2

RESEARCH METHODOLOGY

41

5

MARKET OVERVIEW

Surging polycarbonate demand and eco-friendly solvent adoption drive market growth amidst cost challenges.

56

5.2.1.1

Increasing demand for polycarbonates across various industries

5.2.1.2

Rising use of dimethyl carbonate in lithium-ion battery electrolytes

5.2.1.3

Rising demand for eco-friendly solvents

5.2.2.1

Use of toxic chemicals in dimethyl carbonate synthesis

5.2.2.2

High production costs

5.2.3.1

Adoption of dimethyl carbonate as oxygenated fuel additive

5.2.3.2

Rapid industrialization in Asia Pacific and Africa

5.2.4.1

Fluctuations in oil & gas prices

5.2.4.2

Process integration & scalability

5.3

PORTER’S FIVE FORCES ANALYSIS

5.3.1

BARGAINING POWER OF SUPPLIERS

5.3.2

THREAT OF NEW ENTRANTS

5.3.3

THREAT OF SUBSTITUTES

5.3.4

BARGAINING POWER OF BUYERS

5.3.5

INTENSITY OF COMPETITIVE RIVALRY

5.4

KEY STAKEHOLDERS AND BUYING CRITERIA

5.4.1

KEY STAKEHOLDERS IN BUYING PROCESS

5.5

MACROECONOMIC OVERVIEW AND TRENDS

5.5.1

GDP TRENDS AND FORECAST

5.5.2

OIL AND NATURAL GAS PRICE TRENDS

5.5.3.1

Electric vehicles

5.6

SUPPLY CHAIN ANALYSIS

5.8.1

TARIFFS RELATED TO DIMETHYL CARBONATE

5.8.2

REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

5.9.1

AVERAGE SELLING PRICE OF DIMETHYL CARBONATE, BY REGION

5.9.2

AVERAGE SELLING PRICE OF DIMETHYL CARBONATE OFFERED BY KEY PLAYERS, BY GRADE

5.10.1

GREEN SYNTHESIS OF DIMETHYL CARBONATE FROM CARBON DIOXIDE AND METHANOL USING TUNABLE IONIC LIQUID CATALYST

5.10.1.2

Solution statement

5.10.2

GREEN SYNTHESIS OF DIMETHYL CARBONATE FROM CARBON DIOXIDE AND METHANOL USING TUNABLE IONIC LIQUID CATALYST

5.10.2.2

Solution statement

5.11

TRENDS AND DISRUPTIONS IMPACTING CUSTOMER BUSINESS

5.12

INVESTMENT & FUNDING SCENARIO

5.13.1.1

Methanol phosgenation

5.13.1.5

Urea transesterification

5.13.1.6

Direct CO2 synthesis

5.13.2

COMPLEMENTARY TECHNOLOGIES

5.13.2.1

Catalyst development for phosgene-free alternatives

5.13.2.2

Process intensification (reactive distillation)

5.13.3

ADJACENT TECHNOLOGIES

5.13.3.1

Oxidative carbonylation of methanol

5.13.3.2

Ethylene carbonate transesterification

5.14

KEY CONFERENCES AND EVENTS

5.18.1

IMPORT SCENARIO (HS CODE 292090)

5.18.2

EXPORT SCENARIO (HS CODE 292090)

5.19.1

AI FOR PROCESS OPTIMIZATION IN DIMETHYL CARBONATE PRODUCTION

5.19.2

GENERATIVE AI IN CATALYST DISCOVERY

5.19.3

AI IN SUSTAINABILITY ASSESSMENT AND CARBON TRACKING

5.19.4

AI IN SUPPLY CHAIN AND MARKET FORECASTING

5.19.5

AUTONOMOUS LABS AND DIGITAL TWINS IN DMC RESEARCH

5.19.6

STRATEGIC AND COMMERCIAL SHIFTS DRIVEN BY AI

5.20

IMPACT OF 2025 US TARIFF - DIMETHYL CARBONATE MARKET

5.20.3

PRICE IMPACT ANALYSIS

5.20.4

IMPACT ON COUNTRY/REGION

5.20.5

IMPACT ON END-USE INDUSTRIES

6

DIMETHYL CARBONATE MARKET, BY GRADE

Market Size & Growth Rate Forecast Analysis to 2030 in USD Million and Kilotons | 16 Data Tables

95

6.2

INDUSTRIAL GRADE (>99.0 WEIGHT %)

6.2.1

GROWING ELECTRONICS AND AUTOMOTIVE INDUSTRIES TO DRIVE MARKET

6.3

PHARMACEUTICAL GRADE (>99.5 WEIGHT %)

6.3.1

PRESENCE OF LARGE NUMBER OF MANUFACTURERS AND DISTRIBUTORS TO SUPPORT MARKET GROWTH

6.4

BATTERY GRADE (>99.9 WEIGHT %)

6.4.1

GROWING GLOBAL DEMAND FOR ELECTRIC VEHICLES TO DRIVE MARKET

7

DIMETHYL CARBONATE MARKET, BY SYNTHESIS

Market Size & Growth Rate Forecast Analysis

104

7.2

METHANOL PHOSGENATION

7.3

OXIDATIVE CARBONYLATION OF METHANOL

7.4

OXIDATIVE CARBONYLATION OF METHANOL VIA METHYL NITRATE

7.5

ETHYLENE CARBONATE TRANSESTERIFICATION PROCESS

7.6

UREA TRANSESTERIFICATION

7.7

DIRECT SYNTHESIS FROM CO2

8

DIMETHYL CARBONATE MARKET, BY APPLICATION

Market Size & Growth Rate Forecast Analysis to 2030 in USD Million and Kilotons | 24 Data Tables

