Digital Twin Market Size, Share & Trends 2025-2030

Digital Twin Market Size, share & Analysis by Deployment (PaaS, SaaS), Application (Product Design & Development, Predictive Maintenance, Performance Monitoring, Business Optimization), Industry (Automotive & Transportation, Oil & Gas) and Region - Global Forecast to 2030

OVERVIEW

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

The global digital twin market is expected to grow from USD 21.14 billion in 2025 to USD 149.81 billion in 2030 at a CAGR of 47.9% over the forecast period. The adoption of digital twin technology is revolutionizing operations across sectors by enabling real-time monitoring, simulation, and predictive maintenance. Integration with IoT, AI, and machine learning allows businesses to create precise virtual replicas of physical assets, processes, and systems to optimize performance and reduce downtime.

The digital twin market size is witnessing strong growth as organizations increasingly adopt virtual replicas of physical assets, systems, and processes to improve decision-making and operational efficiency. Digital twins enable real-time monitoring, simulation, and optimization by combining data from sensors, connected devices, and advanced analytics. Their ability to reduce downtime, improve asset performance, and enhance product design is driving adoption across industries such as manufacturing, healthcare, energy, automotive, construction, and smart cities.

As digital transformation accelerates globally, the digital twin market continues to expand due to advancements in artificial intelligence, machine learning, cloud computing, and the Industrial Internet of Things. Enterprises are leveraging digital twins to support predictive maintenance, lifecycle management, and scenario planning, making them a critical component of Industry 4.0 strategies. With growing emphasis on automation, sustainability, and data-driven operations, digital twins are evolving from experimental tools into essential platforms for long-term business and infrastructure planning.

KEY TAKEAWAYS

-

By RegionNorth America digital twin market accounted for a 38% revenue share in 2024.

-

By IndustryBy industry, the healthcare segment is expected to register the highest CAGR of 52.7%.

-

By ApplicationBy application, the busines & optimization segment is projected to grow at the fastest rate from 2025 to 2030.

-

Competitive LandscapeNavVis, Sight Machine, and COSMO TECH among others, have distinguished themselves among startups and SMEs by securing strong footholds in specialized niche areas, underscoring their potential as emerging market leaders

Digital twins are playing a critical role in accelerating digital transformation, particularly in industries such as manufacturing, healthcare, energy, and aerospace. In particular, the ability to simulate scenarios and forecast outcomes is enhancing decision-making and operational efficiency. Advanced analytics and real-time data feedback loops are driving continuous improvements across lifecycle stages, from design and development to operation and maintenance. Furthermore, the convergence of digital twins with augmented reality and edge computing is enhancing visualization and responsiveness. Their deployment is increasingly seen as essential for smart infrastructure, predictive diagnostics, and remote asset management.

TRENDS & DISRUPTIONS IMPACTING CUSTOMERS' CUSTOMERS

Organizations are shifting toward digital infrastructure, and the rising emphasis on digital twins in manufacturing industries is reducing the cost and improving the supply chain, which is accelerating the growth of the digital twin market. The increasing penetration of AI, ML, IoT, and AR/VR/XR technologies in the process and discrete industries is boosting the growth of the digital twin market and will continue to do so in the next 4 to 5 years and beyond. Introducing these technologies in an otherwise traditional factory setting has revolutionized the industries (aerospace, automotive & transportation, retail, infrastructure, and others) and opened new avenues for sustainable and optimized production.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

MARKET DYNAMICS

Level

-

Innovation in rapid design and tailored manufacturing.

-

Surging adoption of predictive maintenance model across industries to reduce downtime.

Level

-

High capital requirement to implement digital twin technology.

-

Cybersecurity threats are limiting the growth and adoption of digital twin technology

Level

-

Development of human-centered digital twins.

-

Emergence of urban-scale digital twins unlock new opportunities in smart city planning.

Level

-

Complexities associated with data collection and mathematical models.

-

Undermined real-time analytics due to unreliable networks.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Driver: Surging adoption of predictive maintenance model across industries to reduce downtime.

