The research study for the AI in chemicals market involved extensive secondary sources, directories, International Journal of Innovation and Technology Management and paid databases. Primary sources were mainly industry experts from the core and related industries, preferred AI in chemicals market providers, third-party service providers, consulting service providers, end users, and other commercial enterprises. In-depth interviews were conducted with various primary respondents, including key industry participants and subject matter experts, to obtain and verify critical qualitative and quantitative information, and assess the market’s prospects.

Secondary Research

The market size of companies offering AI in chemicals hardware, software and services was arrived at hardware, software, and services was determined based on secondary data available through paid and unpaid sources. It was also arrived at by analyzing the product portfolios of major companies and rating the companies based on their performance and quality.

In the secondary research process, various sources were referred to, for identifying and collecting identify and collect information for this study. Secondary sources included annual reports, press releases, and investor presentations of companies; white papers, journals, and certified publications; and articles from recognized authors, directories, and databases. The data was also collected from other secondary sources, such as journals, government websites, blogs, and vendors' websites. Additionally, AI in chemicals spending of spending in various countries was extracted from the respective sources. Secondary research was mainly used to obtain key information related to the industry’s value chain and supply chain to identify key players based on hardware, software, services, market classification, and segmentation according to offerings of major players, industry trends related to components, business applications, end users, and regions, and key developments from both market- and technology-oriented perspectives.

Primary Research

In the primary research process, various primary sources from both the supply and demand sides were interviewed to obtain qualitative and quantitative information on the market. The primary sources from the supply side included various industry experts, including Chief Experience Officers (CXOs); Vice Presidents (VPs); directors from business development, marketing, and AI in chemicals expertise; related key executives from AI in chemicals solution vendors, System Integrators (SIs), professional service providers, and industry associations; and key opinion leaders.

Primary interviews were conducted to gather insights, such as market statistics, revenue data collected from hardware, software, and services, market breakups, market size estimations, market forecasts, and data triangulation. Primary research also helped in understandingunderstand various trends related to technologies, applications, deployments, and regions. Stakeholders from the demand side, such as Chief Information Officers (CIOs), Chief Technology Officers (CTOs), Chief Strategy Officers (CSOs), and end users using AI in chemicals hardware, software, and services, were interviewed to understand the buyer’s perspective on suppliers, products, service providers, and their current usage of AI in chemicals hardware, software, and services and services, which would impact the overall AI in chemicals market.

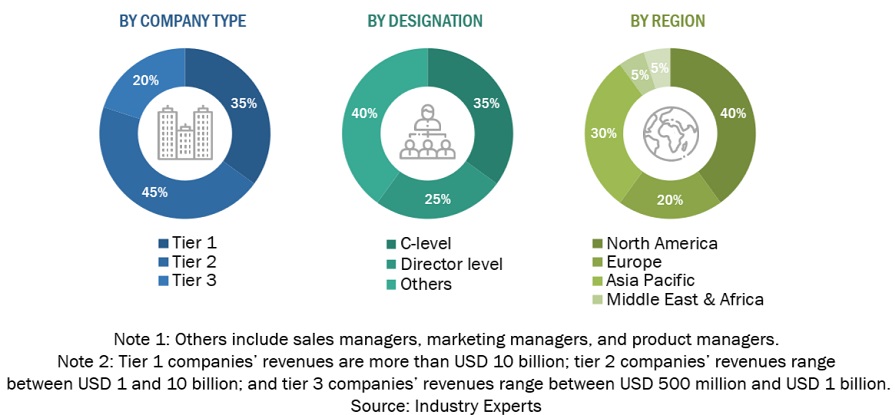

The following is the breakup of primary profiles:

To know about the assumptions considered for the study, download the pdf brochure

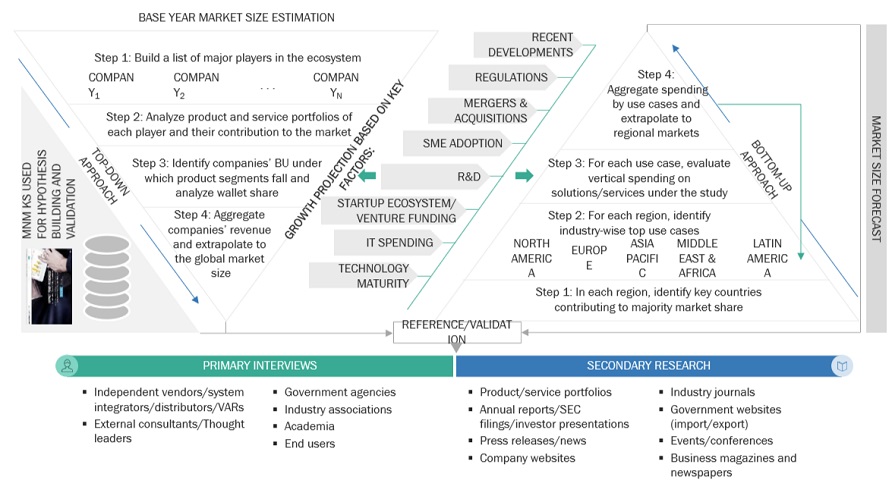

Market Size Estimation

Multiple approaches were adopted for estimating and forecasting the AI in chemicals market. The first approach involves estimating the market size by summation of companies’ revenue generated through the sale of hardware, software and services.

