2

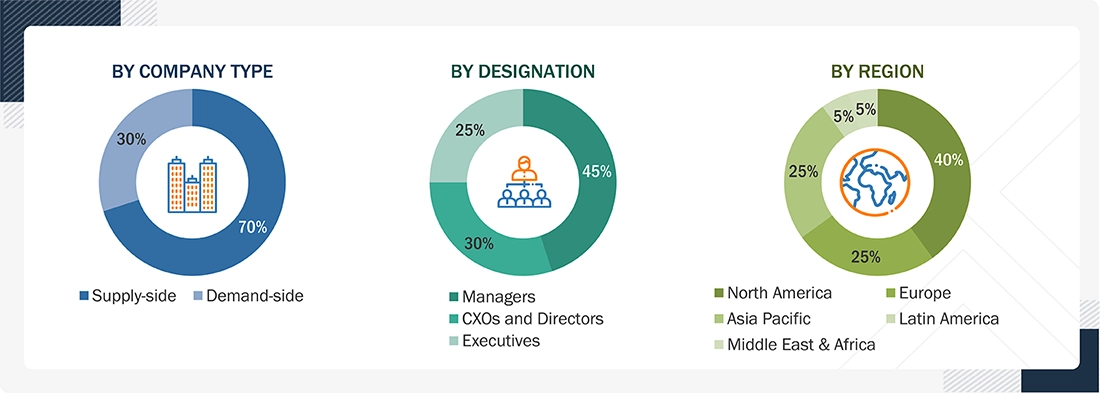

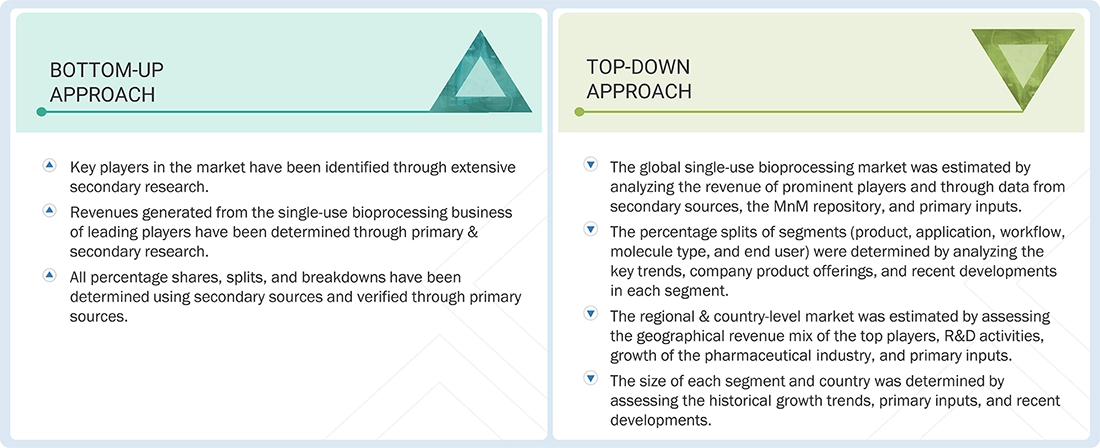

RESEARCH METHODOLOGY

54

5

MARKET OVERVIEW

Single-use bioprocessing boosts efficiency, cuts costs, and drives sustainable growth in biologics markets.

82

5.2.1.1

GROWING ADOPTION AMONG CDMOS & CMOS

5.2.1.2

INCREASED PRODUCTIVITY AND REDUCED RISK OF CROSS-CONTAMINATION

5.2.1.3

REDUCED CAPITAL INVESTMENT COMPARED TO TRADITIONAL STAINLESS-STEEL SYSTEMS

5.2.1.4

BETTER ENVIRONMENTAL SUSTAINABILITY DUE TO REDUCED WATER AND ENERGY CONSUMPTION

5.2.1.5

GROWING BIOLOGICS & BIOSIMILARS MARKET

5.2.2.1

ISSUES RELATED TO LEACHABLES AND EXTRACTABLES

5.2.2.2

IMPACT OF PFAS RESTRICTIONS ON PRODUCT DEVELOPMENT

5.2.3.1

UNTAPPED MARKET POTENTIAL IN EMERGING ECONOMIES

5.2.3.2

CUSTOMIZATION OPTIONS FOR ENHANCED GROWTH AND INNOVATION

5.2.4.1

LACK OF STANDARDIZATION

5.2.4.2

ENVIRONMENTAL AND LOGISTICAL CHALLENGES IN SINGLE-USE BIOPROCESSING WASTE DISPOSAL

5.2.4.3

POTENTIAL BREAKAGE OF SU BAGS

5.2.4.4

REGULATORY COMPLIANCE ISSUES

6

INDUSTRY TRENDS

Navigate market shifts and leverage technology to outpace competition in bioprocessing.

