AI Impact Analysis on Electromechanical Actuators in Aircraft Industry

The global aerospace industry is undergoing one of the most transformative phases in its history, as it increasingly shifts toward electric and digital systems. At the heart of this transformation is the electromechanical actuator, a device that converts electrical energy into mechanical motion to control critical functions in an aircraft. Aviation systems relied heavily on hydraulic and pneumatic actuators, which while powerful, came with disadvantages such as weight, complexity, leakage risks, and maintenance challenges. Electromechanical actuators (EMAs) have emerged as a vital alternative, providing lighter, more efficient, and more reliable solutions.

Artificial Intelligence (AI) has amplified the relevance of these actuators in modern aircraft design. AI driven optimization is redefining the performance capabilities of electromechanical systems by enabling real time decision making, predictive maintenance, and energy efficient operations. The increasing adoption of More Electric Aircraft (MEA) concepts, driven by sustainability goals and cost pressures, has placed electromechanical actuators at the forefront of aerospace innovation. This blog provides an in depth analysis of how AI is impacting the electromechanical actuators in the aircraft market, analyzing growth drivers, challenges, applications, and the future outlook.

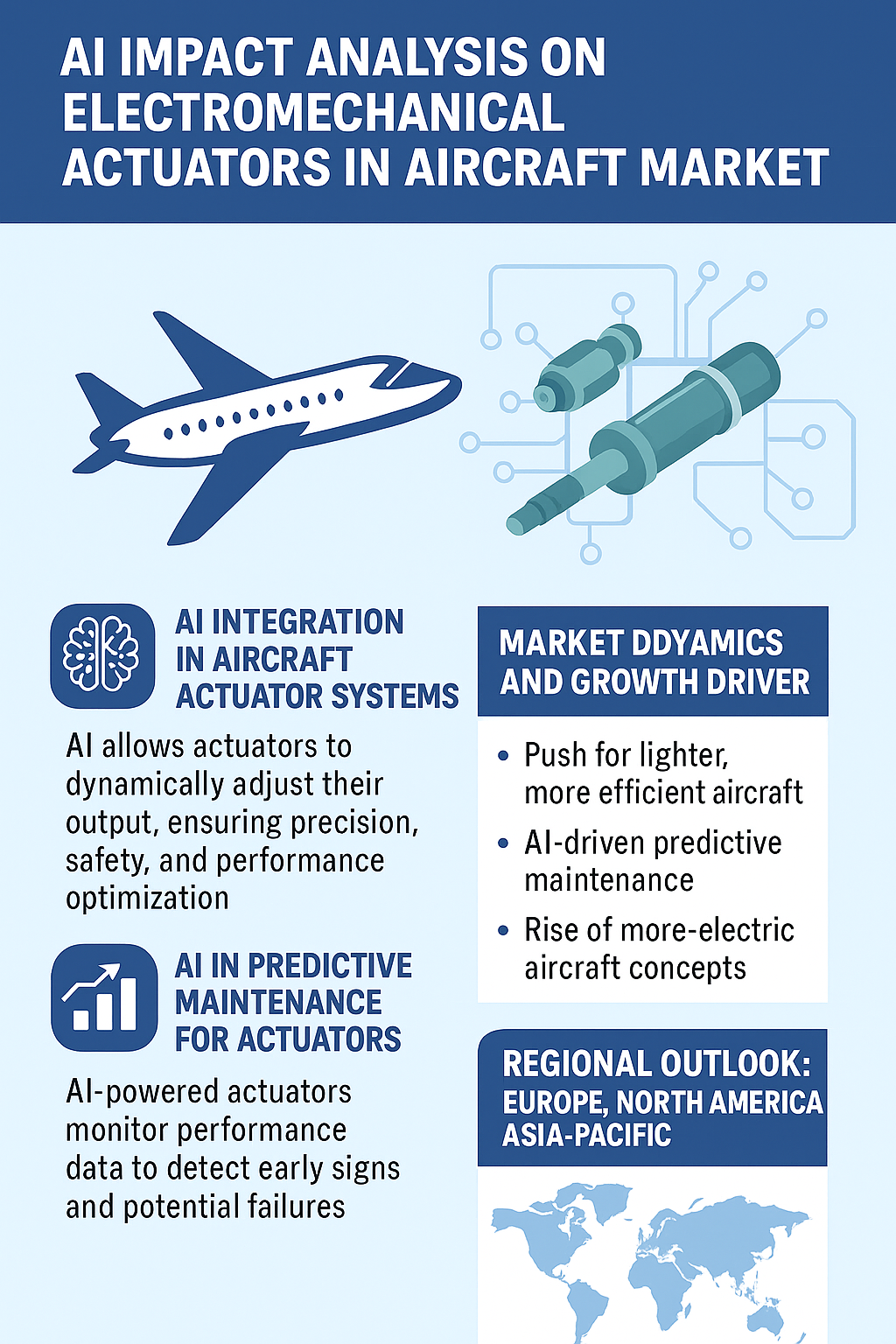

AI Integration in Aircraft Actuator Systems

AI is playing a decisive role in reshaping electromechanical actuator systems. Actuators followed fixed control logics, making them less adaptable to changing flight conditions. AI integration allows actuators to dynamically adjust their output, ensuring precision, safety, and performance optimization.