Market Size Estimation Methodology-Top-down approach

In the top-down approach, an exhaustive list of all the vendors offering hardware, software and services in the AI in chemicals market was prepared. The revenue contribution of the market vendors was estimated through annual reports, press releases, funding, investor presentations, paid databases, and primary interviews. Each vendor’s offerings were evaluated based on the breadth of hardware, solutions, solution by component, business application, end user and regions. The aggregate of all the companies’ revenue was extrapolated to reach the overall market size. Each subsegment was studied and analyzed for its global market size and regional penetration. The markets were triangulated through both primary and secondary research. The primary procedure included extensive interviews for key insights from industry leaders, such as CIOs, CEOs, VPs, directors, and marketing executives. The market numbers were further triangulated with the existing MarketsandMarkets repository for validation.

Market Size Estimation Methodology-Bottom-up approach

In the bottom-up approach, the adoption rate of AI in chemicals hardware, software and services among different end users in key countries with respect to their regions contributing the most to the market share was identified. For cross-validation, the adoption of AI in chemicals hardware, software and services among industries, along with different use cases with respect to their regions, was identified and extrapolated. Weightage was given to use cases identified in different regions for the market size calculation.

Based on the market numbers, the regional split was determined by primary and secondary sources. The procedure included the analysis of the AI in chemicals market’s regional penetration. Based on secondary research, the regional spending on Information and Communications Technology (ICT), socio-economic analysis of each country, strategic vendor analysis of major AI in chemicals hardware, software and services providers, and organic and inorganic business development activities of regional and global players were estimated. With the data triangulation procedure and data validation through primaries, the exact values of the overall AI in chemicals hardware, software and services market size and segments’ size were determined and confirmed using the study.

Top-down and Bottom-up approaches

To know about the assumptions considered for the study, Request for Free Sample Report

Data Triangulation

After arriving at the overall market size using the market size estimation processes as explained above, the market was split into several segments and subsegments. To complete the overall market engineering process and arrive at the exact statistics of each market segment and subsegment, data triangulation and market breakup procedures were employed, wherever applicable. The overall market size was then used in the top-down procedure to estimate the size of other individual markets via percentage splits of the market segmentation.

Market Definition

According to Nexocode, Artificial Intelligence (AI) is a powerful tool that can help chemical companies work smarter and faster. The technology enables more productive processes by automating tasks, providing insights into how chemicals react, or improving manufacturing environments.

AI in chemicals refers to the application of AI technologies and techniques within the chemical industry to enhance processes, improve decision-making, and drive innovation. It uses advanced algorithms, machine learning models, and data analytics to optimize various aspects of chemical production, research and development, supply chain management, and environmental sustainability. AI in chemicals enables companies to streamline operations, develop new materials and products more efficiently, and respond effectively to market dynamics, ultimately leading to improved productivity, cost savings, and competitive advantage.

Stakeholders

-

AI in Chemicals Sofware Providers

-

AI Technology Providers

-

Professional and Managed Service Providers

-

Industry Associations

-

Research Institutions

-

System Integrators

-

Technology Consultants

-

Independent Software Vendors (ISVs)

-

Consulting Firms

-

Value-Added Resellers (VARs)

-

Government Agencies

Report Objectives

-

To define, describe, and predict the AI in chemicals market by component (hardware, software, and services), business application, and end users.

-

To provide detailed information related to major factors (drivers, restraints, opportunities, and industry-specific challenges) influencing the market growth

-

To forecast the market size of segments with respect to five main regions: North America, Europe, Asia Pacific, Middle East & Africa, and Latin America

-

To strategically analyze micromarkets with respect to individual growth trends, prospects, and contributions to the overall AI in chemicals market

-

To analyze opportunities in the market and provide details of the competitive landscape for stakeholders and market leaders

-

To analyze competitive developments, such as partnerships, mergers and acquisitions, and product developments, in the AI in chemicals market

-

To analyze the impact of the recession across all the regions in the AI in chemicals market

Available Customizations

With the given market data, MarketsandMarkets offers customizations as per the company’s specific needs. The following customization options are available for the report:

Product Analysis

-

The product matrix provides a detailed comparison of the product portfolio of each company.

Geographic Analysis as per Feasibility

-

Further breakup of the North American AI in chemicals Market

-

Further breakup of the European Market

-

Further breakup of the Asia Pacific Market

-

Further breakup of the Middle East & Africa Market

-

Further breakup of the Latin American AI in chemicals Market

Company Information

-

Detailed analysis and profiling of additional market players (up to five)

Growth opportunities and latent adjacency in AI in Chemicals Market