94

6.1

TRENDS/DISRUPTIONS IMPACTING CUSTOMERS’ BUSINESSES

6.2

PORTER’S FIVE FORCES ANALYSIS

6.2.1

THREAT OF NEW ENTRANTS

6.2.2

THREAT OF SUBSTITUTES

6.2.3

BARGAINING POWER OF BUYERS

6.2.4

BARGAINING POWER OF SUPPLIERS

6.2.5

INTENSITY OF COMPETITIVE RIVALRY

6.3

KEY STAKEHOLDERS & BUYING CRITERIA

6.3.1

KEY STAKEHOLDERS IN BUYING PROCESS

6.3.2

KEY BUYING CRITERIA

6.3.3

ADOPTION BARRIERS & INTERNAL CHALLENGES

6.4.1

INDICATIVE PRICING ANALYSIS OF SINGLE-USE BIOPROCESSING PRODUCTS, BY KEY PLAYER, 2024

6.4.2

INDICATIVE PRICING ANALYSIS OF SINGLE-USE BIOREACTORS, BY REGION, 2024

6.7.2

COMPLEMENTARY TECHNOLOGIES

6.7.2.1

AUTOMATION & CONTROL SYSTEMS

6.7.2.3

CONTINUOUS BIOPROCESSING

6.7.3

ADJACENT TECHNOLOGIES

6.7.3.1

BIOPROCESS MODELING & SIMULATION

6.7.3.2

BIOPROCESS MONITORING & DATA ANALYSIS

6.8.1

TOP APPLICANTS/OWNERS (COMPANIES) FOR SINGLE-USE BIOPROCESSING PATENTS, 2014–2024

6.8.2

INDICATIVE LIST OF PATENTS

6.9

KEY CONFERENCES & EVENTS, 2025–2026

6.10.1

REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

6.10.2

REGULATORY FRAMEWORK

6.10.3

SUSTAINABILITY INITIATIVES

6.11

INVESTMENT & FUNDING SCENARIO

6.12.1

IMPORT DATA FOR HS CODE 902720 AND 842129, 2020–2024

6.12.2

EXPORT DATA FOR HS CODE 902720 AND 842129, 2020–2024

6.13

SUCCESS STORIES AND REAL-WORLD APPLICATIONS

6.13.1

SARTORIUS: COMMERCIAL BIOMANUFACTURING WITH SINGLE-USE TECHNOLOGIES

6.13.2

REVOLUTIONIZING VACCINES WITH THERMO SCIENTIFIC HYPERFORMA SINGLE-USE FERMENTOR

6.14

TECHNOLOGY/PRODUCT ROADMAP

6.15.1

SINGLE-USE SYSTEMS IN CELL & GENE THERAPY MANUFACTURING

6.15.2

INTEGRATION WITH CONTINUOUS BIOPROCESSING

6.15.3

ADVANCED SINGLE-USE BIOREACTORS FOR PERSONALIZED MEDICINE

6.16.1

STRATEGIC ANALYSIS OF GROWTH OPPORTUNITIES

6.16.2

UNMET NEEDS FROM VARIOUS END-USE INDUSTRIES

6.17

IMPACT OF AI/GENERATIVE AI ON SINGLE-USE BIOPROCESSING MARKET

6.17.1

TOP USE CASES AND MARKET POTENTIAL

6.17.2

CASE STUDIES OF AI IMPLEMENTATION IN SINGLE-USE BIOPROCESSING MARKET

6.17.3

BEST PRACTICES IN SINGLE-USE BIOPROCESSING

6.18

IMPACT OF 2025 US TARIFF ON SINGLE-USE BIOPROCESSING MARKET

6.18.3

PRICE IMPACT ANALYSIS

6.18.4

IMPACT ON COUNTRY/REGION

6.18.5

IMPACT ON END-USE INDUSTRIES

6.18.5.1

PHARMACEUTICAL & BIOTECHNOLOGY COMPANIES

7

SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT

Market Size & Growth Rate Forecast Analysis to 2030 in USD Million | 319 Data Tables

133

7.2.1

SINGLE-USE BIOREACTORS

7.2.1.1

≤10 L BIOREACTORS

7.2.1.2

11–100 L BIOREACTORS

7.2.1.3

101–500 L BIOREACTORS

7.2.1.4

501–1,500 L BIOREACTORS

7.2.1.5

>1,500L BIOREACTORS

7.2.2

SINGLE-USE FILTRATION SYSTEMS

7.2.2.1

MANUFACTURING-SCALE FILTRATION SYSTEMS

7.2.2.2

PILOT-SCALE FILTRATION SYSTEMS

7.2.2.3

R&D-SCALE FILTRATION SYSTEMS

7.2.3

SINGLE-USE MIXING SYSTEMS

7.2.3.1

MANUFACTURING-SCALE MIXING SYSTEMS

7.2.3.2

PILOT-SCALE MIXING SYSTEMS

7.2.3.3

R&D-SCALE MIXING SYSTEMS

7.2.4

SINGLE-USE CHROMATOGRAPHY SYSTEMS

7.2.4.1

REDUCED COST-EFFECTIVENESS AND SLOW ADOPTION IN BIOPHARMACEUTICAL PRODUCTION TO RESTRAIN MARKET GROWTH

7.2.5

OTHER SINGLE-USE EQUIPMENT

7.3.1

SINGLE-USE BAGS & CONTAINERS

7.3.1.1

2D BAGS & CONTAINERS

7.3.1.2

3D BAGS & CONTAINERS

7.3.2.1

SINGLE-USE FILTERS TO BE COST-EFFECTIVE AND HELP IN CONTAMINATION CONTROL AND OPERATIONAL EFFICIENCY

7.3.3

SINGLE-USE ASSEMBLIES

7.3.3.2

FILTRATION ASSEMBLIES

7.3.3.3

BOTTLE ASSEMBLIES

7.3.3.4

MIXING SYSTEM ASSEMBLIES

7.3.4

SINGLE-USE CHROMATOGRAPHY COLUMNS

7.3.4.1

REPRODUCIBILITY, SCALABILITY, SPEED, EASE OF USE, AND OPERATIONAL SAFETY OF CHROMATOGRAPHY COLUMNS TO BOOST DEMAND

7.3.5.4

TEMPERATURE SENSORS

7.3.5.5

CONDUCTIVITY SENSORS

7.3.6

OTHER SINGLE-USE CONSUMABLES

7.3.6.6

OTHER CONSUMABLES

8

SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION

Market Size & Growth Rate Forecast Analysis to 2030 in USD Million | 43 Data Tables

281

8.2.1

FILTRATION TO BE USEFUL IN CLARIFICATION, STERILIZATION, AND VIRUS-REMOVAL OPERATIONS IN BIOPHARMACEUTICAL SECTOR

8.3.1

REDUCED RISK OF CONTAMINATION AND FOCUS ON COST EFFICIENCY TO SUPPORT MARKET GROWTH

8.4.1

COST-EFFICTIVENESS AND ADVANCEMENTS IN SINGLE-USE MIXER DESIGNS TO DRIVE DEMAND FOR DISPOSABLE MIXING SYSTEMS

8.5.1

BENEFITS OF ADVANCED SINGLE-USE PURIFICATION TECHNOLOGIES IN MAB AND CELL & GENE THERAPY TO AID MARKET GROWTH

8.6.1

RISING COMPLEXITY AND VOLUME OF CELL & GENE THERAPIES TO INCREASE DEMAND FOR SINGLE-USE CONTAINERS

9

SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW

Market Size & Growth Rate Forecast Analysis to 2030 in USD Million | 15 Data Tables

304

9.2

UPSTREAM BIOPROCESSING

9.2.1

REDUCED RISK OF CONTAMINATION AND COST EFFICIENCY TO SUPPORT MARKET GROWTH

9.3

DOWNSTREAM BIOPROCESSING

9.3.1

ADVANCEMENTS IN DISPOSABLE CHROMATOGRAPHY, FILTRATION, AND VIRUS CLEARANCE SYSTEMS TO DRIVE MARKET

10

SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE

Market Size & Growth Rate Forecast Analysis to 2030 in USD Million | 35 Data Tables

313

10.2

MONOCLONAL ANTIBODIES

10.2.1

EXPANDING THERAPEUTIC LANDSCAPE AND GROWING PIPELINE DIVERSIFICATION TO DRIVE MARKET

10.2.2

SINGLE-USE BIOPROCESSING MARKET FOR MONOCLONAL ANTIBODIES, BY PRODUCT

10.3.1

HIGHER IMMUNIZATION PROGRAMS AND CONTINUED SUCCESS OF MRNA AND VIRAL VECTOR-BASED TECHNOLOGIES TO AID MARKET

10.3.2

SINGLE-USE BIOPROCESSING MARKET FOR VACCINES, BY PRODUCT

10.4

THERAPEUTIC PROTEINS & PEPTIDES

10.4.1

RISING DEMAND FOR COMPLEX BIOLOGICS AND FLEXIBLE MANUFACTURING TO AUGMENT SINGLE-USE ADOPTION

10.4.2

SINGLE-USE BIOPROCESSING MARKET FOR THERAPEUTIC PROTEINS & PEPTIDES, BY PRODUCT

10.5

CELL & GENE THERAPIES

10.5.1

RISING R&D INITIATIVES AND FUNDS FOR CELL & GENE THERAPY DEVELOPMENT TO DRIVE MARKET

10.5.2

SINGLE-USE BIOPROCESSING MARKET FOR CELL & GENE THERAPIES, BY PRODUCT

11

SINGLE-USE BIOPROCESSING MARKET, BY END USER

Market Size & Growth Rate Forecast Analysis to 2030 in USD Million | 22 Data Tables