108

8.2

POLYCARBONATE SYNTHESIS

8.2.1

GROWING USE OF DIMETHYL CARBONATE AS PHOSGENE SUBSTITUTE IN POLYCARBONATE PRODUCTION TO DRIVE MARKET

8.3.1

GROWING DEMAND FOR LITHIUM-ION BATTERIES IN ELECTRIC VEHICLE INDUSTRY TO DRIVE MARKET

8.4.1

RISING ADOPTION OF DIMETHYL CARBONATE AS VOC-EXEMPT SOLVENT IN PAINTS & COATINGS INDUSTRY TO DRIVE MARKET

8.5.1

EXPANDING PHARMACEUTICAL INDUSTRY TO DRIVE MARKET

8.5.3

METHOXYCARBONYLATION AGENTS

8.6.2

ELECTROLYTES FOR DYE-SENSITIZED SOLAR CELLS

8.6.3

ELECTROLYTES FOR SUPERCAPACITORS

9

DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY

Market Size & Growth Rate Forecast Analysis to 2030 in USD Million and Kilotons | 28 Data Tables

123

9.2.1

GROWING DEMAND FOR POLYCARBONATE IN VARIOUS APPLICATIONS TO DRIVE MARKET

9.3.1

INCREASING DEMAND FOR GREEN SOLVENTS TO DRIVE MARKET

9.4.1

RISING DEMAND FOR ANTIFUNGAL, ANTIBIOTIC, ANTIBACTERIAL, AND ANTI-INFECTION DRUGS TO FUEL MARKET GROWTH

9.5.1

GROWING PRODUCTION OF LI-ION BATTERIES TO DRIVE DEMAND

9.6.1

ESCALATING DEMAND FOR FERTILIZERS AND PESTICIDES TO DRIVE MARKET

9.7

OTHER END-USE INDUSTRIES

10

DIMETHYL CARBONATE MARKET, BY REGION

Market Size & Growth Rate Forecast Analysis to 2030 in USD Million and Kilotons | 408 Data Tables

137

10.2.1.1

High demand for polycarbonates in automotive industry to drive market

10.2.2.1

Expanding automotive and consumer electronics industries to drive demand

10.2.3.1

Growing industrialization to fuel market growth

10.2.4.1

Booming electronics industry to drive market

10.2.5.1

Rising demand in plastics industry to drive market

10.2.6.1

Increasing demand for polycarbonate synthesis to drive market

10.2.7

REST OF ASIA PACIFIC

10.3.1.1

Strong presence of Li-ion battery and electric vehicle manufacturers to drive market

10.3.2.1

Increasing applications of solvent and battery electrolytes in industrial and automotive sectors to drive demand

10.3.3.1

Increased electric vehicle manufacturing to drive demand

10.3.4.1

Growing demand for polycarbonate synthesis to drive market

10.3.5.1

Increasing electric vehicle sales to drive market

10.3.6.1

Growing demand in paints & coatings, battery, and pharmaceuticals industries to drive market

10.4.1.1

Rising demand for polycarbonate synthesis to drive market

10.4.2.1

Booming marine industry to drive demand

10.4.3.1

Growing production of consumer electronics to fuel demand

10.5

MIDDLE EAST & AFRICA

10.5.1.3

Rest of GCC countries

10.5.2.1

Growing construction industry to drive market

10.5.3.1

Growing demand for polycarbonate synthesis in agriculture and textile industries to fuel market growth

10.5.4.1

Growing demand for batteries to drive market

10.5.5

REST OF MIDDLE EAST & AFRICA

10.6.1.1

Booming automotive industry to drive market

10.6.2.1

Increased demand for polycarbonate synthesis in automotive industry to drive market

10.6.3

REST OF SOUTH AMERICA

11

COMPETITIVE LANDSCAPE

Discover strategic insights and market dominance tactics of leading chemical industry players.

297

11.2

KEY PLAYER STRATEGIES/RIGHT TO WIN

11.4

MARKET SHARE ANALYSIS

11.4.2

SHANDONG HUALU HENGSHENG GROUP CO., LTD.

11.4.3

LOTTE CHEMICAL CORPORATION

11.4.4

SHINGHWA ADVANCED MATERIAL GROUP CO., LTD.

11.5

BRAND/PRODUCT COMPARISON

11.5.2

SHANDONG HUALU HENGSHENG GROUP CO., LTD.

11.5.3

LOTTE CHEMICAL CORPORATION

11.5.4

SHINGHWA ADVANCED MATERIAL GROUP CO., LTD.

