Electronic Filtration Market

Electronic Filtration Market by Type (Gas Filter, Liquid Filter, Air Filter), Filter Material, Filtration Technology, Application, End-use Industry (Consumer Electronics, Industrial Electronics, Semiconductors), and Region - Global Forecast to 2030

OVERVIEW

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

The electronic filtration market is expected to reach USD 7.06 billion by 2030, up from USD 4.70 billion in 2025, with a CAGR of 8.5% over the forecast period. Increasing demand for clean water and air, driven by rising pollution levels and growing environmental awareness, is a key factor, as industries and consumers seek advanced filtration systems. Strict government regulations worldwide, aimed at reducing emissions and ensuring water and air quality, are compelling industries such as automotive, healthcare, and manufacturing to adopt high-efficiency electronic filtration technologies.

KEY TAKEAWAYS

-

BY PRODUCT TYPEThe electronic filtration market includes air filters, liquid filters, gas filters, and other product types. Liquid filters hold the largest share of the market mainly because of their crucial role in maintaining the purity and reliability of liquids used in electronics manufacturing. They are also widely used in processes like photolithography, chemical mechanical planarization (CMP), etching, and cleaning, all of which require high-purity liquids.

-

BY FILTRATION TECHNOLOGYKey filtration technologies include mechanical filtration, adsorption filtration, depth filtration, membrane filtration, electrostatic filtration, and other filtration methods. Mechanical filtration leads the electronic filtration market because of its effectiveness in removing particulate contaminants and its broad use in air, water, and chemical purification processes. Its cost-effectiveness, easy maintenance, and compatibility with cleanroom standards make it the top choice in semiconductor and electronics manufacturing.

-

BY APPLICATIONKey applications include cleanroom environments, photolithography, wet etching and cleaning processes, CVD & PVD, gas delivery systems, water purification processes, and other uses. CVD and PVD are the fastest-growing applications in the electronic filtration market because they play a vital role in advanced semiconductor manufacturing and thin-film technology. These deposition processes are used to produce high-performance microelectronic devices such as integrated circuits, sensors, displays, and photovoltaic cells. During CVD and PVD processes, ultra-clean conditions are crucial, as even tiny particles, chemical vapors, or metallic impurities can negatively impact film uniformity, adhesion, and electrical conductivity.

-

BY END-USE INDUSTRYEnd-use industries include consumer electronics, semiconductor, telecommunication equipment, industrial electronics, and other sectors. Consumer electronics is the largest end-use industry in the electronic filtration market due to high production volumes and strict purity requirements in manufacturing devices like smartphones, laptops, and wearables.

-

BY FILTER MATERIALKey filter materials include glass fiber, PP, PTFE, nylon, PES, cellulose, ceramic, stainless steel, and other filter media. Glass fiber holds the largest market share in the electronic filtration industry because it offers superior thermal stability, chemical resistance, filtration efficiency, and durability. This media is favored for its excellent ability to capture submicron particles, with high particulate retention and minimal impact on flow rates. This makes it ideal for applications requiring both precision and efficiency, such as cleanrooms, chemical processing lines, and high-purity liquid filtration systems.

-

BY REGIONThe electronic filtration market includes Europe, North America, Asia Pacific, South America, the Middle East, and Africa. The Asia Pacific market holds the largest share in the electronic filtration industry because it is the global leader in electronics manufacturing and experiences rapid industrial growth. Key countries such as China, South Korea, Japan, and Taiwan are major hubs for manufacturing semiconductors, consumer electronics, and high-end display production, where advanced filtration technologies for cleanrooms and critical processes like photolithography, etching, and deposition are essential to maintain product quality and productivity.

-

COMPETITIVE LANDSCAPEMajor market players have adopted both organic and inorganic strategies, such as partnerships and investments. For instance, Entegris, Inc., Donaldson Company, Inc., and Pall Corporation have made several agreements and partnerships to meet the rising demand for electronic filtration in innovative applications.

The rising demand for higher semiconductor purity is a key factor driving the electronic filtration market. As semiconductor technology advances, there is an increasing need to reduce contaminants during manufacturing, which promotes the adoption of advanced filtration solutions. The electronic filtration industry plays a vital role in semiconductor production, safeguarding critical processes involved in creating electronic components. It is used in areas such as wet etching, cleanrooms, photolithography, chemical vapor deposition (CVD), and physical vapor deposition (PVD) to remove contaminants and boost manufacturing efficiency. Serving industries like consumer electronics, industrial electronics, and semiconductors, it helps produce high-quality parts.

