North America Copper Tubes Market

North America Copper Tubes Market by Type (Type K, Type L, Type M), Form (Straight Tubes, Coils, Capillary Tubes), Application (HVACR, Plumbing, Industrial, Automotive, Medical) - Global Forecast to 2030

OVERVIEW

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

The North America Copper Tubes market is projected to reach USD 3.44 billion by 2030, at a CAGR of 4.0% from USD 2.83 billion in 2025. The demand for North American copper tubes is mainly driven by factors such as the rising construction and development of infrastructure, increasing emphasis on energy-efficient systems, and increased awareness of sustainability. Copper tubes are extensively applied in numerous fields like HVACR, plumbing, medical, and automotive industries. As companies increasingly prioritize minimizing environmental footprint, copper's recyclability and capacity to enable energy-efficient systems further drive demand. Additionally, the need for high-quality materials in producing critical infrastructure and products continues to increase, especially in light of technological advancements and increasing consumer expectations.

KEY TAKEAWAYS

-

BY TYPEThe North America copper tubes market is segmented into Type K, Type L, Type M, and Other types. Type K tubes are used in underground water lines, HVACR systems, and industrial pipelines where higher pressure capacity is required. Type L tubes are commonly applied in residential and commercial plumbing systems, while Type M tubes are suitable for low-pressure installations.

-

BY FORMBased on form, the market is segmented into Straight Tubes, Coils, Capillary Tubes, and Other forms. Straight tubes dominate the regional market due to their extensive application in HVACR and plumbing installations, where ease of assembly and mechanical strength are critical. Coils are preferred in refrigeration and air-conditioning systems that require flexible connections with minimal joints. Capillary tubes find use in precision fluid control for medical and refrigeration systems.

-

BY APPLICATIONMajor applications include HVACR, Plumbing, Industrial, Automotive, Medical, and Other applications. Copper tubes are essential in HVACR systems for heat exchange and refrigerant circulation. In plumbing, they ensure safe water transport and corrosion resistance. Industrial applications include process piping, heat exchangers, and chemical handling. In the automotive and medical sectors, copper tubes are used for fuel lines, braking systems, and gas distribution in healthcare facilities.

-

BY REGIONThe North America market includes the United States, Canada, and Mexico. The United States has strong demand across construction, HVACR, and industrial sectors. Canada utilizes copper tubes in residential plumbing and infrastructure modernization projects. Mexico’s manufacturing and automotive sectors contribute significantly to regional copper tube consumption.

-

COMPETITIVE LANDSCAPEThe major market players have adopted both organic and inorganic strategies, including acquisitions, capacity expansions, and partnerships to strengthen their market position and enhance product portfolios. For instance, Mueller Industries acquired Elkhart Products Corporation (EPC), a U.S.-based manufacturer of copper solder fittings with facilities in Elkhart, Indiana, and Fayetteville, Arkansas.

Technological developments, regulatory requirements, industrial growth, and changing customer expectations are propelling the North American demand for copper tubes. Continuous material science innovations further improve the performance of copper tubes, making them indispensable for use in plumbing, HVAC, and refrigeration applications where durability and thermal conductivity are essential. Industry standards and regulations compel manufacturers to turn to copper tubes that are safe, efficient, and environmentally compliant, especially with increasing pressures related to sustainable construction. The growth of manufacturing, automotive, and electrical industries strengthens the demand for copper tubes that can sustain tough environments and deliver high-performance.

TRENDS & DISRUPTIONS IMPACTING CUSTOMERS' CUSTOMERS

The impact on end users’ business in the North America copper tubes market arises from evolving customer trends and industry disruptions. HVACR equipment manufacturers, plumbing system suppliers, and industrial component producers represent the primary clients of copper tube manufacturers, while building contractors, industrial operators, and automotive assemblers are their customers’ customers. Shifts in construction practices, energy-efficiency regulations, and sustainable material preferences influence demand across these downstream sectors. For instance, growing emphasis on green buildings, energy-efficient HVACR systems, and eco-friendly plumbing materials drives higher consumption of copper tubes due to their recyclability and performance advantages.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

MARKET DYNAMICS

Level

-

Growing need for HVAC systems in buildings

-

High recyclability of copper tubes

Level

-

Increasing dependence of US on imports creating supply risks

-

High cost and vulnerability of copper to corrosion making aluminum tubing more durable and affordable alternative

