Medical Polymer Market

Medical Polymer Market by Type (Medical Plastics, Medical Elastomers), Application (Medical Disposables, Medical Instruments and Devices, Prosthetics, Diagnostics Instruments and Tools), Manufacturing Technology, and Region - Global Forecast to 2030

OVERVIEW

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

The medical polymer market is expected to reach USD 66.3 billion by 2030, up from USD 44.7 billion in 2025, growing at a CAGR of 8.2% from 2025 to 2030. The market's growth is fueled by increasing demand for advanced medical devices, minimally invasive procedures, biocompatible materials, and expanding healthcare infrastructure.

KEY TAKEAWAYS

-

The medical polymer market comprises medical plastics and medical elastomers.

-

Key manufacturing technologies include extrusion tubing, compression molding, injection molding, and other manufacturing technologies.

-

Key applications of medical polymer span medical disposables, medical instruments & devices, prosthetics, diagnostic instruments & tools, and others.

-

The medical polymer market includes Europe, North America, Asia Pacific, South America, the Middle East, and Africa. Asia Pacific is the largest market for medical polymers due to improvements in healthcare infrastructure, higher demand for medical devices, and increased investments in production capacity. A growing population, urbanization, and a rising middle class in countries like China, India, and Southeast Asian nations are driving the significant increase in healthcare spending and access to specialized medical treatments.

-

Major market players have adopted both organic and inorganic strategies, including partnerships and investments. For instance, SABIC (Saudi Arabia) and Covestro AG (Germany) have entered into a number of agreements and partnerships to cater to the growing demand for medical polymer across innovative applications.

The medical polymer market is experiencing steady growth, driven by increasing demand for advanced medical devices, a rising elderly population, and the growing adoption of minimally invasive procedures. Global expansion in this market is further supported by ongoing technological advancements in the development of biocompatible and high-performance materials, expanding healthcare infrastructure, and rising awareness about healthcare quality.

TRENDS & DISRUPTIONS IMPACTING CUSTOMERS' CUSTOMERS

The influence on consumer enterprises derives from prevailing customer trends or disruptions. 'Hotbets' refer to clients of medical polymer manufacturers, and their target applications are also within the scope of these manufacturers. Changes, whether in evolving trends or disruptions, will impact the revenues of end users. This revenue impact on end users will, in turn, affect the revenues of 'hotbets', thereby further influencing the revenue of medical polymer manufacturers.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

MARKET DYNAMICS

Level

-

Increasing demand for biocompatible materials

-

Growing aging population globally

Level

-

Environmental sustainability concerns

-

High competition from alternative materials

Level

-

Demand for minimally invasive devices

-

Growth in regenerative medicine

Level

-

Long-term durability and controlling degradation

-

Cost constraints for novel materials

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Driver: Increasing demand for biocompatible materials

The medical polymer market is fueled by a rise in the demand for biocompatible materials, which are materials that interact safely with the human body, and do not cause adverse effects. These materials can be found in numerous capacities such as implants, surgical tools, catheters, and drug delivery systems, where safety and compatibility are critical components of their use. As monitors of one's health become more personalized and less invasive, the demand for reliable, non-toxic, durable polymers will continue to grow, enhancing innovation and increased use of advanced medical polymers, helping the market as a whole to continue its growth globally.

Restraint: Environmental sustainability concerns

Environmental sustainability concerns restrain the medical polymer market because many polymers are non-biodegradable and contribute to medical waste, posing disposal and ecological challenges. Strict regulations on plastic use and increasing demand for eco-friendly alternatives add pressure on manufacturers. Developing sustainable, biocompatible polymers often involves higher costs and complex processes, limiting rapid adoption and slowing overall market growth despite rising healthcare needs.

Opportunity: Demand for minimally invasive devices

A growing need for minimally invasive devices creates a substantial opportunity for the medical polymer market, given that these procedures utilize lightweight, flexible, and durable materials. Medical polymers facilitate the design of catheters, stents, and surgical devices that improve patient recovery, shorten hospital stays, and improve accuracy for the procedure. The growing adoption of minimally invasive procedures for healthcare providers leads to a growing demand for polymetric materials thus fuieling creativity and increasing opportunities for market expansion globally.