TRENDS & DISRUPTIONS IMPACTING CUSTOMERS' CUSTOMERS

The impact on consumers' businesses arises from customer trends or disruptions. Companies like Intel Corporation, Samsung Electronics, Taiwan Semiconductor Manufacturing Company Limited, Sony Semiconductor Solutions, and Texas Instruments are clients of filtration system providers, while their target applications such as semiconductor fabs, display fabs, and power electronics serve as the end users. Changes like IoT-enabled smart filters, nanofiber membranes, and sustainable filtration solutions affect end-user efficiency and yield, which in turn influence the revenues of these companies and ultimately drive growth for electronic filtration manufacturers.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

MARKET DYNAMICS

Level

-

Expanding semiconductor industry

-

Increasing demand for ultra-pure water in microelectronics manufacturing

Level

-

High cost of advanced filtration technologies

-

Environmental issues associated with waste disposal from membrane filtration

Level

-

Integration of Internet of Things (loT) technology into electronic filtration systems

-

Demand for customized filtration solutions for emerging applications

Level

-

Lack of standardized filtration solutions

-

Prolonged validation cycles

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Driver: Expanding semiconductor industry

The expanding semiconductor industry is a key driver for the electronic filtration market due to its strict requirement for ultra-clean manufacturing environments. Semiconductor fabrication involves highly sensitive processes where even microscopic contaminants can damage wafers or reduce yield. As chip designs become smaller and more advanced, the demand for high-purity air, water, and chemical filtration systems increases. Filtration technologies ensure contaminant-free environments across cleanrooms, process gases, and cooling systems. Additionally, the rise in semiconductor production for applications like AI, 5G, and EVs further boosts investments in advanced filtration solutions, supporting efficiency, reliability, and product quality in semiconductor manufacturing.

Restraint: High cost of advanced filtration technologies

The high cost of advanced filtration technologies serves as a major obstacle for the electronic filtration market, as these systems require precise engineering, high-quality materials, and ongoing maintenance to meet strict purity standards in electronic manufacturing. Technologies like HEPA, ULPA, and nanofiber filters involve substantial R&D and production costs, making them expensive to install and operate. Smaller manufacturers and facilities in developing regions often find it difficult to afford these systems, which limits adoption. Additionally, frequent filter replacements and energy usage increase operational costs, creating financial challenges and slowing market growth despite the rising demand for cleaner production environments.

Opportunity: Integration of Internet of Things (loT) technology into electronic filtration systems

The integration of IoT technology into electronic filtration systems offers a significant opportunity for the market. IoT allows for real-time monitoring, data analysis, and predictive maintenance, enabling users to track filter performance, identify contamination, and plan replacement schedules more effectively. This smart connectivity enhances efficiency, minimizes downtime, and prolongs equipment life. In semiconductor and electronics manufacturing, where precision and cleanliness are essential, IoT-enabled filtration improves process reliability and ensures compliance. As industries increasingly adopt digital solutions and automation, the need for intelligent, connected filtration systems is set to grow, spurring innovation and opening new growth opportunities for market players.

Challenge: Lack of standardized filtration solutions

The lack of standardized filtration systems is a major obstacle for the electronic filtration market, mainly due to the diversity and sensitivity of electronic components. The electronics industry includes a wide range of parts, from semiconductors to printed circuit boards, sensors, and microprocessors, each with different operational requirements and vulnerability to contaminants such as dust, chemical vapors, and moisture. Therefore, the absence of uniform filtration methods makes designing, developing, and implementing effective systems complex, often requiring solutions customized for specific applications. This level of customization introduces costs, extends development times, and lowers overall efficiency for both manufacturers and end users.