Level

-

Urban retrofitting initiatives and development of smart cities

-

Growing construction of hospitals

Level

-

Winter conditions accelerate cracking and leakage in copper tube systems

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Driver:Growing need for HVAC systems in buildings

The rising need for HVAC (Heating, Ventilation, and Air Conditioning) systems in North American buildings is a prime driver of the regional copper tube market growth. This growth is mainly spurred by continuous urbanization, growing population, and a consistent increase in residential, commercial, and industrial building construction activities. With energy efficiency and indoor air quality becoming the core focus of new building design, the HVAC systems are taking priority in new and retrofit construction. In such systems, copper tubes provide the essential requirements with their outstanding thermal conductivity, resistance to corrosion, longevity, and fabrication convenience, which make them the preferred material for refrigerant and fluid transport applications.The rising need for HVAC (Heating, Ventilation, and Air Conditioning) systems in North American buildings is a prime driver of the regional copper tube market growth. This growth is mainly spurred by continuous urbanization, growing population, and a consistent increase in residential, commercial, and industrial building construction activities. With energy efficiency and indoor air quality becoming the core focus of new building design, the HVAC systems are taking priority in new and retrofit construction. In such systems, copper tubes provide the essential requirements with their outstanding thermal conductivity, resistance to corrosion, longevity, and fabrication convenience, which make them the preferred material for refrigerant and fluid transport applications.

Restraint: Increasing dependence of US on imports creating supply risks

Growing American reliance on overseas nations for mined, smelted, and refined copper is generating significant supply risks that are restraining the demand for North American copper tubing. Since there is limited domestic mining and refining capacity, the producers of copper tubes are completely dependent on copper imports to service their production requirement. This reliance exposes the supply chain to global market fluctuations, geopolitical instability, and shifts in trade policies, which translate to delayed shipments and irregular supply of raw materials. This unreliability in supply causes slowdowns in production and cost uncertainties for copper tube producers. Periodic variations in copper availability and pricing compel businesses to take a guarded strategy in operations, tending to restrict volumes of production and postpone project timing.

Opportunity: Urban retrofitting initiatives and development of smart cities

Urban retrofitting efforts and smart city development in North America offer a tremendous opportunity for the copper tube market. With cities upgrading infrastructure to be energy-efficient, sustainable, and connected, demand is increasing for reliable, long-lasting, and efficient materials such as copper. Copper tubes are essential in plumbing and HVAC systems which are at the heart of smart city infrastructure. Most older structures and cities need new water distribution and heating systems, where copper's corrosion resistance, durability, and antimicrobial properties make it a first choice. Moreover, smart city initiatives tend to focus on integrating advanced energy systems, such as solar thermal technologies and high-efficiency heating and cooling, where copper tubing is crucial for heat exchange and fluid transport. The drive for efficiency and lower emissions also favors replacing older materials with copper, which increases system performance while satisfying green building requirements.

Challenge: Winter conditions accelerate cracking and leakage in copper tube systems

Winter conditions in North America pose a considerable challenge to copper tube systems, largely because of the radical changes in temperature and the high frequency of sub-zero conditions. As temperatures decrease, water in copper tubes will freeze and expand. Expansion causes tremendous internal pressure within the pipe walls that can crack or burst, particularly in older or poorly insulated tubing systems. Although copper resists thermal fluctuations fairly well as compared to most materials, if freezing and thawing cycles recur repeatedly, this will eventually damage the metal with time, exposing it to greater risks of leaks. Moreover, connections and seams in copper tubing are particularly sensitive in cold climates because thermal shrinking will loosen and weaken them. This is especially problematic in areas with severe winters, like Canada and the northern United States.

