Standard Modulus Carbon Fiber Market

Standard Modulus Carbon Fiber Market Size by Product Type (Continuous, Long, Short), Application (Composites, Non-Composites), End-use Industry (Aerospace & Defense, Automotive, Wind Energy, Sporting Goods, Construction, Pipe & Tank), and Region - Forecast to 2030

OVERVIEW

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

The standard modulus carbon fiber market is projected to reach USD 4.50 billion by 2030 from USD 3.23 billion in 2025, at a CAGR of 6.9% from 2025 to 2030. The standard modulus carbon fiber market is mainly driven by the expanding use of lightweight composite materials across the aerospace, automotive, wind energy, and industrial sectors. Increasing emphasis on fuel efficiency and emission reduction is accelerating the adoption of carbon fiber in vehicle structures, while the rise of large-scale wind turbine installations is strengthening demand for high-strength yet cost-effective fiber grades.

KEY TAKEAWAYS

-

By RegionThe Asia Pacific region is expected to register the highest CAGR during the forecast period.

-

By Product TypeBy product type, continuous fiber is expected to be the largest segment in the standard modulus carbon fiber market in 2030.

-

By ApplicationBy application, the composites segment is expected to dominate the standard modulus carbon fiber market in 2030.

-

By End-Use IndustryBy end-use industry, the pipes & tanks segment is expected to be fastest-growing segment in the standard modulus carbon fiber market during the forecast period.

-

Competitive Landscape - Key PlayersToray Industries, Inc., Teijin Limited, Mitsubishi Chemical Carbon Fiber & Composites, Hexcel Corporation, and SGL Carbon SE were identified as some of the key players in the standard modulus based carbon fiber market, given their strong market share and product footprint.

-

Competitive Landscape - StartupsAla Chemistry, Procotex, and China Weihai Guangwei Composites Co., Ltd., among others, have distinguished themselves among startups and SMEs by securing strong footholds in specialized niche areas, underscoring their potential emerging market leaders.

Standard modulus carbon fiber is a high-strength, lightweight fiber characterized by a tensile modulus of approximately 230–250 GPa, making it the most commonly used grade for structural and industrial composite applications. The standard modulus carbon fiber market is witnessing robust growth, driven by the rising demand for lightweight, high-strength, and corrosion-resistant materials across multiple end-use sectors. Aerospace and defense remain major contributors, leveraging standard modulus carbon fiber for advanced fuel-efficient aircraft structures and performance-critical components. In the automotive industry, the push toward vehicle lightweighting especially to enhance fuel economy and extend electric vehicle range is accelerating the adoption of carbon fiber composites. The wind energy sector is also strengthening demand as manufacturers increasingly utilize standard modulus carbon fiber to produce longer, more durable, and higher-efficiency turbine blades. Additionally, advancements in recycling technologies, the integration of continuous fiber 3D printing, and progress toward sustainable and cost-efficient production methods are further supporting the expansion of standard modulus carbon fiber in global markets.

TRENDS & DISRUPTIONS IMPACTING CUSTOMERS' CUSTOMERS

Changes in customer trends or disruptions impact consumers’ businesses. These shifts impact the revenues of end users. Consequently, the revenue impact on end users is expected to affect the revenues of standard modulus carbon fiber suppliers, which, in turn, impacts the revenues of standard modulus carbon fiber market manufacturers.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

MARKET DYNAMICS

Level

-

Growth in manufacturing of commercial and military aircrafts

-

Increasing utilization in wind turbine fabrication

Level

-

High production cost of PAN precursor

-

Lack of standardization in manufacturing technologies

Level

-

Next-generation low-cost precursor development

-

Increasing demand in hydrogen storage vessels

Level

-

Competition from intermediate and high-modulus fibers

-

Capital-intensive production and complex manufacturing process

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Driver: Increasing utilization in wind turbine fabrication

The increasing utilization of carbon fiber in wind turbine fabrication, driven by the global shift toward large-scale renewable energy installations is a key growth driver of the standard modulus carbon fiber market. As wind turbines continue to grow in size, offshore rotor diameters now exceeding 200 meters and blade lengths surpassing 120 meters, manufacturers rely heavily on standard modulus carbon fiber for its high strength, stable modulus, and fatigue resistance. These properties are essential for reducing blade weight while maintaining structural performance, enabling longer blades that capture more energy and improve capacity factors. The wind energy sector is projected to add over 680 GW of new capacity between 2023 and 2030, with offshore wind alone expected to grow at over 18% CAGR, significantly increasing demand for standard modulus carbon fiber in spar caps, shear webs, and reinforcement structures. As turbine OEMs shift from glass fiber to carbon fiber to achieve higher efficiency and reduce loads on nacelle and tower components, standard modulus carbon fiber continues to solidify its position as a critical material in next-generation wind turbine blade manufacturing.

