Asia Pacific Automated Guided Vehicle (AGV) Market

Asia Pacific Automated Guided Vehicle (AGV) Market by Type (Tow Vehicles, Unit Load Carriers, Pallet Trucks, Assembly Line Vehicles, Forklift Trucks), Navigation Technology (Laser, Magnetic, Inductive, Optical Tape, Vision) – Forecast to 2032

OVERVIEW

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

The Asia Pacific automated guided vehicle (AGV) market is expected to grow from USD 0.98 billion in 2026 to USD 1.72 billion by 2032, at a CAGR of 9.9% during the forecast period. The market is driven by rapid industrial expansion, rising automation adoption, and increasing focus on productivity, safety, and cost control. AGVs are increasingly deployed to support internal material transport, pallet movement, and production supply within large and complex facilities. Rising labor costs and workforce constraints in key industrial zones are accelerating the shift toward automated material handling. Improvements in navigation technologies, fleet management software, and system monitoring are enhancing reliability and ease of deployment. Continued investment in factory expansion, automation upgrades, and regional distribution infrastructure is supporting sustained AGV adoption across Asia Pacific.

KEY TAKEAWAYS

-

BY COUNTRYChina is expected to grow at the highest CAGR of 11.6% between 2026 and 2032.

-

BY NAVIGATION TECHNOLOGYThe vision guidance segment is expected to grow at a significant CAGR during the forecast period.

-

BY PAYLOAD CAPACITYMedium-duty AGVs are expected to grow at a significant CAGR between 2026 and 2032.

-

BY TYPEThe forklift truck segment is expected to grow at a CAGR in the range of 11–12% during the forecast period.

-

BY INDUSTRYThe automotive segment is expected to account for a 18.1% share of the Asia Pacific automated guided vehicle (AGV) market by 2032.

-

COMPETITIVE LANDSCAPE - KEY PLAYERSDaifuku Co., Ltd. and Toyota Industries Corporation are identified as key players in the Asia Pacific automated guided vehicle (AGV) market, supported by their strong regional manufacturing presence and broad AGV portfolios aligned with large scale factory automation, structured internal material movement, and growing demand for reliable and scalable intralogistics solutions across the region.

-

COMPETITIVE LANDSCAPE - STARTUPS/SMESSuzhou Casun Intelligent Robot Co., Ltd. and Nanchang Industrial Control Robot Co., Ltd. have established strong positions among startups and small to mid sized enterprises in the Asia Pacific automated guided vehicle market by focusing on application specific automation requirements.

The Asia Pacific automated guided vehicle (AGV) market is positioned for strong growth during the forecast period as companies scale automation to manage internal material transport across large and high activity facilities. Increasing emphasis on stable material flow, operational consistency, and workplace safety is supporting wider AGV adoption for pallet movement, production supply, and internal transport tasks. Advancements in navigation technologies, fleet management software, and traffic coordination are improving deployment reliability and system control. As organizations expand capacity and upgrade existing sites, AGVs are increasingly becoming a core element of scalable and efficient intralogistics automation across Asia Pacific.

TRENDS & DISRUPTIONS IMPACTING CUSTOMERS' CUSTOMERS

The impact on customers’ businesses in the Asia Pacific automated guided vehicle (AGV) market is driven by the need to manage high material movement volumes, improve operational consistency, and reduce dependence on manual handling across large and complex facilities. Organizations are adopting AGVs to automate internal transport, improve safety, and support continuous operations under varying workload conditions. Integration with fleet management software, system visibility tools, and condition based maintenance is helping reduce downtime, control operating costs, and maintain stable performance. These capabilities enable customers to streamline internal workflows, sustain predictable throughput, and scale operations with limited disruption, positioning AGVs as a core enabler of long term efficiency and operational stability across Asia Pacific.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