333

11.2

PHARMACEUTICAL & BIOTECHNOLOGY COMPANIES

11.2.1

INCREASE IN R&D EXPENDITURE AND PIPELINE EXPANSION TO SUSTAIN MARKET GROWTH

11.3.1

RISING OUTSOURCING OF CLINICAL DEVELOPMENT AND GMP MANUFACTURING TO AUGMENT MARKET GROWTH

12

SINGLE-USE BIOPROCESSING MARKET, BY REGION

Comprehensive coverage of 7 Regions with country-level deep-dive of 16 Countries | 209 Data Tables.

346

12.2.1

MACROECONOMIC OUTLOOK FOR NORTH AMERICA

12.2.2.1

US TO DOMINATE NORTH AMERICAN SINGLE-USE BIOPROCESSING MARKET DURING FORECAST PERIOD

12.2.3.1

INCREASING DEMAND FOR BIOPHARMACEUTICALS & BIOLOGICS AND RISING GOVERNMENT INVESTMENTS TO DRIVE MARKET

12.3.1

MACROECONOMIC OUTLOOK FOR EUROPE

12.3.2.1

STRONG BIOPHARMACEUTICAL MANUFACTURING BASE AND ADVANCED R&D INFRASTRUCTURE TO SUPPORT MARKET GROWTH

12.3.3.1

STRONG GOVERNMENT SUPPORT FOR BIOMANUFACTURING INNOVATION AND DYNAMIC BIOTECHNOLOGY ECOSYSTEM TO BOOST MARKET GROWTH

12.3.4.1

HIGH BIOMANUFACTURING INVESTMENTS AND GOVERNMENT-BACKED INNOVATION PROGRAMS TO FUEL MARKET GROWTH

12.3.5.1

INCREASING GOVERNMENT FUNDING FOR BIOPHARMACEUTICAL RESEARCH TO SPUR MARKET GROWTH

12.3.6.1

RISING FOCUS ON DEVELOPING PERSONALIZED MEDICINES TO SUPPORT MARKET GROWTH

12.4.1

MACROECONOMIC OUTLOOK FOR ASIA PACIFIC

12.4.2.1

LOW MANUFACTURING COSTS AND HUGE DEMAND FOR PERSONALIZED MEDICINES TO PROPEL MARKET GROWTH

12.4.3.1

INCREASED FOCUS ON QUALITY MANUFACTURING PRACTICES TO SUPPORT MARKET GROWTH

12.4.4.1

RISING COLLABORATIONS AMONG BIOTECHNOLOGY COMPANIES TO DRIVE MARKET

12.4.5.1

FAVORABLE SCENARIO FOR FOREIGN DIRECT INVESTMENT TO PROPEL MARKET GROWTH

12.4.6.1

INCREASING DEMAND FOR INNOVATIVE RESEARCH SOLUTIONS TO PROPEL MARKET

12.4.7

REST OF ASIA PACIFIC

12.5.1

MACROECONOMIC OUTLOOK FOR LATIN AMERICA

12.5.2.1

INCREASED BIOMANUFACTURING OF BIOLOGICS AND PHARMACEUTICAL R&D TO FOSTER MARKET GROWTH

12.5.3.1

RISING DEMAND FOR CHRONIC DISEASE TREATMENT TO SUPPORT MARKET GROWTH

12.5.4

REST OF LATIN AMERICA

12.6.1

MACROECONOMIC OUTLOOK FOR MIDDLE EAST

12.6.2.1

KINGDOM OF SAUDI ARABIA

12.6.2.3

REST OF GCC COUNTRIES

12.6.3

REST OF MIDDLE EAST

12.7.1

GROWING MARKET FOR PHARMACEUTICALS AND INCREASING DEMAND FOR DRUGS TO PROPEL MARKET

12.7.2

MACROECONOMIC OUTLOOK FOR AFRICA

13

COMPETITIVE LANDSCAPE

Discover strategic maneuvers and market positions of key players in single-use bioprocessing.

450

13.2

KEY PLAYER STRATEGY/RIGHT TO WIN

13.2.1

OVERVIEW OF STRATEGIES ADOPTED BY KEY PLAYERS IN SINGLE-USE BIOPROCESSING MARKET

13.3

REVENUE ANALYSIS, 2020–2024

13.4

MARKET SHARE ANALYSIS, 2024

13.5

COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

13.5.5

COMPANY FOOTPRINT: KEY PLAYERS, 2024

13.5.5.1

COMPANY FOOTPRINT

13.5.5.2

REGION FOOTPRINT

13.5.5.3

PRODUCT FOOTPRINT

13.5.5.4

APPLICATION FOOTPRINT

13.5.5.5

WORKFLOW FOOTPRINT

13.6

COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

13.6.1

PROGRESSIVE COMPANIES

13.6.2

RESPONSIVE COMPANIES

13.6.5

COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

13.6.5.1

DETAILED LIST OF KEY STARTUPS/SMES

13.6.5.2

COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES

13.7

COMPANY VALUATION & FINANCIAL METRICS

13.8

BRAND/PRODUCT COMPARISION

13.9

COMPETITIVE SCENARIO

14

COMPANY PROFILES

In-depth Company Profiles of Leading Market Players with detailed Business Overview, Product and Service Portfolio, Recent Developments, and Unique Analyst Perspective (MnM View)

473

14.2.1.1

BUSINESS OVERVIEW

14.2.1.2

PRODUCTS OFFERED

14.2.1.3

RECENT DEVELOPMENTS

14.2.2

DANAHER CORPORATION

14.2.3

THERMO FISHER SCIENTIFIC INC.

14.2.7

REPLIGEN CORPORATION

14.2.10

PARKER HANNIFIN CORP.

14.2.14

CORNING INCORPORATED

14.3.2

SINGLE USE SUPPORT

14.3.4

BROADLEY-JAMES CORPORATION

14.3.6

SENTINEL PROCESS SYSTEMS INC.

14.3.7

MEISSNER FILTRATION PRODUCTS, INC.

