AI Impact Analysis on Aerospace Robotics Industry

The integration of artificial intelligence into aerospace robotics marks a transformative shift in how the aerospace industry designs, manufactures, maintains, and operates complex machinery and vehicles. The traditional model of robotic automation, largely based on static programming and manual oversight, is being replaced with intelligent systems capable of learning, adapting, and autonomously making decisions. From smart robotic arms in assembly lines to autonomous satellites in orbit, AI is enabling next generation aerospace robotics to be more efficient, precise, and responsive. This evolution is reshaping production paradigms, optimizing cost structures, and enhancing the reliability and safety of critical aerospace operations. As the market grows, aerospace companies are increasingly investing in AI powered robotics to stay competitive, meet rising demand, and address the complexities of modern aerospace ecosystems.

Intelligent Manufacturing Robots in Aerospace Production

One of the most significant areas where AI is making an impact is in intelligent robotic systems used in aircraft production. Traditional assembly processes, while highly accurate, require substantial human oversight and suffer from inefficiencies due to their rigidity. AI powered robots, however, introduce adaptive capabilities that allow them to learn and improve over time. These smart manufacturing robots are used for tasks such as fuselage drilling, riveting, composite material placement, and even aerodynamic structure alignment. Through the application of machine learning, these robots can optimize their performance based on sensor feedback, production data, and environmental changes on the assembly floor. They also reduce the margin for human error while maintaining flexibility in adjusting to design modifications or varying product lines. As aircraft structures become more advanced and lightweight, intelligent robotics will become indispensable in ensuring precision, repeatability, and scalability in manufacturing.

AI Integration in Space Robotics and Autonomous Spacecraft

In the realm of space exploration and satellite servicing, AI is playing a transformative role in enabling autonomous space robotics. Unlike terrestrial systems, space robots operate in environments where real time human control is not feasible due to communication delays and constraints. AI allows these robots to make independent decisions, navigate obstacles, and execute complex tasks such as satellite repair, payload deployment, and surface exploration. Robotic systems on the International Space Station, for example, leverage AI to perform routine maintenance and logistics. Similarly, autonomous spacecraft equipped with AI powered navigation and control systems are being used in deep space missions, where intelligent course correction and resource management are critical. AI also facilitates robotic docking, refueling, and orbital debris removal by equipping space robots with the capability to analyze their surroundings and adapt accordingly. As space missions become more ambitious and commercialized, AI integrated robotics will be essential for enabling sustainable and autonomous operations beyond Earth’s orbit.

AI for Predictive Maintenance in Robotic Aerospace Systems

The maintenance of robotic systems within aerospace environments is another critical area where AI is delivering substantial value. Predictive maintenance uses AI algorithms to analyze operational data from robotic components, including motors, actuators, joints, and control systems. By identifying anomalies and degradation patterns, AI can forecast when a robotic unit is likely to fail or require servicing. This proactive approach reduces unexpected downtimes, enhances safety, and extends the lifespan of high value robotic assets. For example, AI systems can detect subtle changes in vibration or torque levels that might indicate wear in a robotic arm used in aircraft assembly. These insights allow maintenance teams to schedule interventions before failures occur, thus maintaining productivity and avoiding disruptions. Additionally, AI can analyze maintenance logs, environmental conditions, and historical fault data to improve the reliability of robotic systems across different aerospace applications.

Autonomous Drones and AI in Aerospace Surveillance

Unmanned aerial systems, or drones, have become an integral part of aerospace surveillance, inspection, and monitoring operations. With the infusion of AI, these drones are evolving from remotely piloted vehicles to fully autonomous systems capable of real time decision making. AI enables drones to process visual and sensor data onboard, identify anomalies, and navigate complex environments without human intervention. In aerospace applications, drones are used for inspecting aircraft surfaces, runway conditions, and maintenance facilities. AI algorithms allow them to detect structural damage, corrosion, and foreign object debris with high accuracy. Additionally, in spaceport or defense settings, AI powered drones enhance perimeter surveillance by identifying unusual activity, predicting potential security breaches, and coordinating with ground systems. Their versatility, speed, and intelligence make AI enabled drones an indispensable tool for enhancing safety and operational efficiency across the aerospace value chain.