Restraint: Lack of standardization in manufacturing technologies

Lack of standardization in manufacturing technologies, which leads to variability in fiber quality, mechanical properties, and processing performance across suppliers is a major restraint in the market. Differences in precursor formulation, oxidation stabilization, carbonization conditions, and surface treatment chemistry result in inconsistencies in tensile strength, modulus uniformity, and interfacial bonding, complicating downstream composite fabrication. Industry assessments indicate that variations in fiber surface energy and sizing chemistry can reduce composite performance by 10–20%, forcing OEMs to conduct extensive qualification and testing before adopting new suppliers. This fragmentation also hinders mass adoption in the automotive, wind energy, and industrial sectors, where standardized, repeatable high-volume manufacturing is critical. As demand accelerates for large-scale applications such as EV components, hydrogen storage cylinders, and wind blades, the absence of harmonized production standards slows market expansion and increases production costs for standard modulus carbon fiber.

Opportunity: Increasing use in 3D printing

The adoption of 3D printing in the composites industry is rising rapidly, driven by its ability to manufacture complex, high-precision components directly from digital models with minimal tooling and setup requirements. Continuous carbon fibers are increasingly integrated into additive manufacturing due to their superior strength, stiffness, and lightweight characteristics compared to many metallic materials. The capability to precisely control fiber orientation and content within printed structures enhances material performance and simplifies part optimization. This advancement enables the production of high-accuracy, load-bearing components for aerospace, automotive, medical, and industrial applications. As continuous-fiber 3D printing scales, it is expected to transform carbon fiber part production by reducing waste, shortening lead times, and expanding design possibilities, thereby creating significant growth opportunities for market participants.

Challenge: Capital-intensive production and complex manufacturing process

Standard modulus carbon fiber offers high strength, low weight, and excellent durability, but its adoption is limited by significant recyclability challenges. Separating the fiber from resin requires complex, energy-intensive processes, making recycling costly and difficult to scale. These constraints hinder sustainable waste management across industries using large volumes of composites. To address this, companies such as Toray Industries and Mitsubishi are developing recycled carbon fiber solutions that offer more affordable, lower-impact alternatives, particularly appealing for automotive applications.

Standard Modulus Carbon Fiber Market: COMMERCIAL USE CASES ACROSS INDUSTRIES

| COMPANY | USE CASE DESCRIPTION | BENEFITS |

|---|---|---|

|

Utilizes carbon fiber composites in aircraft fuselage and wings for commercial and defense aviation programs | Lightweight structure for fuel efficiency, high tensile strength, fatigue and corrosion resistance |

|

Applies carbon fiber in EV body panels, interior components, and structural reinforcements | Improved range through weight reduction, enhanced performance, structural rigidity |

|

Uses carbon fiber in wind turbine blades for large offshore and onshore models | Increased stiffness-to-weight ratio, extended blade length potential, higher energy efficiency |

|

Integrates carbon fiber composites in automotive chassis and body structures (e.g., BMW i-series) | Lightweighting for better acceleration and fuel economy, durability, reduced CO2 emissions |

|

Employs carbon fiber reinforced polymers in aircraft wings, tail assemblies, and fuselage | High mechanical performance, corrosion resistance, reduced maintenance, longer lifespan |

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET ECOSYSTEM

The standard modulus carbon fiber ecosystem analysis involves identifying and analyzing interconnected relationships among various stakeholders, including raw material suppliers, manufacturers, distributors, and end users. The raw material suppliers provide polymers, such as polyacrylonitrile, to carbon fiber manufacturers. The distributors and suppliers establish contact between the manufacturing companies and end users to streamline the supply chain, increasing operational efficiency and profitability.