14.3.8

SATAKE MULTIMIX CORPORATION

14.3.10

MEMBRANE SOLUTIONS

14.3.11

ANTYLIA SCIENTIFIC

14.3.13

ESCO LIFESCIENCES GROUP

15.2

KNOWLEDGESTORE: MARKETSANDMARKETS’ SUBSCRIPTION PORTAL

15.3

CUSTOMIZATION OPTIONS

TABLE 1

SINGLE–USE BIOPROCESSING MARKET: INCLUSIONS & EXCLUSIONS

TABLE 2

IMPACT ANALYSIS OF SUPPLY– AND DEMAND–SIDE FACTORS

TABLE 3

SINGLE–USE BIOPROCESSING MARKET: RISK ANALYSIS

TABLE 4

SINGLE-USE BIOPROCESSING MARKET: EMERGING BUSINESS MODELS & TARGET SEGMENTS

TABLE 5

SINGLE-USE BIOPROCESSING MARKET: STRATEGIC ANALYSIS OF GROWTH OPPORTUNITIES

TABLE 6

SINGLE-USE BIOPROCESSING MARKET: IMPACT ANALYSIS

TABLE 7

WATER AND ENERGY CONSUMPTION FOR COMMERCIAL MAB PRODUCTION AT 3 X 2,000 L SCALE

TABLE 8

EXAMPLES OF ORGANIZATIONS INVOLVED IN SU STANDARDS

TABLE 9

COMPARISON OF SINGLE-USE BIOPROCESS SYSTEM DISPOSAL OPTIONS

TABLE 10

SINGLE-USE BIOPROCESSING MARKET: PORTER’S FIVE FORCES

TABLE 11

BUYING CRITERIA FOR SINGLE-USE BIOPROCESSING PRODUCTS, BY END USER

TABLE 12

INDICATIVE PRICING ANALYSIS OF SINGLE-USE BIOPROCESSING PRODUCTS, BY KEY PLAYER, 2024

TABLE 13

INDICATIVE PRICING ANALYSIS OF SINGLE-USE BIOREACTORS, BY REGION, 2024

TABLE 14

SINGLE-USE BIOPROCESSING MARKET: ROLE IN ECOSYSTEM

TABLE 15

SINGLE-USE BIOPROCESSING MARKET: INDICATIVE LIST OF PATENTS, 2024–2025

TABLE 16

SINGLE-USE BIOPROCESSING MARKET: LIST OF CONFERENCES & EVENTS, JANUARY 2025–DECEMBER 2026

TABLE 17

NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 18

EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 19

ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 20

LATIN AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 21

MIDDLE EAST & AFRICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 22

IMPORT VALUE FOR HS CODE 902720, 2020–2024 (USD THOUSAND)

TABLE 23

IMPORT VOLUME FOR HS CODE 902720, 2020–2024 (TONS)

TABLE 24

IMPORT VALUE FOR HS CODE 842129, 2020–2024 (USD THOUSAND)

TABLE 25

IMPORT VOLUME FOR HS CODE 842129, 2020–2024 (TONS)

TABLE 26

EXPORT VALUE FOR HS CODE 902720, 2020–2024 (USD THOUSAND)

TABLE 27

EXPORT VOLUME FOR HS CODE 902720, 2020–2024 (TONS)

TABLE 28

EXPORT VALUE FOR HS CODE 842129, 2020–2024 (USD THOUSAND)

TABLE 29

EXPORT VOLUME FOR HS CODE 842129, 2020–2024 (TONS)

TABLE 30

CASE STUDIES OF AI IMPLEMENTATION IN SINGLE-USE BIOPROCESSING MARKET

TABLE 31

US-ADJUSTED RECIPROCAL TARIFF RATES

TABLE 32

SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 33

SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 34

SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 35

NORTH AMERICA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 36

EUROPE: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 37

ASIA PACIFIC: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 38

LATIN AMERICA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 39

MIDDLE EAST: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 40

GCC COUNTRIES: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 41

COMPARISON OF SINGLE-USE AND MULTIUSE BIOREACTORS

TABLE 42

SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 43

NORTH AMERICA: SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 44

EUROPE: SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 45

ASIA PACIFIC: SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 46

LATIN AMERICA: SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 47

MIDDLE EAST: SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 48

GCC COUNTRIES: SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 49

SINGLE-USE BIOREACTORS MARKET, BY SCALE RANGE, 2023–2030 (USD MILLION)

TABLE 50

≤10 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 51

NORTH AMERICA: ≤10 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 52

EUROPE: ≤10 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 53

ASIA PACIFIC: ≤10 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 54

LATIN AMERICA: ≤10 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 55

MIDDLE EAST: ≤10 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 56

GCC COUNTRIES: ≤10 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 57

11–100 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 58

NORTH AMERICA: 11–100 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 59

EUROPE: 11–100 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 60

ASIA PACIFIC: 11–100 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 61

LATIN AMERICA: 11–100 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 62

MIDDLE EAST: 11–100 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 63

GCC COUNTRIES: 11–100 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 64

101–500 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 65

NORTH AMERICA: 101–500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 66

EUROPE: 101–500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 67

ASIA PACIFIC: 101–500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 68

LATIN AMERICA: 101–500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 69

MIDDLE EAST: 101–500 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 70

GCC COUNTRIES: 101–500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 71

501–1,500 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 72

NORTH AMERICA: 501–1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 73

EUROPE: 501–1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 74

ASIA PACIFIC: 501–1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 75

LATIN AMERICA: 501–1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 76

MIDDLE EAST: 501–1,500 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 77

GCC COUNTRIES: 501–1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 78

>1,500 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 79

NORTH AMERICA: >1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 80

EUROPE: >1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 81

ASIA PACIFIC: >1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 82

LATIN AMERICA: >1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 83

MIDDLE EAST: >1,500 L SINGLE-USE BIOREACTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 84

GCC COUNTRIES: >1,500 L SINGLE-USE BIOREACTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 85

SINGLE-USE FILTRATION SYSTEMS MARKET, BY SCALE, 2023–2030 (USD MILLION)

TABLE 86

SINGLE-USE FILTRATION SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 87

NORTH AMERICA: SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 88

EUROPE: SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 89

ASIA PACIFIC: SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 90

LATIN AMERICA: SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 91

MIDDLE EAST: SINGLE-USE FILTRATION SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 92

GCC COUNTRIES: SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 93

MANUFACTURING-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 94

NORTH AMERICA: MANUFACTURING-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 95

EUROPE: MANUFACTURING-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 96

ASIA PACIFIC: MANUFACTURING-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 97

LATIN AMERICA: MANUFACTURING-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 98

MIDDLE EAST: MANUFACTURING-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 99

GCC COUNTRIES: MANUFACTURING-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 100