One of the key drivers propelling the growth of the digital twin market size is the rising demand for predictive maintenance and asset optimization across industries. As organizations seek to minimize unplanned downtime, reduce maintenance costs, and extend asset life, digital twin technology has emerged as a critical enabler. By creating a virtual replica of physical assets, digital twins enable real-time monitoring, diagnostics, and forecasting of equipment performance based on data collected through sensors and IoT devices. Predictive maintenance powered by digital twins uses advanced analytics and machine learning models to detect early signs of wear, performance anomalies, or potential failures. This proactive approach significantly reduces operational disruptions and enhances decision-making for maintenance scheduling.

Restraint:Cybersecurity threats are limiting the growth and adoption of digital twin technology.

Data security and privacy concerns represent a significant restraint in the growth of the digital twin market. Digital twin solutions rely heavily on real-time data collection, transmission, and integration from physical assets, sensors, and connected devices. This data often includes sensitive information related to operational processes, proprietary system designs, and in some cases, personal or confidential data. The risk of cyberattacks, data breaches, and unauthorized access increases as more endpoints and networks become part of a digital twin ecosystem. Industries such as aerospace, defense, healthcare, and manufacturing are particularly cautious, given their operations' critical and confidential nature. Moreover, compliance with data protection regulations such as the General Data Protection Regulation (GDPR) in Europe, the California Consumer Privacy Act (CCPA) in the US, and other regional cybersecurity standards further complicates implementation.

Opportunity: Development of human-centered digital twins.

Digital twins that incorporate human-in-the-loop (HIL) technology empower artificial intelligence to leverage both human and machine intelligence, enabling the creation of advanced machine-learning models. This approach links human, product, and system data to computational toolkits, facilitating the integration of ergonomic decision-making into digital twin-driven design. When developing a model, it becomes essential to consider human factors such as work-session breaks, fatigue management, and working hours. The human-centric design of digital twins allows for realistic output optimization, focusing on boosting production and efficiency and accounting for human variables.

Challenge: Complexities associated with data collection and mathematical models.

Despite the benefits, many organizations have yet to implement a digital twin model for asset management and business and operational optimization. A digital twin should be capable of modeling simple as well as complex objects and their relationships by accurately capturing their physical properties and simulating behaviors. Obtaining asset data from the supplier may pose a challenge, as it requires close collaboration with multiple supply chain tiers. Moreover, establishing the required level of communication in a supply chain to retrieve asset data may be challenging to maintain.

Digital Twin Market: COMMERCIAL USE CASES ACROSS INDUSTRIES

| COMPANY | USE CASE DESCRIPTION | BENEFITS |

|---|---|---|

|

Design, simulate, and verify physical products and manufacturing processes using digital twins with historical and live data integration. | Accurate predictions, reduced development time, continuous lifecycle traceability. |

|

Monitor production lines, evaluate equipment performance, and optimize energy assets like wind turbines through digital twin simulations. | Enhanced decision-making, reduced downtime via failure anticipation, improved energy generation. |

|

Create virtual twin experiences for real-time manufacturing simulations to test products and processes before physical builds. | Faster product development, predictive maintenance, increased operational agility. |

|

Develop virtual prototypes for real-time system analysis, predictive maintenance, and full product lifecycle management. | Prevent unanticipated failures, optimize asset management, enable hybrid physics-AI insights. |

|

Implement digital twins for real-time product data collection across engineering, manufacturing, and service for predictive maintenance. | Improved customer satisfaction, enhanced product quality, reduced time to market, sustainability gains. |

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET ECOSYSTEM

Digital twins represent a revolutionary convergence of physical and virtual worlds, creating real-time digital replicas of assets, processes, and systems that enable unprecedented insights and optimization capabilities. This comprehensive ecosystem brings together leading technology providers like Dassault Systèmes, Bosch, ANSYS, Inc., PTC, Ansys, and Siemens, who deliver the foundational platforms, simulation tools, and IoT connectivity that make digital twin implementations possible. These solutions span diverse end-user industries—from automotive and aerospace to healthcare and retail, transforming how organizations design, monitor, and optimize their operations.

Logos and trademarks shown above are the property of their respective owners. Their use here is for informational and illustrative purposes only.

