This research involved the use of extensive secondary sources and databases, such as Factiva and Bloomberg, to identify and collect information useful for a technical and market-oriented study of the EPDM market. Primary sources included industry experts from related industries and preferred suppliers, manufacturers, distributors, technologists, standards & certification organizations, and organizations related to all segments of the value chain of this industry. In-depth interviews have been conducted with various primary respondents, such as key industry participants, subject matter experts (SMEs), executives of key companies, and industry consultants, to obtain and verify critical qualitative and quantitative information as well as to assess growth prospects.

Secondary Research

In the secondary research process, various sources such as annual reports, press releases, and investor presentations of companies; white papers; and publications from recognized websites and databases have been referred to for identifying and collecting information. Secondary research has been used to obtain key information about the industry's supply chain, the total pool of key players, market classification and segmentation according to the industry trends to the bottom-most level, regional markets, and key developments from both market- and technology-oriented perspectives.

Primary Research

The EPDM market comprises several stakeholders in the supply chain, which include suppliers, processors, and end-product users. Various primary sources from the supply and demand sides of the markets have been interviewed to obtain qualitative and quantitative information. The primary participants from the demand side include key opinion leaders, executives, managers, directors, and CEOs of companies in the EPDM market. Primary sources from the supply side include associations and institutions involved in the EPDM industry, key opinion leaders, and processing players.

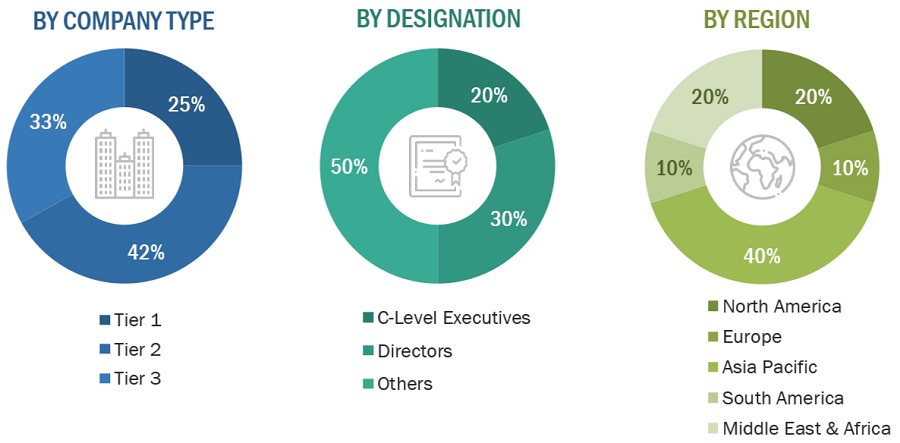

Following is the breakdown of primary respondents—

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

Both top-down and bottom-up approaches were used to estimate and validate the size of the global EPDM market. The research methodology used to estimate the market size includes the following:

-

The key players in the industry were identified through extensive secondary research.

-

The supply chain of the industry and market size, in terms of value, were determined through primary and secondary research.

-

All percentage shares split, and breakdowns were determined using secondary sources and verified through primary sources.

-

All possible parameters that affect the markets covered in this research study were accounted for, viewed in extensive detail, verified through primary research, and analyzed to obtain the final quantitative and qualitative data.

-

The research includes the study of reports, reviews, and newsletters of key industry players along with extensive interviews with key officials, such as directors and marketing executives.