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET SEGMENTS

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Standard Modulus Carbon Fiber Market, By Product Type

Continuous fiber accounts for the largest share of the standard modulus carbon fiber market due to its superior tensile properties, consistent modulus, and suitability for high-performance structural applications. Its ability to deliver excellent strength-to-weight ratios makes it the preferred choice in aerospace, automotive, wind energy, and industrial composites. Continuous fibers offer superior processability in prepregs, filament winding, and pultrusion, supporting large-scale production of advanced composite components.

Standard Modulus Carbon Fiber Market, By Application

Composites represent the largest application segment, driven by their high stiffness, rigidity, fatigue resistance, and lightweight characteristics. Standard modulus carbon fiber composites are widely used in aerospace structures, automotive lightweighting, wind turbine blades, sporting goods, marine parts, and industrial equipment. Their ability to replace metals such as aluminum and titanium in performance-critical components continues to fuel strong demand within this segment.

Standard Modulus Carbon Fiber Market, By End-use Industry

In 2024, aerospace & defense was the leading end-use industry for standard modulus carbon fiber, supported by the material’s essential role in aircraft structures, control surfaces, fuselage components, and military platforms. The industry’s focus on reducing weight, improving fuel efficiency, and enhancing durability drives extensive use of standard modulus grades. Growing production of commercial aircraft, UAVs, and space systems further strengthens demand from this segment.

REGION

Asia Pacific to be fastest-growing region in global standard modulus carbon fiber market during forecast period

The Asia Pacific region is expected to record the fastest growth in the standard modulus carbon fiber market, driven by rapid industrialization and strong expansion across automotive, aerospace, wind energy, and industrial manufacturing sectors in China, Japan, and South Korea. Rising demand for lightweight, high-strength materials to support electric vehicle production, large wind turbine installations, and advanced aerospace programs is accelerating the adoption of standard modulus grades. Growing investments in domestic carbon fiber production, coupled with government-led initiatives to strengthen composite material capabilities, further position Asia Pacific as the most dynamic and rapidly expanding market for standard modulus carbon fiber.

Standard Modulus Carbon Fiber Market: COMPANY EVALUATION MATRIX

In the standard modulus carbon fiber market matrix, Toray Industries, Inc. (Star) leads with a strong market share and extensive product footprint, which are widely adopted in aerospace & defense, automotive, sporting goods, and wind energy industries. Zhongfu Shenying Carbon Fiber Co., Ltd. (Emerging Leader) is gaining visibility as it focuses on innovation and backs this with high performance standard modulus carbon fibers for wind blades, sports, pressure vessels, and construction sector. While Toray Industries, Inc. dominates through scale and a diverse portfolio, Zhongfu Shenying Carbon fiber Co., Ltd. shows significant potential to move toward the leaders’ quadrant as demand for standard modulus carbon fiber continues to rise.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

KEY MARKET PLAYERS

MARKET SCOPE

| REPORT METRIC | DETAILS |

|---|---|

| Market Size in 2024 (Value) | USD 3.01 Billion |

| Market Forecast in 2030 (value) | USD 4.50 Billion |

| Growth Rate | CAGR of 6.9% from 2025-2030 |

| Years Considered | 2022-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million), Volume (Kiloton) |

| Report Coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments Covered |

|

| Regions Covered | North America, Asia Pacific, Europe, Latin America, Middle East & Africa |

WHAT IS IN IT FOR YOU: Standard Modulus Carbon Fiber Market REPORT CONTENT GUIDE

RECENT DEVELOPMENTS

- March 2025 : Teijin Carbon’s launched Tenax Next circular carbon fiber line, a new class of sustainable, high-performance materials engineered for advanced composite applications. Developed using circular feedstock and low-emission production methods, Tenax Next maintains the mechanical integrity and stiffness required for demanding engineering environments while reducing environmental impact.

- Feb-25 : Sinopec announced a major USD 450 million investment to expand its carbon fiber production capacity, adding 60,000 t/year of precursor output in Shanghai and establishing a new 30,000 t/year large-tow carbon fiber facility in Inner Mongolia. This expansion strengthens China’s domestic supply chain and supports rising demand from wind energy, transportation, and industrial composite applications.