MARKET DYNAMICS

Level

-

High production volumes and continuous operations

-

Rapid expansion of large warehouses and fulfillment centers

Level

-

Deployment complexity in dense, high-traffic facilities

-

Higher upfront investment for large-scale AGV fleets

Level

-

Growing demand for AGVs designed for high-throughput, multi-shift operations

-

Increased adoption of AGVs in newly built manufacturing and logistics facilities

Level

-

Complexities in maintaining traffic coordination, safety, and system uptime at scale

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Driver: High production volumes and continuous operations

Manufacturing and logistics facilities across Asia Pacific operate at high utilization levels, often running continuous or multi-shift operations. AGVs are increasingly adopted to ensure predictable material movement, reduce congestion, and maintain throughput stability in these high-volume environments.

Restraint: Deployment complexity in dense, high-traffic facilities

Asia Pacific facilities often combine high vehicle density, mixed traffic, and compact layouts. This increases planning and commissioning effort for AGV systems and can extend deployment timelines.

Opportunity: Growing demand for AGVs designed for high-throughput, multi-shift operations

Operators are prioritizing AGV systems that can support long operating hours, frequent task cycles, and large fleet sizes without performance degradation. Demand is increasing for solutions with robust vehicle design, efficient charging strategies, and scalable fleet management software suited for high-intensity operations.

Challenge: Complexities in maintaining traffic coordination, safety, and system uptime at scale

As AGV fleets grow in size, managing vehicle interactions, avoiding bottlenecks, and ensuring safe operation becomes more complex. Any disruption can quickly impact throughput, making reliable traffic management, monitoring, and maintenance critical challenges for large-scale AGV deployments across Asia Pacific.

ASIA PACIFIC AUTOMATED GUIDED VEHICLE (AGV) MARKET: COMMERCIAL USE CASES ACROSS INDUSTRIES

| COMPANY | USE CASE DESCRIPTION | BENEFITS |

|---|---|---|

|

Daifuku deploys AGVs across Asia Pacific for pallet transport, line-side delivery, and work-in-process movement within high-volume manufacturing plants and large logistics facilities, often integrated with conveyors and automated storage systems. | Improves throughput and material flow consistency while supporting continuous operations in dense, high-capacity facilities |

|

Toyota Industries Corporation provides AGVs for internal material transport and production supply across automotive, electronics, and industrial manufacturing environments, supporting synchronized and just-in-time workflows. | Enhances production stability and material handling accuracy across automated facilities | Supports lean manufacturing and synchronized production flows | Reduces reliance on manual transport while improving safety and operational consistency |

|

KUKA supplies AGVs in Asia Pacific as part of integrated production automation solutions, supporting line-side logistics and inter-process material movement within smart manufacturing facilities. | Improves coordination between material movement and production operations | Supports digitally connected factory environments |

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET ECOSYSTEM

The Asia Pacific automated guided vehicle (AGV) ecosystem is built around a broad network of raw material/component providers, software/service providers, automated guided vehicle providers, and end users. This ecosystem supports the full AGV lifecycle, from solution design and customization to deployment, operation, and long-term service across large-scale facilities. Strong manufacturing capabilities, growing automation expertise, and expanding software and service capabilities across the region support effective system integration in new and operating sites. Close collaboration between AGV providers and software and service providers enables accurate system configuration, stable traffic management, and seamless connectivity with warehouse and factory systems. This coordinated structure improves deployment consistency, supports phased automation rollouts, and enables sustained adoption of AGV solutions across Asia Pacific.

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET SEGMENTS

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Asia Pacific Automated Guided Vehicle (AGV) Market, By Industry

Logistics/3PL is expected to grow at the highest CAGR during the forecast period as operators expand automation to manage rising shipment volumes, tighter delivery timelines, and increasing service expectations. AGVs are being adopted to support internal transport, pallet movement, and order staging within large, high activity facilities. The need to reduce labor dependency, improve throughput consistency, and support extended operating hours is accelerating AGV deployment. Flexible system design and software controlled operations also enable Logistics/3PL providers to adapt quickly to layout changes and shifting customer requirements, reinforcing strong growth momentum for this segment.