PILOT-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 101

NORTH AMERICA: PILOT-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 102

EUROPE: PILOT-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 103

ASIA PACIFIC: PILOT-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 104

LATIN AMERICA: PILOT-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 105

MIDDLE EAST: PILOT-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 106

GCC COUNTRIES: PILOT-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 107

R&D-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 108

NORTH AMERICA: R&D-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 109

EUROPE: R&D-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 110

ASIA PACIFIC: R&D-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 111

LATIN AMERICA: R&D-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 112

MIDDLE EAST: R&D-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 113

GCC COUNTRIES: R&D-SCALE SINGLE-USE FILTRATION SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 114

SINGLE-USE MIXING SYSTEMS MARKET, BY SCALE, 2023–2030 (USD MILLION)

TABLE 115

SINGLE-USE MIXING SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 116

NORTH AMERICA: SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 117

EUROPE: SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 118

ASIA PACIFIC: SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 119

LATIN AMERICA: SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 120

MIDDLE EAST: SINGLE-USE MIXING SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 121

GCC COUNTRIES: SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 122

MANUFACTURING-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 123

NORTH AMERICA: MANUFACTURING-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 124

EUROPE: MANUFACTURING-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 125

ASIA PACIFIC: MANUFACTURING-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 126

LATIN AMERICA: MANUFACTURING-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 127

MIDDLE EAST: MANUFACTURING-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 128

GCC COUNTRIES: MANUFACTURING-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 129

PILOT-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 130

NORTH AMERICA: PILOT-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 131

EUROPE: PILOT-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 132

ASIA PACIFIC: PILOT-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 133

LATIN AMERICA: PILOT-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 134

MIDDLE EAST: PILOT-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 135

GCC COUNTRIES: PILOT-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 136

R&D-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 137

NORTH AMERICA: R&D-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 138

EUROPE: R&D-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 139

ASIA PACIFIC: R&D-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 140

LATIN AMERICA: R&D-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 141

MIDDLE EAST: R&D-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 142

GCC COUNTRIES: R&D-SCALE SINGLE-USE MIXING SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 143

SINGLE-USE CHROMATOGRAPHY SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 144

NORTH AMERICA: SINGLE-USE CHROMATOGRAPHY SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 145

EUROPE: SINGLE-USE CHROMATOGRAPHY SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 146

ASIA PACIFIC: SINGLE-USE CHROMATOGRAPHY SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 147

LATIN AMERICA: SINGLE-USE CHROMATOGRAPHY SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 148

MIDDLE EAST: SINGLE-USE CHROMATOGRAPHY SYSTEMS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 149

GCC COUNTRIES: SINGLE-USE CHROMATOGRAPHY SYSTEMS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 150

OTHER SINGLE-USE EQUIPMENT MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 151

NORTH AMERICA: OTHER SINGLE-USE EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 152

EUROPE: OTHER SINGLE-USE EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 153

ASIA PACIFIC: OTHER SINGLE-USE EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 154

LATIN AMERICA: OTHER SINGLE-USE EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 155

MIDDLE EAST: OTHER SINGLE-USE EQUIPMENT MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 156

GCC COUNTRIES: OTHER SINGLE-USE EQUIPMENT MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 157

SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 158

SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 159

NORTH AMERICA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 160

EUROPE: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 161

ASIA PACIFIC: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 162

LATIN AMERICA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 163

MIDDLE EAST: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 164

GCC COUNTRIES: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 165

SINGLE-USE BAGS & CONTAINERS MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 166

SINGLE-USE BAGS & CONTAINERS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 167

NORTH AMERICA: SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 168

EUROPE: SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 169

ASIA PACIFIC: SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 170

LATIN AMERICA: SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 171

MIDDLE EAST: SINGLE-USE BAGS & CONTAINERS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 172

GCC COUNTRIES: SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 173

2D SINGLE-USE BAGS & CONTAINERS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 174

NORTH AMERICA: 2D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 175

EUROPE: 2D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 176

ASIA PACIFIC: 2D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 177

LATIN AMERICA: 2D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 178

MIDDLE EAST: 2D SINGLE-USE BAGS & CONTAINERS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 179

GCC COUNTRIES: 2D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 180

3D SINGLE-USE BAGS & CONTAINERS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 181

NORTH AMERICA: 3D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 182

EUROPE: 3D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 183

ASIA PACIFIC: 3D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 184

LATIN AMERICA: 3D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 185

MIDDLE EAST: 3D SINGLE-USE BAGS & CONTAINERS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 186

GCC COUNTRIES: 3D SINGLE-USE BAGS & CONTAINERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 187

SINGLE-USE FILTERS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 188

NORTH AMERICA: SINGLE-USE FILTERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 189

EUROPE: SINGLE-USE FILTERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 190

ASIA PACIFIC: SINGLE-USE FILTERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 191

LATIN AMERICA: SINGLE-USE FILTERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 192

MIDDLE EAST: SINGLE-USE FILTERS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 193

GCC COUNTRIES: SINGLE-USE FILTERS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 194

SINGLE-USE ASSEMBLIES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 195

SINGLE-USE ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 196

NORTH AMERICA: SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 197

EUROPE: SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 198

ASIA PACIFIC: SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 199

LATIN AMERICA: SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 200

MIDDLE EAST: SINGLE-USE ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 201

GCC COUNTRIES: SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 202

SINGLE-USE BAG ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 203

NORTH AMERICA: SINGLE-USE BAG ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 204

EUROPE: SINGLE-USE BAG ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 205

ASIA PACIFIC: SINGLE-USE BAG ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 206

LATIN AMERICA: SINGLE-USE BAG ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 207

MIDDLE EAST: SINGLE-USE BAG ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 208

GCC COUNTRIES: SINGLE-USE BAG ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 209

SINGLE-USE FILTRATION ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 210

NORTH AMERICA: SINGLE-USE FILTRATION ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 211

EUROPE: SINGLE-USE FILTRATION ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 212

ASIA PACIFIC: SINGLE-USE FILTRATION ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 213

LATIN AMERICA: SINGLE-USE FILTRATION ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 214

MIDDLE EAST: SINGLE-USE FILTRATION ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 215

GCC COUNTRIES: SINGLE-USE FILTRATION ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 216

SINGLE-USE BOTTLE ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 217

NORTH AMERICA: SINGLE-USE BOTTLE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 218

EUROPE: SINGLE-USE BOTTLE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 219

ASIA PACIFIC: SINGLE-USE BOTTLE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 220

LATIN AMERICA: SINGLE-USE BOTTLE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 221

MIDDLE EAST: SINGLE-USE BOTTLE ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 222

GCC COUNTRIES: SINGLE-USE BOTTLE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 223

SINGLE-USE MIXING SYSTEM ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 224

NORTH AMERICA: SINGLE-USE MIXING SYSTEM ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 225

EUROPE: SINGLE-USE MIXING SYSTEM ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 226

ASIA PACIFIC: SINGLE-USE MIXING SYSTEM ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 227

LATIN AMERICA: SINGLE-USE MIXING SYSTEM ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 228

MIDDLE EAST: SINGLE-USE MIXING SYSTEM ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 229

GCC COUNTRIES: SINGLE-USE MIXING SYSTEM ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 230

