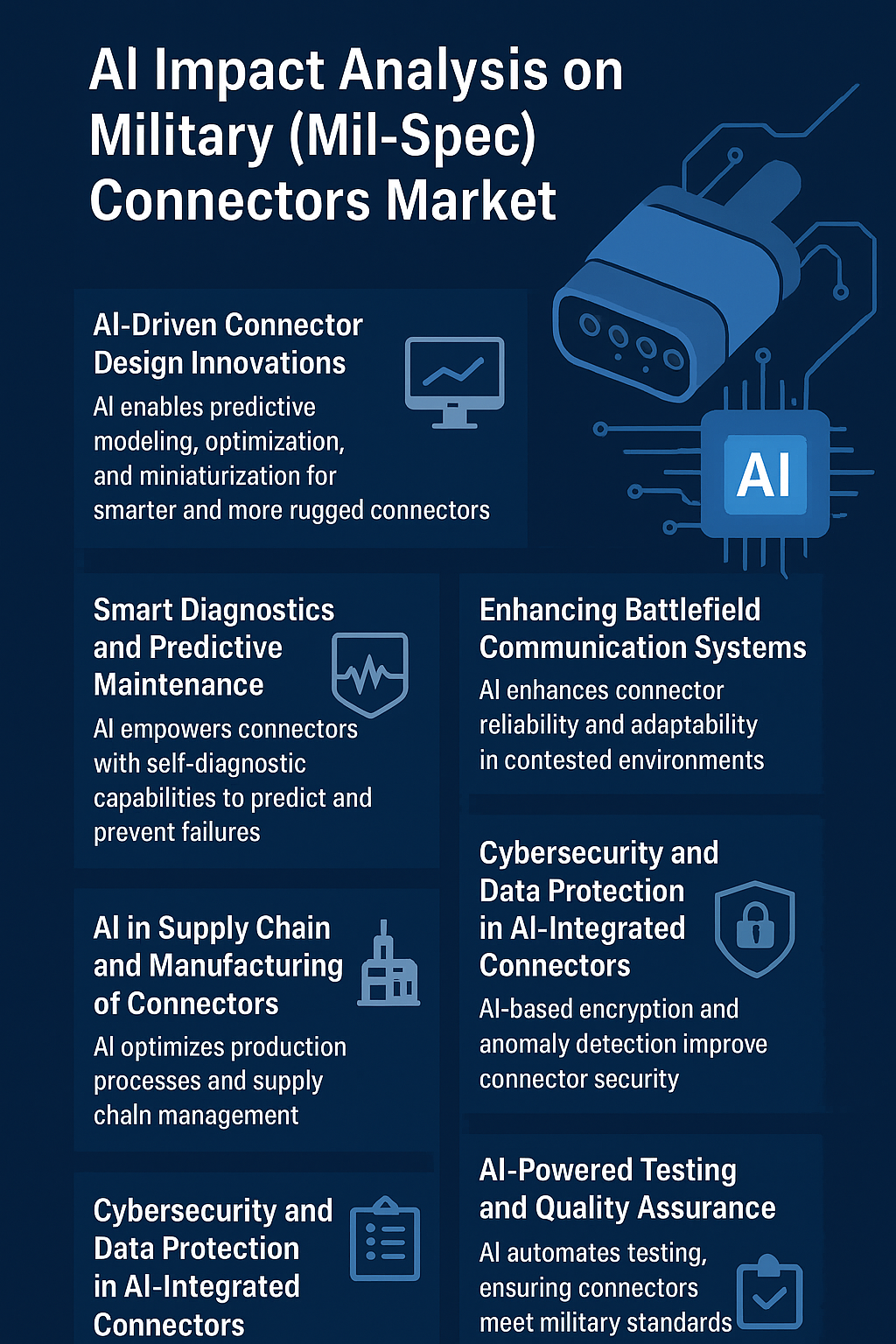

AI Impact Analysis on Military Connectors Industry

The military industry has always been at the forefront of adopting advanced technologies to enhance battlefield readiness, mission reliability, and long term defense capabilities. Among the many innovations reshaping modern defense systems, the role of military grade connectors, commonly referred to as Mil-Spec connectors, cannot be overlooked. These ruggedized, high performance connectors form the backbone of communication systems, avionics, armored vehicles, naval platforms, and electronic warfare systems. With artificial intelligence now entering the defense ecosystem at scale, the way these connectors are designed, manufactured, tested, and deployed is undergoing a massive transformation.