Challenge: Long-term durability and controlling degradation

Long-term durability and degradation control pose a significant challenge for medical polymers because devices like prosthetics, implants, and drug delivery systems need to maintain their structural integrity and functionality when used inside the human body for extended periods. Exposure to bodily fluids, mechanical stresses, and chemical reactions can cause premature wear or failure. Managing performance while minimizing material degradation is an inherently technical challenge, which increases development costs and limits the longevity and reliability of products made from medical polymers.

Medical Polymer Market: COMMERCIAL USE CASES ACROSS INDUSTRIES

| COMPANY | USE CASE DESCRIPTION | BENEFITS |

|---|---|---|

|

Supplies biocompatible polymers and polyurethane systems for medical devices, prosthetics, and wound care | High durability, chemical resistance, safe skin contact, and long-term performance |

|

Provides specialty thermoplastics (PEI, PC, PP) for surgical instruments, drug delivery devices, and trays | Lightweight, sterilization resistance, superior toughness, and cost-effective manufacturing |

|

Offers high-performance thermoplastics (POM, PEEK, UHMW-PE) for orthopedic implants and dental devices | High wear resistance, excellent dimensional stability, and lightweight metal alternatives |

|

Develops medical-grade polycarbonate and TPU for infusion sets, dialysis equipment, and surgical tools | Transparency, impact strength, sterilizability, and patient safety compliance |

|

Manufactures bioresorbable polymers (PLGA, PLA) for implants, stents, and controlled drug release systems | Biodegradability, reduced need for secondary surgery, and precise therapeutic release |

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET ECOSYSTEM

The medical polymer market ecosystem consists of raw material suppliers (DSM-Firmenich, Eastman Chemical Company), manufacturers (BASF, SABIC, Covestro AG, Celanese Corporation), and end users (Medtronic, GE HealthCare). Raw materials include monomers, such as ethylene oxide and propylene oxide, as well as various petrochemical-derived compounds used in polymer synthesis. End users drive demand for product development, quality standards, and pricing strategies. Collaboration across the value chain is key to innovation and market growth.

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET SEGMENTS

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Medical Polymer Market, By Type

The medical plastics segment is expected to be the largest in the medical polymer industry because of their affordability, versatility, and widespread use in medical devices. Medical plastics are biocompatible, chemically resistant, and capable of withstanding sterilization processes, which allows manufacturers to produce syringes, catheters, IV bags, surgical equipment, devices, and analytical and diagnostic tools. Medical plastics are lightweight, can be molded into various shapes and complex designs, and are rigid yet safe for patients. The healthcare industry continues to favor the adoption of single-use and disposable medical devices to reduce cross-contamination and healthcare-associated infections (HCAIs), ensuring that the demand for medical plastics will keep growing. Advancements in polymer formulations, such as antimicrobial or bioresorbable plastics, are further enhancing their functionality. In terms of performance, usability, and compliance with healthcare regulations, medical plastics are leading as the most common products within the medical polymer sector.

Medical Polymer Market, By Manufacturing Technology

Extrusion tubing is the largest manufacturing technology in the medical polymer market owing to its accuracy, consistency, and adaptability in manufacturing components that are critical to the function of a medical device. The extrusion process allows for continuous processing of smooth, dimensionally accurate tubing used in catheters, intravenous lines, hemodialysis, and infusion devices. All of these devices are critical to patient safety and assuring that a medical device functions reliably. Compatibility with many lower cost polymers such as PVC, polyethylene, polyurethane, and silicone, makes extrusion appropriate for both single and multilayer tubing designs which can provide more sophisticated performance properties. The low-cost extrusion process is suitable for scaling up production and is ready for automation. This provides competitive incentives especially with the increasing trend of medical device products to be more sophisticated, less invasive and single-use.

Medical Polymer Market, By Application

Medical instruments & devices lead the medical polymer industry because of their many uses and applications in healthcare, such as surgical instruments, catheters, implants, diagnostic devices, tubing, and equipment housing. The main factors driving demand for these materials are the need for durability, precision tolerances, and biocompatibility, along with the benefits of miniaturization and lightweight designs for vaccine distribution. The rise in surgical procedures, diagnostic testing, and the trend toward disposable devices has boosted the demand for polymers. Advances in polymer science have opened up possibilities for drug delivery, antimicrobial surfaces, and increased flexibility, which strengthen the market’s leading position and will continue to promote growth and innovation.