MARKET SEGMENTS

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

Digital Twin Market, By Grade

Large enterprises held a larger share of the digital twin market in 2024, and a similar trend is expected to be observed throughout the forecast period. Digital twin solutions are still in the nascent stage of development and implementation, and large enterprises have abundant resources to incorporate the latest digital twin technologies and solutions. Hence, large enterprises are expected to dominate the market

Digital Twin Market, By Application

By applicaion, predictive maintenance hold the largest market in digital twin makret. Predictive maintenance offered by digital twins increases content productivity, enabling improved ongoing operations, maintenance, and other services. This virtual copy of a product allows for better communication and collaboration among organizations or manufacturers for product management, manufacturing, supply chain management, and service offering. For example, a digital twin of a wind turbine with intelligent data processing capability enables predictive maintenance of its behavior and condition. Also, the virtual models combine mathematical models to describe the physics of the turbine operation, with sensor data collected and processed from tangible assets during real-world operations

Digital Twin Market size, By Industry

The automotive & transportation segment is expected to hold the largest share of the digital twin market. The adoption of digital twin technology in the automotive & transportation sector is expanding rapidly, driven by the ongoing digitization of vehicles and mobility systems. Digital twins are transforming the industry by enabling virtual representations of physical assets, systems, and processes. These virtual models facilitate improvements in product design, manufacturing efficiency, and vehicle maintenance, leading to higher-quality products, streamlined operations, and enhanced reliability.

REGION

North America to be fastest-growing region in global digital twin market during forecast period

North America dominates the global digital twin market, with projections indicating it will maintain this leadership position throughout the forecast period. The region's dominance stems from several key factors that create a perfect ecosystem for digital twin adoption. North America's technological infrastructure provides the foundation for widespread digital twin implementation, supported by robust internet connectivity, cloud computing capabilities, and advanced IoT networks essential for real-time data synchronization. The region's industrial maturity is crucial, particularly in manufacturing, automotive, and aerospace sectors that heavily utilize digital twin technology for product development, predictive maintenance, and operational optimization.

The North America digital twin market is projected to grow from USD 8.08 billion in 2025 to USD 58.92 billion in 2030 at a CAGR of 48.8% during the forecast period. North America’s digital twin industry benefits from a mature cloud, edge, and AI ecosystem that allows for quick implementation and scaling. Significant investments in infrastructure upgrades, grid modernization, and the energy transition are fueling demand for real-time modeling and operational insights.

The digital twin market in Europe is projected to reach USD 49.32 billion by 2030, up from USD 7.08 billion in 2025, at a CAGR of 47.4% from 2025 to 2030. The growth of the europe digital twin market is driven by the region’s aggressive sustainability and decarbonization agenda, which pushes industries to adopt advanced modeling and real-time monitoring to meet strict EU regulations. This push for energy efficiency, emissions tracking, and lifecycle optimization is accelerating digital twin deployments across manufacturing, energy grids, transport networks, and buildings, making sustainability compliance a major catalyst for market growth.

The Asia Pacific digital twin market is projected to reach USD 4.57 billion in 2025 and USD 32.57 billion in 2030, growing at a CAGR of 48.1% from 2025 to 2030. The regional market growth is fueled by large-scale infrastructure development and strong government initiatives promoting digital transformation across emerging and developed economies. China, Japan, South Korea, and India are increasingly adopting advanced simulation and real-time monitoring technologies to enhance manufacturing productivity, improve asset performance, and support smart city programs. Rising investments in sectors such as automotive, electronics, energy, and transportation further accelerate digital twin deployment.

Digital Twin Market: COMPANY EVALUATION MATRIX

In the digital twin market matrix, Siemens (Star) leads with a strong market shareleveraging its comprehensive ecosystem of software and automation solutions to drive innovation across industries. With platforms like Siemens Xcelerator, the company seamlessly integrates the physical and digital worlds, enabling real-time simulation, optimization, and predictive insights. Robert Bosch GmbH (Emerging Leader) is emerging as a strong contender in the digital twin space, rapidly expanding its capabilities through IoT integration, AI-driven analytics, and connected manufacturing solutions.

