AI Impact Analysis on Hypersonic Flight Market Industry

AI Driven Design Optimization in Hypersonic Vehicles

AI is revolutionizing aerodynamic modeling and vehicle design under extreme thermal and pressure loads. Machine learning accelerates CFD modeling far faster than conventional methods, enabling hundreds of virtual design iterations in the time it traditionally took to run one or two. Deep learning frameworks now predict drag and lift characteristics from 3D geometric inputs, reducing reliance on physical wind tunnel testing. AI also assists in heat resistant material selection by analyzing performance patterns under simulated stress. These capabilities help refine designs early, reducing the prototype and test cycle and saving cost and time. Coverage is especially strong among North American manufacturers, who are investing heavily in AI driven design tools to gain competitive advantage in the expanding hypersonic aircraft market.

ODAV and Combustion Modeling

As hypersonic flight approaches Mach 5 and beyond, accurate modeling of combustion, shock interactions, and boundary layer heating becomes essential. AI powered surrogate models replicate complex flow phenomena, capturing phenomena such as turbulent mixing and surface separation faster than traditional solvers. These tools help optimize surfaces and control planform integration before hardware is built a breakthrough for reducing R&D cycle lengths.

Accelerating Hypersonic Simulation Through AI

Simulation often becomes the bottleneck in hypersonic vehicle development. CFD traditionally requires high end computing clusters and extended runtime. AI driven simulation models, particularly those that combine CFD outputs with neural network approximators, provide near real time predictive results with reasonable accuracy. Reinforcement learning agents simulate optimized flight paths or maneuvers in line with Mach number, load constraints, and efflux temperature limits. This shrink in simulation time accelerates design maturity and informs structural integration decisions approaching flight test calls.

In commercial and defense programs, AI has reduced simulation times from hours to minutes for standard design scenarios, marking a key enabler in bringing new hypersonic aircraft to market rapidly .

AI in Hypersonic Flight Navigation and Control Systems

Creating stable and precise control in hypersonic flight presents a unique challenge response must be near instantaneous. AI powered guidance and control systems, often based on reinforcement learning, manage flight corrections in real time. Neural network controllers adjust control surfaces and propulsion commands under rapid environmental changes. Research prototypes show these adaptive controllers can respond within milliseconds to atmospheric deviations or surface loads critical for hypersonic regimes .

These systems are especially valuable during atmospheric reentry or glide phase descent, where adaptive control reduces structural stress and ensures mission accuracy.

Predictive Maintenance for Hypersonic Vehicles Using AI

Hypersonic vehicles endure intense thermal cycles and structural loads, demanding precision maintenance. AI powered predictive maintenance uses telemetry from test flights and bench runs to forecast component degradation before failures occur. Systems track engine fluctuations, thermal stress cycles, and material strains to model fatigue rates. These models integrate with Integrated Vehicle Health Management systems to automate alerts, reducing downtime and optimizing part replacements critical for reusable platforms. Autonomous programs like Air Force PANDA indicate the success of similar AI predictive frameworks.

AI Powered Threat Detection and Evasion Capabilities

Military hypersonic vehicles must dodge increasingly capable air and missile defenses. AI enabled threat systems ingest radar, infrared, and SIGINT data in real time to guide evasive maneuvers. Reinforcement based guidance systems have demonstrated evasive reroutes, adjusting bank angles thousands of times per second. These methods have already shown reliability in concept studies, including reinforcement learning based terminal guidance algorithms that adapt to varying missile defense system responses. These capabilities increase survivability and reduce mission risk.

AI in Testing and Validation of Hypersonic Prototypes

Flight test is one of the most complex gates in hypersonic development. AI is improving test integrity by aiding anomaly detection, sensor fusion, and data quality checks. Onboard systems can alert operators when sensor readings diverge from expected norms, triggering corrective actions or adaptive logging. This reduces test failure risk and ensures comprehensive data capture. Additionally, AI assists in optimal sensor placement on prototypes by analyzing structural response points and anticipated vibration modes enabling robust sensor layouts before commitments. This accelerates certification cycles and improves first time success rates.

