Variable Frequency Drive Market

Variable Frequency Drive Market by Type (AC Drive, DC Drive, Servo Drive), Application (Pumps, Fans, Compressors, Conveyors), Power Rating (Micro, Low, Medium, High), Voltage, End User and Region - Global Forecast to 2030

OVERVIEW

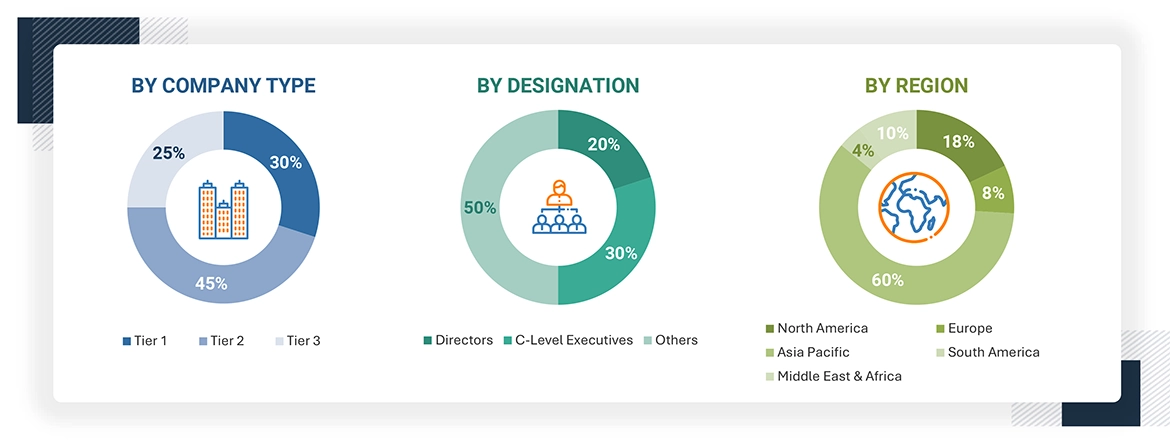

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

The global Variable Frequency Drive market is projected to grow from USD 24.7 billion in 2025 to USD 32.0 billion by 2030, at a CAGR of 5.3% due to increased industrial automation and energy-saving requirements, in manufacturing, oil and gas, and other sectors, where VFD maximizes motor performance and reduces operating costs and energy consumption

KEY TAKEAWAYS

-

BY TYPEThe type segment has AC Drive and DC Drive segments. The demand for AC drives in VFDs is much higher because AC drives can control speed and torque more efficiently, and it is pretty much in use in all industries. The frequency of the motor is changed by AC drives according to the operational need. Therefore, they save a lot of energy and give better efficiency. Actually, these are more adaptable and energy-efficient for applications with pumps, fans, or conveyors. Because of the strict requirements of industries in terms of energy efficiency and cost reduction, the market found AC drives in order to save energy without compromising the desired output at which it should operate. Moreover, their capacity to integrate with advanced automation and Internet of Things (IoT) technologies enhances operational efficiency and corresponds with the increasing emphasis on energy efficiency and sustainability across various sectors, thereby further propelling their adoption.

-

BY VOLTAGEBy voltage, the market has been segmented as low voltage and medium voltage. The medium voltage segment is the fastest-growing market for variable frequency drives because industries are increasingly focused on minimizing operating costs and maximizing efficiency. Medium-voltage VFDs, typically used for motors above 690 V, are essential for large-scale operations in sectors like oil & gas, mining, water treatment, power generation, cement, steel, and chemicals. These drives reduce energy consumption, extend motor lifespan, and lower mechanical stress, which optimizes operational expenses. Their ability to provide precise speed control and decrease wear on motors results in significantly reduced downtime and maintenance costs, making them an attractive solution as companies prioritize cost savings and process reliability.

-

BY APPLICATIONThe application segment includes Pumps, Fans & Blowers, Compressors, Conveyors, and Other Applications. The compressor application segment is the fastest-growing in the VFD market because compressors are critical across multiple industries, powering pneumatic tools, regulating air conditioning, managing pipelines, and supporting precision processes. Integrating VFDs with compressors allows for efficient control of motor speed and torque, enabling them to match output with demand and thus optimize energy use. This leads to significant reductions in energy consumption—often by 20–50%—and helps maintain stable pressure for process reliability. Beyond energy efficiency, VFDs extend compressor lifespan, decrease maintenance costs, and improve overall process control, making them an increasingly attractive solution for industries pursuing cost savings and enhanced operational efficiency.