11.6

COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

11.6.5

COMPANY FOOTPRINT: KEY PLAYERS, 2024

11.6.5.1

Company footprint

11.6.5.2

Region footprint

11.6.5.3

Synthesis footprint

11.6.5.5

Application footprint

11.6.5.6

End-use industry footprint

11.7

COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

11.7.1

PROGRESSIVE COMPANIES

11.7.2

RESPONSIVE COMPANIES

11.7.5

COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

11.7.5.1

Detailed list of key startups/SMEs

11.7.5.2

Competitive benchmarking of key startups/SMEs

11.8

COMPETITIVE SCENARIO

11.9

COMPANY VALUATION AND FINANCIAL METRICS

12

COMPANY PROFILES

In-depth Company Profiles of Leading Market Players with detailed Business Overview, Product and Service Portfolio, Recent Developments, and Unique Analyst Perspective (MnM View)

321

12.1.1.1

Business overview

12.1.1.2

Products offered

12.1.1.3

Recent developments

12.1.2

SHANDONG HUALU HENGSHENG GROUP CO., LTD.

12.1.3

LOTTE CHEMICAL CORPORATION

12.1.4

SHINGHWA ADVANCED MATERIAL GROUP CO., LTD.

12.1.6

SANKYO CHEMICAL CO., LTD.

12.1.7

SHANDONG DEPU CHEMICAL INDUSTRY SCIENCE & TECHNOLOGY CO., LTD.

12.1.8

SHANDONG WANLING CHEMICAL CO., LTD

12.1.9

ENAM ORGANICS INDIA LTD

12.1.10

SHANDONG AIVK CHEMICAL CO., LTD.

12.1.11

ZHENGZHOU MEIYA CHEMICAL PRODUCTS CO., LTD.

12.1.12

SHANDONG DAZE CHEMICAL GROUP

12.1.14

SHANDONG FEIYANG CHEMICAL CO., LTD.

12.1.15

HENAN GP CHEMICALS CO., LTD.

12.1.16

SHANDONG LONGZE CHEMICAL CO., LTD.

12.2.1

SUNECO CHEMICAL CO., LTD.

12.2.2

DONGYING RICH CHEMICAL CO., LTD.

12.2.5

SHANDONG HANGDA CHEMICAL CO., LTD.

13

ADJACENT AND RELATED MARKETS

357

13.3

INTERCONNECTED MARKETS

13.3.1

BATTERY ELECTROLYTE MARKET

13.3.1.1

Market definition

13.4

BATTERY ELECTROLYTE MARKET, BY BATTERY TYPE

13.4.1.1

Use as backup for uninterruptible power supply to propel market

13.4.2

LITHIUM-ION BATTERY

13.4.2.1

Increasing demand for electric vehicles to drive market

14.2

KNOWLEDGESTORE: MARKETSANDMARKETS’ SUBSCRIPTION PORTAL

14.3

CUSTOMIZATION OPTIONS

TABLE 1

DIMETHYL CARBONATE MARKET: INCLUSIONS & EXCLUSIONS OF STUDY

TABLE 2

DIMETHYL CARBONATE MARKET SNAPSHOT, 2025 VS. 2030

TABLE 3

INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES (%)

TABLE 4

KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

TABLE 5

GLOBAL GDP PER CAPITA, 2014–2024 (USD)

TABLE 6

GLOBAL OIL AND GAS PRICES, 2013–2024 (USD)

TABLE 7

ROLE OF COMPANIES IN DIMETHYL CARBONATE ECOSYSTEM

TABLE 8

TARIFFS RELATED TO DIMETHYL CARBONATE

TABLE 9

ASIA PACIFIC: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 10

EUROPE: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 11

NORTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

TABLE 12

AVERAGE SELLING PRICE OF DIMETHYL CARBONATE, BY REGION, 2020–2024 (USD/KILOTON)

TABLE 13

AVERAGE SELLING PRICE OF DIMETHYL CARBONATE OFFERED BY KEY PLAYERS, BY GRADE (USD)

TABLE 14

DIMETHYL CARBONATE MARKET: KEY CONFERENCES AND EVENTS, 2025–2026

TABLE 15

LIST OF MAJOR PATENTS

TABLE 16

CAPEX EXPENDITURES OF DIMETHYL CARBONATE PRODUCTION METHODS (USD MILLION)

TABLE 17

COST OF PHOSGENE-FREE DIMETHYL CARBONATE PRODUCTION PROCESS (USD/TON)

TABLE 18

COST OF DIMETHYL CARBONATE PRODUCTION FROM FLUE GAS (USD/TON)

TABLE 19

COST OF DIMETHYL CARBONATE PRODUCTION FROM METHANOL AND CARBON DIOXIDE (USD/TON)

TABLE 20

COST OF ENI VS. UBE VS. ASAHI-KASEI DIMETHYL CARBONATE PRODUCTION PROCESSES (USD/TON)

TABLE 21

PRODUCTION COST OF DIMETHYL CARBONATE, BY LOCATION (USD/TON)