Get AI Impact Analysis on Hypersonic Flight Market, Request Pdf Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=36801525

Enhancing Mission Planning and Simulation with AI

Hypersonic operations demand meticulous mission planning. AI driven mission simulators integrate environmental data, electromagnetic activity, and threat overlays to optimize flight routes and launch windows. Digital twin environments simulate full mission profiles, including ground support constraints and flight path transitions, providing planners with pre mission insights. Virtual wargames enhance team readiness using realistic hypersonic threat scenarios. These simulations improve outcome choices and align closely with real world constraints, lowering operational risk and enabling adaptive deployment planning.

HumanAI Teaming in Hypersonic Command Environments

AI systems aboard hypersonic platforms and at command centers provide actionable recommendations, but human leadership remains essential. Human AI teaming provides early warning flags and responsive options, while operators review critical decisions. This collaboration reduces cognitive burden and enhances decision speed. Explainable AI modules provide insight into reasoning, building trust in systems managing high risk autonomy. For example, AI controllers might propose multiple evasive paths, allowing human commanders to weigh mission risks in near real time all within seconds.

AI Enabled Supply Chain and Manufacturing Efficiency

Hypersonic vehicles require advanced materials and complex subsystems. AI enhanced supply chain tools forecast disruptions for rare alloys or composite materials, estimating aerospace grade machining yield and procurement delays. Real time quality control uses machine vision to inspect parts during production, detecting anomalies both in geometry and surface texture. With additive manufacturing, AI controls layer consistency, reducing voids and defects in hypersonic structures. Vendors are scored on data performance to ensure timely deliveries and improved yield rates.

Challenges and Ethical Considerations of AI in Hypersonics

Deploying AI under extreme conditions introduces significant challenges. High temperature environments can distort sensor data, requiring AI models to remain robust to noise. Transparency is another issue; black box neural nets may make critical flight decisions without human comprehension. Security is paramount since adversaries might exploit AI systems with cyber or sensor spoofing. The ethics of AI enabled weapons especially in hypersonic strike roles require policy frameworks enforcing human accountability. Testing AI reliability at Mach 5+ speeds in real environments also faces regulatory and safety scrutiny.

International norms must address potential escalation driven by stealthy, AI guided hypersonic deployment. Responsible development remains essential to prevent destabilizing arms races .