OTHER SINGLE-USE ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 231

NORTH AMERICA: OTHER SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 232

EUROPE: OTHER SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 233

ASIA PACIFIC: OTHER SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 234

LATIN AMERICA: OTHER SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 235

MIDDLE EAST: OTHER SINGLE-USE ASSEMBLIES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 236

GCC COUNTRIES: OTHER SINGLE-USE ASSEMBLIES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 237

SINGLE-USE CHROMATOGRAPHY COLUMNS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 238

NORTH AMERICA: SINGLE-USE CHROMATOGRAPHY COLUMNS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 239

EUROPE: SINGLE-USE CHROMATOGRAPHY COLUMNS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 240

ASIA PACIFIC: SINGLE-USE CHROMATOGRAPHY COLUMNS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 241

LATIN AMERICA: SINGLE-USE CHROMATOGRAPHY COLUMNS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 242

MIDDLE EAST: SINGLE-USE CHROMATOGRAPHY COLUMNS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 243

GCC COUNTRIES: SINGLE-USE CHROMATOGRAPHY COLUMNS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 244

SINGLE-USE SENSORS MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 245

SINGLE-USE SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 246

NORTH AMERICA: SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 247

EUROPE: SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 248

ASIA PACIFIC: SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 249

LATIN AMERICA: SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 250

MIDDLE EAST: SINGLE-USE SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 251

GCC COUNTRIES: SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 252

SINGLE-USE PH SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 253

NORTH AMERICA: SINGLE-USE PH SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 254

EUROPE: SINGLE-USE PH SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 255

ASIA PACIFIC: SINGLE-USE PH SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 256

LATIN AMERICA: SINGLE-USE PH SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 257

MIDDLE EAST: SINGLE-USE PH SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 258

GCC COUNTRIES: SINGLE-USE PH SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 259

SINGLE-USE OXYGEN SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 260

NORTH AMERICA: SINGLE-USE OXYGEN SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 261

EUROPE: SINGLE-USE OXYGEN SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 262

ASIA PACIFIC: SINGLE-USE OXYGEN SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 263

LATIN AMERICA: SINGLE-USE OXYGEN SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 264

MIDDLE EAST: SINGLE-USE OXYGEN SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 265

GCC COUNTRIES: SINGLE-USE OXYGEN SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 266

SINGLE-USE PRESSURE SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 267

NORTH AMERICA: SINGLE-USE PRESSURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 268

EUROPE: SINGLE-USE PRESSURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 269

ASIA PACIFIC: SINGLE-USE PRESSURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 270

LATIN AMERICA: SINGLE-USE PRESSURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 271

MIDDLE EAST: SINGLE-USE PRESSURE SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 272

GCC COUNTRIES: SINGLE-USE PRESSURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 273

SINGLE-USE TEMPERATURE SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 274

NORTH AMERICA: SINGLE-USE TEMPERATURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 275

EUROPE: SINGLE-USE TEMPERATURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 276

ASIA PACIFIC: SINGLE-USE TEMPERATURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 277

LATIN AMERICA: SINGLE-USE TEMPERATURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 278

MIDDLE EAST: SINGLE-USE TEMPERATURE SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 279

GCC COUNTRIES: SINGLE-USE TEMPERATURE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 280

SINGLE-USE CONDUCTIVITY SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 281

NORTH AMERICA: SINGLE-USE CONDUCTIVITY SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 282

EUROPE: SINGLE-USE CONDUCTIVITY SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 283

ASIA PACIFIC: SINGLE-USE CONDUCTIVITY SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 284

LATIN AMERICA: SINGLE-USE CONDUCTIVITY SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 285

MIDDLE EAST: SINGLE-USE CONDUCTIVITY SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 286

GCC COUNTRIES: SINGLE-USE CONDUCTIVITY SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 287

SINGLE-USE FLOW SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 288

NORTH AMERICA: SINGLE-USE FLOW SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 289

EUROPE: SINGLE-USE FLOW SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 290

ASIA PACIFIC: SINGLE-USE FLOW SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 291

LATIN AMERICA: SINGLE-USE FLOW SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 292

MIDDLE EAST: SINGLE-USE FLOW SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 293

GCC COUNTRIES: SINGLE-USE FLOW SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 294

OTHER SINGLE-USE SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 295

NORTH AMERICA: OTHER SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 296

EUROPE: OTHER SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 297

ASIA PACIFIC: OTHER SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 298

LATIN AMERICA: OTHER SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 299

MIDDLE EAST: OTHER SINGLE-USE SENSORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 300

GCC COUNTRIES: OTHER SINGLE-USE SENSORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 301

OTHER SINGLE-USE CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 302

OTHER SINGLE-USE CONSUMABLES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 303

NORTH AMERICA: OTHER SINGLE-USE CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 304

EUROPE: OTHER SINGLE-USE CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 305

ASIA PACIFIC: OTHER SINGLE-USE CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 306

LATIN AMERICA: OTHER SINGLE-USE CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 307

MIDDLE EAST: OTHER SINGLE-USE CONSUMABLES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 308

GCC COUNTRIES: OTHER SINGLE-USE CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 309

SINGLE-USE TUBING MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 310

NORTH AMERICA: SINGLE-USE TUBING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 311

EUROPE: SINGLE-USE TUBING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 312

ASIA PACIFIC: SINGLE-USE TUBING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 313

LATIN AMERICA: SINGLE-USE TUBING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 314

MIDDLE EAST: SINGLE-USE TUBING MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 315

GCC COUNTRIES: SINGLE-USE TUBING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 316

SINGLE-USE CONNECTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 317

NORTH AMERICA: SINGLE-USE CONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 318

EUROPE: SINGLE-USE CONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 319

ASIA PACIFIC: SINGLE-USE CONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 320

LATIN AMERICA: SINGLE-USE CONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 321

MIDDLE EAST: SINGLE-USE CONNECTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 322

GCC COUNTRIES: SINGLE-USE CONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 323

SINGLE-USE DISCONNECTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 324

NORTH AMERICA: SINGLE-USE DISCONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 325

EUROPE: SINGLE-USE DISCONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 326

ASIA PACIFIC: SINGLE-USE DISCONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 327

LATIN AMERICA: SINGLE-USE DISCONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 328

MIDDLE EAST: SINGLE-USE DISCONNECTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 329

GCC COUNTRIES: SINGLE-USE DISCONNECTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 330

SINGLE-USE ADAPTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 331

NORTH AMERICA: SINGLE-USE ADAPTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 332

EUROPE: SINGLE-USE ADAPTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 333

ASIA PACIFIC: SINGLE-USE ADAPTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 334

LATIN AMERICA: SINGLE-USE ADAPTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 335

MIDDLE EAST: SINGLE-USE ADAPTORS MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 336

GCC COUNTRIES: SINGLE-USE ADAPTORS MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 337

SINGLE-USE VALVES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 338

NORTH AMERICA: SINGLE-USE VALVES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 339