Asia Pacific Automated Guided Vehicle (AGV) Market, By Type

Forklift trucks are expected to grow at a significant CAGR from 2026 to 2032 as organizations accelerate automation of pallet handling and short distance material movement. Automated forklift AGVs are increasingly deployed for loading, unloading, stacking, and internal transfers where heavy loads and repetitive cycles are common. Their ability to operate within existing layouts and alongside manual equipment supports faster adoption with limited operational change. Rising focus on safety, consistent handling performance, and labor efficiency is further supporting demand for forklift based AGV solutions.

Asia Pacific Automated Guided Vehicle (AGV) Market, By Payload Capacity

Medium-duty AGVs are expected to grow at a commendable CAGR during the forecast period as they offer a balance between load handling capability and operational flexibility. These AGVs are widely adopted for repetitive internal transport tasks that require higher payloads without the cost and space requirements of heavy duty systems. Their suitability for mixed traffic environments, stable performance over long operating hours, and compatibility with scalable automation strategies is supporting increased adoption across Asia Pacific.

REGION

China to be fastest-growing country in Asia Pacific automated guided vehicle (AGV) market during forecast period

China is expected to lead growth as large scale facilities accelerate AGV adoption to manage high internal transport volumes and improve operational consistency. Rising labor costs, safety compliance requirements, and pressure to improve throughput are pushing faster automation uptake. Ongoing expansion of new facilities, along with automation upgrades in existing sites, is further supporting sustained AGV demand across the country.

ASIA PACIFIC AUTOMATED GUIDED VEHICLE (AGV) MARKET: COMPANY EVALUATION MATRIX

In the Asia Pacific automated guided vehicle (AGV) market matrix, Daifuku Co., Ltd. (Star) and Toyota Industries Corporation (Star) are positioned as leading players. Daifuku leads through a wide AGV portfolio, strong system engineering capability, and deep integration with warehouse and manufacturing control platforms, enabling stable deployment across large scale and high throughput facilities. Toyota Industries Corporation strengthens its position through industrial vehicle expertise, mature fleet control capabilities, and close alignment with production workflows, supporting reliable AGV operation within complex, multi shift environments. Their focus on scalable system design, software driven coordination, and consistent execution supports dependable AGV adoption across diverse manufacturing and intralogistics operations in Asia Pacific.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

KEY MARKET PLAYERS

- Daifuku Co., Ltd. (Japan)

- Toyota Industries Corporation (Japan)

- MITSUBISHI LOGISNEXT CO.,LTD. (Japan)

- KUKA (Germany)

- KION Group AG (Germany)

- Scott (New Zealand)

- MEIDENSHA CORPORATION (Japan)

- SSI SCHAEFER (Germany)

- JBT (US)

- Hyster-Yale, Inc. (US)

MARKET SCOPE

| REPORT METRIC | DETAILS |

|---|---|

| Market Size in 2025 (Value) | USD 0.91 Billion |

| Market Forecast in 2032 (Value) | USD 1.72 Billion |

| Growth Rate | CAGR of 9.9% from 2026-2032 |

| Years Considered | 2021-2032 |

| Base Year | 2025 |

| Forecast Period | 2026-2032 |

| Units Considered | Value (USD Million/Billion), Volume (Thousand Units) |

| Report Coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends. |

| Segments Covered |

|

| Countries Covered | China, Japan, Australia, South Korea, India, Malaysia, Indonesia, Singapore, Thailand, and Rest of Asia Pacific |

DELIVERED CUSTOMIZATIONS

We have successfully delivered the following deep-dive customizations:

| CLIENT REQUEST | CUSTOMIZATION DELIVERED | VALUE ADDS |

|---|---|---|

| E commerce Operator / 3PL Provider |

|

|

| Automotive / Industrial Manufacturer |

|

|

RECENT DEVELOPMENTS

- March 2025 : Scott launched NexBot, a modular automated guided vehicle, at ProMat 2025. NexBot is designed to reduce automation deployment time and costs through a standardized, modular AGV architecture. The platform supports multiple back-end modules, including counterbalance fork, straddle fork, lift deck, conveyor deck, and tugger configurations, enabling flexible material handling across warehousing, manufacturing, logistics, and e-commerce environments.