North America Copper Tubes Market: COMMERCIAL USE CASES ACROSS INDUSTRIES

| COMPANY | USE CASE DESCRIPTION | BENEFITS |

|---|---|---|

|

Supplies copper tubes for HVACR systems in commercial and residential buildings, ensuring reliable thermal performance and efficient heat transfer. | Provides superior thermal conductivity, enhances energy efficiency, extends service life, and reduces operational maintenance costs over time. |

|

Provides copper tubes for plumbing and water supply systems in residential, commercial, and industrial applications. | Offers excellent corrosion resistance, ensures reliable water flow, minimizes maintenance requirements, and maintains long-term structural integrity. |

|

Delivers copper tubes for automotive heat exchangers, refrigeration, and fluid transfer systems across multiple industrial sectors. | Ensures high durability, provides efficient thermal performance, optimizes fluid transfer, and supports long-term operational reliability under varying conditions. |

|

Manufactures copper tubes for medical, pharmaceutical, and industrial fluid handling systems requiring high precision and cleanliness. | Offers biocompatibility, chemical resistance, dimensional accuracy, consistent performance, and compliance with industry safety and quality standards. |

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET ECOSYSTEM

The North America copper tubes ecosystem comprises interconnected relationships among raw material suppliers, tube manufacturers, distributors, contractors, and end users. Raw material suppliers provide refined copper cathodes and billets to manufacturers, ensuring consistent metal quality and purity. Manufacturers use processes such as casting, extrusion, and drawing to produce copper tubes in various grades and specifications. Distributors and wholesalers connect manufacturers with downstream industries by maintaining inventories across regions and ensuring timely delivery to contractors and equipment makers. Contractors and system integrators use these tubes in HVACR, plumbing, industrial, and automotive systems. End users such as building owners, industrial operators, and equipment producers benefit from copper’s strength, corrosion resistance, and heat transfer efficiency. Together, this interconnected network ensures stable supply, efficient operations, and long service life across the construction and manufacturing sectors in North America.

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET SEGMENTS

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

North America Copper Tubes Market, By Type

Type K copper tubes are the largest segment in the North American market primarily because they are more durable, versatile, and adaptable to most rigorous applications. Type K has the highest thickness among all the prevalent types of copper tubes and is therefore best suited for high-pressure systems, buried water service, and severe industrial applications. As water system upgrades become increasingly important to cities and as infrastructure in North America continues to age, Type K's long lifespan and reliability have made the product the go-to option for contractors and municipalities alike. Further driving the need for high-quality, durable materials such as Type K copper are increasing green building efforts and stringent building codes. Its superior corrosion resistance also has a major role to play, especially in areas with hostile soil or water conditions. Additionally, the revival of construction activity in residential and commercial sectors is boosting the demand for long-lasting plumbing and HVAC systems, where Type K's high strength and pressure resistance provide major benefits. Increasing investments in medical facilities and mass infrastructure projects also are driving demand, since Type K is typically specified for medical gas piping and other critical systems. In addition, while Type K is generally more costly than other types such as Type L or M, customers increasingly are willing to trade off initial price for long-term value and performance.

North America Copper Tubes Market, By Form

Straight copper tubes represent the North American copper tubes market's largest form segment, whose performance, adaptability, and adherence to modern construction trends drive the demand. Straight copper tubes ensure accuracy in size, stiffness, and ease of handling, which are essential for applications that require exact installations such as plumbing, HVAC, refrigeration units, fire systems, and health care gas pipe systems. Their straight form makes them eliminate in-site straightening and uncoiling requirements, saving on on-site labor costs, time spent on installations, and the potential for errors or material wastage. It is very advantageous in mass projects in commercial and industrial fields where building schedules are limited, and quality requirements for reliable installation are crucial.

North America Copper Tubes Market, By Applicatin

The HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) market is the largest application in the North America copper tubes industry based on a number of factors. First is that there is an increasing need for energy-efficient systems because both consumers and businesses seek to reduce energy costs and comply with stringent environmental regulations. Copper tube are preferred within HVACR installations due to their high thermal conductance and longevity, due to which they are best for heat transfer with high efficiency. Second, continuous urbanization coupled with new development projects of both residential and commercial nature in the U.S., Canada, and Mexico is making modern HVACR installations a prerequisite.

REGION

Mexico to be fastest-growing country in North America Copper Tubes market during forecast period

Mexico is the fastest-growing country in the North American copper tubes market due to a combination of strong industrial growth, infrastructure development, and strategic proximity to the United States. The country has seen significant expansion in residential, commercial, and industrial construction, driving demand for copper tubes in plumbing, HVACR, and refrigeration systems. Additionally, Mexico’s growing automotive and manufacturing sectors rely heavily on copper tubes for heat exchangers, fluid transfer, and cooling applications. Favorable trade agreements, such as USMCA, and increasing foreign direct investment are supporting production scale-up and export opportunities. Low manufacturing costs, skilled labor availability, and supportive government policies further enhance competitiveness. These factors collectively make Mexico a key growth hub for copper tube production and consumption in North America.