AI Powered Human-Robot Collaboration in Aerospace Assembly

As aerospace manufacturing becomes more complex, the need for effective collaboration between human workers and robotic systems also known as cobots has grown significantly. AI plays a crucial role in facilitating this collaboration by enabling robots to perceive, interpret, and respond to human actions in real time. In aerospace assembly, cobots are used alongside technicians to handle delicate components, perform precise positioning, and manage tool transitions. AI ensures these cobots can operate safely by detecting human presence, predicting movements, and adapting their behavior accordingly. This interaction not only enhances productivity but also reduces the physical strain on human workers by taking over repetitive or ergonomically challenging tasks. Furthermore, AI driven cobots can learn from their human counterparts, improving their own capabilities over time. The future of aerospace assembly lies in environments where humans and intelligent robots work side by side, each enhancing the strengths of the other.

Machine Learning for Aerospace Robotic Navigation and Control

Navigation and control systems are at the heart of every aerospace robotic platform, whether on Earth or in orbit. Machine learning provides a powerful set of tools for improving these systems by allowing them to learn from experience and adapt to dynamic conditions. In manufacturing settings, ML powered robotic arms use reinforcement learning to refine their movement paths, avoid obstacles, and optimize task sequences. In aerial robotics, AI helps drones maintain stability in turbulent conditions, map unknown environments, and land precisely on constrained surfaces. Space robotics benefit from machine learning algorithms that enable autonomous rovers and arms to operate in unstructured terrains like the Moon or Mars. These systems can identify landmarks, assess terrain risk, and generate navigation strategies on the fly. By embedding intelligence into navigation and control systems, aerospace robotics can operate more independently and effectively across a wide range of missions and environments.

Get AI Impact Analysis on Aerospace Robotics Market, Request Pdf Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=164758944

Computer Vision in Aerospace Inspection and Quality Control

Visual inspection is a critical component of quality assurance in aerospace manufacturing and maintenance. AI powered computer vision systems are revolutionizing this function by providing fast, accurate, and automated defect detection. These systems use high resolution cameras and deep learning algorithms to analyze surfaces for cracks, scratches, misalignments, or contaminants. In aircraft assembly, vision guided robots inspect structural joints, rivet placements, and sealant applications to ensure compliance with engineering specifications. During maintenance checks, mobile robotic platforms equipped with computer vision can navigate around aircraft and scan for surface anomalies in real time. The integration of AI enables these systems to differentiate between cosmetic blemishes and structural concerns, reducing false alarms and prioritizing actionable issues. Moreover, AI can create inspection reports automatically, complete with annotated images and historical comparisons, streamlining the documentation process and supporting regulatory compliance.

AI in Simulation, Digital Twins, and Training for Aerospace Robotics

Simulation technologies are essential for developing, testing, and training aerospace robotic systems before they are deployed in the field. AI enhances simulation environments by introducing dynamic learning and behavior modeling capabilities. Through digital twinsvirtual replicas of physical robotic systems engineers can simulate real world operations under various scenarios. AI augments digital twins by enabling them to predict outcomes, simulate failures, and recommend design improvements based on simulated performance. These simulations can also be used to train robotic systems through reinforcement learning, where the robot improves by interacting with the virtual environment. For human operators and technicians, AI powered simulators provide immersive training experiences that adapt to user performance, identify skill gaps, and offer personalized guidance. This approach accelerates the learning curve and ensures safe, effective deployment of robotic systems in aerospace applications.