-

BY POWER RATINGThe power rating segment includes Micro Power Drive, Low Power Drive, Medium Power Drive, and High Power Drive. The high power drive segment is the fastest-growing in the VFD market due to increasing modernization and energy efficiency initiatives in steel and mining industries. Significant investments in advanced technologies, such as high-power VFDs, enable these sectors to control motor speeds, optimize energy consumption, and improve process control in large-scale equipment. The adoption of such solutions is accelerating as companies aim to enhance operational efficiency, reduce carbon footprints, and achieve sustainability goals. As infrastructure upgrades and energy-efficient technologies become a priority across steel and mining, demand for high-power drives is expected to continue its rapid growth trajectory.

-

BY END USERThe end user segment includes Oil & gas, Mining & Metal, Chemicals & Petrochemicals, Power, Food & Beverage, Water & Wastewater Treatment, Automotive, Construction/Infrastructure, and Other End Users. The oil & gas segment is the second-fastest growing segment in the VFD market due to a major surge in upstream investment, with capital expenditures in 2024 reaching record highs driven by improved commodity prices and increased spending, especially in North and Latin America. This wave of investment has accelerated the adoption of VFDs to optimize operational efficiency and energy management in drilling operations, pumps, and compressors. VFDs enable precise speed control, reduce energy consumption, lower mechanical stress, and maintain steady flow rates in fluid transport systems, making them essential for supporting the industry's efficiency and reliability goals as capital inflows continue.

-

BY REGIONThe regions considered are North America, Europe, Asia Pacific, the Middle East & Africa, and South Africa. Asia-Pacific is the largest and the fastest market for variable frequency drives (VFDs) owing to rapid industrialization and infrastructural development in key countries like China, India, Japan, and South Korea. Having adopted energy-saving solutions, the countries are witnessing a strong demand for VFDs across industries of production, HVAC applications, and water treatment solutions. VFDs are needed for saving energy and increasing efficiency. Therefore, they form an area of keen interest to industries working on sustainability and cost effectiveness. Further, Asia's rapid urbanization and large-scale infrastructure projects further propel this growth. Technological advancements and high automation in the region have also contributed to the growth of the region's VFD market. As countries like India and China continuously grow and their energy consumption increases, optimizing motor performance, thus saving more on electricity usage, has become a necessity by incorporating VFDs, and this market is to grow more, driven by beneficial government policies, increasing industrial activities, and adapting to smart technologies in all sectors.

-

COMPETITIVE LANDSCAPEThe major market players have adopted both organic and inorganic strategies, including expansions, sales contracts, acquisitions, agreements, investments, product launches, partnerships, and collaborations. For instance, ABB launched a product that is utilized for outdoor installation and extreme environments in the HVACR industry. The product is certified to UL Type 4X, which ensures protection against rain, cold, snow, salt spray, and dust, as well as corrosion due to caustic chemicals, gases, and damage from the formation of exterior ice, high levels of humidity, or UV radiation.

Increasing demand for energy efficiency in industrial automation and production processes continues to drive the adoption of variable frequency drives (VFDs), as companies seek to reduce energy consumption and optimize process control. However, high installation and maintenance costs, coupled with the stagnant growth of the oil & gas industry, pose notable restraints to market expansion. Government regulations supporting sustainability and the integration of Industrial Internet of Things and robotics create substantial opportunities for growth, encouraging further VFD deployment in smart manufacturing and automated environments. Nonetheless, a persistent shortage of skilled professionals for VFD installation, programming, and maintenance remains a key challenge in ensuring reliable, widespread utilization across industries.

TRENDS & DISRUPTIONS IMPACTING CUSTOMERS' CUSTOMERS

The Variable Frequency Drive market is poised for significant growth in the coming years due to rising demand for energy efficiency, renewable integration, and automation. Trends like IoT, AI in drives, and smart manufacturing are reshaping revenue streams. Industries, electric utilities, and infrastructure providers benefit from reduced energy costs, improved productivity, and regulatory compliance. Decentralized power generation and predictive maintenance minimize downtime and enhance system reliability. By embracing these shifts, businesses can unlock new revenue opportunities and stay competitive in an evolving energy landscape.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

MARKET DYNAMICS

Level

-

Rising need for enhancing energy efficiency and decreasing energy consumption

-

Increasing need of motion control systems in automated production plants

Level

-

High installation and maintenance costs

-

Stagnant growth of oil & gas industry

Level

-

Government regulations for sustainability

-

Growing use of Industrial Internet of Things and robotics technologies

Level

-

Lack of skilled workforce for installation, programming, and maintenance of variable frequency drives