REGION

North America to be fastest-growing region in global medical polymer market during forecast period

The medical polymer market in North America is fueled by rising demand for advanced medical devices, an aging population requiring implants and prosthetics, continuous R&D investments, and strict regulatory standards. Additionally, the growing use of minimally invasive surgeries, biocompatible materials, and expanded healthcare infrastructure further drives market adoption across various medical applications.

Medical Polymer Market: COMPANY EVALUATION MATRIX

In the medical polymer market matrix, BASF (Star) leads with a strong market share and extensive product range due to its wide portfolio of high-performance, biocompatible polymers designed for medical applications. Solvay (Emerging Leader) has advanced specialty polymers that provide high performance, biocompatibility, and durability for next-generation medical devices. While BASF maintains dominance through scale and a diverse product lineup, Solvay shows significant potential to move into the leaders’ quadrant as demand for high-performance polymers continues to grow.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

KEY MARKET PLAYERS

MARKET SCOPE

| REPORT METRIC | DETAILS |

|---|---|

| Market Size in 2024 (Value) | USD 41.4 Billion |

| Market Forecast in 2030 (value) | USD 66.3 Billion |

| Growth Rate | CAGR of 8.2% from 2025-2030 |

| Years Considered | 2022-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million/Billion), Volume (Kiloton) |

| Report Coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments Covered |

|

| Regions Covered | North America, Asia Pacific, Europe, South America, Middle East & Africa |

WHAT IS IN IT FOR YOU: Medical Polymer Market REPORT CONTENT GUIDE

DELIVERED CUSTOMIZATIONS

We have successfully delivered the following deep-dive customizations:

| CLIENT REQUEST | CUSTOMIZATION DELIVERED | VALUE ADDS |

|---|---|---|

| Medical Device OEM |

|

|

| Polymer Manufacturer |

|

|

| Hospital & Healthcare Providers |

|

|

| Raw Material Supplier |

|

|

| Pharma & Biotech Companies |

|

|

RECENT DEVELOPMENTS

- March 2024 : SABIC, one of the world's largest chemical companies, explored new market opportunities to recycle medical plastics back into the medical materials stream with the dialysis department at Jessa Hospital, one of the largest non-university medical clusters in Limburg, Flanders, Belgium. As a pilot proof-of-concept, used medical plastic from Jessa’s hospitals was processed through an advanced recycling process into pyrolysis oil, which provided circular feedstock for SABIC to make TRUCIRCLE polymers. Each product was manufactured to medical-grade specifications and had equal or superior performance, purity, and physiological safety compared to virgin-based medical grade polymers.

- October 2023 : Covestro installed the first mechanical recycling (MCR) compounding line dedicated to polycarbonates in operation at its integrated site in Shanghai, China. The compounding line will produce more than 25,000 tons of polycarbonates, and blends containing mechanically recycled materials, every year in response to sustainability commitments, especially for post-consumer-recycled (PCR) plastics used in electrical/electronic products, automotive, healthcare, and consumer goods applications.

- October 2023 : Covestro increased production capacities associated to thermoplastic polyurethane (TPU) films in the Platilon product range, and associated infrastructure and logistics in Bomlitz, Lower Saxony, Germany.