TABLE 22

US-ADJUSTED RECIPROCAL TARIFF RATES

TABLE 23

KEY PRODUCT-RELATED TARIFF EFFECTIVE FOR DIMETHYL CARBONATE MARKET

TABLE 24

EXPECTED CHANGE IN PRICES AND LIKELY IMPACT ON END-USE MARKETS DUE TO TARIFF IMPACT

TABLE 25

DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 26

DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 27

DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 28

DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 29

INDUSTRIAL GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 30

INDUSTRIAL GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 31

INDUSTRIAL GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 32

INDUSTRIAL GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 33

PHARMACEUTICAL GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 34

PHARMACEUTICAL GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 35

PHARMACEUTICAL GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 36

PHARMACEUTICAL GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 37

BATTERY GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 38

BATTERY GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 39

BATTERY GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 40

BATTERY GRADE: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 41

DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 42

DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 43

DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 44

DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 45

POLYCARBONATE SYNTHESIS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 46

POLYCARBONATE SYNTHESIS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 47

POLYCARBONATE SYNTHESIS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 48

POLYCARBONATE SYNTHESIS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 49

BATTERY ELECTROLYTES: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 50

BATTERY ELECTROLYTES: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 51

BATTERY ELECTROLYTES: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 52

BATTERY ELECTROLYTES: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 53

SOLVENTS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 54

SOLVENTS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 55

SOLVENTS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 56

SOLVENTS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 57

REAGENTS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 58

REAGENTS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 59

REAGENTS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 60

REAGENTS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 61

OTHER APPLICATIONS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 62

OTHER APPLICATIONS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 63

OTHER APPLICATIONS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 64

OTHER APPLICATIONS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 65

DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 66

DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 67

DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 68

DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 69

PLASTICS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 70

PLASTICS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 71

PLASTICS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 72

PLASTICS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 73

PAINTS & COATINGS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 74

PAINTS & COATINGS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 75

PAINTS & COATINGS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 76

PAINTS & COATINGS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 77

PHARMACEUTICAL: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 78

PHARMACEUTICAL: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 79

PHARMACEUTICAL: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 80

PHARMACEUTICAL: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 81

BATTERY: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 82

BATTERY: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 83

BATTERY: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 84

BATTERY: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 85

AGROCHEMICALS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 86

AGROCHEMICALS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 87

AGROCHEMICALS: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 88

AGROCHEMICALS: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 89

OTHER END-USE INDUSTRIES: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 90

OTHER END-USE INDUSTRIES: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 91

OTHER END-USE INDUSTRIES: DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 92

OTHER END-USE INDUSTRIES: DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 93

DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (KILOTON)

TABLE 94

DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (KILOTON)

TABLE 95

DIMETHYL CARBONATE MARKET, BY REGION, 2021–2024 (USD MILLION)

TABLE 96

DIMETHYL CARBONATE MARKET, BY REGION, 2025–2030 (USD MILLION)

TABLE 97

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (KILOTON)

TABLE 98

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (KILOTON)

TABLE 99

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (USD MILLION)

TABLE 100

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (USD MILLION)

TABLE 101

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 102

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 103

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 104

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 105

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 106

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 107

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 108

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 109

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 110

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 111

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 112

ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 113

CHINA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 114

CHINA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 115

CHINA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 116

CHINA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 117

CHINA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 118

CHINA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 119

CHINA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 120

CHINA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 121

CHINA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 122

CHINA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 123

CHINA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 124

CHINA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 125

JAPAN: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 126

JAPAN: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 127

JAPAN: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 128

JAPAN: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 129

JAPAN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 130

JAPAN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 131

JAPAN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 132

JAPAN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 133

JAPAN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 134

JAPAN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 135

JAPAN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 136

JAPAN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 137

INDIA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 138

INDIA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 139

INDIA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 140

INDIA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 141

INDIA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 142

INDIA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 143

INDIA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 144

INDIA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 145

INDIA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 146

INDIA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 147

INDIA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 148

INDIA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 149

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 150

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 151

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 152

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 153

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 154

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 155

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 156

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 157

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 158

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 159

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 160

SOUTH KOREA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 161

TAIWAN: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 162

TAIWAN: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 163

TAIWAN: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 164

TAIWAN: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 165

TAIWAN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 166

TAIWAN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 167

TAIWAN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 168

TAIWAN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 169

TAIWAN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 170

TAIWAN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 171

TAIWAN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 172

TAIWAN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 173

THAILAND: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 174

THAILAND: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 175

THAILAND: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 176

THAILAND: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 177

THAILAND: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 178

THAILAND: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 179

THAILAND: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 180

THAILAND: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 181

THAILAND: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 182

THAILAND: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 183

THAILAND: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 184

THAILAND: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 185

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 186

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 187

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 188

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 189

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 190

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 191

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 192

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 193

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 194

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 195

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 196

REST OF ASIA PACIFIC: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 197

EUROPE: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (KILOTON)

TABLE 198

EUROPE: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (KILOTON)

TABLE 199

EUROPE: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (USD MILLION)

TABLE 200

EUROPE: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (USD MILLION)

