Europe Carbon Fiber Market

Europe Carbon Fiber Market by Raw Material Type (Pan, Pitch), Fiber Type (Virgin, Recycled), Modulus (Standard, Intermediate, High), Product Type (Continuous, Long, Short), Application (Composites, Non-Composites), End-use Industry (Aerospace & Defense, Automotive, Wind Energy, Pipe, Pressure Vessels, Sporting Goods, Construction & Infrastructure, Medical & Healthcare, and Marine), By Region - Forecast to 2030

OVERVIEW

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

The Europe carbon fiber market is projected to reach USD 2.69 billion by 2030 from USD 1.91 billion in 2025, at a CAGR of 7.0% from 2025 to 2030. The market is mainly driven by the increasing demand for lightweight materials in high-performance applications, advancements in manufacturing processes, and growing investments in infrastructural projects. The growing adoption of lightweight and high-performance materials is driving the use of carbon fiber in various end-use industries to improve efficiency, performance, and durability.

KEY TAKEAWAYS

-

By CountryGermany dominated the carbon fiber market in Europe with a share of 32.0%, in terms of value, in 2024.

-

By Product TypeThe continuous fiber segment is projected to witness the highest CAGR of 7.1% during the forecast period.

-

By Raw MaterialThe PAN-based carbon fiber segment is projected to register the highest CAGR of 7.1% during the forecast period, in terms of value.

-

By ModulusThe standard modulus segment is estimated to dominate the Europe carbon fiber market during the forecast period.

-

By ApplicationThe composites segment is estimated to dominate the Europe carbon fiber market during the forecast period.

-

By End-use IndustryThe pressure vessels segment is projected to be the fastest-growing end-use industry in the Europe carbon fiber market during the forecast period.

-

Competitive Landscape - Key PlayersToray Industries, Inc., Teijin Limited, Hexcel Corporation, Solvay, and SGL Carbon were identified as star players in the Europe carbon fiber market, based on their broad industry coverage and strong operational and financial strength.

-

Competitive Landscape - StartupsUmatex Group and Bcircular have distinguished themselves among startups and SMEs in the Europe carbon fiber market due to their well-developed marketing channels and extensive funding to build their service portfolios.

The Europe carbon fiber market is projected to grow rapidly over the next decade, supported by rapid industrialization, technological advancements, and increasing focus on energy efficiency, especially in developing countries. Growing demand from end-use industries, such as aerospace & defense, automotive, sporting goods, and wind energy, is driving the carbon fiber market.

TRENDS & DISRUPTIONS IMPACTING CUSTOMERS' CUSTOMERS

Changes in customer trends or disruptions affect consumers' businesses. These shifts influence the revenues of end users. As a result, the revenue changes for end users are likely to impact the revenues of carbon fiber suppliers, which, in turn, affect the revenues of carbon fiber manufacturers.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

MARKET DYNAMICS

Level

-

High demand from aerospace & defense industry

-

Stringent eco-friendly regulations to drive adoption of carbon fiber and related composites in automotive applications

Level

-

High cost of carbon fiber

-

Lack of standardization in manufacturing technologies

Level

-

Increased investments for development of low-cost coal-based carbon fibers

-

Increased demand for fuel cell electric vehicles (FCEVs)

Level

-

Production of low-cost carbon fiber

-

Capital-intensive production and complex manufacturing process

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Driver: High demand from aerospace & defense industry

Carbon fibers are unique materials that can be easily molded in any required shape. One of the greatest advantages of carbon fiber for aerospace applications is its lightweight nature. Carbon fiber has become a highly sought-after material in the aerospace industry due to its exceptional properties. One of the key benefits of carbon fiber is its high strength-to-weight ratio, which makes it a lightweight alternative to traditional materials such as aluminum, steel, and titanium. This property is crucial in aerospace applications where weight reduction is critical for improving fuel efficiency and reducing emissions.

Restraint: High cost of carbon fiber

In the automotive industry, carbon fiber is currently used only in racing cars and some high-end sports cars, as the cost of carbon fiber at present is about USD 10 to USD 20/lb. If the cost of carbon fiber decreases to about USD 5 to USD 7/lb., it is expected to be used on a much larger scale in automobiles. The usage of carbon fiber composite structural parts is expected to increase significantly, provided the cost is reduced. The Oak Ridge National Laboratory (ORNL), located in the US, is working aggressively to develop low-cost carbon fiber (LCCF) technologies. The price for aerospace-grade carbon fiber currently ranges from USD 80 to USD 120/lb. In other applications such as industrial, sports goods, and wind energy, the price ranges from USD 10 to USD 20/lb. Many new applications of carbon fiber-based composites have been added, though they are not yet commercially feasible as they are expensive.