Table of Contents

Methodology

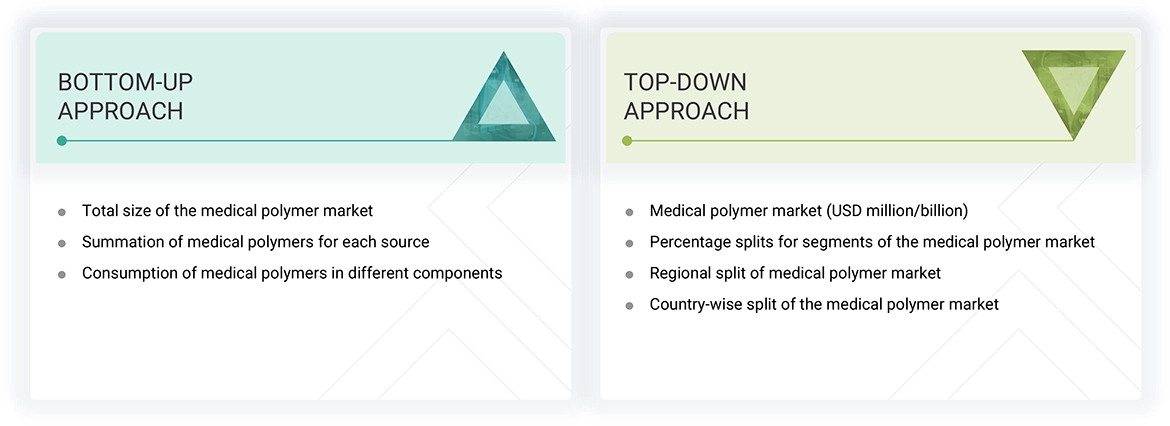

The study involved four major activities for estimating the current size of the global medical polymer market. Exhaustive secondary research was conducted to collect information on the market, the peer product market, and the parent product group market. The next step was to validate these findings, assumptions, and sizes with the industry experts across the value chain of medical polymer through primary research. Both the top-down and bottom-up approaches were employed to estimate the overall size of the medical polymer market. After that, market breakdown and data triangulation procedures were used to determine the size of different segments and sub-segments of the market.

Secondary Research

In the secondary research process, various secondary sources such as Hoovers, Factiva, Bloomberg BusinessWeek, and Dun & Bradstreet were referred, to identify and collect information for this study on the medical polymer market. These secondary sources included annual reports, press releases & investor presentations of companies; white papers; certified publications; articles by recognized authors; regulatory bodies, trade directories, and databases.

Primary Research

The medical polymer market comprises several stakeholders in the supply chain, which include raw material suppliers, distributors, end-product manufacturers, buyers, and regulatory organizations. Various primary sources from the supply and demand sides of the market have been interviewed to obtain qualitative and quantitative information. The primary participants from the demand side include key opinion leaders, executives, vice presidents, and CEOs of companies in the medical polymer market. Primary sources from the supply side include associations and institutions involved in the medical polymer market, key opinion leaders, and processing players.

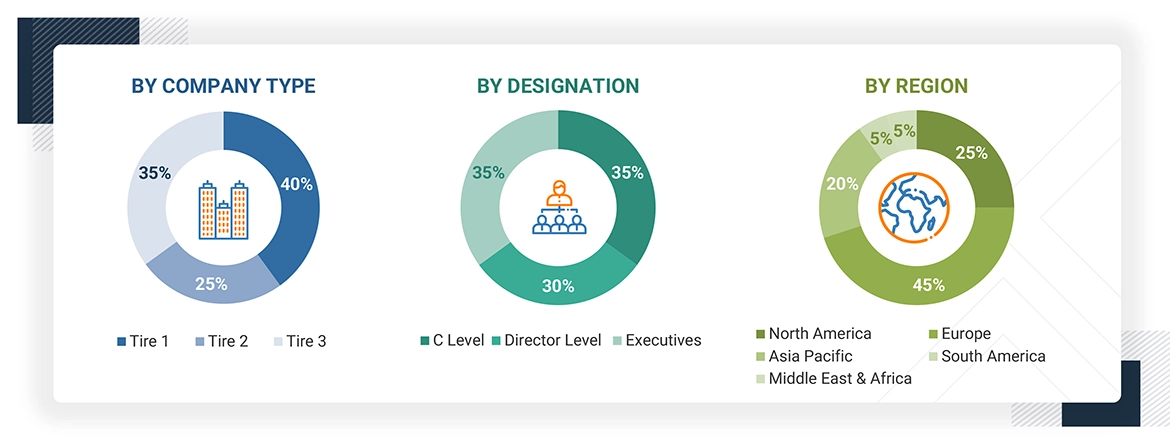

Following is the breakdown of interviews with experts:

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

The bottom-up and top-down approaches have been used to estimate the medical polymer market by type, application, manufacturing technology, and region. The research methodology used to calculate the market size includes the following steps:

- The key players in the industry and markets were identified through extensive secondary research.

- In terms of value, the industry’s supply chain and market size were determined through primary and secondary research processes.

- All percentage shares, splits, and breakdowns were determined using secondary sources and verified through primary sources.