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Driver: Rising need for enhancing energy efficiency and decreasing energy consumption

All industries have pursued technological developments in order to deliver high energy efficiency, which has become a significant concern. The industrial sector reportedly consumes 37% of the energy consumed globally, whereas 30% is consumed worldwide by buildings. By optimizing motor speed to match specific load requirements, VFDs eliminate the need for wasteful constant-speed operation. This results in substantial energy savings, lower operational costs, and a reduced carbon footprint. As industries and governments worldwide increase energy efficiency and sustainability, the use of VFDs will continue to grow. At the present rate, it is expected that electrical motors in industrial applications would consume a quarter of global electrical energy. Energy experts agree that 90% of motor life-cycle expenditures for fans and pumps are spent on energy. When these motors are fitted with variable frequency drives in service conditions with centrifugal load, their efficiency improves. Motors are applied in pumps, compressors, conveyors, and machines that depend on the rotational force to function. Variable frequency drives allow motors to be run on demand for required current, rather than running full speed and then reducing output through mechanical controls like throttles, dampers, or gears.

Restraint: Stagnant growth of oil & gas industry and decline in exploration and production activities

Variable frequency drives is among the top end-user industries in the oil & gas industry. This industry has been under stagnant growth phase for last few years due to declining exploration and production activities. The demand for variable frequency drives in this industry depends directly on the parameters of exploration, development, and production activities, as well as capital spending by oil and natural gas companies. Activities Fluctuations in oil and natural gas prices directly affect these activities. The fluctuations are experienced due to changes in the supply of and demand for oil and natural gas, governmental regulations, including policies on the exploration, production, and development of oil and natural gas reserves, weather conditions, natural disasters, and other factors. Oil and gas companies may cut or postpone major investments on the presumption of lower oil and natural gas prices over a long run, considering that most large-scale developmental projects undertaken are for a long-term period. In addition, the market growth for variable frequency drives is also directly impacted by lower capital expenditures by oilfield operators and service providers.

Opportunity: Modernization of power infrastructure

Stable, reliable T&D networks have been created to meet growing energy demand. The DOE can ensure a continuous supply of electricity only through a system that can manage sudden power fluctuations. Such an increase in blackouts has been caused by several reasons, including aging infrastructure, limited investments, and unclear policies to modernize the grid. More often than any other developed country, the US experiences blackouts. Power cuts in the country take longer than an hour and have risen steadily in the last few years, thus costing American businesses about USD 150 billion per year. According to the Canadian Electricity Association, at current consumption rates, it will require a USD 400 billion investment for the electricity sector over the next 20 years in Canada. Over the last ten years, electricity demand has increased by 10% even though there are more energy-efficient products and buildings than ever. Many regulations are being introduced to prevent or limit power blackouts and upgrade the aging power networks within the whole world, but especially in North America, Europe, and parts of Asia Pacific.

Challenge: Availability of low-cost products in gray market

The variable frequency drive market is highly fragmented, with many local and international players. Product quality is the primary differentiating parameter in this market. The players from the organized sector target industrial buyers and maintain high product quality by following various industrial standards. At the same time, the players from the unorganized sector offer low-cost alternatives. The local manufacturers in most countries operate in the unorganized sector and compete strongly with global suppliers. These gray market players overpower the big players in terms of price competitiveness and local distribution networks. Gray market products are sold at a fraction of the price for legitimate, branded VFDs. The result is extremely intense pricing competition, with traditional manufacturers struggling to explain higher prices that reflect R&D and compliance charges. Moreover, gray market VFDs do not come equipped with advanced features and after-sales service, which prevents innovation and uptake of newer technologies in the market. Better ways to address this are customer education, authentication of the product, cost-effective solutions, and collaborative regulation so as to protect the market and ensure a sustainable growth.