TABLE 201

EUROPE: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 202

EUROPE: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 203

EUROPE: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 204

EUROPE: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 205

EUROPE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 206

EUROPE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 207

EUROPE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 208

EUROPE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 209

EUROPE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 210

EUROPE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 211

EUROPE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 212

EUROPE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 213

GERMANY: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 214

GERMANY: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 215

GERMANY: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 216

GERMANY: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 217

GERMANY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 218

GERMANY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 219

GERMANY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 220

GERMANY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 221

GERMANY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 222

GERMANY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 223

GERMANY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 224

GERMANY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 225

FRANCE: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 226

FRANCE: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 227

FRANCE: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 228

FRANCE: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 229

FRANCE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 230

FRANCE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 231

FRANCE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 232

FRANCE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 233

FRANCE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 234

FRANCE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 235

FRANCE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 236

FRANCE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 237

UK: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 238

UK: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 239

UK: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 240

UK: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 241

UK: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 242

UK: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 243

UK: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 244

UK: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 245

UK: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 246

UK: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 247

UK: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 248

UK: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 249

SPAIN: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 250

SPAIN: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 251

SPAIN: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 252

SPAIN: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 253

SPAIN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 254

SPAIN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 255

SPAIN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 256

SPAIN: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 257

SPAIN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 258

SPAIN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 259

SPAIN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 260

SPAIN: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 261

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 262

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 263

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 264

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 265

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 266

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 267

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 268

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 269

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 270

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 271

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 272

NETHERLANDS: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 273

ITALY: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 274

ITALY: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 275

ITALY: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 276

ITALY: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 277

ITALY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 278

ITALY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 279

ITALY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 280

ITALY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 281

ITALY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 282

ITALY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 283

ITALY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 284

ITALY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 285

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 286

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 287

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 288

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 289

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 290

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 291

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 292

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 293

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 294

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 295

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 296

REST OF EUROPE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 297

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (KILOTON)

TABLE 298

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (KILOTON)

TABLE 299

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (USD MILLION)

TABLE 300

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (USD MILLION)

TABLE 301

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 302

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 303

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 304

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 305

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 306

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 307

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 308

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 309

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 310

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 311

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 312

NORTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 313

US: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 314

US: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 315

US: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 316

US: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 317

US: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 318

US: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 319

US: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 320

US: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 321

US: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 322

US: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 323

US: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 324

US: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 325

CANADA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 326

CANADA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 327

CANADA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 328

CANADA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 329

CANADA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 330

CANADA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 331

CANADA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 332

CANADA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 333

CANADA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 334

CANADA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 335

CANADA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 336

CANADA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY,2025–2030 (USD MILLION)

TABLE 337

MEXICO: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 338

MEXICO: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 339

MEXICO: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 340

MEXICO: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 341

MEXICO: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 342

MEXICO: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 343

MEXICO: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 344

MEXICO: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 345

MEXICO: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 346

MEXICO: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 347

MEXICO: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 348

MEXICO: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 349

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (KILOTON)

TABLE 350

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (KILOTON)

TABLE 351

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (USD MILLION)

TABLE 352

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (USD MILLION)

TABLE 353

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 354

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 355

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 356

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 357

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 358

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 359

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 360

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 361

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 362

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 363

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 364

MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 365

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 366

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 367

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 368

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 369

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 370

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 371

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 372

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 373

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 374

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 375

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 376

SAUDI ARABIA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 377

UAE: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 378

UAE: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 379

UAE: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 380

UAE: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 381

UAE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 382

UAE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 383

UAE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 384

UAE: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 385

UAE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 386

UAE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 387

UAE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 388

UAE: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 389

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 390

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 391

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 392

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 393

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 394

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 395

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 396

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 397

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 398

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 399

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 400

REST OF GCC COUNTRIES: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 401

ISRAEL: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 402

ISRAEL: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 403

ISRAEL: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 404

ISRAEL: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 405

ISRAEL: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 406

ISRAEL: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 407

ISRAEL: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 408

ISRAEL: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 409

ISRAEL: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 410

ISRAEL: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 411

ISRAEL: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 412

ISRAEL: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 413

TURKEY: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 414

TURKEY: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 415

TURKEY: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 416

TURKEY: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 417

TURKEY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 418

TURKEY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 419

TURKEY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 420

TURKEY: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 421

TURKEY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 422

TURKEY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 423

TURKEY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 424

TURKEY: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 425

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 426

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 427

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 428

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 429

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 430

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 431

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 432

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 433

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 434

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 435

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 436

SOUTH AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 437

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 438

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 439

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 440

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 441

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 442

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 443

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 444

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 445

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 446

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 447

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 448

REST OF MIDDLE EAST & AFRICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 449

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (KILOTON)

TABLE 450

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (KILOTON)

TABLE 451

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2021–2024 (USD MILLION)

TABLE 452

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY COUNTRY, 2025–2030 (USD MILLION)

TABLE 453

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 454

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 455

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 456

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 457

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 458

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 459

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 460

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 461

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 462

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 463

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 464

SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 465

BRAZIL: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 466

BRAZIL: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 467

BRAZIL: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 468

BRAZIL: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 469

BRAZIL: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 470

BRAZIL: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 471

BRAZIL: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 472

BRAZIL: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 473

BRAZIL: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 474

BRAZIL: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 475

BRAZIL: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 476

BRAZIL: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 477

ARGENTINA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 478

ARGENTINA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 479

ARGENTINA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 480

ARGENTINA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 481

ARGENTINA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 482

ARGENTINA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 483

ARGENTINA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 484

ARGENTINA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 485

ARGENTINA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 486

ARGENTINA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 487

ARGENTINA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 488

ARGENTINA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 489

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (KILOTON)

TABLE 490

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (KILOTON)

TABLE 491

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2021–2024 (USD MILLION)

TABLE 492

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY GRADE, 2025–2030 (USD MILLION)

TABLE 493

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (KILOTON)

TABLE 494

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (KILOTON)

TABLE 495

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2021–2024 (USD MILLION)

TABLE 496

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY APPLICATION, 2025–2030 (USD MILLION)