Opportunity: Increased investments for development of low-cost coal-based carbon fibers

Owing to the cost benefits, researchers are harnessing carbon in coal to create products such as carbon fiber and graphene. The price of carbon fiber lowers significantly when coal is used as feedstock. For instance, coal costs approximately USD 12/ton. On the other hand, an equivalent amount of petroleum (7 or 8 barrels) costs approximately USD 60/barrel. This means using coal as a precursor would be 30 or 35 times less expensive. Thus, to achieve cost benefits, companies and governments are investing in producing coal-based carbon fiber. Ramaco Carbon is presently exploring various possibilities for using repurposed coal to make carbon fiber and use it in the automotive industry. To achieve this, Ramaco has established a carbon ecosystem and collaborated with the Wyoming Western Research Institute under the DOE project called Coal to Cars. The project has received funding of USD 5 million and focuses on using coal-based carbon fiber to decrease vehicle manufacturing costs.

Challenge: Production of low-cost carbon fiber

The high cost of PAN and pitch carbon fibers is one of the major concerns associated with its growth. Carbon fiber still has low usage in large applications due to its high cost. Developing low-cost technologies is a major challenge for researchers and key manufacturers. In the automotive industry, carbon fiber composites are only introduced in high-end and luxury cars due to their high cost. With the increased availability of low-cost carbon fiber, there is expected to be a surge in its usage within the automotive industry.

Europe Carbon Fiber Market: COMMERCIAL USE CASES ACROSS INDUSTRIES

| COMPANY | USE CASE DESCRIPTION | BENEFITS |

|---|---|---|

|

Develops robotic automation solutions for carbon fiber preforming and filament winding of complex CFRP parts | Increases throughput, lowers labor intensity, and enables cost-efficient production of lightweight CFRP structures |

|

Uses automated pultrusion lines to manufacture carbon and glass fiber reinforced polymer structural profiles | Delivers consistent quality, reduces material waste, and supports lower-carbon construction solutions |

|

Implement automated layup and preforming systems for carbon fiber aircraft components such as skins and stiffeners | Improves material deposition rates, cuts manufacturing cost per part, and enhances repeatability for safety-critical components |

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET ECOSYSTEM

The carbon fiber ecosystem involves identifying and analyzing interconnected relationships among various stakeholders, including raw material suppliers, manufacturers, distributors, contractors, and end users. The raw material suppliers are the source of raw materials like PAN and Pitch for the carbon fiber manufacturers. The manufacturers use technologies such as spinning, stabilization, carbonization, graphitization, surface treatment, and sizing to produce carbon fiber. The distributors and suppliers are the ones who establish contact between the manufacturing companies and end users to concentrate the supply chain, increasing operational efficiency and profitability.

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET SEGMENTS

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Europe Carbon Fiber Market, By Raw Material

PAN-based carbon fiber will account for the largest market share in 2030, as it offers a higher carbon yield and better mechanical properties than pitch-based carbon fiber. PAN-based carbon fibers are stronger, stiffer, and more durable, which makes them an ideal choice for a wide range of applications in aerospace & defense, wind energy, automotive, pressure vessels, and sporting goods industries.

Europe Carbon Fiber Market, By Fiber Type

In the Europe carbon fiber market, the recycled carbon fiber segment is expected to register the highest CAGR due to growing sustainability goals and stricter environmental regulations, which push industries to reduce waste and carbon emissions. It offers a cost-effective alternative to virgin carbon fiber, making it attractive for automotive, aerospace & defense, wind energy, and sporting goods manufacturers. Advancements in recycling technologies have improved the quality and consistency of recycled carbon fiber, expanding its applications. Additionally, companies are seeking lightweight, high-performance materials to enhance fuel efficiency and product durability.

Europe Carbon Fiber Market, By Modulus

Intermediate modulus carbon fiber accounted for the second-largest market share as it offers a balance between strength and stiffness, making it ideal for high-performance applications. It has a higher tensile modulus than standard modulus carbon fiber (typically around 42–49 million psi) but is more flexible than high-modulus fibers. Intermediate modulus carbon fiber provides improved strength-to-weight ratio and durability, making it popular in aerospace & defense, automotive, and sporting goods industries. It is commonly used in aircraft structures, high-end bicycles, and performance sports equipment where both strength and flexibility are needed.