Variable Frequency Drive Market: COMMERCIAL USE CASES ACROSS INDUSTRIES

| COMPANY | USE CASE DESCRIPTION | BENEFITS |

|---|---|---|

|

DSI Inc. modernizes well-pad motor control infrastructure by replacing aging VFDs using dynamic braking resistors (DBRs) with PowerFlex® 755TR regeneration drives. Drive improvements were needed for reduced energy waste, lower costs, and enhanced sustainability. | By using the VFD, DSI Inc. achieved faster and more efficient well-pad operations. Regenerative drives recycled excess energy, producing projected $3M/month energy savings and accomplished 17% regeneration with 95% reuse of energy. Benefits included lower operational costs, eligibility for carbon credits, better reliability, and improved reporting on pump performance. |

|

CAESB improves operational reliability and predictability for water and wastewater management through tailored maintenance, refurbished drives, and ultra-low-harmonic (AFE) drive upgrades. The requirement focused on minimizing downtime risk and maintaining full visibility and control of 500+ critical drives operating in harsh conditions. | By using a Danfoss VFD, CAESB achieved reliable, planned maintenance with guaranteed response time. Extended equipment lifetime, reduced risk of downtime, enhanced operational and budgetary control, and improved power quality. The tailored service program and upgraded units gave peace of mind and secured long-term performance of critical water and wastewater infrastructure. |

|

Enhance energy efficiency and reduce operating costs at the Gliwice ceramics factory by modernizing ventilation, conveyors, and mixers. Required investment in Danfoss VLT® variable frequency drives (VFDs) to allow process-demand-based speed control across multiple systems. | By using a VFD, the Gliwice ceramics factory achieved approximately 30% reduction in annual energy consumption, faster payback (7 months), reduced CO2 emissions, and improved equipment reliability. Enabled process optimization, minimized waste, reduced the need for new equipment, and supported Roca's sustainability and climate neutrality goals. |

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET ECOSYSTEM

The variable frequency drive market ecosystem comprises raw material suppliers, manufacturers, distributors, end users, and regulatory bodies/standards organizations. The end users in the market primarily include oil & gas, mining & metal, chemicals & petrochemicals, power generation, food & beverage, water & wastewater treatment, automotive, and construction/infrastructure, among others. This list is not exhaustive and is meant to explain the key players involved in the market.

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET SEGMENTS

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

VARIABLE FREQUENCY DRIVE MARKET, BY TYPE

The type segment has AC Drive and DC Drive segments. The demand for AC drives in VFDs is much higher because AC drives can control speed and torque more efficiently, and it is pretty much in use in all industries. The frequency of the motor is changed by AC drives according to the operational need. Therefore, they save a lot of energy and give better efficiency. Actually, these are more adaptable and energy-efficient for applications with pumps, fans, or conveyors. Because of the strict requirements of industries in terms of energy efficiency and cost reduction, the market found AC drives in order to save energy without compromising the desired output at which it should operate. Moreover, their capacity to integrate with advanced automation and Internet of Things (IoT) technologies enhances operational efficiency and corresponds with the increasing emphasis on energy efficiency and sustainability across various sectors, thereby further propelling their adoption.

VARIABLE FREQUENCY DRIVE MARKET, BY VOLTAGE

By voltage, the market has been segmented as low voltage and medium voltage. The largest market of the power variable frequency drive market is the low-power drive segment due to several reasons. Low power VFDs, typically with a power rating under 6 kW, are widely used in small-scale industrial applications and residential settings for HVAC systems, pumps, fans, etc. because these applications use less energy but require precise speed control. Cost effectiveness and high energy efficiency have made these drives very attractive. Industries focused on low operation cost are found to be highly interested in them. Also, the trend of automation with energy-saving technology in manufacturing, water treatment, and agriculture industries is now greatly raising the demand for low-power VFDs. Inasmuch as there is an increasing demand for energy-efficient solutions in all sectors, the low-power VFD segment will definitely sustain its fast growth, especially in emerging markets where industrialization is picking up.

VARIABLE FREQUENCY DRIVE MARKET, BY APPLICATION

The application segment includes Pumps, Fans & Blowers, Compressors, Conveyors, and Other Applications. Pumps is the largest market for VFDs because pumps are critical to numerous industrial operations including oil & gas, water & wastewater, mining, chemicals, petrochemicals, cement, and pulp & paper. VFDs enable precise adjustment of pump motor speed to match process requirements, significantly improving efficiency and energy savings.

VARIABLE FREQUENCY DRIVE MARKET, BY POWER RATING

The power rating segment includes Micro Power Drive, Low Power Drive, Medium Power Drive, and High Power Drive. The low power drives segment is the largest market for variable frequency drives due to their extensive use across manufacturing, HVAC, water & wastewater treatment, food & beverage, and automotive industries. In manufacturing, low-power drives efficiently control motors for conveyors, pumps, compressors, and fans, ensuring precise operations. HVAC systems utilize these drives in air handling units, chillers, and cooling towers to optimize energy use, while water & wastewater industries benefit from improved pump control and reduced energy consumption. In food & beverage, and automotive sectors, low-power drives support automation for processing, mixing, packaging, assembly line automation, and robotic systems. The demand for energy efficiency, compliance with stringent regulations, and seamless integration with smart manufacturing and IoT-enabled automation further drive strong growth for this segment.

