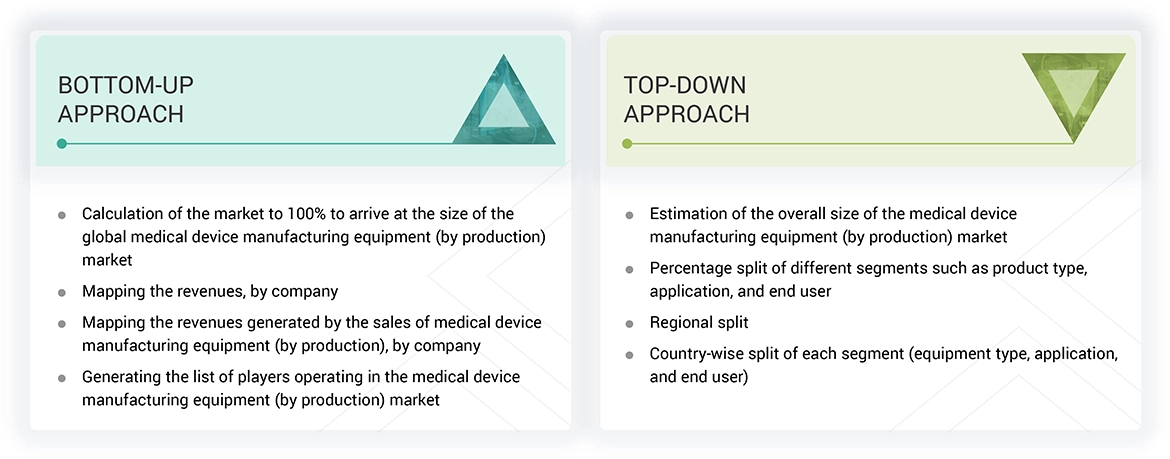

The study involved major activities in estimating the current market size for the medical device manufacturing equipment (by production) market. Exhaustive secondary research was done to collect information on the medical device manufacturing equipment (by production) market. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain using primary research. Different approaches, such as top-down and bottom-up, were employed to estimate the total market size. After that, the market breakup and data triangulation procedures were used to estimate the market size of the segments and subsegments of the medical device manufacturing equipment (by production) market.

Secondary Research

This research study involved the wide use of secondary sources, directories, databases such as Dun & Bradstreet, Bloomberg Businessweek, Factiva, whitepapers, and companies’ house documents. Secondary research was undertaken to identify and collect information for this extensive, technical, market-oriented, and commercial study of the medical device manufacturing equipment (by production) market. It was also used to obtain important information about the top players, market classification, and segmentation according to industry trends, to the bottom-most level, geographic markets, and key developments related to the market. A database of the key industry leaders was also prepared using secondary research.