- April 2024 : Daifuku Co., Ltd. modified its Shiga facility to enhance production capacity and optimize logistics. Building G will include a cleanroom designed for semiconductor and LCD production systems, while Building M will focus on managing maintenance parts and manufacturing automated guided vehicles (AGVs).

Table of Contents

Methodology

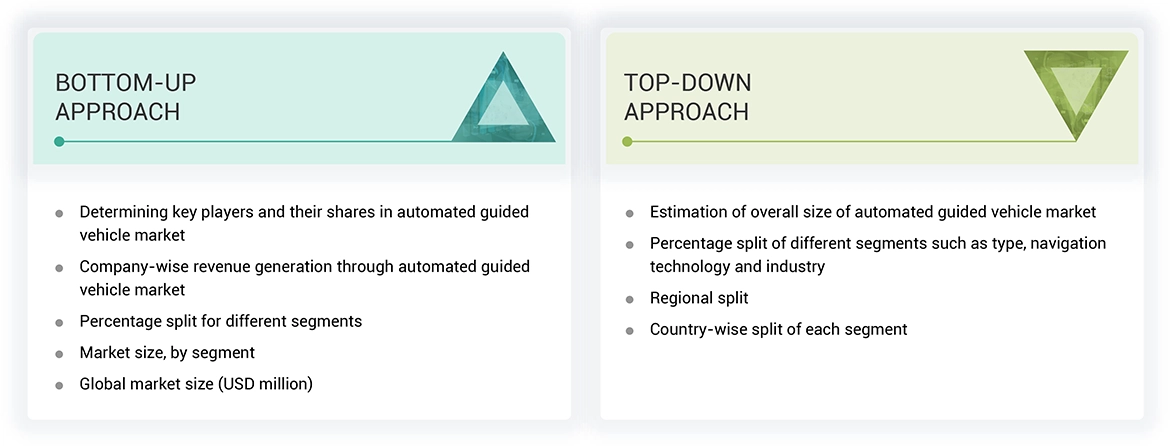

The study involved four major activities in estimating the current size of the Asia Pacific automated guided vehicle market. Exhaustive secondary research has been done to collect information on the market, peer market, and parent market. To validate these findings, assumptions, and sizing with industry experts across the value chain through primary research has been the next step. Both top-down and bottom-up approaches have been employed to estimate the complete market size. After that, market breakdown and data triangulation methods have been used to estimate the market size of segments and subsegments. Two sources of information—secondary and primary—have been used to identify and collect information for an extensive technical and commercial study of the Asia Pacific automated guided vehicle market.

Secondary Research

Various secondary sources have been referred to in the secondary research process to identify and collect information important for this study. The secondary sources include annual reports, press releases, and investor presentations of companies; white papers; journals and certified publications; and articles from recognized authors, websites, directories, and databases. Secondary research has been conducted to obtain key information about the industry’s supply chain, the market’s value chain, the total pool of key players, market segmentation according to the industry trends (to the bottom-most level), regional markets, and key developments from market- and technology-oriented perspectives. The secondary data has been collected and analyzed to determine the overall market size, further validated by primary research.

Primary Research

Extensive primary research was conducted after gaining knowledge about the current scenario of the Asia Pacific automated guided vehicle market through secondary research. Several primary interviews were conducted with experts from the demand and supply sides across Asia Pacific. This primary data was collected through questionnaires, emails, and telephonic interviews.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

Both top-down and bottom-up approaches have been used to estimate and validate the total size of the Asia Pacific automated guided vehicle market. These methods have also been used extensively to estimate the size of various subsegments in the market. The following research methodology has been used to estimate the market size:

- Major players in the industry and markets have been identified through extensive secondary research.