TABLE 497

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (KILOTON)

TABLE 498

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (KILOTON)

TABLE 499

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2021–2024 (USD MILLION)

TABLE 500

REST OF SOUTH AMERICA: DIMETHYL CARBONATE MARKET, BY END-USE INDUSTRY, 2025–2030 (USD MILLION)

TABLE 501

DIMETHYL CARBONATE MARKET: OVERVIEW OF STRATEGIES ADOPTED BY KEY PLAYERS, 2020–2025

TABLE 502

DIMETHYL CARBONATE MARKET: DEGREE OF COMPETITION, 2024

TABLE 503

DIMETHYL CARBONATE MARKET: REGION FOOTPRINT

TABLE 504

DIMETHYL CARBONATE MARKET: SYNTHESIS FOOTPRINT

TABLE 505

DIMETHYL CARBONATE MARKET: GRADE FOOTPRINT

TABLE 506

DIMETHYL CARBONATE MARKET: APPLICATION FOOTPRINT

TABLE 507

DIMETHYL CARBONATE MARKET: END-USE INDUSTRY FOOTPRINT

TABLE 508

DIMETHYL CARBONATE MARKET: DETAILED LIST OF KEY STARTUPS/SMES

TABLE 509

DIMETHYL CARBONATE MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES

TABLE 510

DIMETHYL CARBONATE MARKET: PRODUCT LAUNCHES, JANUARY 2020–JUNE 2025

TABLE 511

DIMETHYL CARBONATE MARKET: EXPANSIONS, JANUARY 2020–JUNE 2025

TABLE 512

UBE CORPORATION: COMPANY OVERVIEW

TABLE 513

UBE CORPORATION: PRODUCTS OFFERED

TABLE 514

UBE CORPORATION: PRODUCT LAUNCHES

TABLE 515

UBE CORPORATION: EXPANSIONS

TABLE 516

SHANDONG HUALU HENGSHENG GROUP CO., LTD.: COMPANY OVERVIEW

TABLE 517

SHANDONG HUALU HENGSHENG GROUP CO., LTD.: PRODUCTS OFFERED

TABLE 518

SHANDONG HUALU HENGSHENG GROUP CO., LTD.: EXPANSIONS

TABLE 519

LOTTE CHEMICAL CORPORATION: COMPANY OVERVIEW

TABLE 520

LOTTE CHEMICAL CORPORATION: PRODUCTS OFFERED

TABLE 521

LOTTE CHEMICAL CORPORATION: EXPANSIONS

TABLE 522

SHINGHWA ADVANCED MATERIAL GROUP CO., LTD.: COMPANY OVERVIEW

TABLE 523

SHINGHWA ADVANCED MATERIAL GROUP CO., LTD.: PRODUCTS OFFERED

TABLE 524

SHINGHWA ADVANCED MATERIAL GROUP CO., LTD.: EXPANSIONS

TABLE 525

HI-TECH SPRING: COMPANY OVERVIEW

TABLE 526

HI-TECH SPRING: PRODUCTS OFFERED

TABLE 527

SANKYO CHEMICAL CO., LTD.: COMPANY OVERVIEW

TABLE 528

SANKYO CHEMICAL CO., LTD.: PRODUCTS OFFERED

TABLE 529

SHANDONG DEPU CHEMICAL INDUSTRY SCIENCE & TECHNOLOGY CO., LTD.: COMPANY OVERVIEW