Europe Carbon Fiber Market, By Product Type

Based on product type, the short carbon fiber segment is expected to register the second-highest CAGR due to its cost-effectiveness, versatility, and ability to enhance material properties in various industries. It is widely used in injection molding and 3D printing, allowing for the mass production of lightweight, high-strength components in automotive, aerospace, and consumer goods. Short carbon fiber improves mechanical strength, thermal conductivity, and wear resistance when blended with plastics, making it an attractive alternative to metals. Additionally, its ease of processing and recyclability align with sustainability goals, further driving its adoption. As industries seek stronger, lighter, and more affordable materials, the demand for short carbon fiber continues to rise.

Europe Carbon Fiber Market, By Application

Composites accounted for the largest market share due to their exceptional strength-to-weight ratio, making them ideal for industries requiring lightweight yet durable materials. In aerospace and automotive sectors, carbon fiber composites enhance fuel efficiency and performance by reducing overall weight. Its high stiffness, corrosion resistance, and thermal stability make it valuable in sporting goods, wind energy, and industrial applications. Additionally, advancements in manufacturing processes have made carbon fiber composites more cost-effective and accessible. As industries continue to prioritize sustainability and performance, carbon fiber remains a key material for next-generation composite structures.

Europe Carbon Fiber Market, By End-use Industry

The pressure vessels segment is projected to register the highest CAGR in the carbon fiber market during the forecast period. This can be attributed to the increasing demand for renewable sources like hydrogen and natural gas, which require advanced pressure vessels for storage and transportation. Carbon fiber composite pressure vessels are essential for handling and storing high-pressure gases safely when low weight is a priority, making them crucial for hydrogen fuel systems and carbon, capture, and storage (CCS).

REGION

Germany to be fastest-growing region in Europe carbon fiber market during forecast period

Germany dominated the Europe carbon fiber market due to its devotion to sustainability and decarbonization and the rising shift towards the adoption of electric vehicles. The demand for carbon fiber is driven by the need for lightweight, durable, and high-performance materials. In the automotive sector, manufacturers are increasingly using carbon fiber to reduce vehicle weight, thereby improving fuel efficienct and lowering CO2 emissions to comply with strict EU regulations. Similarly, the aerospace industry relies on carbon fiber composites to manufacture lighter aircraft, which helps reduce fuel consumption and operating costs. Companies like Airbus integrate these materials extensively to meet sustainability targets and enhance aircraft performance.

Europe Carbon Fiber Market: COMPANY EVALUATION MATRIX

In the carbon fiber market matrix, Toray Industries, Inc. (Star) leads with a strong market presence and wide product portfolio, driving large-scale adoption across industries like automotive and aerospace. Kureha Corporation (Emerging Leader) is gaining traction with sustainable carbon fiber solutions in pipes, automotive, pressure vessels, marine, and other applications . While Toray dominates with scale, Toray Industries, Inc. shows strong growth potential to advance toward the leaders' quadrant.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

KEY MARKET PLAYERS

- Toray Industries, Inc.

- Dowaksa

- Mitsubishi Chemical Corporation

- Solvay

- Teijin Limited

- SGL Carbon

- Hexcel Corporation

- Hyosung Advanced Materials

- Zhongfu Shenying Carbon Fiber Co., Ltd.

- Formosa Plastics Corporation

- Jiangsu Hengshen Co., Ltd.

- Jilin Chemical Fiber Group Co., Ltd.

- Anshan Senoda Carbon Fiber Co., Ltd.

- China National Bluestar (Group) Co., Ltd.

MARKET SCOPE

| REPORT METRIC | DETAILS |

|---|---|

| Market Size in 2024 (Value) | USD 1.79 Billion |

| Market Forecast in 2030 (Value) | USD 2.69 Billion |

| Growth Rate | CAGR of 7.0% from 2025 to 2030 |

| Years Considered | 2022-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (Billion), Volume (Kiloton) |

| Report Coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments Covered | By Raw Material Type (Pan, Pitch), By Fiber Type (Virgin, Recycled), By Modulus (Standard, Intermediate, High), By Product Type (Continuous, Long, Short), By Application (Composites, Non-Composites), By End-use Industry (Aerospace & Defense, Automotive, Wind Energy, Pipe, Pressure Vessels, Sporting Goods, Construction & Infrastructure, Medical & Healthcare, and Marine), By Region |

| Regions Covered | North America, Asia Pacific, Europe, South America, Middle East & Africa |