- May 2025 : Dymag entered a strategic partnership with Borbet and Advanced International Multitech (AIM) to accelerate the development and industrial-scale production of lightweight carbon fiber hybrid wheels, combining Dymag’s carbon wheel expertise with Borbet’s OEM wheel experience and AIM’s advanced composites manufacturing. The collaboration aims to expand the reach of high-performance carbon wheel technology into broader automotive and motorcycle markets by offering robust, scalable carbon wheel solutions that deliver strength, stiffness, and weight savings over conventional alloy wheels.

- February 2024 : Syensqo partnered with Trillium Renewable Chemicals to develop sustainable raw materials for carbon fiber applications. Trillium's bio-based acrylonitrile (Bio-ACN) is being evaluated by Syensqo for its potential in carbon fiber manufacturing, aiming to advance sustainable solutions from bio-based or recycled sources.

Table of Contents

Methodology

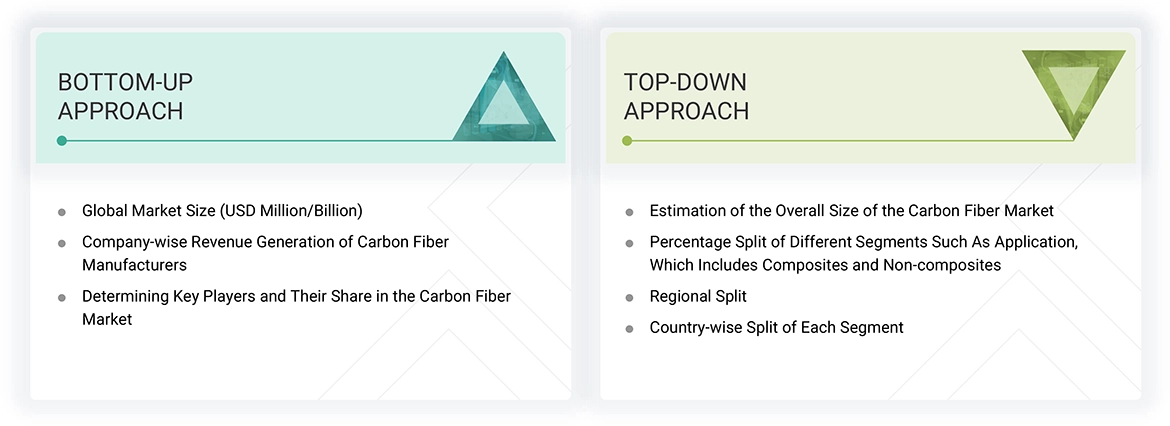

The study involves two major activities in estimating the current market size for the standard modulus carbon fiber market. Exhaustive secondary research was done to collect information on the market, peer market, and parent market. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain through primary research. Both top-down and bottom-up approaches were employed to estimate the complete market size. After that, market breakdown and data triangulation were used to estimate the market size of segments and subsegments.

Secondary Research

Secondary sources referred to for this research study include financial statements of companies offering standard modulus carbon fiber and information from various trade, business, and professional associations. Secondary research has been used to obtain critical information about the industry’s value chain, the total pool of key players, market classification, and segmentation according to industry trends to the bottom-most level and regional markets. The secondary data was collected and analyzed to arrive at the overall size of the standard modulus carbon fiber market, which was validated by primary respondents.

Primary Research

Extensive primary research was conducted after obtaining information regarding the standard modulus carbon fiber market scenario through secondary research. Several primary interviews were conducted with market experts from both the demand and supply sides across major countries of North America, Europe, Asia Pacific, the Middle East & Africa, and Latin America. Primary data was collected through questionnaires, emails, and telephonic interviews. The primary sources from the supply side included various industry experts, such as chief experience officers (CXOs), vice presidents (VPs), business development/marketing directors, product development/innovation teams, related key executives from the standard modulus carbon fiber industry, system integrators, component providers, distributors, and key opinion leaders. Primary interviews were conducted to gather insights such as market statistics, data on revenue collected from the products and services, market breakdowns, market size estimations, market forecasting, and data triangulation. Primary research also helped in understanding the various trends related to raw material type, fiber type, modulus, product type, application, end-use industry, and region. Stakeholders from the demand side, such as CIOs, CTOs, CSOs, and installation teams of the customers/end users who are seeking standard modulus carbon fiber services, were interviewed to understand the buyer’s perspective on the suppliers, products, component providers, and their current usage of standard modulus carbon fiber and future outlook of their business which will affect the overall market.