TABLE 530

SHANDONG DEPU CHEMICAL INDUSTRY SCIENCE &TECHNOLOGY CO., LTD.: PRODUCTS OFFERED

TABLE 531

SHANDONG WANLING CHEMICAL CO., LTD.: COMPANY OVERVIEW

TABLE 532

SHANDONG WANLING CHEMICAL CO., LTD.: PRODUCTS OFFERED

TABLE 533

ENAM ORGANICS INDIA LTD: COMPANY OVERVIEW

TABLE 534

ENAM ORGANICS INDIA LTD: PRODUCTS OFFERED

TABLE 535

SHANDONG AIVK CHEMICAL CO., LTD.: COMPANY OVERVIEW

TABLE 536

SHANDONG AIVK CHEMICAL CO., LTD.: PRODUCTS OFFERED

TABLE 537

ZHENGZHOU MEIYA CHEMICAL PRODUCTS CO., LTD.: COMPANY OVERVIEW

TABLE 538

ZHENGZHOU MEIYA CHEMICAL PRODUCTS CO., LTD.: PRODUCTS OFFERED

TABLE 539

SHANDONG DAZE CHEMICAL GROUP: COMPANY OVERVIEW

TABLE 540

SHANDONG DAZE CHEMICAL GROUP: PRODUCTS OFFERED

TABLE 541

HAIHANG INDUSTRY: COMPANY OVERVIEW

TABLE 542

HAIHANG INDUSTRY: PRODUCTS OFFERED

TABLE 543

SHANDONG FEIYANG CHEMICAL CO., LTD.: COMPANY OVERVIEW

TABLE 544

SHANDONG FEIYANG CHEMICAL CO., LTD.: PRODUCTS OFFERED

TABLE 545

HENAN GP CHEMICALS CO., LTD.: COMPANY OVERVIEW

TABLE 546

HENAN GP CHEMICALS CO., LTD.: PRODUCTS OFFERED

TABLE 547

SHANDONG LONGZE CHEMICAL CO., LTD.: COMPANY OVERVIEW

TABLE 548

SHANDONG LONGZE CHEMICAL CO., LTD.: PRODUCTS OFFERED

TABLE 549

SUNECO CHEMICAL CO., LTD.: COMPANY OVERVIEW

TABLE 550

DONGYING RICH CHEMICAL CO., LTD.: COMPANY OVERVIEW

TABLE 551

SMC GLOBAL: COMPANY OVERVIEW

TABLE 552

EMCO DYESTUFF: COMPANY OVERVIEW

TABLE 553

SHANDONG HANGDA CHEMICAL CO., LTD.: COMPANY OVERVIEW

TABLE 554

BATTERY ELECTROLYTE MARKET, BY BATTERY TYPE, 2018–2020 (USD MILLION)

TABLE 555

BATTERY ELECTROLYTE MARKET, BY BATTERY TYPE, 2021–2027 (USD MILLION)

TABLE 556

BATTERY ELECTROLYTE MARKET, BY BATTERY TYPE, 2018–2020 (KILOTON)

TABLE 557

BATTERY ELECTROLYTE MARKET, BY BATTERY TYPE, 2021–2027 (KILOTON)

FIGURE 1

DIMETHYL CARBONATE MARKET SEGMENTATION

FIGURE 2

DIMETHYL CARBONATE MARKET: RESEARCH DESIGN

FIGURE 3

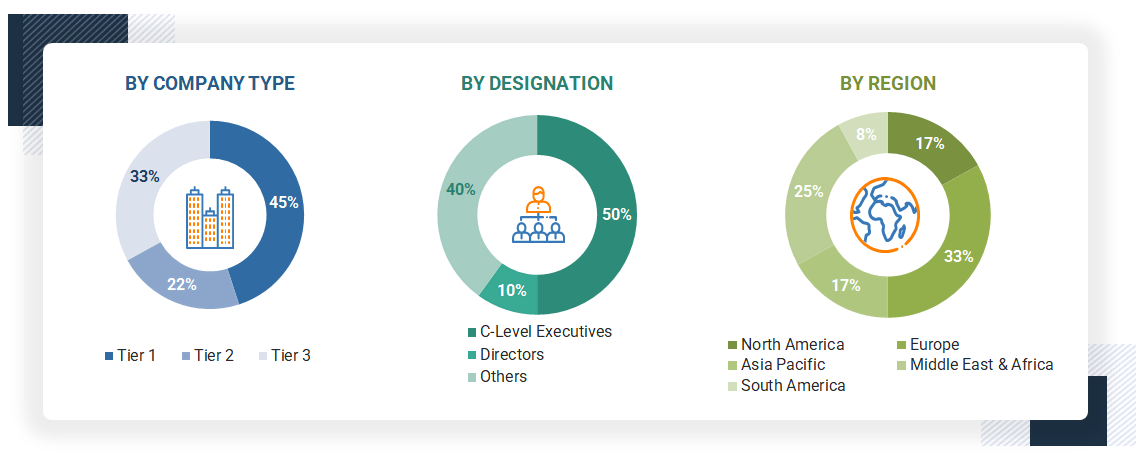

BREAKDOWN OF PRIMARY INTERVIEWS

FIGURE 4

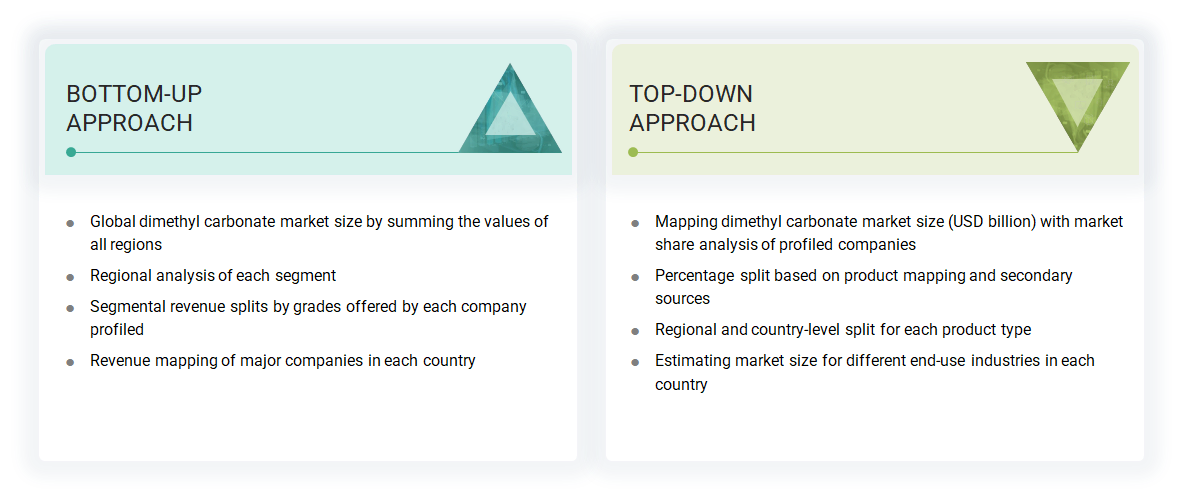

BOTTOM-UP APPROACH

FIGURE 5

TOP-DOWN APPROACH

FIGURE 6

MARKET SIZE ESTIMATION METHODOLOGY: APPROACH 1 (SUPPLY SIDE)