Market Outlook: AI’s Role in Hypersonic Industry Growth

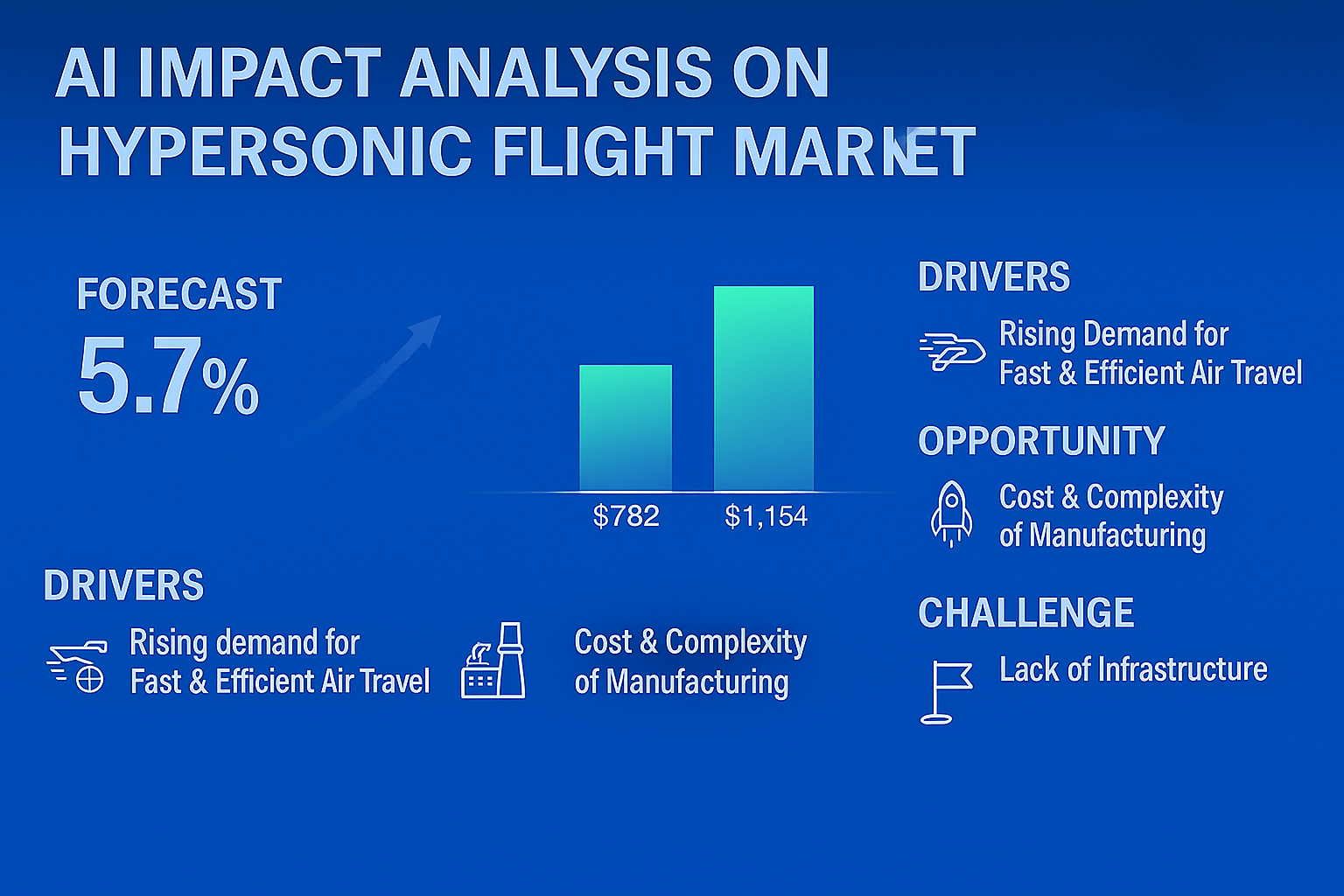

The Hypersonic Flight Market is estimated to be USD 782 Million in 2023 and is projected to reach USD 1,154 Million by 2030, at a CAGR of 5.7% from 2023 to 2030.. North America leads in investment, driven by both military programs and private startups like Hermeus, Stratolaunch, and Venus Aerospace USA. These firms rely heavily on AI to compress the development cycle, reduce costs, and enable reusable or semi autonomous hypersonic platforms. Sector funds are increasingly flowing into AI enabling RDE systems and propulsion optimization, motivated by both defense applications and emerging passenger or cargo use cases like those proposed by Hyperian Aerospace.

AI as the Wind Tunnel of Tomorrow

AI is not just enhancing hypersonic flight it is reshaping the entire ecosystem from design to mission execution. From accelerated design cycles and adaptive flight control to predictive maintenance and ethical deployment, AI is building a smarter, faster, and more reliable hypersonic frontier. This technology centric approach is essential if the U.S. and North American partners hope to stay ahead in development pace, cost effectiveness, and strategic leverage. Yet, as AI assumes more responsibility, frameworks for transparency, safety, and oversight must evolve alongside.

The runway ahead is no longer defined by wind tunnels it’s sculpted by algorithms and shaped in seconds by autonomy. As hypersonic flight enters the mainstream, AI will remain the unseen co-pilot ensuring performance, flexibility, and security at Mach speeds. The hypersonic flight market’s future depends as much on smart code as it does on advanced materials.

Related Report:

Hypersonic Flight Market by Vehicle Type (Hypersonic Aircraft, Hypersonic Spacecraft), Industry (Military, Space, Commercial), Component ( Propulsion, Aerostructure, Avionics) and Region - Global Forecast to 2030

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

SEND ME A FREE SAMPLE