Electronic Filtration Market: COMMERCIAL USE CASES ACROSS INDUSTRIES

| COMPANY | USE CASE DESCRIPTION | BENEFITS |

|---|---|---|

|

Provides advanced filtration for microelectronics and semiconductors, ensuring ultra-pure environments from polysilicon to wafer processing | Superior particle and contaminant removal, enhanced process purity, and improved production yields |

|

Supplies liquid filtration for chemicals and slurries in semiconductor fabrication, targeting particle and organic contamination | High retention efficiency, protection against airborne molecular contamination, and increased manufacturing yields |

|

Develops filtration solutions for electronics assembly and cleanrooms, purifying air and liquids for component production | Effective contaminant separation, reliable performance, and seamless integration into production systems |

|

Offers membrane and depth filters for high-purity electronics processes, focusing on sterile filtration and impurity removal | Excellent virus and endotoxin removal, decolorization capabilities, and adsorption of small molecular contaminants |

|

Provides filtration for microelectronics, optimizing fluid and gas purity in chemical processing and wafer fabrication | High-effectiveness filtration, cost and performance optimization, and enhanced equipment reliability |

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET ECOSYSTEM

The electronic filtration market ecosystem includes raw material suppliers such as Hollingsworth & Vose, Cabot Corporation, and Ahlstrom; manufacturers like 3M, Pall Corporation, Entegris, Inc., and Cobetter; distributors such as MSC Industrial Direct Co., W.W. Grainger, Inc., and ISCO Industries; and end users like Dyson, Taiwan Semiconductor Manufacturing Company Limited, and Telefonaktiebolaget LM Ericsson. Raw material suppliers provide essential materials including plastic, metal, stainless steel, and woven fabric, along with key components like filter media, frames, and adhesives. End-use industries, which include consumer electronics, the semiconductor industry, telecommunications equipment, and industrial electronics, are the final consumers of electronic filtration products. These industries have specific needs, with consumer electronics focusing on portable solutions and industrial sectors requiring high-precision filtration for manufacturing processes. Electronic filtration plays a crucial role in influencing the performance, reliability, and lifespan of equipment in these industries.

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET SEGMENTS

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Electronic Filtration Market, By Product Type

In 2024, liquid filters dominated the largest share of the electronic filtration market mainly because of their crucial role in ensuring the purity and reliability of liquid processes, which are vital in electronics manufacturing. During the production of semiconductors, printed circuit boards (PCBs), and other microelectronic devices, ultra-pure water and high-purity chemicals are absolutely essential. These liquids must be free of particulates, metallic ions, organic impurities, and microorganisms, as even tiny contaminants can cause defects, reduce yields, or lead to device failure. Liquid filtration systems are essential for removing these impurities, ensuring high product quality and process reliability. Additionally, the increasing complexity of electronic materials and the trend toward miniaturization have made manufacturing processes more sensitive to contamination. This has created a greater need for advanced liquid filtration technologies capable of providing precise and consistent removal of pollutants.

Electronic Filtration Market, By Application

In 2025, CVD & PVD will be the fastest-growing applications in the electronic filtration market because they play an important role in advanced semiconductor manufacturing and thin-film technology. High-performance microelectronic devices such as integrated circuits, sensors, displays, and photovoltaic cells are produced using these deposition processes. During CVD and PVD processes, ultra-clean conditions are crucial, as even tiny particles, chemical vapors, or metallic impurities can negatively impact film uniformity, adhesion, and electrical conductivity. Therefore, high-efficiency electronic filtration systems are increasingly necessary to keep gases, liquids, and ambient environments used in deposition processes free from contamination. The significant rise in demand for compact, high-power, and low-power electronic devices has driven the growth and development of semiconductor manufacturing processes, with CVD and PVD forming the foundation.

Electronic Filtration Market, By Filter Material

In 2024, glass fiber held the largest market share in the electronic filtration industry because it offers superior thermal stability, chemical resistance, filtration efficiency, and durability. This media is preferred for its excellent ability to capture submicron particles, with high particulate retention and minimal impact on flow rates. It is suitable for applications requiring both precision and efficiency, such as cleanrooms, chemical processing lines, and high-purity liquid filtration systems. A key benefit of glass fiber is its resistance to a wide range of chemicals and high temperatures, making it ideal for harsh environments common in electronic manufacturing processes like chemical vapor deposition (CVD), etching, and cleaning. Its long lifespan and compatibility with both air and liquid filtration systems enhance its cost-effectiveness, further increasing its adoption across the industry.