VARIABLE FREQUENCY DRIVE MARKET, BY END USER

The end user segment includes Oil & gas, Mining & Metal, Chemicals & Petrochemicals, Power, Food & Beverage, Water & Wastewater Treatment, Automotive, Construction/Infrastructure, and Other End Users. The power end user segment is the largest market for variable frequency drives because the power industry places a major emphasis on energy efficiency, which drives extensive adoption of VFDs in conventional and nuclear power generation. VFDs are widely used in draft fans, cooling tower pumps, compressors, and auxiliary systems such as feedwater pumps, optimizing internal power consumption and improving operational efficiency in power plants. Significant investments in capacity expansion, such as India’s major nuclear initiatives and the diverse US energy mix including fossil fuels, nuclear, and renewables, further accelerate VFD deployment. The ability of VFDs to provide precise control of motor speeds leads to substantial energy savings and operational cost reductions, making them crucial for utilities and power generators worldwide.

REGION

Asia Pacific to be largest-growing region in global variable frequency drive market during forecast period

Asia Pacific accounted for a 44.0% share of the variable frequency drive market in 2024. The region includes countries such as China, India, Japan, Australia, Indonesia, and South Korea. China led the Asia Pacific market with a 48.5 percent share, followed by Japan at 18.4% and India at 10.7 %. Asia Pacific variable frequency drive market is witnessing rapid industrialization and substantial infrastructure investments in countries such as China, India, Japan, and South Korea. These developments are driving demand for energy-efficient solutions to optimize motor performance, reduce energy consumption, and support operational efficiency. The region’s strong focus on sustainability, cost-effectiveness, and environmental impact has accelerated VFD adoption across key industries, such as power, chemicals, mining, oil & gas, automotive, food & beverage, and water & wastewater treatment. VFD applications range from turbine and pump control to process automation, contributing to consistent quality gains and significant energy savings, all of which underpin robust market growth in Asia Pacific. China is the largest country in the Asia Pacific region for the variable frequency drive (VFD) market because of its dominant position in global manufacturing and its substantial contribution to the region’s economic growth. In 2023, China accounted for about 30% of global manufacturing added value, making it the world's leading manufacturing powerhouse. The country benefits from strong government support, robust policies promoting energy efficiency, and widespread adoption of automation in industrial processes. China's immense industrial base, competitive costs, comprehensive supply chains, skilled labor, and advanced infrastructure further stimulate high demand for VFDs in applications such as pumps, conveyors, and compressors. Additionally, the government’s emphasis on energy conservation and environmental protection, coupled with large-scale infrastructure projects, continues to drive VFD adoption at scale.

The Europe variable frequency drive market is likely to reach USD 6.78 billion by 2030 from USD 5.50 billion in 2025, recording a CAGR of 4.3% during the forecast period. A variable frequency drive (VFD) can be described as a motor controller that acts as a device for controlling or regulating the speed of an electric motor. The control and regulation are achieved via manipulation or adjustment of the frequency and voltage fed to an electric motor. Key advantages of VFDs include energy savings, improved control during operation, an extension of equipment life, and facilitation of maintenance. The uses and applications of VFDs include oil and gas operations, water and wastewater.

The Asia Pacific variable frequency drive market is projected to reach USD 15.04 billion by 2030 from USD 10.98 billion in 2025, at a CAGR of 6.5% during the forecast period.The Asia Pacific variable frequency drive market is experiencing significant growth due to several key factors. Rapid industrialization and infrastructural development in countries such as China, India, Japan, and South Korea have led to an increased demand for energy-efficient solutions across various sectors. VFDs are essential for optimizing motor performance, reducing energy consumption, and enhancing operational efficiency, aligning with the region’s focus on sustainability and cost-effectiveness.

The US variable frequency drive market is projected to grow from USD 4.08 billion in 2025 to USD 4.92 billion by 2030, at a CAGR of 3.8% during the forecast period. This is due to increased industrial automation and energy-saving requirements in manufacturing, oil and gas, and other sectors, where VFD maximizes motor performance and reduces operating costs and energy consumption.