EUROPE: SINGLE-USE VALVES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 340

ASIA PACIFIC: SINGLE-USE VALVES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 341

LATIN AMERICA: SINGLE-USE VALVES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 342

MIDDLE EAST: SINGLE-USE VALVES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 343

GCC COUNTRIES: SINGLE-USE VALVES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 344

OTHER CONSUMABLES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 345

NORTH AMERICA: OTHER CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 346

EUROPE: OTHER CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 347

ASIA PACIFIC: OTHER CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 348

LATIN AMERICA: OTHER CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 349

MIDDLE EAST: OTHER CONSUMABLES MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 350

GCC COUNTRIES: OTHER CONSUMABLES MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 351

SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 352

SINGLE-USE BIOPROCESSING MARKET FOR FILTRATION, BY REGION, 2023–2030 (USD MILLION)

TABLE 353

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR FILTRATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 354

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR FILTRATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 355

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR FILTRATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 356

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR FILTRATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 357

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR FILTRATION, BY REGION, 2023–2030 (USD MILLION)

TABLE 358

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR FILTRATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 359

SINGLE-USE BIOPROCESSING MARKET FOR CELL CULTURE, BY REGION, 2023–2030 (USD MILLION)

TABLE 360

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR CELL CULTURE, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 361

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR CELL CULTURE, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 362

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR CELL CULTURE, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 363

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR CELL CULTURE, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 364

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR CELL CULTURE, BY REGION, 2023–2030 (USD MILLION)

TABLE 365

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR CELL CULTURE, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 366

SINGLE-USE BIOPROCESSING MARKET FOR MIXING, BY REGION, 2023–2030 (USD MILLION)

TABLE 367

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR MIXING, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 368

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR MIXING, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 369

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR MIXING, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 370

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR MIXING, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 371

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR MIXING, BY REGION, 2023–2030 (USD MILLION)

TABLE 372

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR MIXING, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 373

SINGLE-USE BIOPROCESSING MARKET FOR PURIFICATION, BY REGION, 2023–2030 (USD MILLION)

TABLE 374

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR PURIFICATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 375

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR PURIFICATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 376

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR PURIFICATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 377

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR PURIFICATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 378

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR PURIFICATION, BY REGION, 2023–2030 (USD MILLION)

TABLE 379

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR PURIFICATION, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 380

SINGLE-USE BIOPROCESSING MARKET FOR STORAGE & TRANSFER, BY REGION, 2023–2030 (USD MILLION)

TABLE 381

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR STORAGE & TRANSFER, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 382

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR STORAGE & TRANSFER, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 383

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR STORAGE & TRANSFER, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 384

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR STORAGE & TRANSFER, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 385

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR STORAGE & TRANSFER, BY REGION, 2023–2030 (USD MILLION)

TABLE 386

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR STORAGE & TRANSFER, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 387

SINGLE-USE BIOPROCESSING MARKET FOR OTHER APPLICATIONS, BY REGION, 2023–2030 (USD MILLION)

TABLE 388

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR OTHER APPLICATIONS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 389

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR OTHER APPLICATIONS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 390

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR OTHER APPLICATIONS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 391

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR OTHER APPLICATIONS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 392

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR OTHER APPLICATIONS, BY REGION, 2023–2030 (USD MILLION)

TABLE 393

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR OTHER APPLICATIONS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 394

SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 395

SINGLE-USE UPSTREAM BIOPROCESSING MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 396

NORTH AMERICA: SINGLE-USE UPSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 397

EUROPE: SINGLE-USE UPSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 398

ASIA PACIFIC: SINGLE-USE UPSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 399

LATIN AMERICA: SINGLE-USE UPSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 400

MIDDLE EAST: SINGLE-USE UPSTREAM BIOPROCESSING MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 401

GCC COUNTRIES: SINGLE-USE UPSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 402

SINGLE-USE DOWNSTREAM BIOPROCESSING MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 403

NORTH AMERICA: SINGLE-USE DOWNSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 404

EUROPE: SINGLE-USE DOWNSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 405

ASIA PACIFIC: SINGLE-USE DOWNSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 406

LATIN AMERICA: SINGLE-USE DOWNSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 407

MIDDLE EAST: SINGLE-USE DOWNSTREAM BIOPROCESSING MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 408

GCC COUNTRIES: SINGLE-USE DOWNSTREAM BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 409

SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 410

LIST OF MONOCLONAL ANTIBODIES APPROVED BY FDA IN 2024

TABLE 411

SINGLE-USE BIOPROCESSING MARKET FOR MONOCLONAL ANTIBODIES, BY REGION, 2023–2030 (USD MILLION)

TABLE 412

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR MONOCLONAL ANTIBODIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 413

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR MONOCLONAL ANTIBODIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 414

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR MONOCLONAL ANTIBODIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 415

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR MONOCLONAL ANTIBODIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 416

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR MONOCLONAL ANTIBODIES, BY REGION, 2023–2030 (USD MILLION)

TABLE 417

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR MONOCLONAL ANTIBODIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 418

SINGLE-USE BIOPROCESSING MARKET FOR MONOCLONAL ANTIBODIES, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 419

SINGLE-USE BIOPROCESSING MARKET FOR VACCINES, BY REGION, 2023–2030 (USD MILLION)

TABLE 420

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR VACCINES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 421

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR VACCINES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 422

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR VACCINES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 423

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET VACCINES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 424

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR VACCINES, BY REGION, 2023–2030 (USD MILLION)

TABLE 425

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR VACCINES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 426

SINGLE-USE BIOPROCESSING MARKET FOR VACCINES, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 427

SINGLE-USE BIOPROCESSING MARKET FOR THERAPEUTIC PROTEINS & PEPTIDES, BY REGION, 2023–2030 (USD MILLION)

TABLE 428

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR THERAPEUTIC PROTEINS & PEPTIDES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 429

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR THERAPEUTIC PROTEINS & PEPTIDES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 430

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR THERAPEUTIC PROTEINS & PEPTIDES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 431

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR THERAPEUTIC PROTEINS & PEPTIDES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 432

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR THERAPEUTIC PROTEINS & PEPTIDES, BY REGION, 2023–2030 (USD MILLION)

TABLE 433

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR THERAPEUTIC PROTEINS & PEPTIDES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 434

SINGLE-USE BIOPROCESSING MARKET FOR THERAPEUTIC PROTEINS & PEPTIDES, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 435

NATIONAL INSTITUTES OF HEALTH FUNDING FOR STEM CELL-BASED RESEARCH, 2020–2024 (USD MILLION)

TABLE 436

SINGLE-USE BIOPROCESSING MARKET FOR CELL & GENE THERAPIES, BY REGION, 2023–2030 (USD MILLION)

TABLE 437

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR CELL & GENE THERAPIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 438

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR CELL & GENE THERAPIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 439

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR CELL & GENE THERAPIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 440

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET CELL & GENE THERAPIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 441