Electronic Filtration Market, By Filtration Technology

Mechanical filtration dominated the electronic filtration market in 2024 due to its reliability and efficiency in removing physical contaminants like dust, particles, and debris from air and liquids used in semiconductor and microelectronics manufacturing. Its straightforward design ensures consistent performance across various applications, maintaining high-purity environments essential for sensitive processes. The technology's cost-effectiveness and ease of maintenance further increased its adoption, attracting manufacturers seeking scalable solutions. Additionally, improvements in filter media and design enhanced its precision, meeting strict industry standards.

Electronic Filtration Market, By End-use Industry

The semiconductor industry is set to be the fastest-growing segment in the electronic filtration market by 2030, driven by increasing demand for advanced chips in AI, 5G, electric vehicles, and IoT applications, all of which require ultra-pure manufacturing environments. The rapid growth of new fabrication plants and a greater focus on contamination control propel this expansion. Improved filtration systems are crucial to reduce defects and maximize yields, while innovations such as advanced membrane technologies enhance precision. Rising cleanroom standards and regulatory demands further increase the need for effective filtration, reinforcing the semiconductor industry's leading role in this market.

REGION

Asia Pacific to be fastest-growing region in global electronic filtration market during forecast period

Asia Pacific is emerging as the fastest-growing region in the electronic filtration market, driven by its role as the global hub for semiconductor and microelectronics manufacturing, especially in hubs like Taiwan, South Korea, China, and Japan. Rapid industrialization and urbanization in countries such as India and Vietnam are leading to the development of new fabrication facilities, which require advanced filtration systems to maintain ultra-pure air and liquids essential for high-yield production. Cost advantages, including lower labor and operational costs, attract international investments, while strict environmental regulations and increasing health awareness encourage the adoption of efficient filters. Innovations in membrane technologies further improve precision, aligning with the region's vibrant economic growth and technological progress, positioning it for lasting leadership.

Electronic Filtration Market: COMPANY EVALUATION MATRIX

In the electronic filtration market matrix, Pall Corporation (Star) leads with a strong market share and extensive product footprint. Porvair plc emerges as a leader with its innovative porous media and precision filters for semiconductor cleanrooms.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

KEY MARKET PLAYERS

MARKET SCOPE

| REPORT METRIC | DETAILS |

|---|---|

| Market Size in 2024 (Value) | USD 4.34 Billion |

| Market Forecast in 2030 (Value) | USD 7.06 Billion |

| Growth Rate | CAGR of 8.5% from 2025-2030 |

| Years Considered | 2022-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million/Billion), Volume (Million Unit) |

| Report Coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments Covered |

|

| Regions Covered | North America, Asia Pacific, Europe, South America, Middle East & Africa |

WHAT IS IN IT FOR YOU: Electronic Filtration Market REPORT CONTENT GUIDE

DELIVERED CUSTOMIZATIONS

We have successfully delivered the following deep-dive customizations:

| CLIENT REQUEST | CUSTOMIZATION DELIVERED | VALUE ADDS |

|---|---|---|

| Leading Device OEM |

|

|

| Composite Material Manufacturer | Benchmarking adoption of filter technologies across consumer, industrial, and medical electronics | Switching cost analysis between HEPA, ULPA, and nanofiber membranes |

| Engine Manufacturer | Technical and cost-benefit analysis of advanced filtration media (ceramics, nanofibers, polymers) | Forecasting adoption of ultrafine filtration in fabs to 2030 |

| Raw Material Supplier |

|

|

| Consumer Electronic Contractor |

|

|

RECENT DEVELOPMENTS

- June 2023 : Entegris broke ground on its state-of-the-art manufacturing plant in Colorado Springs. The new facility is set to begin operations early in 2025 and is expected to strengthen local semiconductor production. The 100,000 sq. ft. plant will support Entegris' filtration and purification solutions, boosting the growth of the US semiconductor industry and reinforcing the country's position as a leader in innovation and supply chain resilience.

- May 2023 : Entegris expanded a facility in Kaohsiung Science Park in Southern Taiwan. With an investment of approximately USD 550 million, the 54,000-square-meter facility boosts Entegris' capacity to produce key products like advanced liquid filters, high-purity drums, and advanced deposition materials.

- January 2023 : Donaldson Company, Inc. launched managed filtration services. This new offering, which combines Donaldson's iCue technology with extensive OEM expertise, provides connected and consultative solutions to ensure top-tier industrial filtration performance and durability.