WHAT IS IN IT FOR YOU: Europe Carbon Fiber Market REPORT CONTENT GUIDE

DELIVERED CUSTOMIZATIONS

We have successfully delivered the following deep-dive customizations:

| CLIENT REQUEST | CUSTOMIZATION DELIVERED | VALUE ADDS |

|---|---|---|

| EU-based Carbon Fiber Manufacturer |

|

|

| European Carbon Fiber Composites Manufacturer |

|

|

| European Wind Blade & Hydrogen Tank OEM |

|

|

| EU-based Carbon Fiber Raw Material Supplier (PAN, Pitch, Precursors) |

|

|

RECENT DEVELOPMENTS

- April 2022 : DowAksa planned to make an investment worth USD 535 million at its Yalova site. This investment is intended to raise manufacturing capacity from 3,500 tons to 13,400 tons per annum.

- February 2021 : Teijin Limited announced its new Tenax PW (power series) and Tenax BM (beam series) brands of carbon fiber intermediate materials for sports applications. Tenax PW is an advanced aircraft-quality material that helps maximize power and speed due to its exceptional durability and toughness.

- April 2021 : Toray Industries, Inc. announced that it innovated a carbon dioxide (CO2) separation membrane with a dual all-carbon structure. This comprises a hollow fiber porous carbon fiber as a support and a thin carbon membrane separation layer on the surface. The membrane offers superb CO2 separation performance and high durability. It is more suitable than conventional inorganic separation membranes for making facilities more compact.

- July 2020 : Mitsubishi Chemical Corporation planned to acquire two companies involved in recycling carbon fiber. The companies are carboNXT GmbH, and CFK Valley Stade Recycling GmbH & Co. KG.

Table of Contents

Methodology

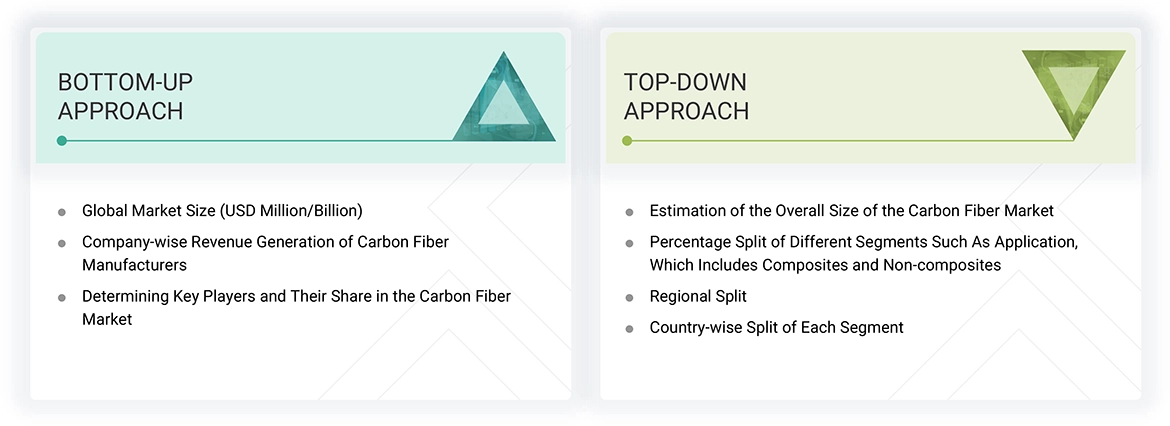

The study involves two major activities in estimating the current market size for the Europe carbon fiber market. Exhaustive secondary research was done to collect information on the market, peer market, and parent market. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain through primary research. Both top-down and bottom-up approaches were employed to estimate the complete market size. After that, market breakdown and data triangulation were used to estimate the market size of segments and subsegments.

Secondary Research

Secondary sources referred to for this research study include financial statements of companies offering carbon fiber and information from various trade, business, and professional associations. Secondary research has been used to obtain critical information about the industry’s value chain, the total pool of key players, market classification, and segmentation according to industry trends to the bottom-most level and regional markets. The secondary data was collected and analyzed to arrive at the overall size of the Europe carbon fiber market, which was validated by primary respondents.