North America Copper Tubes Market: COMPANY EVALUATION MATRIX

Mueller Industries (Star) leads with a strong market share and extensive product footprint, driven by its established manufacturing scale, broad distribution network, and consistent product quality. Cambridge-Lee Industries LLC (Emerging Leader) is gaining visibility with its specialized copper tube solutions and innovative offerings, strengthening its position through targeted product development and niche market focus. While Mueller Industries dominates through scale, brand recognition, and a diversified portfolio, Cambridge-Lee Industries shows significant potential to move toward the leaders’ quadrant as demand for high-performance and reliable copper tubes continues to grow.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

KEY MARKET PLAYERS

MARKET SCOPE

| REPORT METRIC | DETAILS |

|---|---|

| Market Size in 2024 (Value) | USD 3.18 Billion |

| Market Forecast in 2030 (Value) | USD 3.44 Billion |

| Growth Rate | CAGR of 4.0% from 2025-2030 |

| Years Considered | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million/Billion), Volume (Kiloton) |

| Report Coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments Covered |

|

| Regions Covered | North America |

WHAT IS IN IT FOR YOU: North America Copper Tubes Market REPORT CONTENT GUIDE

DELIVERED CUSTOMIZATIONS

We have successfully delivered the following deep-dive customizations:

| CLIENT REQUEST | CUSTOMIZATION DELIVERED | VALUE ADDS |

|---|---|---|

| Country-Level Breakdown | Instead of only providing North America as a single region, the report includes country-specific market data for the United States, Canada, and Mexico. This covers demand trends in HVACR, plumbing, industrial, automotive, and medical applications, along with regulatory standards for copper tubing installation and usage. | Helps companies identify high-growth national markets and plan market entry strategies with greater accuracy. |

| Type-Specific Deep Dive | A detailed analysis of copper tubes by type—Type K, Type L, Type M, and Others. Includes insights on wall thickness, pressure ratings, material properties, and performance requirements for each type, along with adoption trends across HVACR, Plumbing, Industrial, Automotive, and Medical applications. | Enables clients to focus on high-potential tube types and tailor copper tube solutions to meet specific operational, regulatory, and performance requirements. |

| Form Comparison | A comprehensive evaluation of copper tubes by form including Straight Tubes, Coils, Capillary Tubes, and Others. Covers differences in installation methods, flexibility, pressure handling, and suitability for various applications. | Assists manufacturers and distributors in selecting appropriate tube forms for projects or end-user requirements while improving installation efficiency and operational reliability. |

| Competitive Benchmarking | Detailed profiling of North American manufacturers and distributors such as Mueller Industries, Cerro Flow Products, Wieland North America, Cambridge-Lee Industries, and Hailiang USA. Covers market positioning, product offerings, capacity expansions, acquisitions, and strategic partnerships. | Provides a clear view of the competitive landscape and helps clients identify potential collaborators, acquisition targets, or competitive threats while planning market strategy and production investments. |

RECENT DEVELOPMENTS

- August 2024 : Mueller Industries acquired Elkhart Products Corporation (EPC), a US-based manufacturer of copper solder fittings, with manufacturing facilities in Elkhart, Indiana, and Fayetteville, Arkansas. EPC was previously a subsidiary of Dutch company Aalberts N.V., and its integration enhances Mueller’s ability to serve diverse industries such as plumbing, HVACR, automotive, and aerospace.

- July 2023 : Wieland Group acquired Farmers Copper Ltd., a leading supplier of copper, brass, and bronze alloys in North America, further strengthening its footprint in the region. Farmers Copper has two sites in Texas, with headquarters in Texas City and another facility in San Antonio. With the acquisition of Farmers Copper Ltd., the company further strengthens Wieland’s large footprint and broad market participation in North America.

- March 2023 : Wieland officially launched Cuprolife, a new copper tube made from 100% recycled copper, marking a significant step toward sustainable and circular construction. With cuprolife, Wieland advances building technology by integrating fully recycled materials without compromising performance or quality. The method for calculating the 100% recycled content has been independently verified by TÜV SÜD, reinforcing the credibility of this innovation.