Variable Frequency Drive Market: COMPANY EVALUATION MATRIX

Danfoss (Stars) is recognized in the variable frequency drive (VFD) market because it consistently launches innovative and energy-efficient drive technologies, such as the iC2 and iC7 series, which are engineered for optimal motor speed, energy savings, and operational efficiency. The company further strengthens its global position through strategic partnerships, notably with Innomotics GmbH, allowing Danfoss to enhance product competitiveness, technical compatibility, and customer satisfaction. These collaborations support tailored solutions for a wide range of motor and drive combinations. Danfoss’s extensive market presence covers Asia Pacific, North America, South America, Middle East & Africa, and Europe, reflecting its ability to serve diverse industries at a global scale. WEG (Emerging Leaders) is emerging as a leader in the variable frequency drive (VFD) market due to its strategic investments in digital transformation and global manufacturing expansion. The company's acquisition of BirminD has strengthened its capabilities in industrial analytics, sensor diagnostics, and AI-driven process control, enhancing the value and intelligence of its drive solutions. WEG’s continued investment in expanding automation and high-voltage drive manufacturing facilities in Mexico and China demonstrates its commitment to increasing production capacity, efficiency, and market reach. These moves position WEG as an innovation-driven company able to offer advanced VFD products tailored to diverse regions and customer needs, solidifying its status as a key player in the global VFD market.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

KEY MARKET PLAYERS

MARKET SCOPE

| REPORT METRIC | DETAILS |

|---|---|

| Market Size in 2024 (Value) | USD 23.5 BN |

| Market Forecast in 2030 (Value) | USD 32.0 BN |

| Growth Rate | 5.3% |

| Years Considered | 2021–2030 |

| Base Year | 2024 |

| Forecast Period | 2025–2030 |

| Units Considered | Value (USD Billion), Volume (Thousand Units) |

| Report Coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments Covered | By Type: AC Drive and DC Drive By Voltage: Low voltage and Medium voltage By Application: Pumps, Fans & Blowers, Compressors, Conveyors, and Other Applications By Power Rating: Micro Power Drive, Low Power Drive, Medium Power Drive, and High Power Drive By End User: Oil & gas, Mining & Metal, Chemicals & Petrochemicals, Power, Food & Beverage, Water & Wastewater Treatment, Automotive, Construction/Infrastructure, and Other End Users |

| Regions Covered | North America, Asia Pacific, Europe, Middle East & Africa and South America |

WHAT IS IN IT FOR YOU: Variable Frequency Drive Market REPORT CONTENT GUIDE

DELIVERED CUSTOMIZATIONS

We have successfully delivered the following deep-dive customizations:

| CLIENT REQUEST | CUSTOMIZATION DELIVERED | VALUE ADDS |

|---|---|---|

| Variable Frequency Drive Market | Market sizing for Middle East & African countries | Country level analysis, Key insights on verticals, potential application of VFDs |

| Variable Frequency Drive Market | Market sizing for GCC countries | Country level analysis, Key insights on verticals, potential application of VFDs |

| Variable Frequency Drive Market | Market sizing for African countries | Country level analysis, Key insights on verticals, potential application of VFDs |

RECENT DEVELOPMENTS

- April 2024 : ABB launched a product that is utilized for outdoor installation and extreme environments in the HVACR industry. The product is certified to UL Type 4X, that ensures protection against rain, cold, snow, salt spray, and dust as well as corrosion due to caustic chemicals, gases, and damage from the formation of exterior ice, high levels of humidity or UV radiation.

- March 2024 : Siemens has signed an agreement to acquire the industrial drive technology (IDT) business of ebm-papst. This business includes intelligent, integrated mechatronic systems in the protective extra-low voltage range and innovative motion control systems. This acquisition will complement the Siemens Xcelerator portfolio and strengthen Siemens’ position as a leading solutions provider for flexible production automation.

- November 2024 : Schneider Electric has expanded its Altivar Medium Voltage Drives portfolio with the launch of Altivar Process ATV6100. This product features a more compact design and versatile functionality aimed at helping to improve energy efficiency, further optimize processes, and reduce total cost of ownership.

- June 2024 : Danfoss launched its energy-efficient technology, iC2 and iC7 VFDs in India. These drives are engineered to operate motors at optimal speeds, leading to substantial energy savings and operational efficiency.