Source: Secondary Research, Interviews with Experts, MarketsandMarkets Analysis

KEY MARKET PLAYERS

MARKET SCOPE

| REPORT METRIC | DETAILS |

|---|---|

| Market Size in 2024 (Value) | USD 14.46 Billion |

| Market Forecast in 2030 (Value) | USD 149.81 Billion |

| Growth Rate | CAGR of 47.9% from 2025-2030 |

| Years Considered | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Billion/Million) |

| Report Coverage | Revenue forecast, company ranking, competitive landscape, growth factors, and trends |

| Segments Covered |

|

| Regions Covered | North America, Asia Pacific, Europe, RoW |

WHAT IS IN IT FOR YOU: Digital Twin Market REPORT CONTENT GUIDE

DELIVERED CUSTOMIZATIONS

We have successfully delivered the following deep-dive customizations:

| CLIENT REQUEST | CUSTOMIZATION DELIVERED | VALUE ADDS |

|---|---|---|

| Manufacturing & Industrial Operator | Vendor landscape & platform benchmarking (PTC, Siemens, Ansys, etc.) | TCO/ROI modeling for specific asset classes (e.g., turbines, production lines) |

| Digital Twin Platform Vendor | Competitive profiling (features, pricing, GTM) across key verticals | Market adoption benchmarking (e.g., automotive vs. energy vs. smart cities) |

| IoT & IIoT Sensor Supplier | Analysis of data requirements for high-fidelity digital twins | Partnership ecosystem mapping (integration with leading software platforms) |

RECENT DEVELOPMENTS

- April 2025 : Hexagon AB (Sweden) launched Digital Factory, a cloud-based digital twin service designed to create accurate 3D replicas of manufacturing facilities using laser scanning. This solution helps manufacturers plan factory upgrades, test new layouts, and optimize space without making physical changes. It also enables faster decision-making, reduces the need for on-site visits, and lowers operational costs through virtual simulations and remote collaboration.

- March 2025 : Siemens (Germany) acquired Altair Engineering Inc. (US) for USD 10 billion to strengthen its digital twin and industrial AI capabilities. Altair's advanced simulation, HPC, and AI tools will be integrated into the Siemens Xcelerator platform. This acquisition aims to deliver one of the most comprehensive AI-powered industrial software suites, making simulation-driven digital twins more accessible and scalable for businesses of all sizes.

- March 2025 : Emerson Electric Co. (US) completed the acquisition of Aspen Technology (US). This acquisition strengthened Emerson's position in industrial automation by adding advanced software capabilities to its portfolio. This move helps Emerson Electric Co. offer more complete digital solutions by combining its control systems with Aspen Technology's powerful tools for simulation, optimization, and asset performance, supporting Emerson's strategy to lead in industrial software and deliver greater value to customers.

Table of Contents

Methodology

The study involved major activities in estimating the current market size for the digital twin market. Exhaustive secondary research was done to collect information on the industry. The next step was to validate these findings, assumptions, and sizing with industry experts across the value chain using primary research. Different approaches, such as top-down and bottom-up, were employed to estimate the total market size. After that, the market breakup and data triangulation procedures were used to estimate the market size of the segments and subsegments of the digital twin market.

Secondary Research

The market for companies offering digital twin is arrived at by secondary data available through paid and unpaid sources, analyzing the product portfolios of the major companies in the ecosystem, and rating the companies by their performance and quality. Various sources were referred to in the secondary research process to identify and collect information for this study. The secondary sources include annual reports, press releases, investor presentations of companies, white papers, journals, certified publications, and articles from recognized authors, directories, and databases. In the secondary research process, various secondary sources were referred to identify and collect information related to the study. Secondary sources included annual reports, press releases, and investor presentations of vendors, forums, certified publications, and whitepapers. The secondary research was used to obtain critical information on the industry's value chain, the total pool of key players, market classification, and segmentation from the market and technology-oriented perspectives.

