AI Impact Analysis on Digital Shipyard Industry

Artificial Intelligence is redefining the very foundations of modern shipyards. The once labor intensive and manually orchestrated operations are now transitioning into intelligent, connected ecosystems where machines think, adapt, and collaborate. Digital shipyards, at their core, are powered by the integration of AI technologies that streamline shipbuilding, maintenance, workforce management, inventory control, and system diagnostics. As global defense and commercial maritime sectors demand faster construction timelines and greater efficiency, AI has emerged as a strategic enabler. It facilitates adaptive design, intelligent automation, and real time decision making that spans from the dry dock to onboard operations. By incorporating AI into their digital infrastructure, shipbuilders are moving toward predictive maintenance regimes, smart fabrication processes, and integrated production planning. This transformation enhances output quality, minimizes rework, and reduces costs while strengthening the competitiveness of both naval and civilian shipbuilding programs.

Predictive Maintenance and AI in Naval MRO Operations

Maintenance, repair, and overhaul (MRO) operations are the lifeblood of naval fleet readiness. In a traditional setup, ship maintenance relied on scheduled interventions or reactive repairs. AI introduces a paradigm shift toward predictive maintenance by leveraging real time operational data and machine learning algorithms to foresee potential failures. Ships equipped with sensors relay continuous diagnostics on engines, hull integrity, electronic warfare systems, and propulsion units. AI analyzes this data to detect abnormal patterns, vibration inconsistencies, or temperature deviations that suggest component fatigue or degradation. The impact on naval MRO efficiency is profound. Maintenance teams are alerted before a fault manifests, allowing targeted interventions that prevent downtime. Beyond failure prevention, AI also helps optimize spare parts inventory and labor deployment based on risk forecasts. As naval vessels grow in technological complexity, the role of AI in enabling mission critical reliability and reducing maintenance costs will only increase.

AI in Ship Design and Virtual Simulation Processes

The ship design process is becoming more intelligent, flexible, and responsive thanks to AI. Designing a modern naval or commercial vessel involves balancing numerous parameters including hydrodynamics, structural integrity, cost, emissions, and mission capability. AI driven software solutions are now capable of performing thousands of iterative design simulations within minutes. These generative design platforms allow naval architects to feed in constraints and objectives, while AI produces optimal configurations. In tandem, AI enhanced simulation platforms can model fluid dynamics, stress tests, and environmental exposure scenarios more efficiently than traditional finite element methods. This accelerates development timelines and improves design robustness. By integrating real time data from digital twins or historical build records, AI ensures that new designs are not only innovative but also grounded in operational feasibility. Moreover, AI's ability to simulate hull vibrations, predict load distributions, and identify design flaws early in the process significantly reduces the risk of costly revisions.

Robotics and AI for Autonomous Welding and Assembly

Robotic automation is rapidly becoming a staple in modern shipyard production lines. The addition of AI transforms these robots into intelligent collaborators capable of adapting to design changes, workpiece variations, and environmental shifts. In welding and assembly tasks, AI guided robotic arms use sensors and machine vision to execute precise operations across the ship's hull, piping, or substructure sections. Unlike conventional programmed robots, AI enabled systems learn from past jobs, adjust parameters in real time, and detect anomalies such as misalignments or temperature fluctuations. This not only improves weld quality but also enhances safety and efficiency. In large scale fabrication yards, multiple robotic systems coordinated by AI algorithms can operate in unison, optimizing space, time, and energy usage. As labor shortages and cost pressures continue to affect the shipbuilding sector, AI powered robotics offer a scalable and consistent solution that ensures uninterrupted workflows even under challenging conditions.

AI-Powered Supply Chain and Inventory Optimization in Shipyards

Shipbuilding involves complex logistics where thousands of components must be delivered and installed in precise sequences. Any delay or mismatch can lead to cascading production bottlenecks. AI is solving these challenges by enabling predictive supply chain management and real time inventory optimization. By analyzing procurement trends, vendor reliability, lead times, and consumption patterns, AI systems forecast material demand and schedule just in time deliveries. These algorithms account for external variables such as port disruptions, geopolitical risks, or raw material shortages. Inside the shipyard, AI monitors stock levels, tracks component locations using RFID and IoT sensors, and auto generates restocking orders before shortages occur. This synchronization between inventory and project schedules ensures that critical systems such as engine modules or electronic suites are available when needed. AI also supports dynamic pricing and supplier negotiations by assessing cost trends and benchmarking performance across vendors. Ultimately, intelligent supply chain systems reduce idle time, lower warehousing costs, and improve overall build accuracy.