Table of Contents

Methodology

This research study involves the use of extensive secondary sources, directories, and databases, such as Hoovers, Bloomberg L.P., Factiva, ICIS, and OneSource, to identify and collect information useful for this technical, market-oriented, and commercial study of the global variable frequency drive market. Primary sources are mainly industry experts from core and related industries, preferred suppliers, manufacturers, distributors, service providers, and organizations related to all segments of the value chain of this industry. In-depth interviews were conducted with various primary respondents, including key industry participants, subject matter experts, C-level executives of key market players, and industry consultants, among other experts, to obtain and verify critical qualitative and quantitative information as well as assess growth prospects of the market.

Secondary Research

Secondary sources include annual reports, press releases, and investor presentations of companies; directories and databases, which include D&B, Bloomberg, and Factiva; white papers and articles from recognized authors, and publications and databases from associations, such as International Energy Agency (IEA), US Energy Information Administration (EIA), International Renewable Energy Agency (IRENA), National Electrical Manufacturers Association (NEMA). Secondary research has been used to obtain important information about the key players and market classification & segmentation according to industry trends to the bottom-most level and key developments related to market and technology perspectives. A database of the key industry leaders has also been prepared using secondary research.

Primary Research

In the primary research process, various sources from both the supply and demand sides have been interviewed to obtain and verify qualitative and quantitative information for this report and analyze prospects. Primary sources from the supply side include industry experts such as CEOs, vice presidents, marketing directors, technology and innovation directors, and related executives from various leading companies and organizations operating in the variable frequency drive market. Primary sources from the demand side include experts and key persons.

After the complete market engineering process (which includes calculations of market statistics, market breakdown, market size estimations, market forecasts, and data triangulation), extensive primary research has been conducted to gather information and verify and validate the critical numbers arrived at. Primary research has also been conducted to identify the segmentation, applications, Porter’s Five Forces, key players, competitive landscape, and key market dynamics such as drivers, opportunities, challenges, industry trends, and strategies adopted by key players.

To know about the assumptions considered for the study, download the pdf brochure

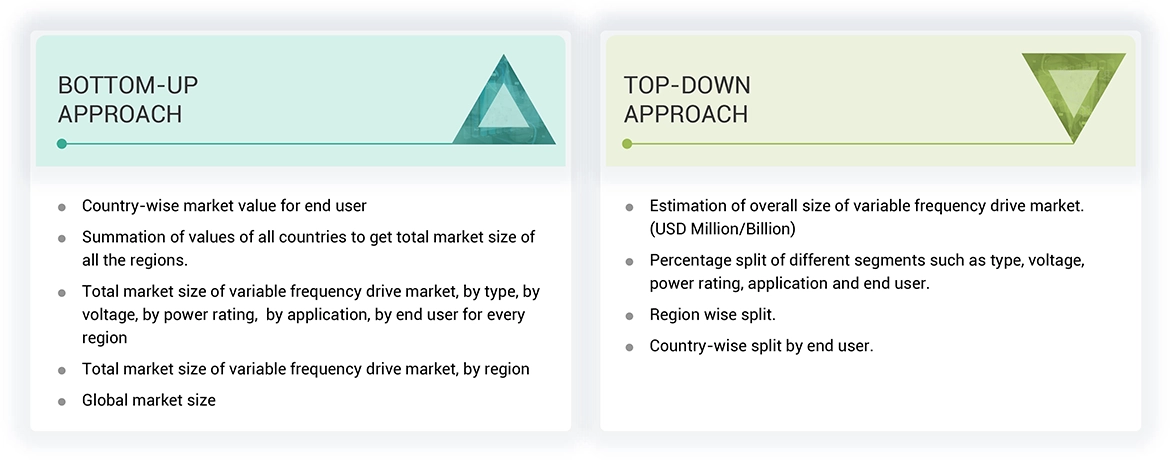

Market Size Estimation

In the complete market engineering process, both top-down and bottom-up approaches have been extensively used along with several data triangulation methods to estimate and forecast the overall market segments listed in this report.

Top-down and bottom-up approaches have been used to estimate and validate the market size of variable frequency drives for various end user in each region. The key players in the market have been identified through secondary research, and their market share in respective regions has been determined through primary and secondary research. This entire procedure includes the study of annual and financial reports of the key market players and extensive interviews for insights from industry leaders such as CEOs, vice presidents, directors, and marketing executives. All percentage shares, splits, and breakdowns have been determined using secondary sources and verified through primary sources.

Variable Frequency Drive Market : Top-Down and Bottom-Up Approach

Data Triangulation

After arriving at the overall market size from the estimation process explained above, the total market has been split into several segments and sub-segments. Data triangulation and market breakdown procedures have been used wherever applicable to complete the overall market engineering process and to arrive at the exact statistics for all segments and sub-segments. The data has been triangulated by studying various factors and trends from both the demand and supply sides. The market has been validated using both the top-down and bottom-up approaches. Then, it was verified through primary interviews. Hence, for every data segment, there are three sources—the top-down approach, the bottom-up approach, and expert interviews. When the values arrived at from the three points matched, the data was assumed to be correct.