Table of Contents

Methodology

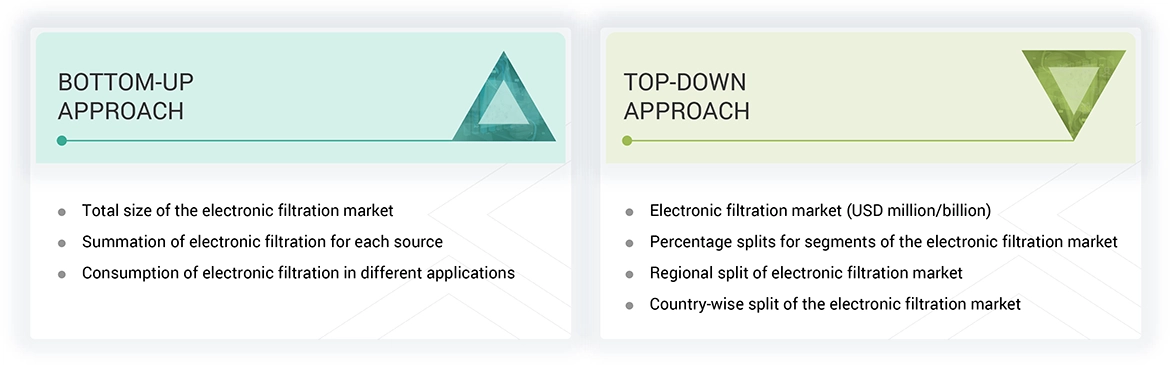

The research encompassed four key activities to quantify the current dimensions of the global electronic filtration market. A comprehensive secondary analysis was conducted to gather data on the market landscape, including adjacent product markets and the broader parent product category. Subsequently, these findings, underlying assumptions, and estimates were corroborated through primary research involving discussions with industry experts across the electronic filtration value chain. To derive the overall market size, both top-down and bottom-up methodologies were applied. Following this, we employed market segmentation strategies and data triangulation techniques to accurately delineate the sizes of various segments and sub-segments within the electronic filtration market.

Secondary Research

The market size for the companies offering electric filtration is arrived at by secondary data available through paid and unpaid sources, analyzing the product portfolios of the major companies in the ecosystem, and rating the companies by their performance and quality. Various secondary sources, such as Business Standard, Bloomberg, World Bank, and Factiva, were referred to identify and collect information for this study on the electronic filtration market. In the secondary research process, various secondary sources were referred to identify and collect information related to the study. Secondary sources included annual reports, press releases, and investor presentations of electronic filtration vendors, forums, certified publications, and whitepapers. The secondary research was used to obtain critical information on the industry’s value chain, the total pool of key players, market classification, and segmentation from the market and technology-oriented perspectives.