- January 2023 : Wieland Group acquired Small Tube Products, a key producer of small-diameter and thin-wall specialty tubing made from copper, copper alloys, and aluminum. This acquisition enhances Wieland's product portfolio by introducing capillary tubes and expanding its manufacturing capabilities while strengthening its market presence in North America.

- August 2020 : Mueller Industries acquired Kessler Sales and Distribution Business from Wieland-Kessler LLC for USD 57.2 million. The acquisition encompassed Kessler's distribution operations, inventory, manufacturing equipment, and related assets. Kessler Sales and Distribution is vertically integrated with Mueller Streamline and Howell Metals to provide customers with US-produced copper tubes. This strategic move strengthens Mueller Industries' position in the copper tubes market while enhancing its supply chain capabilities and manufacturing footprint.

Table of Contents

Methodology

The study involved four major activities in estimating the market size of the North American copper tubes market. Exhaustive secondary research was done to collect information on the market, the peer market, and the parent market. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain through primary research. Both top-down and bottom-up approaches were employed to estimate the complete market size. Thereafter, the market breakdown and data triangulation procedures were used to estimate the market size of the segments and subsegments.

Secondary Research

In the secondary research process, various secondary sources were referred to identify and collect information for this study. These secondary sources include annual reports, press releases, investor presentations of companies, white papers, certified publications, trade directories, certified publications, articles from recognized authors, gold standard and silver standard websites, and databases.

Secondary research has been used to obtain key information about the value chain of the industry, the monetary chain of the market, the total pool of key players, market classification, and segmentation according to industry trends to the bottom-most level and regional markets. It was also used to obtain information about the key developments from a market-oriented perspective.

Primary Research

The North American copper tubes market comprises several stakeholders in the value chain, which include raw material suppliers, manufacturers, and end users. Various primary sources from the supply and demand sides of the North American copper tubes market have been interviewed to obtain qualitative and quantitative information. The primary interviewees from the demand side include key opinion leaders in end-use sectors. The primary sources from the supply side include manufacturers, associations, and institutes involved in the North American copper tubes industry.

Primary interviews were conducted to gather insights such as market statistics, data on revenue collected from the products and services, market breakdowns, market size estimations, market forecasting, and data triangulation. Primary research also helped in understanding the various trends related to the types, forms, and applications. Stakeholders from the demand side, such as CIOs, CTOs, and CSOs, were interviewed to understand the buyer’s perspective on the suppliers, products, component providers, and their current usage of copper tubes and the future outlook of their business, which will affect the overall market.

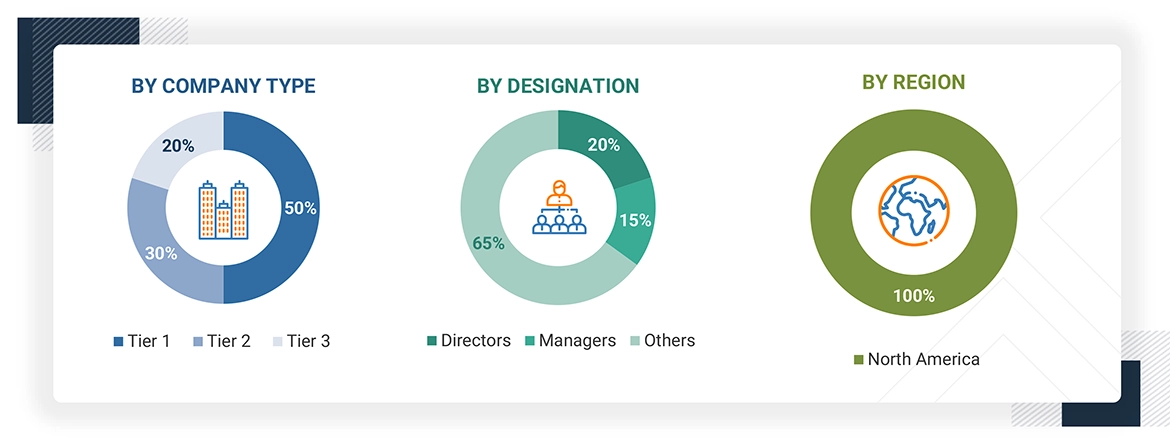

The breakdown of profiles of the primary interviewees is illustrated in the figure below:

Note: Tier 1, Tier 2, and Tier 3 companies are classified based on their market revenue in 2024, available in the public domain, product portfolios, and geographical presence.