- The industry’s value chain and market size (in terms of value) have been determined through primary and secondary research processes.

- All percentage shares, splits, and breakdowns have been determined using secondary sources and verified through primary sources.

Asia Pacific Automated Guided Vehicle (AGV) Market: Top-Down and Bottom-Up Approach

Data Triangulation

After arriving at the overall size of the Asia Pacific automated guided vehicle market from the market size estimation process explained above, the total market has been split into several segments and subsegments. Data triangulation and market breakdown procedures have been employed, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics for all segments and subsegments of the market. The data has been triangulated by studying various factors and trends from both the demand and supply sides. Along with this, the market size has been validated using both top-down and bottom-up approaches.

Market Definition

The Automated Guided Vehicle (AGV) market encompasses the design, manufacturing, and distribution of vehicles that operate autonomously to transport materials and goods within industrial, commercial, and logistics environments. These vehicles include various types such as tow vehicles, unit load carriers, pallet trucks, assembly line vehicles, forklift AGVs, and others, each utilizing advanced technologies like laser navigation, magnetic guidance, and vision-based systems to ensure efficient operation. With the rise of Industry 4.0, increasing adoption of automation across industries, and a growing emphasis on enhancing operational efficiency and workplace safety, the AGV market has become a pivotal component of modern material handling and supply chain management systems.

Key Stakeholders

- AGV manufacturers

- End users

- Government bodies, venture capitalists, and private equity firms

- Manufacturers of sensors, microcontrollers, RFID modems, and related accessories

- Material handling associations

- Professional service/solution providers

- Research institutions and organizations

- Standards organizations and regulatory authorities related to the material handling industry

Report Objectives

- To define, describe, and forecast the Asia Pacific automated guided vehicle market, in terms of value, by type, navigation technology, industry, and region.

- To provide detailed information regarding the major factors influencing the growth of the market, namely, drivers, restraints, opportunities, and challenges.

- To strategically analyze micromarkets with respect to individual growth trends, prospects, and contributions to the total market.

- To analyze the probable impact of the recession on the market in the future.

- To study the complete value chain of the Asia Pacific automated guided vehicle ecosystem, along with market trends and use cases.

- To analyze opportunities in the market for stakeholders by identifying high-growth segments of the market.

- To strategically profile key players and comprehensively analyze their core competencies along with detailing the competitive landscape for market leaders.

- To analyze competitive developments such as product launches, acquisitions, partnerships, and expansions in the Asia Pacific automated guided vehicle market.

- To benchmark market players using the Company Evaluation Matrix quadrant, which analyzes players based on various parameters within broad business categories and product strategies.

Available Customizations

With the given market data, MarketsandMarkets offers customizations according to the company’s specific needs. The following customization options are available for the report:

Company Information:

- Detailed analysis and profiling of additional market players (up to 5)

Need a Tailored Report?

Customize this report to your needs

Get 10% FREE Customization

Customize This ReportPersonalize This Research

- Triangulate with your Own Data

- Get Data as per your Format and Definition

- Gain a Deeper Dive on a Specific Application, Geography, Customer or Competitor

- Any level of Personalization

Let Us Help You

- What are the Known and Unknown Adjacencies Impacting the Asia Pacific Automated Guided Vehicle (AGV) Market

- What will your New Revenue Sources be?

- Who will be your Top Customer; what will make them switch?

- Defend your Market Share or Win Competitors

- Get a Scorecard for Target Partners

Custom Market Research Services

We Will Customise The Research For You, In Case The Report Listed Above Does Not Meet With Your Requirements

Get 10% Free Customisation

Growth opportunities and latent adjacency in Asia Pacific Automated Guided Vehicle (AGV) Market