Primary Research

Extensive primary research was conducted after obtaining information regarding the Europe carbon fiber market scenario through secondary research. Primary data was collected through questionnaires, emails, and telephonic interviews. The primary sources from the supply side included various industry experts, such as chief experience officers (CXOs), vice presidents (VPs), business development/marketing directors, product development/innovation teams, related key executives from the Europe carbon fiber industry, system integrators, component providers, distributors, and key opinion leaders. Primary interviews were conducted to gather insights such as market statistics, data on revenue collected from the products and services, market breakdowns, market size estimations, market forecasting, and data triangulation. Primary research also helped in understanding the various trends related to raw material type, fiber type, modulus, product type, application, end-use industry, and region. Stakeholders from the demand side, such as CIOs, CTOs, CSOs, and installation teams of the customers/end users who are seeking carbon fiber services, were interviewed to understand the buyer’s perspective on the suppliers, products, component providers, and their current usage of carbon fiber and future outlook of their business which will affect the overall market.

To know about the assumptions considered for the study, download the pdf brochureMarket Size Estimation

The research methodology used to estimate the size of the Europe carbon fiber market includes the following details. The market sizing was undertaken from the demand side. The market was upsized based on the demand for Europe carbon fiber in different applications at the regional level. Such procurements provide information on the demand aspects of the Europe carbon fiber industry for each application. For each application, all possible segments of the Europe carbon fiber market were integrated and mapped.

Data Triangulation

After arriving at the overall size from the market size estimation process explained above, the total market was split into several segments and subsegments. The data triangulation and market breakdown procedures explained below were implemented, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics for various market segments and subsegments. The data was triangulated by studying various factors and trends from the demand and supply sides. Along with this, the market size was validated using both the top-down and bottom-up approaches.

Market Definition

Carbon fiber is a long, thin strand of material made from carbon. It is produced by baking precursors, such as polyacrylonitrile (PAN), pitch, and rayon, in an inert atmosphere to dissociate elements other than carbon through a process called pyrolysis. Carbon fiber is lightweight and has excellent strength, low specific gravity, excellent modulus of elasticity, and high corrosion resistance. There are different types of carbon fibers, including high-strength (HS)/standard modulus, intermediate modulus, and high-modulus, each with varying mechanical properties. Carbon fibers used as composite materials are used to make aircraft & spacecraft parts, bicycle frames, pipes & tanks, wind blades, golf shafts, badminton rackets, automobile springs, sailboat masts, automotive structural parts, and various other parts where lightweight and high strength are required. Non-composite applications of carbon fiber include filtration materials, conductive electrodes in batteries and supercapacitors, heat shields, industrial brushes, and electrical components, utilizing its strength, conductivity, and heat resistance in various industries.

Stakeholders

- Europe Carbon Fiber Manufacturers

- Europe Carbon Fiber Distributors and Suppliers

- Universities, Governments, and Research Organizations

- Associations and Industrial Bodies

- R&D Institutes

- Environmental Support Agencies

- Investment Banks and Private Equity Firms

- Research and Consulting Firms

Report Objectives

- To define, describe, and forecast the Europe carbon fiber market size in terms of volume and value

- To provide detailed information regarding the key factors, such as drivers, restraints, opportunities, and challenges influencing the market growth

- To analyze and project the Europe carbon fiber market by raw material type, fiber type, modulus, product type, application, end-use industry, and region

- To strategically analyze micromarkets with respect to individual growth trends, prospects, and contributions of the submarkets to the overall market

- To analyze the market opportunities and the competitive landscape for stakeholders and market leaders

- To assess recent market developments and competitive strategies, such as agreements, contracts, acquisitions, and product developments/product launches, to draw the competitive landscape

- To strategically profile the key market players and comprehensively analyze their core competencies

Need a Tailored Report?

Customize this report to your needs

Get 10% FREE Customization

Customize This ReportPersonalize This Research

- Triangulate with your Own Data

- Get Data as per your Format and Definition

- Gain a Deeper Dive on a Specific Application, Geography, Customer or Competitor

- Any level of Personalization

Let Us Help You

- What are the Known and Unknown Adjacencies Impacting the Europe Carbon Fiber Market

- What will your New Revenue Sources be?

- Who will be your Top Customer; what will make them switch?

- Defend your Market Share or Win Competitors

- Get a Scorecard for Target Partners

Custom Market Research Services

We Will Customise The Research For You, In Case The Report Listed Above Does Not Meet With Your Requirements

Get 10% Free Customisation

Growth opportunities and latent adjacency in Europe Carbon Fiber Market