Other designations include sales representatives, production heads, and technicians.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

The top-down approach was used to estimate and validate the size of various submarkets for the North American copper tubes market. The research methodology used to estimate the market size included the following steps:

- The key players in the industry have been identified through extensive secondary research.

- The industry’s supply chain has been determined through primary and secondary research.

- All percentage shares, splits, and breakdowns based on type, form, application, and country were determined using secondary sources and verified through primary sources.

- All possible parameters that affect the markets covered in this research study were accounted for, viewed in extensive detail, verified through primary research, and analyzed to get the final quantitative and qualitative data. This data was consolidated and added with detailed inputs and analysis and presented in this report.

Data Triangulation

After arriving at the total market size from the estimation process above, the overall market has been split into several segments and subsegments. To complete the overall market engineering process and arrive at the exact statistics for all the segments and subsegments, data triangulation and market breakdown procedures have been employed, wherever applicable. The data has been triangulated by studying various factors and trends from both the demand and supply sides. Along with this, the market size has been validated by using both the top-down and bottom-up approaches and primary interviews. Hence, for every data segment, there are three sources: the top-down approach, the bottom-up approach, and expert interviews. The data was assumed correct when the values arrived from the three sources matched.

Market Definition

The copper tubes industry is the sector dedicated to the production, distribution, and consumption of copper tubes, which are vital cylindrical commodities of refined copper, valued due to their excellent thermal conductivity, corrosion resistance, strength, and recyclability. Copper tubes are produced by a variety of precise processes, including extrusion, drawing, and annealing, and are often complemented with frontier technologies like inner grooving and microfin geometries to optimize the efficiency of heat transfer, particularly for compact and high-performance applications. Copper tubes find vital applications in a wide range of industries, such as HVACR equipment, plumbing, healthcare facilities, automotive thermal management systems, and industrial processes, where guaranteed thermal performance and extended material life are essential. The growth of the North American copper tubes market is mainly fueled by the increasing demand for energy-efficient HVACR systems inspired by urbanization, smart building trends, and climate-influenced energy legislation. Copper’s inherent antimicrobial properties, along with its long-term lifecycle advantages, also contribute to its increased uptake in safety-critical and green-certified applications. Meanwhile, the market presents several opportunities, especially in smart city buildings, retrofit of mature infrastructure, and electric and hybrid car growth, where copper tubing is essential in cooling batteries and managing heat. Improvements in high-efficiency copper tubing in smaller diameters and government support-based incentives for expanding local manufacturing value chains generate further impetus to the sector.

Stakeholders

- Copper Tube Manufacturers

- Copper Tube Traders, Distributors, and Suppliers

- Raw Material Suppliers

- Government and Private Research Organizations

- Associations and Industrial Bodies

- R&D Institutes

- Environmental Support Agencies

Report Objectives

- To define, describe, and forecast the size of the North American copper tubes market in terms of value and volume

- To provide detailed information regarding the major factors (drivers, opportunities, restraints, and challenges) influencing the market growth

- To estimate and forecast the market size based on type, form, application, and country

- To forecast the size of the market with respect to North America along with the key countries in the region

- To strategically analyze micromarkets with respect to individual growth trends, prospects, and their contribution to the overall market

- To analyze opportunities in the market for stakeholders and provide a competitive landscape of market leaders

- To track and analyze recent developments such as product launches, acquisitions, and investments in the market

- To strategically profile the key market players and comprehensively analyze their core competencies

Key Questions Addressed by the Report

Need a Tailored Report?

Customize this report to your needs

Get 10% FREE Customization

Customize This ReportPersonalize This Research

- Triangulate with your Own Data

- Get Data as per your Format and Definition

- Gain a Deeper Dive on a Specific Application, Geography, Customer or Competitor

- Any level of Personalization

Let Us Help You

- What are the Known and Unknown Adjacencies Impacting the North America Copper Tubes Market

- What will your New Revenue Sources be?

- Who will be your Top Customer; what will make them switch?

- Defend your Market Share or Win Competitors

- Get a Scorecard for Target Partners

Custom Market Research Services

We Will Customise The Research For You, In Case The Report Listed Above Does Not Meet With Your Requirements

Get 10% Free Customisation

Growth opportunities and latent adjacency in North America Copper Tubes Market