AI Integration with Digital Twins in Shipbuilding

Digital twins are virtual replicas of physical ships, systems, or shipyard assets. When integrated with AI, these twins evolve into intelligent platforms that not only replicate but also predict, diagnose, and optimize performance. Throughout the ship’s lifecycle from initial design through construction, deployment, and maintenance AI enabled digital twins provide unparalleled visibility. For example, a digital twin of a naval destroyer continuously updates based on real time telemetry from onboard systems. AI algorithms compare actual behavior to expected performance models, flagging deviations and recommending corrective actions. During construction, digital twins mirror the progress of modular assembly and welding, enabling remote quality assurance and predictive risk assessment. AI also uses digital twins to simulate different operating environments, test new mission configurations, and evaluate system responses under stress. By integrating AI into the digital twin ecosystem, shipyards can build smarter, reduce waste, and ensure each ship enters service fully validated and performance optimized.

Augmented Reality and AI for Workforce Training and Assistance

Shipyard environments are increasingly relying on augmented reality to train, guide, and support human workers. AI enhances these AR platforms by providing context aware information, adaptive instruction, and real time performance analysis. New technicians can use AR glasses to see step by step overlays during complex assembly tasks, with AI monitoring their accuracy and offering corrective suggestions. For experienced workers, AI interprets hand gestures or verbal commands to navigate through schematics, manuals, and diagnostic data without disrupting workflow. During inspections, AR devices combined with AI help workers visualize internal components, simulate operational scenarios, or cross reference historical faults. In safety critical environments, AI tracks worker fatigue, hazardous proximity, and tool usage to enforce protocols and reduce risks. Training modules powered by AI adapt to the learner’s pace and previous performance, offering customized learning paths. As shipyard technology evolves, AR and AI will continue to bridge the skill gap and enhance workforce efficiency in both civilian and defense applications.

Get AI Impact Analysis on Digital Shipyard Market, Request Pdf Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=6854923

AI-Enhanced Project Scheduling and Work Order Automation

Project management in shipbuilding involves juggling multiple dependencies, shifting deadlines, and unforeseen disruptions. AI enhances this process by automating work orders, optimizing resource allocation, and forecasting project risks. Through historical data and realtime project status updates, AI predicts how delays in one area will impact downstream operations. It then suggests re sequencing, resource reallocation, or overtime scheduling to stay on track. Work orders are automatically generated and assigned based on technician availability, skill level, and task urgency. AI also factors in environmental conditions such as tides, temperature, or power usage to fine tune scheduling for outdoor operations. Moreover, the system tracks daily progress, highlights bottlenecks, and generates reports for managers and clients. These insights empower shipyard leadership to make data driven decisions and respond proactively to schedule variances. The end result is higher productivity, lower costs, and more reliable delivery timelines for complex shipbuilding projects.

AI in Quality Control and Defect Detection in Shipyards

Precision is non negotiable in shipbuilding, where a minor flaw can compromise safety or operational integrity. AI brings a new level of sophistication to quality control by leveraging computer vision, deep learning, and pattern recognition. Automated inspection drones and robotic arms equipped with cameras scan welds, joints, and surface coatings for defects. AI identifies microfractures, thickness inconsistencies, or corrosion that would be missed by the human eye. These systems learn from labeled datasets and continuously refine their detection accuracy over time. Unlike manual inspections, AI based systems can operate 24/7 and analyze large areas in a fraction of the time. AI also correlates defect trends with manufacturing variables such as ambient temperature, operator skill, or equipment settings to trace root causes. The data collected feeds into quality dashboards, supporting continuous improvement programs and regulatory compliance. As shipyards pursue lean manufacturing goals, AI enabled quality control is emerging as a mission critical function.

Future Outlook: Market Trends and AI-Driven Innovation in Digital Shipyards

The digital shipyard market is on a rapid upward trajectory, fueled by increasing global naval budgets, commercial fleet modernization, and a push for smarter maritime infrastructure. AI is at the core of this transformation, driving innovation across every aspect of shipbuilding and lifecycle management. In the near future, shipyards will witness the rise of fully autonomous production lines where AI coordinates human workers, robotic units, and logistical assets in harmony. Quantum computing may further accelerate AI’s capabilities in design and simulation. Regulatory bodies are developing frameworks to standardize AI usage in defense and commercial maritime sectors, emphasizing cybersecurity, transparency, and human oversight. Regionally, Asia Pacific is set to become a key growth area, particularly in South Korea, China, and India, as they invest in AI powered naval shipbuilding. Strategic partnerships between shipbuilders, defense ministries, AI startups, and software firms will fuel co innovation. The digital shipyard of tomorrow will not just build ships it will build intelligent, resilient, and mission ready maritime assets at unprecedented speed and precision.

