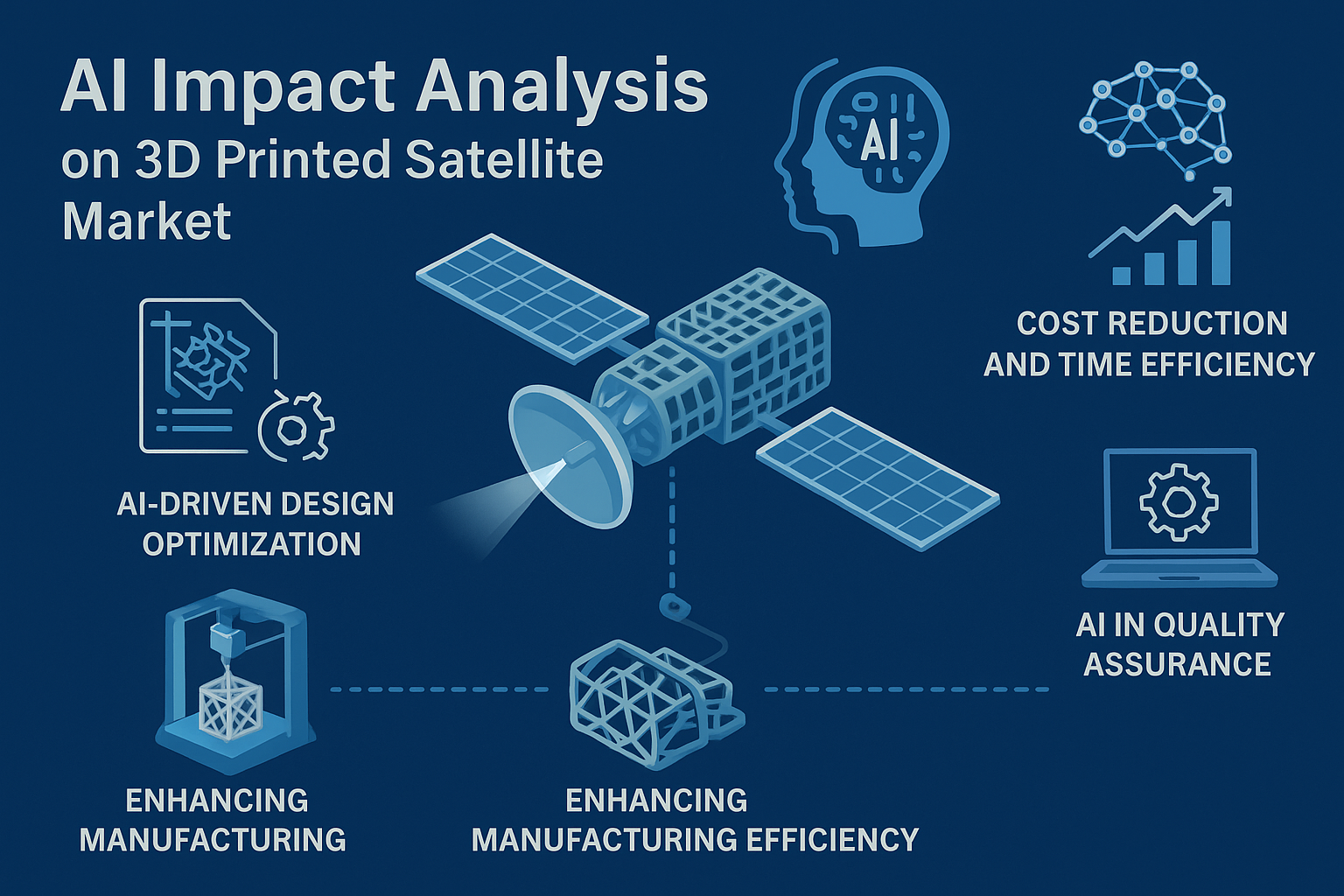

AI Impact Analysis on 3D Printed Satellite Industry

The aerospace sector is undergoing a transformation with the rise of 3D printing technology, also known as additive manufacturing, which allows satellites to be designed, customized, and manufactured at an unprecedented speed and scale. Coupled with artificial intelligence, this shift is redefining how space systems are conceived, built, and deployed. AI plays a pivotal role in optimizing every step of the process, from conceptual design and materials selection to testing, quality assurance, and lifecycle management. As satellite demand increases for communication, defense, and Earth observation, AI driven additive manufacturing is enabling cost effective, lightweight, and resilient spacecraft that meet the needs of next generation space missions.

AI-Driven Design Optimization for 3D Printed Satellites

The design phase of satellite manufacturing is often complex, requiring engineers to consider weight, durability, structural integrity, and mission specific features. This process could take months or even years. Artificial intelligence is reshaping this timeline through generative design tools and simulation based modeling. AI algorithms can process thousands of potential designs, selecting optimal configurations that minimize weight while maximizing strength.

In the case of CubeSats and nanosatellites, AI driven design models help achieve compact, modular structures that fit within the constraints of limited space but deliver maximum utility. Predictive modeling further enhances design integrity by simulating performance under extreme conditions, such as radiation exposure, vacuum environments, and mechanical stress during launch. This AI enabled generative design shortens development cycles, cuts costs, and improves overall mission success.