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

The research methodology used to estimate the size of the standard modulus carbon fiber market includes the following details. The market sizing was undertaken from the demand side. The market was upsized based on the demand for standard modulus carbon fiber in different applications at the regional level. Such procurements provide information on the demand aspects of the standard modulus carbon fiber industry for each application. For each application, all possible segments of the standard modulus carbon fiber market were integrated and mapped.

Data Triangulation

After arriving at the overall size from the market size estimation process explained above, the total market was split into several segments and subsegments. The data triangulation and market breakdown procedures explained below were implemented, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics for various market segments and subsegments. The data was triangulated by studying various factors and trends from the demand and supply sides. Along with this, the market size was validated using both the top-down and bottom-up approaches.

Market Definition

Standard modulus carbon fiber is a long, thin strand of material made from carbon. It is produced by baking precursors, such as polyacrylonitrile (PAN), pitch, and rayon, in an inert atmosphere to dissociate elements other than carbon through a process called pyrolysis. Standard modulus carbon fiber is lightweight and has excellent strength, low specific gravity, excellent modulus of elasticity, and high corrosion resistance. There are different types of standard modulus carbon fibers, including high-strength (HS)/standard modulus, intermediate modulus, and high-modulus, each with varying mechanical properties. Standard modulus carbon fibers used as composite materials are used to make aircraft & spacecraft parts, bicycle frames, pipes & tanks, wind blades, golf shafts, badminton rackets, automobile springs, sailboat masts, automotive structural parts, and various other parts where lightweight and high strength are required. Non-composite applications of standard modulus carbon fiber include filtration materials, conductive electrodes in batteries and supercapacitors, heat shields, industrial brushes, and electrical components, utilizing its strength, conductivity, and heat resistance in various industries.

Stakeholders

- Standard modulus carbon fiber Manufacturers

- Standard modulus carbon fiber Distributors and Suppliers

- Universities, Governments, and Research Organizations

- Associations and Industrial Bodies

- R&D Institutes

- Environmental Support Agencies

- Investment Banks and Private Equity Firms

- Research and Consulting Firms

Report Objectives

- To define, describe, and forecast the standard modulus carbon fiber market size in terms of volume and value

- To provide detailed information regarding the key factors, such as drivers, restraints, opportunities, and challenges influencing the market growth

- To analyze and project the global standard modulus carbon fiber market by raw material type, fiber type, modulus, product type, application, end-use industry, and region

- To forecast the market size concerning five main regions (along with country-level data), namely, North America, Europe, Asia Pacific, the Middle East & Africa, and Latin America, and analyze the significant region-specific trends

- To strategically analyze micromarkets with respect to individual growth trends, prospects, and contributions of the submarkets to the overall market

- To analyze the market opportunities and the competitive landscape for stakeholders and market leaders

- To assess recent market developments and competitive strategies, such as agreements, contracts, acquisitions, and product developments/product launches, to draw the competitive landscape

- To strategically profile the key market players and comprehensively analyze their core competencies

Need a Tailored Report?

Customize this report to your needs

Get 10% FREE Customization

Customize This ReportPersonalize This Research

- Triangulate with your Own Data

- Get Data as per your Format and Definition

- Gain a Deeper Dive on a Specific Application, Geography, Customer or Competitor

- Any level of Personalization

Let Us Help You

- What are the Known and Unknown Adjacencies Impacting the Standard Modulus Carbon Fiber Market

- What will your New Revenue Sources be?

- Who will be your Top Customer; what will make them switch?

- Defend your Market Share or Win Competitors

- Get a Scorecard for Target Partners

Custom Market Research Services

We Will Customise The Research For You, In Case The Report Listed Above Does Not Meet With Your Requirements

Get 10% Free Customisation

Growth opportunities and latent adjacency in Standard Modulus Carbon Fiber Market