advancing technology, and growing usage area in several industries ensure that Japan keeps at the forefront in this cobot innovation

Related Report

Collaborative Robot Market Size, Share, Statistics and Industry Growth Analysis Report by Payload (Up to 5 kg, 5-10 kg, 10-25 kg, & More than 25 kg), Application (Handling, Assembling & Disassembling, Dispensing), Industry (Automotive, Electronics, Metals & Machining) & Region - Global Growth Driver and Industry Forecast to 2030

Contact:

Mr. Rohan Salgarkar

MarketsandMarkets™ INC.

1615 South Congress Ave.

Suite 103

Delray Beach, FL 33445

USA : 1-888-600-6441

sales@marketsandmarkets.com

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

SEND ME A FREE SAMPLE