Future Outlook and Market Trends in AI-Enabled Aerospace Robotics

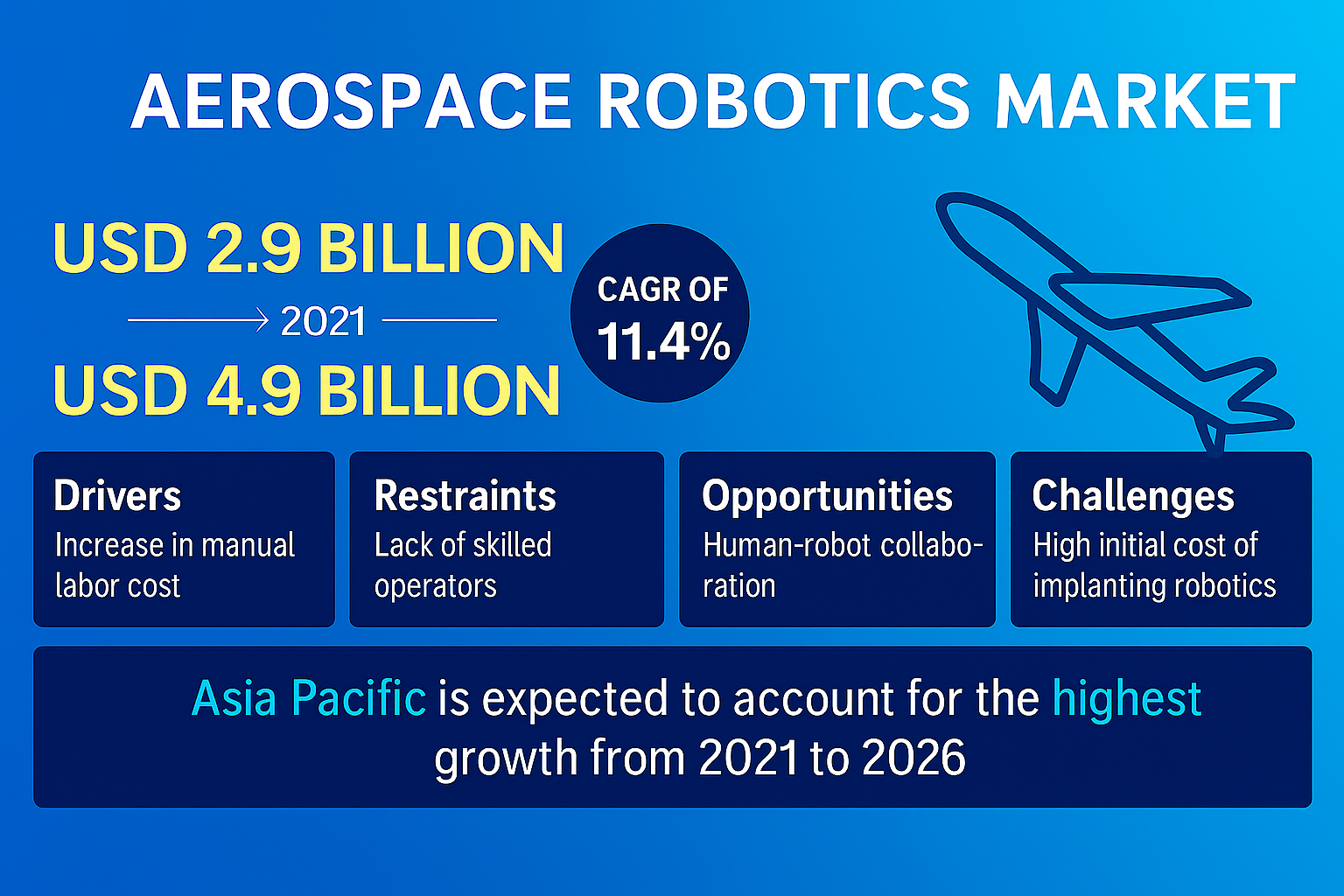

The future of the aerospace robotics market lies in the continued convergence of AI, robotics, and aerospace engineering. Market trends indicate a significant increase in adoption across both commercial and defense sectors, driven by the need for cost efficiency, operational reliability, and advanced capabilities. Investment in AI enabled robotics is expanding across areas such as satellite servicing, hypersonic vehicle production, deep space missions, and autonomous drone fleets. Regionally, North America and Europe are leading in R&D and deployment, while Asia Pacific is emerging rapidly due to government backed aerospace initiatives. The rise of Industry 4.0 principles in aerospace manufacturing further accelerates the demand for smart robotics. Future innovations may include self repairing robotic systems, AI generated design blueprints, and quantum computing enhanced AI models. Regulatory frameworks are also evolving to ensure the safe integration of AI in mission critical aerospace functions. As this sector matures, companies that leverage AI for robotics will not only achieve higher productivity and innovation but also position themselves at the forefront of a transformative aerospace era.

Artificial intelligence is fundamentally reshaping the aerospace robotics market by infusing intelligence into machines that build, maintain, and operate aircraft and spacecraft. From intelligent manufacturing robots to autonomous space systems and AI powered inspection tools, the integration of AI is unlocking new levels of precision, adaptability, and efficiency. This synergy is not only improving operational performance but also redefining the boundaries of what aerospace robotics can achieve. As technological advancements continue and market demand rises, AI will become the central pillar supporting the next wave of aerospace innovation. Companies that embrace this shift will be better equipped to tackle the challenges of complex missions, evolving regulations, and competitive pressures. The future of aerospace robotics belongs to intelligent systems that think, learn, and act autonomously and AI is the force driving them forward.

Related Report:

Aerospace Robotics Market by Robot Type (Traditional Robots, Collaborative Robots), Component (Controllers, Arm Processor, Sensors, Drive, End Effectors), Payload, Application, Region (North America, Europe, Asia Pacific, RoW)

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

SEND ME A FREE SAMPLE