Artificial intelligence is not just an incremental upgrade in the Mil-Spec connectors market it is redefining operational reliability, predictive intelligence, and future proofing military systems. The convergence of AI and connector technologies is allowing defense organizations to transition from reactive operations to proactive strategies. Connectors are no longer passive components but are evolving into intelligent systems capable of self diagnostics, data optimization, and adaptive performance.

AI-Driven Connector Design Innovations

Design is the starting point of transformation, and AI is playing a central role in reshaping Mil-Spec connectors to meet the increasing demands of modern warfare. Traditionally, connectors were designed for ruggedness and durability to withstand extreme environments. Today, AI is enhancing those design principles by introducing predictive modeling tools that simulate real world conditions before prototypes are built. This shortens development cycles while ensuring connectors meet stringent defense standards.

AI algorithms are also being applied to optimize miniaturization. The defense industry’s push toward lightweight platforms, such as unmanned systems and wearable soldier technologies, requires connectors that are smaller yet more powerful. AI driven design software can optimize materials, geometry, and thermal management to balance strength and performance in confined spaces. These design advancements are allowing the industry to develop connectors that are not only smaller and lighter but also smarter and more reliable in extreme scenarios.

Smart Diagnostics and Predictive Maintenance

AI is turning passive connectors into active diagnostic tools. One of the biggest challenges in defense operations is unexpected equipment failure, often caused by unnoticed connector degradation. AI enabled sensors embedded in connectors can monitor real time performance metrics such as voltage levels, temperature, vibration, and corrosion. These connectors then feed data into AI models that can predict potential failure long before it occurs.

Predictive maintenance powered by AI ensures military systems are always mission ready. For example, in combat aircraft or naval ships, AI enabled connectors can detect early warning signs of degradation, prompting maintenance teams to replace components before failure. This not only saves costs but also minimizes downtime and enhances operational efficiency. By transforming connectors into diagnostic nodes, AI is reshaping the way defense forces manage critical assets.

Enhancing Battlefield Communication Systems

Communication is the foundation of modern warfare, and connectors are the unseen heroes ensuring seamless data flow across systems. AI is taking this role further by improving the reliability and adaptability of connectors in highly contested environments. In battlefield communication systems, from tactical radios to radar arrays, AI enhanced connectors are reducing latency and optimizing bandwidth.

The integration of AI also helps connectors dynamically adjust to signal interference, electromagnetic disruptions, or jamming attempts. This is particularly critical in satellite communication systems, where data integrity directly impacts strategic decision making. In future battlefields dominated by network centric warfare, AI enabled connectors will ensure secure, fast, and uninterrupted communication between allied forces, drones, ground vehicles, and command centers.

AI in Supply Chain and Manufacturing of Connectors

The manufacturing of Mil-Spec connectors is a complex process involving precision engineering, compliance with military standards, and rigorous testing. AI is bringing efficiency to this process by enabling predictive manufacturing, robotics driven assembly, and quality analytics. Machine learning algorithms can identify defects in real time during production, reducing wastage and accelerating time to market.

In addition, AI is revolutionizing the supply chain of connectors. Defense organizations often face challenges related to procurement delays, material shortages, and geopolitical risks. By using AI driven predictive analytics, companies can forecast supply chain disruptions and adjust procurement strategies accordingly. This ensures connectors are available when and where they are needed, reducing vulnerabilities in defense readiness.