The integration of Artificial Intelligence into digital shipyard operations represents a profound evolution in maritime manufacturing. From predictive maintenance and AI powered robotics to intelligent design and immersive training, AI is reshaping how ships are built, maintained, and operated. These advancements are not just technological luxuries they are strategic imperatives in an era of rising complexity, tight budgets, and global competition. As shipyards around the world adapt to this new paradigm, AI will become the cornerstone of digital transformation, driving efficiency, innovation, and competitiveness. The future of the shipbuilding industry belongs to those who harness the full potential of intelligent automation, and the digital shipyard is the launchpad for that future.

Related Report:

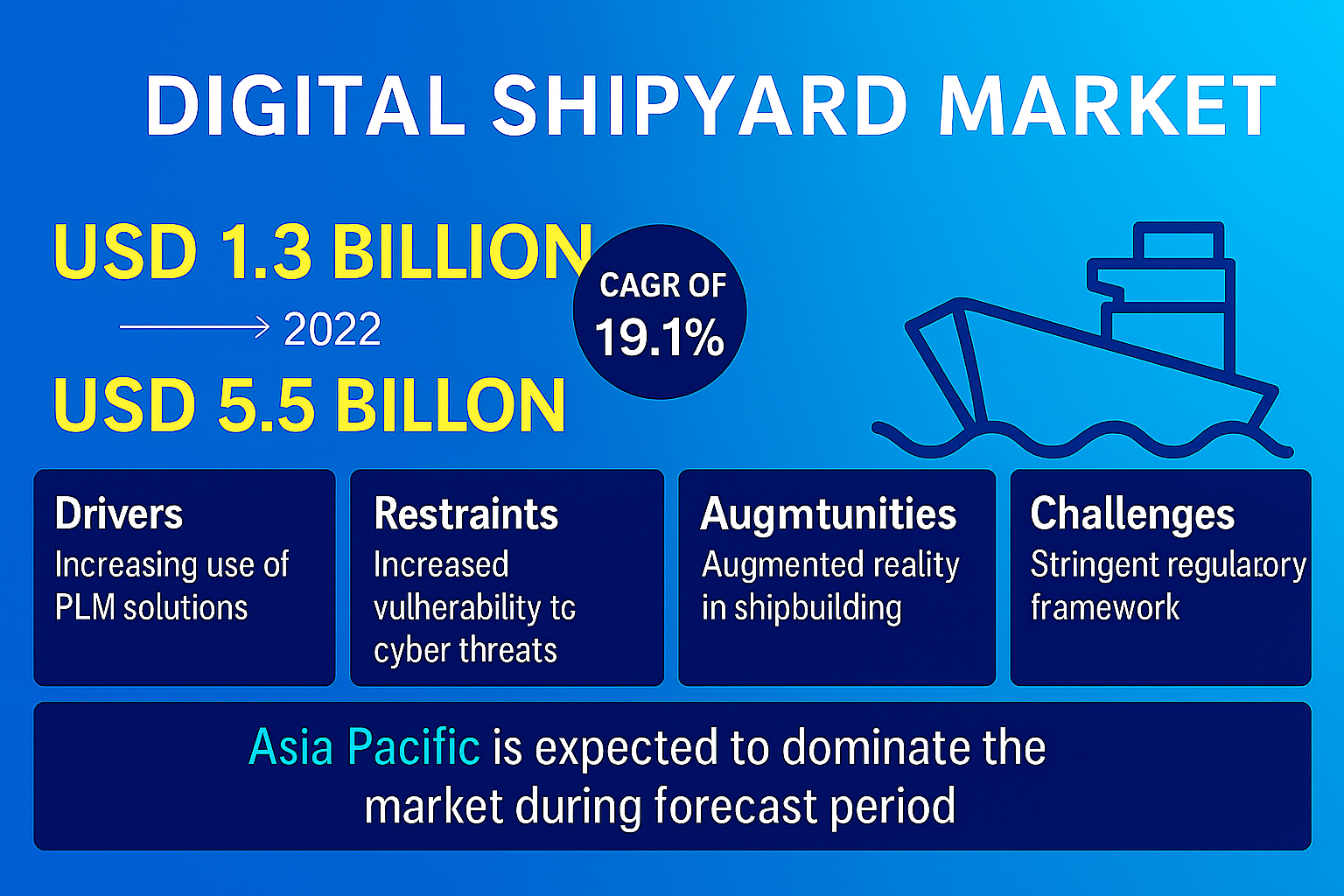

Digital Shipyard Market by Shipyard Type (Commercial, Military), Capacity (Large, Medium, Small), End Use (Implementation, Upgrades & Services), Digitalization Level, Process, Technology, and Region-Global Forecast to 2030

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

SEND ME A FREE SAMPLE