Enhancing Manufacturing Efficiency with AI in Additive Manufacturing

Manufacturing efficiency has historically been one of the biggest challenges in aerospace engineering. Additive manufacturing makes it possible to print satellite components layer by layer, but defects, inconsistencies, or inefficiencies in the process can compromise entire missions. AI addresses this challenge by monitoring 3D printing processes in real time. Machine learning models analyze parameters such as temperature, print speed, and material deposition to ensure accuracy.

When irregularities arise, AI systems detect and correct them instantly, reducing waste and preventing production failures. By combining additive manufacturing with AI oversight, production timelines are shortened significantly. The industry now has the ability to produce satellites faster than ever before, without compromising on quality. This manufacturing revolution directly supports growing global demand for rapid satellite deployment.

AI in Material Science for 3D Printed Satellites

Material science is central to the success of 3D printed satellites. Traditional metals used in aerospace are often expensive, heavy, and challenging to manufacture. With AI, new possibilities emerge in the discovery and optimization of space grade alloys and composites. AI driven material research identifies compounds that combine light weight with durability, resistance to extreme temperatures, and resistance to radiation exposure.

High performance polymer composites reinforced with carbon fiber or ceramic based materials are being tailored for satellite structures. AI algorithms simulate and test thousands of possible combinations to find the best fit for specific mission needs. This reduces reliance on trial and error experimentation and accelerates innovation. As a result, 3D printed satellites can be more resilient, lighter, and cost effective, supporting long term sustainability in space missions.

Cost Reduction and Time Efficiency through AI Integration

One of the most compelling benefits of integrating AI into the 3D printed satellite market is cost and time efficiency. The aerospace sector has long faced high production costs, with traditional satellites requiring years of research and development and massive capital investment. AI accelerates prototyping by simulating designs virtually, eliminating the need for costly iterations.

Material wastage is another key concern in aerospace. With AI enhanced 3D printing, every layer of material is optimized for function and strength, reducing excess usage. Predictive analytics also streamline procurement processes, ensuring materials are available just in time and in the right quantity. These efficiencies lower costs not only for manufacturers but also for governments, private operators, and space startups eager to launch new constellations.

AI-Enabled Quality Assurance and Testing of 3D Printed Satellites

Quality assurance is vital in satellite production since the smallest defect can cause catastrophic mission failure. Traditional testing methods often rely on destructive analysis, which is costly and impractical. AI revolutionizes this process by enabling non destructive testing. Advanced imaging combined with AI pattern recognition detects microcracks, weak points, and inconsistencies invisible to the human eye.

Predictive failure analysis adds another layer of reliability, allowing engineers to forecast when components might fail under operational conditions. This predictive capability ensures satellites are robust enough to survive harsh environments, from atmospheric reentry to deep space operations. As AI continues to evolve, quality assurance in the 3D printed satellite market will reach levels of precision that far surpass traditional methods.

AI Applications in Customization and Modular Satellite Design

The growing demand for CubeSats, nanosatellites, and microsatellites has shifted the industry’s focus toward customization and modularity. AI allows manufacturers to create tailored designs for specific missions, whether they involve Earth observation, scientific research, or defense. AI guided modeling enables modular designs that can be reconfigured depending on mission requirements.

This flexibility not only reduces costs but also expands opportunities for private companies and academic institutions to participate in space exploration. With AI and 3D printing, even small organizations can design, produce, and deploy satellites tailored to unique goals, democratizing access to space.

Get AI Impact Analysis on 3D Printed Satellite Market, Request Pdf Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=227584767

AI in Supply Chain and Logistics for Satellite Manufacturing

Satellite manufacturing involves a complex global supply chain, including specialized materials, electronics, and propulsion systems. AI improves supply chain efficiency by forecasting demand, managing inventory, and predicting potential disruptions. For 3D printed satellites, this translates into smarter logistics for raw material procurement and distribution.

Distributed manufacturing, where satellites or components are printed closer to launch facilities, is also enabled by AI driven supply chain systems. This reduces transportation costs and speeds up deployment timelines. As the space economy becomes increasingly globalized, AI powered supply chain management ensures resilience and responsiveness.

AI in Satellite Lifecycle Management and Maintenance

The lifecycle of a satellite extends beyond manufacturing and launch. AI plays a key role in lifecycle management by enabling predictive maintenance of 3D printed parts. By monitoring operational data in real time, AI can forecast wear and tear, preventing costly failures during missions.

Digital twin technology is another breakthrough, where a virtual model of a satellite mirrors its real time performance. This allows engineers to test scenarios, predict malfunctions, and optimize performance throughout the satellite’s life. As satellites become more sophisticated and numerous, AI driven lifecycle management will ensure their long term viability in orbit.

Future Outlook: AI and 3D Printing Synergy in the Satellite Market

The future of the 3D printed satellite market lies in deeper integration between AI and additive manufacturing. Research and development efforts are now focused on creating next generation propulsion systems, advanced antennas, and reusable satellite structures using AI optimized 3D printing techniques. Sustainability is also a priority, with AI helping design recyclable or reusable satellite components that reduce space debris.

As the global space industry grows with mega constellations, defense applications, and interplanetary missions, AI enabled 3D printing will be at the forefront of innovation. This synergy is not only driving down costs but also creating a scalable, sustainable model for the future of space exploration.

Related Report:

3D Printed Satellite Market by Component (Antenna, Bracket, Shield, Housing and Propulsion), Satellite Mass (Nano and microsatellite, small satellite, medium and large satellite), Application and Region - Global Forecast to 2030

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

SEND ME A FREE SAMPLE