FIGURE 7

DIMETHYL CARBONATE MARKET: DATA TRIANGULATION

FIGURE 9

POLYCARBONATE SYNTHESIS SEGMENT TO DOMINATE MARKET IN 2025

FIGURE 10

BATTERY SEGMENT TO REGISTER HIGH GROWTH DURING FORECAST PERIOD

FIGURE 11

INDUSTRIAL-GRADE SEGMENT TO HOLD LARGEST SHARE OF DIMETHYL CARBONATE MARKET IN 2030

FIGURE 12

GROWING USE OF DIMETHYL CARBONATE AS FUEL ADDITIVE TO CREATE LUCRATIVE OPPORTUNITIES FOR MARKET PLAYERS

FIGURE 13

ASIA PACIFIC TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

FIGURE 14

INDUSTRY-GRADE SEGMENT ACCOUNTED FOR LARGEST MARKET SHARE IN 2024

FIGURE 15

CHINA TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

FIGURE 16

DIMETHYL CARBONATE MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

FIGURE 17

GLOBAL POLYCARBONATE DEMAND, 2011–2024 (MILLION TON)

FIGURE 18

FLUCTUATIONS IN CRUDE OIL PRICES, 2000–2024 (USD/BARREL)

FIGURE 19

PORTER’S FIVE FORCES ANALYSIS

FIGURE 20

INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

FIGURE 21

KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

FIGURE 22

GLOBAL CRUDE OIL PRICE FLUCTUATIONS, 2013–2024 (USD)

FIGURE 23

GLOBAL ELECTRIC VEHICLE SALES, 2020–2024 (THOUSAND UNITS)

FIGURE 24

SUPPLY CHAIN ANALYSIS

FIGURE 25

DIMETHYL CARBONATE MARKET: ECOSYSTEM

FIGURE 26

AVERAGE SELLING PRICE TREND OF DIMETHYL CARBONATE, BY REGION, 2020–2024 (USD/KILOTON)

FIGURE 27

AVERAGE SELLING PRICE OF DIMETHYL CARBONATE OFFERED BY KEY PLAYERS, BY GRADE (USD)

FIGURE 28

TRENDS AND DISRUPTIONS IMPACTING CUSTOMER BUSINESS

FIGURE 29

DIMETHYL CARBONATE MARKET: PATENT ANALYSIS, 2014–2024

FIGURE 30

IMPORT DATA FOR HS CODE 292090-COMPLIANT PRODUCTS, BY COUNTRY, 2018–2024 (USD THOUSAND)

FIGURE 31

EXPORT DATA FOR HS CODE 292090-COMPLIANT PRODUCTS, BY COUNTRY, 2018–2024 (USD THOUSAND)

FIGURE 32

INDUSTRIAL-GRADE SEGMENT TO DOMINATE MARKET DURING FORECAST PERIOD

FIGURE 33

POLYCARBONATE SYNTHESIS SEGMENT TOLEAD MARKET DURING FORECAST PERIOD

FIGURE 34

PLASTICS SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

FIGURE 35

ASIA PACIFIC TO REGISTER HIGHEST GROWTH DURING FORECAST PERIOD

FIGURE 36

ASIA PACIFIC: DIMETHYL CARBONATE MARKET SNAPSHOT

FIGURE 37

EUROPE: DIMETHYL CARBONATE MARKET SNAPSHOT

FIGURE 38

NORTH AMERICA: DIMETHYL CARBONATE MARKET SNAPSHOT

FIGURE 39

DIMETHYL CARBONATE MARKET: REVENUE ANALYSIS OF KEY COMPANIES, 2022–2024 (USD BILLION)

FIGURE 40

DIMETHYL CARBONATE MARKET SHARE ANALYSIS, 2024

FIGURE 41

DIMETHYL CARBONATE MARKET: BRAND/PRODUCT COMPARISON

FIGURE 42

DIMETHYL CARBONATE MARKET: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

FIGURE 43

DIMETHYL CARBONATE MARKET: COMPANY FOOTPRINT

FIGURE 44

DIMETHYL CARBONATE MARKET: COMPANY EVALUATION MATRIX (STARTUPS/SMES), 2024

FIGURE 45

DIMETHYL CARBONATE MARKET: EV/EBITDA

FIGURE 46

DIMETHYL CARBONATE MARKET: ENTERPRISE VALUE (USD BILLION)

FIGURE 47

DIMETHYL CARBONATE MARKET: YEAR-TO-DATE (YTD) PRICE TOTAL RETURN AND FIVE-YEAR STOCK BETA OF KEY MANUFACTURERS

FIGURE 48

UBE CORPORATION: COMPANY SNAPSHOT

FIGURE 49

SHANDONG HUALU HENGSHENG GROUP CO., LTD.: COMPANY SNAPSHOT

FIGURE 50

LOTTE CHEMICAL CORPORATION: COMPANY SNAPSHOT

FIGURE 51

SHINGHWA ADVANCED MATERIAL GROUP CO., LTD.: COMPANY SNAPSHOT

Growth opportunities and latent adjacency in Dimethyl Carbonate Market