Primary Research

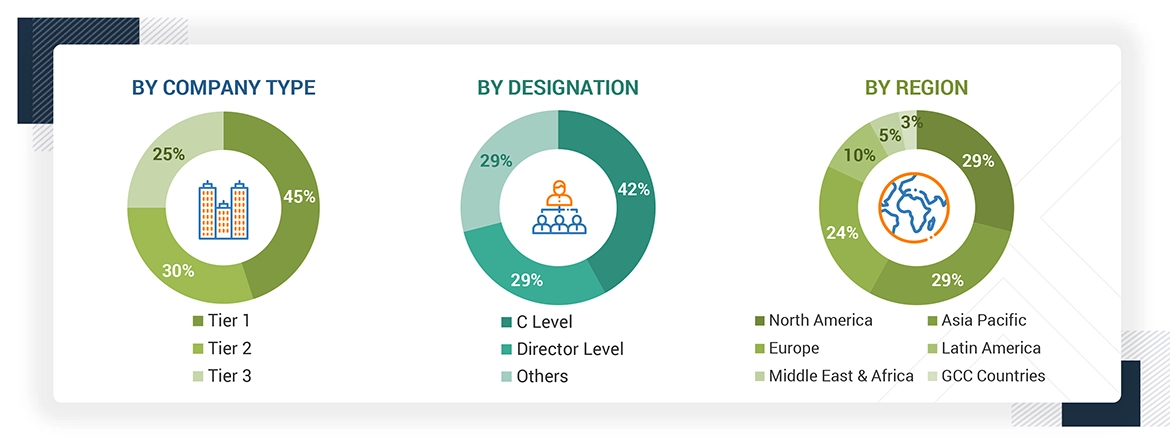

In the primary research process, various supply- and demand-side sources were interviewed to obtain qualitative and quantitative information for this report. Primary sources from the supply side included industry experts such as CEOs, vice presidents, marketing and sales directors, technology & innovation directors, engineers, and related key executives from various companies and organizations operating in the medical device manufacturing equipment (by production) market. Primary sources from the demand side included pediatric hospitals, maternity & birthing centers, clinics, researchers, lab technicians, purchase managers, and stakeholders in corporate & government bodies.

Breakdown of Primary Interviews

Note 1: C-level primaries include CEOs, COOs, and CTOs.

Note 2: Others include sales managers, marketing managers, and product managers.

Note 3: Companies are classified into tiers based on their total revenue. As of 2024: Tier 1 = More than USD 1 billion, Tier 2 = USD 500 million to USD 1 billion, Tier 3 = Less than USD 500 million

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

Both top-down and bottom-up approaches were used to estimate and validate the total size of the medical device manufacturing equipment (by production) market. These methods were also used extensively to estimate the size of various subsegments in the market. The research methodology used to estimate the market size includes the following:

Data Triangulation

The entire market was split into three segments when the market size was determined. Data triangulation and market breakdown processes were used where necessary to complete the entire market engineering process and arrive at precise statistics for all segments.

Approach to derive the market size and estimate market growth.

Using secondary data from paid and unpaid sources, the market rankings for the major players were determined following a thorough analysis of their sales of medical device manufacturing equipment (by production). Due to data restrictions, the revenue share in certain cases was determined after a thorough analysis of the product portfolio of big corporations and their individual sales performance. This information was verified at each stage by in-depth interviews with professionals in the field.

Market Definition

Medical device manufacturing equipment (by production) refers to the specialized machinery, systems, and technologies used by medical device manufacturers to design, process, assemble, test, package, and sterilize medical devices. This includes equipment for material processing (cutting, welding, molding, coating, additive manufacturing), assembly & automation systems (robotics, inspection, testing), and cleanroom & packaging solutions (sterilization, sealing, environmental control).

Stakeholders

-

Medical device manufacturing equipment and accessory manufacturers

-

Medical device manufacturing equipment and accessory distributors

-

Research & development (R&D) companies

-

Medical device procurement agencies

-

Government bodies/municipal corporations

-

Business research and consulting service providers

-

Venture capitalists

-

US FDA

-

European Union (EU)

Report Objectives

-

To describe, analyze, and forecast the medical device manufacturing equipment (by production) market, by equipment type, application, end user, and region

-

To describe and forecast the medical device manufacturing equipment (by production) market for key regions, namely, North America, Europe, the Asia Pacific, Latin America, the Middle East and Africa, and GCC Countries

-

To provide detailed information regarding drivers, restraints, opportunities, and challenges influencing the growth of the medical device manufacturing equipment (by production) market

-

To strategically analyze the ecosystem, regulations, patenting trend, value chain, Porter’s five forces, and prices pertaining to the market under study

-

To strategically analyze micromarkets with respect to individual growth trends, prospects, and contributions to the overall market

-

To analyze market opportunities for stakeholders and provide details of the competitive landscape for market players

-

To profile key players and comprehensively analyze their market shares and core competencies in the medical device manufacturing equipment (by production) market

-

To analyze competitive developments such as collaborations, acquisitions, product launches, expansions, and R&D activities in the medical device manufacturing equipment (by production) market

Growth opportunities and latent adjacency in Medical Device Manufacturing Equipment (by Production) Market