AI enabled electromechanical actuators can self monitor their health and report anomalies long before failures occur. Through embedded sensors and intelligent algorithms, these actuators continuously analyze parameters such as temperature, vibration, torque, and wear levels. The insights derived from this data help operators optimize performance and reduce energy wastage.

Another area where AI is significantly transforming actuators is in load management. In aircraft with multiple control surfaces, actuators must synchronize precisely. AI can coordinate electromechanical actuators to ensure smooth, accurate movements while minimizing stress on components. This not only enhances flight stability but also extends the lifespan of the actuators.

The integration of AI also complements the growing autonomy of aviation systems. Autonomous drones and pilot assist systems depend on actuators that can execute commands with impeccable accuracy and reliability. AI ensures that these actuators adapt to rapidly changing environments, making them indispensable for the future of aviation.

Market Dynamics and Growth Drivers

The market for electromechanical actuators in aircraft is expanding at a steady pace, supported by several key dynamics. Airlines and defense organizations are pushing for lighter, more efficient aircraft to reduce operating costs and carbon emissions. Electromechanical actuators, being lighter and more energy efficient compared to hydraulic systems, contribute directly to these goals.

AI further strengthens the market potential by reducing lifecycle costs. Airlines and maintenance organizations spend billions annually on aircraft servicing and component replacements. AI driven predictive maintenance capabilities in EMAs allow stakeholders to minimize unexpected breakdowns and optimize maintenance schedules, translating into significant cost savings.

Another growth driver is the rise of more electric aircraft concepts. Aircraft manufacturers are designing platforms where hydraulic and pneumatic systems are replaced by electric equivalents. This shift not only simplifies aircraft architectures but also enables advanced digital integration. AI powered actuators play a central role in this transformation by aligning seamlessly with digital flight control systems.

Defense modernization programs are also fueling market demand. Militaries worldwide are investing in next generation aircraft, UAVs, and autonomous platforms, where AI enabled electromechanical actuators provide agility, accuracy, and operational efficiency. As geopolitical tensions rise and defense budgets expand, the demand for such advanced systems is expected to surge further.

AI in Predictive Maintenance for Actuators

One of the most significant contributions of AI in the electromechanical actuator market lies in predictive maintenance. Safety and reliability are paramount, and even minor component failures can lead to catastrophic outcomes or expensive grounding of aircraft. AI powered actuators are equipped with sensors that collect real time performance data during every flight cycle.

AI algorithms process this data to detect early signs of wear and tear. Unusual vibrations or torque fluctuations can indicate potential issues with bearings or motor components. Instead of waiting for failures, predictive maintenance alerts technicians to intervene proactively. This approach minimizes downtime, reduces costs, and ensures aircraft availability.

Predictive maintenance enhances sustainability by extending the usable life of actuators. Airlines benefit from fewer replacements and more efficient resource utilization, aligning with global sustainability goals. In the military sector, predictive maintenance ensures combat readiness and reduces operational risks during missions.

The impact of AI in this area goes beyond cost savings. It transforms how maintenance is perceived in aviation from a reactive, schedule based task to a proactive, intelligence driven process. As predictive maintenance becomes mainstream, AI enabled electromechanical actuators will be integral to the long term efficiency of aviation fleets.

Enhanced Flight Safety and Control Systems

Flight safety remains the cornerstone of aerospace engineering, and AI enabled actuators contribute significantly to achieving higher safety standards. Electromechanical actuators already provide advantages over hydraulic systems by eliminating fluid leaks and pressure failures. When coupled with AI, they offer even greater reliability.

AI enhances safety by enabling actuators to perform real time diagnostics and automatically compensate for potential malfunctions. If one actuator in a control surface begins to underperform, AI algorithms can redistribute loads to other actuators, ensuring continued flight stability. This fail safe mechanism greatly reduces the risk of flight control loss.

AI allows actuators to adapt to extreme weather or turbulence conditions. By analyzing flight dynamics and environmental data, AI powered actuators can make micro adjustments that improve stability and passenger comfort. These adaptive responses enhance not only safety but also fuel efficiency.

The growing emphasis on autonomous and semi autonomous flight systems makes AI enabled actuators even more crucial. For drones, UAVs, and future autonomous passenger aircraft, actuator reliability directly determines mission success and safety. As such, AI integration is not just a performance enhancer but a fundamental enabler of next generation aviation safety.