Market Definition

A variable frequency drive (VFD) is an electronic motor control device that drives an electric motor by changing the voltage and frequency supplied in the electric motor circuit. VFD works by converting fixed frequency and fixed voltage sine wave power to a variable frequency or variable output voltage, which is used to control the speed of a motor. It is also referred to as variable speed drive, adjustable speed drive, adjustable frequency drive, AC drive, micro drive, and inverter. The primary advantages associated with the use of VFD include less energy consumption and energy cost, controlled performance, extended equipment life, and low maintenance cost. It is mainly used for variable torque applications in various industries, such as oil & gas, water & wastewater treatment, power, paper & pulp, textile, and mining. The market for variable frequency drives is defined as the sum of revenues generated by companies through the sale of variable frequency drives.

Stakeholders

- Government organizations and regulatory agencies

- VFD manufacturing companies

- Automotive, aerospace, marine, and industrial equipment manufacturers

- Research and development institutes

- Environmental and sustainability organizations

- Trade associations and industry forums related to VFD technologies

- Original Equipment Manufacturers (OEMs)

- Component and parts suppliers for VFD

- Consulting companies in energy, automotive, and manufacturing sectors

- Transportation and logistics companies

- Maintenance and repair service providers

Report Objectives

- To describe and forecast the variable frequency drive market in terms of value based on type, voltage, power rating, application, end user, region

- To describe and forecast the variable frequency drive market in terms of volume based on region and power rating segment

- To provide detailed information about the key factors such as drivers, restraints, opportunities, and challenges influencing the growth of the variable frequency drive market

- To strategically analyze the subsegments with respect to individual growth trends, prospects, and contributions of each segment to the overall market size

- To forecast the market size for five key regions: North America, Europe, Asia Pacific, Middle East & Africa, and South America, along with their key countries

- To strategically analyze micromarkets with respect to individual growth trends, prospects, and contributions to the total market

- To study the complete supply chain and allied industry segments and perform a supply chain analysis of the variable frequency drive market’ landscape

- To study market trends, patent analysis, trade analysis, tariff and regulatory landscape, Porter’s five forces analysis, ecosystem mapping, technologies, investment and funding scenario, key stakeholders & buying criteria, case studies pertaining to off variable frequency drive market

- To analyze the opportunities for various stakeholders by identifying the high-growth segments of the variable frequency drivemarket

- To profile the key players and comprehensively analyze their market positions in terms of ranking and core competencies, along with detailing the competitive landscape for the market leaders

- To analyze competitive developments, such as contracts, collaborations, expansions, product launches, investments, and acquisitions, in the variable frequency drivemarket

Note: 1. Micro markets are defined as the further segments and subsegments of the variable frequency drive market included in the report.

2. Core competencies of companies are captured in terms of their key developments and product portfolios, as well as key strategies adopted to sustain their position in the variable frequency drive market.

Available Customizations

MarketsandMarkets offers customizations according to the specific needs of the companies with the given market data.

The following customization options are available for the report:

Product Analysis

- Product matrix, which gives a detailed comparison of the product portfolio of each company

Regional Analysis

- Further breakdown of the VFD market, by country

Company Information

- Detailed analysis and profiling of additional market players (up to five)

Key Questions Addressed by the Report

Need a Tailored Report?

Customize this report to your needs

Get 10% FREE Customization

Customize This ReportPersonalize This Research

- Triangulate with your Own Data

- Get Data as per your Format and Definition

- Gain a Deeper Dive on a Specific Application, Geography, Customer or Competitor

- Any level of Personalization

Let Us Help You

- What are the Known and Unknown Adjacencies Impacting the Variable Frequency Drive Market

- What will your New Revenue Sources be?

- Who will be your Top Customer; what will make them switch?

- Defend your Market Share or Win Competitors

- Get a Scorecard for Target Partners

Custom Market Research Services

We Will Customise The Research For You, In Case The Report Listed Above Does Not Meet With Your Requirements

Get 10% Free CustomisationGrowth opportunities and latent adjacency in Variable Frequency Drive Market

Susan

Jun, 2022

Explore more revenue pockets in Variable Frequency Drive Market for forecast period 2022 to 2030..