- All possible parameters that affect the markets covered in this research study were accounted for, viewed in extensive detail, verified through primary research, and analyzed to obtain the final quantitative and qualitative data.

- The research included studying reports, reviews, and newsletters of top market players and extensive interviews with leaders such as directors and marketing executives to obtain opinions.

The following figure illustrates the overall market size estimation process employed for this study.

Data Triangulation

After arriving at the overall size of the medical polymer market from the estimation process explained above, the total market was split into several segments and subsegments. The data triangulation and market breakdown procedures were employed, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics for all segments and subsegments. The data was triangulated by studying various factors and trends from both the demand and supply sides. Along with this, the market size was validated using both the top-down and bottom-up approaches.

Market Definition

The medical polymer market represents the industry that develops and implements polymer materials intended for medical and healthcare purposes. In the medical sector, these polymers must adhere to strict specifications related to biocompatibility, durability, elasticity, and sterilization or aseptic requirements. Various medical products, like surgical instruments, implants, diagnostic devices, drug delivery systems, and disposables including syringes and gloves use medical polymers. The market includes many different types of polymers such as medical plastics, elastomer polymers, and biodegradable polymers. The medical polymer market is an important institutional component in the advancement of modern healthcare to enable affordable, safe, efficient medical solutions.

Stakeholders

- Medical Polymer Manufacturers

- Raw Material Suppliers

- Regulatory Bodies and Government Agencies

- Distributors and Suppliers

- End-use Industries

- Associations and Industrial Bodies

- Market Research and Consulting Firms

Report Objectives

- To define, describe, and forecast the size of the medical polymer market in terms of value and volume

- To provide detailed information regarding the key factors influencing the growth of the market (drivers, restraints, opportunities, and challenges)

- To forecast the market size based on type, application, manufacturing technology, and region

- To forecast the market size for the five main regions—North America, Europe, Asia Pacific (APAC), South America, and the Middle East & Africa (MEA),—along with their key countries

- To strategically analyze micromarkets with respect to individual growth trends, prospects, and contributions to the total market

- To analyze the opportunities in the market for stakeholders and provide details of the competitive landscape for the market leaders

- To strategically profile leading players and comprehensively analyze their key developments, such as product launches, expansions, and deals in the medical polymer market

- To strategically profile key players and comprehensively analyze their market shares and core competencies

- To study the impact of AI/Gen AI on the market under study, along with the macroeconomic outlook

Key Questions Addressed by the Report

Which factors are propelling the growth of the medical polymer market?

Increasing demand for minimally invasive surgical procedures, technological advancements in medical devices, the rise in chronic diseases, and the expanding geriatric population requiring healthcare are the primary factors propelling the growth of the medical polymer market.

Which are the key applications driving the medical polymer market?

The key applications driving demand include medical disposables, prosthetics, medical instruments and devices, and others.

Who are the major manufacturers?

Major manufacturers include BASF SE (Germany), SABIC (Saudi Arabia), Covestro AG (Germany), Celanese Corporation (US), and Evonik Industries (Germany).

What will be the growth prospects of the medical polymer market?

The market is expected to witness robust growth due to rising global healthcare needs, advancements in polymer technology, increasing demand for biocompatible materials, and expanding applications such as drug delivery systems and implants.

What will be the growth prospects of the medical polymer market in terms of CAGR in the next five years?

The CAGR of the medical polymer market is expected to be between 8–9% over the next five years.

Need a Tailored Report?

Customize this report to your needs

Get 10% FREE Customization

Customize This ReportPersonalize This Research

- Triangulate with your Own Data

- Get Data as per your Format and Definition

- Gain a Deeper Dive on a Specific Application, Geography, Customer or Competitor

- Any level of Personalization

Let Us Help You

- What are the Known and Unknown Adjacencies Impacting the Medical Polymer Market

- What will your New Revenue Sources be?

- Who will be your Top Customer; what will make them switch?

- Defend your Market Share or Win Competitors

- Get a Scorecard for Target Partners

Custom Market Research Services

We Will Customise The Research For You, In Case The Report Listed Above Does Not Meet With Your Requirements

Get 10% Free Customisation

Growth opportunities and latent adjacency in Medical Polymer Market