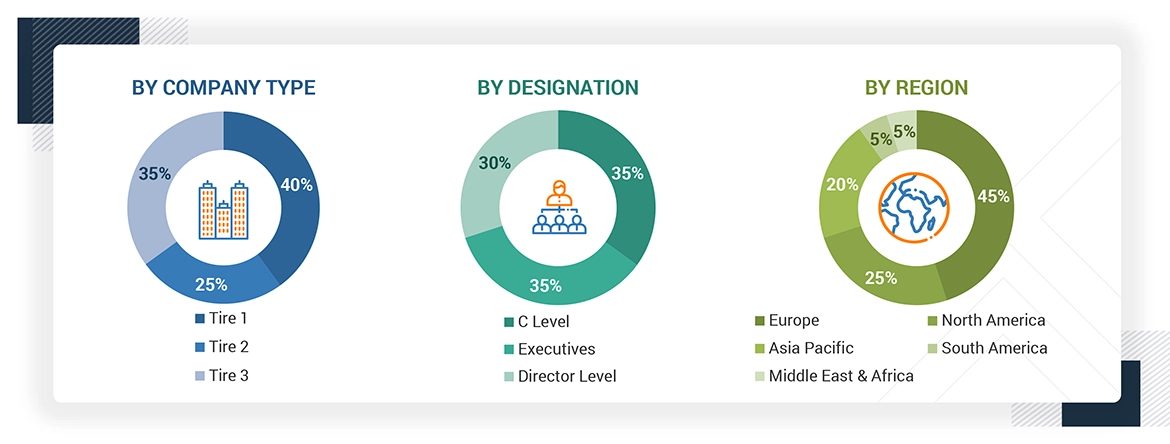

Primary Research

In the primary research process, various primary sources from both the supply and demand sides were interviewed to obtain qualitative and quantitative information for this report. The primary sources from the supply side included industry experts, such as Chief Executive Officers (CEOs), Vice Presidents (VPs), marketing directors, technology and innovation directors, and related key executives from several key companies and organizations operating in the electronic filtration market. After the complete market engineering (calculations for market statistics, market breakdown, market size estimations, market forecasting, and data triangulation), extensive primary research was conducted to gather information and verify and validate the critical numbers arrived at. Primary research was also conducted to identify the segmentation types, industry trends, competitive landscape of the electric filtration market offered by various market players, and key market dynamics, such as drivers, restraints, opportunities, challenges, industry trends, and key player strategies. In the complete market engineering process, the top-down and bottom-up approaches and several data triangulation methods were extensively used to perform the market estimation and market forecasting for the overall market segments and subsegments listed in this report. Extensive qualitative and quantitative analysis was performed on the complete market engineering process to list the key information/insights throughout the report.

Notes: Other designations include sales, marketing, and product managers

Tier 1: >USD 1 Billion; Tier 2: USD 500 million–1 Billion; and Tier 3: USD 500 million.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

The top-down and bottom-up approaches were used to estimate and validate the size of the global electronic filtration market. These approaches were also used extensively to estimate the size of various dependent market segments. The research methodology used to estimate the market size included the following:

Electronic Filtration Market : Top-Down and Bottom-Up Approach

Data Triangulation

After arriving at the overall market size using the market size estimation processes, the market was split into several segments and subsegments. The data triangulation and market breakup procedures were employed, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics of each market segment and subsegment. The data was triangulated by studying various factors and trends from both the demand and supply sides.

Market Definition

Electronic filtration products play a vital role in avoiding contamination of sensitive electronic systems and delivering the best performance. These filters are typically used in industries such as telecommunications, consumer electronics, automotive electronics, medical equipment, and industrial applications. Key market drivers include increasing demand for cleaner environments in electronics manufacturing, increased air and water pollution concerns, and the need for electronics compliant with environmental standards and regulations.

Key Stakeholders

- Filter manufacturers

- End users

- Technology and R&D institutions

- Regulatory bodies and standards organizations

- Distributors and suppliers

- Consultants and system integrators

- Investors and financial entities

Report Objectives

- To define, describe, and forecast the size of the global electronic filtration market based on product type, filter technology, filter material, application, end-use industry, and region in terms of value and volume

- To provide detailed information on the significant drivers, restraints, opportunities, and challenges influencing the market

- To strategically analyze micromarkets concerning individual growth trends, prospects, and their contribution to the market

- To assess the growth opportunities in the market for stakeholders and provide details on the competitive landscape for market leaders

- To forecast the market size of segments and subsegments for North America, Europe, Asia Pacific, South America, and the Middle East & Africa

- To strategically profile key players and comprehensively analyze their market shares and core competencies

- To analyze competitive developments such as product launches, acquisitions, partnerships, expansions, and investments in the electronic filtration market.

- To provide the impact of AI/Gen AI on the market

Available Customizations

With the given market data, MarketsandMarkets offers customizations according to client-specific needs.

- The following customization options are available for the electronic filtration market report:

Product Analysis

- A product matrix that gives a detailed comparison of the product portfolio of each company

Regional Analysis

- A further breakdown of the electronic filtration market for additional countries

Company Information

- Detailed analysis and profiling of additional market players (up to five)

Need a Tailored Report?

Customize this report to your needs

Get 10% FREE Customization

Customize This ReportPersonalize This Research

- Triangulate with your Own Data

- Get Data as per your Format and Definition

- Gain a Deeper Dive on a Specific Application, Geography, Customer or Competitor

- Any level of Personalization

Let Us Help You

- What are the Known and Unknown Adjacencies Impacting the Electronic Filtration Market

- What will your New Revenue Sources be?

- Who will be your Top Customer; what will make them switch?

- Defend your Market Share or Win Competitors

- Get a Scorecard for Target Partners

Custom Market Research Services

We Will Customise The Research For You, In Case The Report Listed Above Does Not Meet With Your Requirements

Get 10% Free Customisation

Growth opportunities and latent adjacency in Electronic Filtration Market