Regional Outlook: Europe, North America, Asia-Pacific

The adoption of AI in electromechanical actuators is being driven by regional aerospace priorities and investments. North America, with its strong aerospace industry and leading OEMs such as Boeing, Lockheed Martin, and Honeywell, is at the forefront of this market. The U.S. Department of Defense has also been funding AI integration in military aviation, ensuring robust demand for advanced actuators.

Europe follows closely, with Airbus leading the push for More Electric Aircraft. The European Union’s sustainability goals and regulatory frameworks are accelerating the adoption of AI enabled systems to reduce carbon emissions. European defense programs are also incorporating AI driven actuators in fighter jets and transport aircraft.

Asia Pacific is emerging as the fastest growing market. China, India, and Japan are investing heavily in aerospace R&D, with significant emphasis on UAVs and commercial aviation expansion. AI adoption is being prioritized in actuator systems to improve local manufacturing capabilities and reduce reliance on foreign technology.

Together, these regions represent a global ecosystem where AI enabled electromechanical actuators are not just optional upgrades but strategic necessities for competitiveness and sustainability in aviation.

Get AI Impact Analysis on Electromechanical Actuators in Aircraft Market, Request Pdf Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=161099073

Defense vs. Commercial Aviation Applications

The impact of AI on electromechanical actuators can be observed distinctly in defense and commercial aviation sectors. In defense aviation, the focus is on performance, reliability, and mission readiness. AI enabled actuators are critical in fighter jets, UAVs, and helicopters, where precise control and adaptive responses can determine mission success. In UAVs, particularly, lightweight AI powered actuators extend flight time, improve maneuverability, and support autonomous operations.

Commercial aviation, on the other hand, prioritizes cost efficiency, passenger safety, and operational reliability. Airlines see immense value in predictive maintenance, fuel efficiency, and reduced downtime offered by AI powered actuators. The integration of electromechanical actuators in passenger aircraft aligns with the growing push toward sustainability and reduced emissions.

While the motivations differ, the common denominator across both defense and commercial aviation is that AI enhanced actuators are becoming indispensable. The dual demand ensures a broad market base and fosters technological innovations that benefit both sectors.

Key Industry Players and Competitive Landscape

The competitive landscape of the electromechanical actuator market is shaped by a combination of established aerospace giants and innovative AI startups. Leading players such as Moog Inc., Honeywell International, Safran, Collins Aerospace, and Parker Hannifin are heavily investing in AI integration to enhance the reliability and performance of their actuator systems.

These companies are also forming partnerships with AI technology providers to accelerate innovation. Collaborations between aerospace OEMs and AI driven predictive analytics firms are becoming increasingly common. The result is a new generation of intelligent actuators that seamlessly integrate with broader aircraft systems.

Startups and smaller firms are also entering the market with specialized AI solutions for actuator diagnostics and monitoring. This competition is driving down costs while pushing technological boundaries, ensuring continuous advancements in the sector.

Challenges in AI Adoption for Aircraft Actuators

Despite the promise of AI, several challenges hinder its widespread adoption in electromechanical actuators. Cybersecurity is one of the foremost concerns, as AI enabled systems increase the risk of hacking and data breaches. Ensuring robust cybersecurity protocols is vital for the safe deployment of AI driven actuators.

Another challenge lies in regulatory approval and certification. Aviation is a highly regulated industry, and integrating AI into safety critical components like actuators requires rigorous testing and compliance. The certification process can delay deployment and increase costs for manufacturers.

Integrating AI into legacy systems poses technical and financial hurdles. Airlines and militaries operating older fleets may find it costly to retrofit aircraft with AI enabled actuators, slowing adoption rates.

While these challenges are significant, they also represent opportunities for innovation in cybersecurity, certification frameworks, and cost effective integration strategies. Addressing these issues will be critical for unlocking the full potential of AI in the actuator market.

Future Outlook of AI in Aircraft Actuator Market

The future of electromechanical actuators in aircraft is closely intertwined with AI advancements. As aviation moves toward fully autonomous systems, AI powered actuators will become indispensable in managing flight controls, optimizing energy use, and ensuring safety.

In commercial aviation, the integration of AI driven actuators will accelerate the adoption of More Electric Aircraft, directly contributing to decarbonization goals. Airlines will increasingly view AI not only as a cost saving tool but also as a competitive differentiator in sustainability.

In defense, AI enabled actuators will support the development of sixth generation fighter jets, swarming UAVs, and advanced space systems. These applications will require actuators that can operate autonomously under extreme conditions, further solidifying the role of AI.

The long term outlook suggests a robust growth trajectory for the electromechanical actuators market, with AI serving as the key enabler of innovation, safety, and sustainability.

Related Report:

Electromechanical Actuators in Aircraft Market by Application (Flight Control, Fuel distribution, Cabin Actuation, Door, Landing Gear), Mechanism Type (Linear, Rotary), Motor Torque (<25, 25-100,100-300,>300 Nm), Platform, Region - Global Forecast to 2030

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

SEND ME A FREE SAMPLE