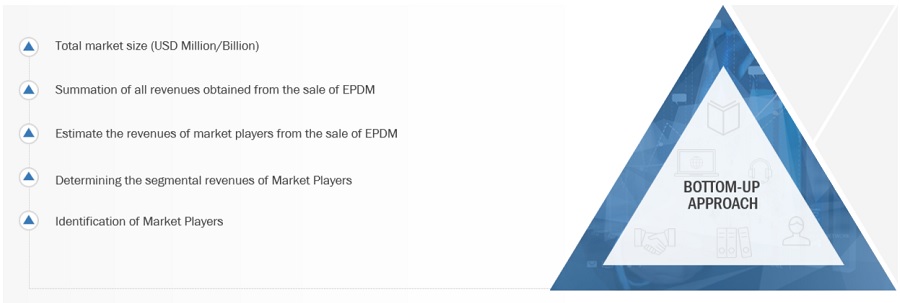

Market Size Estimation: Bottom-Up Approach

To know about the assumptions considered for the study, Request for Free Sample Report

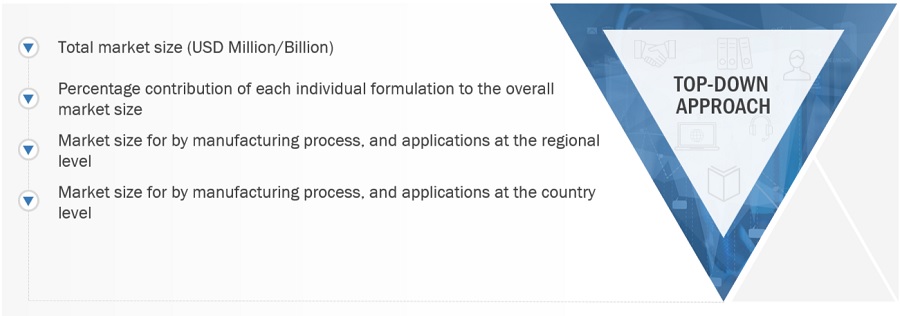

Market Size Estimation: Top-Down Approach

Data Triangulation

After arriving at the total market size from the estimation process explained above, the overall market was split into several segments and subsegments. To complete the overall market size estimation process and arrive at the exact statistics for all segments and subsegments, the data triangulation and market breakdown procedures have been employed, wherever applicable. The data have been triangulated by studying various factors and trends from both the demand and supply sides. In addition, the market size has been validated by using both the top-down and bottom-up approaches.

Market Definition

Ethylene propylene diene monomer or EPDM is a copolymer of ethylene, propylene, and non-conjugated diene monomers. EPDM is a synthetic rubber that is an M-class rubber under ASTM standard D-1418. It is a saturated elastomer that provides resistance against polar solvents. The major catalysts used in the production of EPDM are Ziegler–Natta catalysts or Metallocene catalysts. The major processes used in the manufacturing of EPDM are slurry (suspension), gas-phase, and solution. The solution polymerization process is usually used in the commercial production of EPDM. EPDM rubber provides resistance against heat, aging, UV, and ozone. However, EPDM shows poor resistance against hydrocarbon fuel and solvents.

Key Stakeholders

-

Government, and consulting firms

-

End User

-

Research and Development Organizations

-

EPDM manufacturers, dealers, traders, and suppliers.

Report Objectives

-

To define, describe, and forecast the global EPDM market in terms of value.

-

To provide insights regarding the significant factors influencing the growth of the market (drivers, restraints, opportunities, and challenges)

-

To analyze and forecast the market based on manufacturing process, application, and region

-

To forecast the market size, in terms of value, with respect to five main regions: North America, Europe, Asia Pacific, South America, and Middle East & Africa.

-

To analyze the opportunities in the market for stakeholders and provide details of the competitive landscape.

-

To strategically profile key players in the market.

-

To analyze competitive developments in the market, such as new product launches, capacity expansions, and mergers & acquisitions.

-

To strategically profile the leading players and comprehensively analyze their key developments in the market.

Available Customizations:

Along with the given market data, MarketsandMarkets offers customizations as per the specific needs of the companies. The following customization options are available for the report:

Product Analysis:

-

Product Matrix which gives a detailed comparison of the product portfolio of each company

Regional Analysis:

-

Further breakdown of the Rest of the APAC EPDM market

-

Further breakdown of the Rest of Europe’s EPDM market

Company Information:

-

Detailed analysis and profiling of additional market players (up to 5)

Growth opportunities and latent adjacency in EPDM Market