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR CELL & GENE THERAPIES, BY REGION, 2023–2030 (USD MILLION)

TABLE 442

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR CELL & GENE THERAPIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 443

SINGLE-USE BIOPROCESSING MARKET FOR CELL & GENE THERAPIES, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 444

SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 445

SINGLE-USE BIOPROCESSING MARKET FOR PHARMACEUTICAL & BIOTECHNOLOGY COMPANIES, BY REGION, 2023–2030 (USD MILLION)

TABLE 446

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR PHARMACEUTICAL & BIOTECHNOLOGY COMPANIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 447

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR PHARMACEUTICAL & BIOTECHNOLOGY COMPANIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 448

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR PHARMACEUTICAL & BIOTECHNOLOGY COMPANIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 449

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR PHARMACEUTICAL & BIOTECHNOLOGY COMPANIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 450

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR PHARMACEUTICAL & BIOTECHNOLOGY COMPANIES, BY REGION, 2023–2030 (USD MILLION)

TABLE 451

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR PHARMACEUTICAL & BIOTECHNOLOGY COMPANIES, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 452

SINGLE-USE BIOPROCESSING MARKET FOR CROS & CMOS, BY REGION, 2023–2030 (USD MILLION)

TABLE 453

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR CROS & CMOS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 454

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR CROS & CMOS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 455

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR CROS & CMOS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 456

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET CROS & CMOS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 457

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR CROS & CMOS, BY REGION, 2023–2030 (USD MILLION)

TABLE 458

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR CROS & CMOS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 459

SINGLE-USE BIOPROCESSING MARKET FOR OTHER END USERS, BY REGION, 2023–2030 (USD MILLION)

TABLE 460

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR OTHER END USERS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 461

EUROPE: SINGLE-USE BIOPROCESSING MARKET FOR OTHER END USERS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 462

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET FOR OTHER END USERS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 463

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET FOR OTHER END USERS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 464

MIDDLE EAST: SINGLE-USE BIOPROCESSING MARKET FOR OTHER END USERS, BY REGION, 2023–2030 (USD MILLION)

TABLE 465

GCC COUNTRIES: SINGLE-USE BIOPROCESSING MARKET FOR OTHER END USERS, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 466

SINGLE-USE BIOPROCESSING MARKET, BY REGION, 2023–2030 (USD MILLION)

TABLE 467

NORTH AMERICA: KEY MACROINDICATORS

TABLE 468

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 469

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 470

NORTH AMERICA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 471

NORTH AMERICA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 472

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 473

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 474

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 475

NORTH AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 476

US: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 477

US: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 478

US: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 479

US: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 480

US: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 481

US: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 482

US: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 483

CANADA: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 484

CANADA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 485

CANADA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 486

CANADA: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 487

CANADA: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 488

CANADA: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 489

CANADA: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 490

EUROPE: KEY MACROINDICATORS

TABLE 491

EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 492

EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 493

EUROPE: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 494

EUROPE: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 495

EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 496

EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 497

EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 498

EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 499

GERMANY: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 500

GERMANY: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 501

GERMANY: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 502

GERMANY: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 503

GERMANY: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 504

GERMANY: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 505

GERMANY: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 506

UK: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 507

UK: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 508

UK: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 509

UK: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 510

UK: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 511

UK: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 512

UK: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 513

FRANCE: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 514

FRANCE: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 515

FRANCE: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 516

FRANCE: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 517

FRANCE: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 518

FRANCE: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 519

FRANCE: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 520

ITALY: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 521

ITALY: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 522

ITALY: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 523

ITALY: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 524

ITALY: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 525

ITALY: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 526

ITALY: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 527

SPAIN: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 528

SPAIN: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 529

SPAIN: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 530

SPAIN: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 531

SPAIN: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 532

SPAIN: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 533

SPAIN: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 534

REST OF EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 535

REST OF EUROPE: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 536

REST OF EUROPE: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 537

REST OF EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 538

REST OF EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 539

REST OF EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 540

REST OF EUROPE: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 541

ASIA PACIFIC: KEY MACROINDICATORS

TABLE 542

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 543

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 544

ASIA PACIFIC: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 545

ASIA PACIFIC: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 546

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 547

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 548

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 549

ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 550

CHINA: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 551

CHINA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 552

CHINA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 553

CHINA: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 554

CHINA: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 555

CHINA: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 556

CHINA: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 557

SOUTH KOREA: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 558

SOUTH KOREA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 559

SOUTH KOREA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 560

SOUTH KOREA: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 561

SOUTH KOREA: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 562

SOUTH KOREA: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 563

SOUTH KOREA: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 564

JAPAN: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 565

JAPAN: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 566

JAPAN: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 567

JAPAN: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 568

JAPAN: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 569

JAPAN: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 570

JAPAN: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 571

INDIA: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 572

INDIA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 573

INDIA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 574

INDIA: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 575

INDIA: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 576

INDIA: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 577

INDIA: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 578

AUSTRALIA: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 579

AUSTRALIA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 580

AUSTRALIA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 581

AUSTRALIA: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 582

AUSTRALIA: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 583

AUSTRALIA: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 584

AUSTRALIA: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 585

REST OF ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 586

REST OF ASIA PACIFIC: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 587

REST OF ASIA PACIFIC: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 588

REST OF ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 589

REST OF ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 590

REST OF ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 591

REST OF ASIA PACIFIC: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 592

LATIN AMERICA: KEY MACROINDICATORS

TABLE 593

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY COUNTRY, 2023–2030 (USD MILLION)

TABLE 594

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 595

LATIN AMERICA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 596

LATIN AMERICA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 597

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 598

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 599

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 600

LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 601

BRAZIL: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 602

BRAZIL: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 603

BRAZIL: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 604

BRAZIL: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 605

BRAZIL: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 606

BRAZIL: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 607

BRAZIL: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 608

MEXICO: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 609

MEXICO: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 610

MEXICO: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 611

MEXICO: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 612

MEXICO: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 613

MEXICO: SINGLE-USE BIOPROCESSING MARKET, BY MOLECULE TYPE, 2023–2030 (USD MILLION)

TABLE 614

MEXICO: SINGLE-USE BIOPROCESSING MARKET, BY END USER, 2023–2030 (USD MILLION)

TABLE 615

REST OF LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY PRODUCT, 2023–2030 (USD MILLION)

TABLE 616

REST OF LATIN AMERICA: SINGLE-USE BIOPROCESSING EQUIPMENT MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 617

REST OF LATIN AMERICA: SINGLE-USE BIOPROCESSING CONSUMABLES MARKET, BY TYPE, 2023–2030 (USD MILLION)

TABLE 618

REST OF LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY APPLICATION, 2023–2030 (USD MILLION)

TABLE 619

REST OF LATIN AMERICA: SINGLE-USE BIOPROCESSING MARKET, BY WORKFLOW, 2023–2030 (USD MILLION)

TABLE 620