Cybersecurity and Data Protection in AI-Integrated Connectors

In today’s digital battlefield, cybersecurity is just as critical as physical defense. Connectors, which serve as gateways for data transmission, are now being enhanced with AI based security protocols. AI driven encryption technologies embedded in connectors can prevent unauthorized access and protect mission critical communications from interception.

Beyond encryption, AI enabled connectors can detect anomalies in data transmission patterns, signaling potential cyberattacks. For instance, if a hostile actor attempts to manipulate signals in an electronic warfare environment, AI algorithms can identify the deviation and alert defense networks in real time. The fusion of AI and cybersecurity is transforming connectors into frontline guardians of secure defense communications.

AI-Powered Testing and Quality Assurance

Military standards for connectors are among the most stringent in the world. Compliance with MIL-STD ensures these connectors can operate in harsh environments such as deserts, deep seas, and outer space. Traditionally, testing was time intensive and costly, but AI has introduced automation and intelligence into this process.

Machine learning models are now being used to automate quality assurance, identifying defects invisible to human inspection. Automated testing platforms use AI to simulate thousands of operating conditions, ensuring connectors meet performance benchmarks without exhaustive manual testing. This not only reduces costs but also increases confidence in the reliability of connectors deployed in critical missions.

Get AI Impact Analysis on Military (Mil-Spec) Connectors Market, Request Pdf Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=162901490

Integration with Emerging Defense Technologies

The next generation battlefield is defined by unmanned systems, electronic warfare, and space based operations. AI powered connectors are playing an essential role in supporting these advancements. In unmanned aerial vehicles (UAVs), ground robots, and underwater drones, connectors must withstand extreme environments while ensuring uninterrupted data transfer. AI is enabling these connectors to adapt to varying operating conditions, such as pressure changes underwater or electromagnetic interference in electronic warfare.

Similarly, in space defense, AI enabled connectors are being designed for radiation resistance and autonomous operation. As militaries increasingly rely on space assets for surveillance, navigation, and communication, connectors enhanced with AI will provide the resilience needed for orbital defense operations.

Regional and Defense Strategy Impacts

The adoption of AI in Mil-Spec connectors is not uniform across the globe but varies depending on defense budgets, technological capabilities, and strategic priorities. The United States is leading in AI integration, leveraging its vast defense R&D ecosystem to build intelligent connectors for advanced platforms like the F-35, next gen naval ships, and missile defense systems. Europe is focusing on interoperability among NATO forces, where AI enabled connectors ensure seamless communication across multinational forces.

Asia Pacific, driven by countries such as China, India, and Japan, is witnessing rapid adoption of AI in military electronics, including connectors, to strengthen regional defense capabilities. These regional strategies are shaping the competitive landscape of the global Mil-Spec connectors market and pushing manufacturers to innovate continuously.

Future Outlook: AI and Next-Gen Mil-Spec Connectors

The future of the military connectors market lies in adaptive, intelligent, and self healing systems. AI is paving the way for connectors that can automatically detect damage, reroute signals, and repair themselves in real time. This futuristic concept will significantly enhance the resilience of defense platforms in high stakes combat scenarios.

Market projections indicate strong growth in the Mil-Spec connectors market as AI adoption accelerates. Defense modernization programs worldwide are prioritizing intelligent connectors as integral components of future military architectures. The convergence of AI, cybersecurity, and material sciences will define the next decade, creating opportunities for defense manufacturers and technology providers alike.

Related Report:

Military (Mil-Spec) Connectors Market by Shape {Circular [Mil-DTL-(38999,26482,5015)], Rectangular [MIL-DTL-(24308, 83513, 55302)]}, Type (Power, Signal, Data, RF & Microwave, Fiber Optic, Hybrid), Platform, Point of Sale and Region - Global Forecast to 2030

This FREE sample includes market data points, ranging from trend analyses to market estimates & forecasts. See for yourself.

SEND ME A FREE SAMPLE