Primary Research

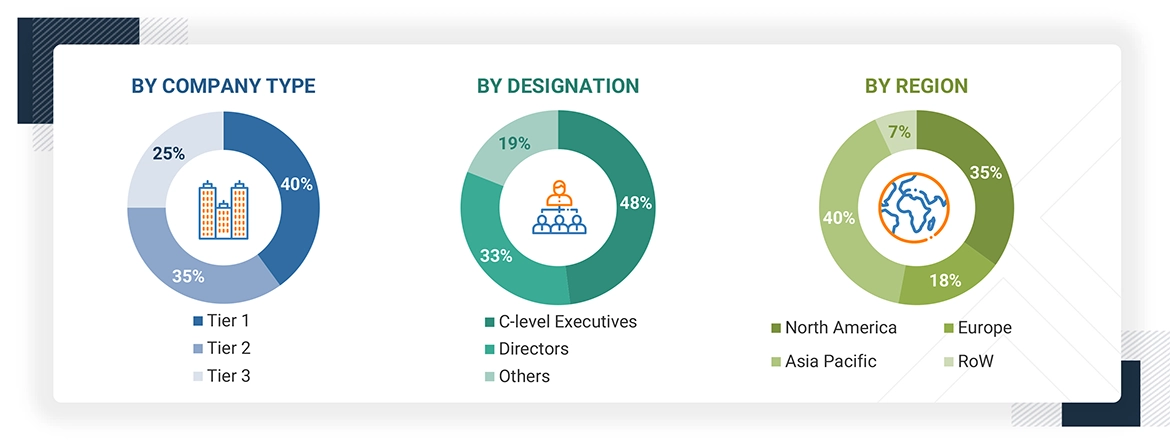

Extensive primary research has been conducted after understanding and analyzing the current scenario of the digital twin market through secondary research. Several primary interviews have been conducted with the key opinion leaders from the demand and supply sides across four main regions—North America, Europe, Asia Pacific, and the Rest of the World. Approximately 30% of the primary interviews were conducted with the demand-side respondents, while approximately 70% were conducted with the supply-side respondents. The primary data has been collected through questionnaires, emails, and telephone interviews.

After interacting with industry experts, brief sessions were conducted with highly experienced independent consultants to reinforce the findings from our primary research. This, along with the in-house subject matter experts' opinions, has led us to the findings as described in the remainder of this report. The breakdown of primary respondents is as follows:

To know about the assumptions considered for the study, download the pdf brochure

Market Size Estimation

Both top-down and bottom-up approaches were used to estimate and validate the total size of the digital twin market. These methods were also used extensively to estimate the size of various subsegments in the market. The research methodology used to estimate the market size includes the following:

Digital Twin Market : Top-Down and Bottom-Up Approach

Data Triangulation

The market was split into several segments and subsegments after arriving at the overall market size using the market size estimation processes as explained above. The data triangulation and market breakdown procedures were employed, wherever applicable, to complete the overall market engineering process and arrive at the exact statistics of each market segment and subsegment. The data was triangulated by studying various factors and trends from the demand and supply sides.

Market Definition

A digital twin is a virtual replica or digital copy of a physical object, process, or system. It serves as a digital counterpart that accurately captures the essential characteristics and behaviors of the real-world entity. Digital twins utilize advanced technologies such as sensors, data analysis, and simulations to collect real-time data from their physical counterparts. This data is then used to create and maintain an up-to-date digital representation that closely resembles the behavior of the actual object or system. The primary purpose of digital twins is to provide valuable insights and drive operational improvements in the business. By analyzing the digital twin, organizations can gain a deeper understanding of how the physical entity will perform, identify opportunities for enhancement, and test different strategies or scenarios before implementing them in the real world. Digital twins find applications in various industries, such as manufacturing, healthcare, transportation, energy, and construction.

Key Stakeholders

- Government bodies and policymakers

- Industry organizations, forums, alliances, and associations

- Market research and consulting firms

- Raw material suppliers and distributors

- Research institutes and organizations

- Analysts and strategic business planners

- End users of digital twins across various industries such as the aerospace, automotive & transportation, energy & utilities, oil & gas, infrastructure, healthcare, agriculture, retail, telecommunications, and other industries (semiconductors, chemicals, paper & pulp, and food & beverages)

Report Objectives

- To define, describe, and forecast the digital twin market size, by industry, application, and enterprise, in terms of value

- To assess the size of the digital twin market across four regions, namely, North America, Europe, Asia Pacific, and the RoW, along with their respective country-level market sizes, in terms of value

- To provide detailed information regarding the drivers, restraints, opportunities, and challenges influencing the market growth

- To give ecosystem analysis, case study analysis, patent analysis, technology analysis, pricing analysis, Porter's five forces analysis, key stakeholders and buying criteria, key conferences and events, regulatory bodies, government agencies, and regulations pertaining to the market under study

- To analyse the impact of AI and the US Tariff on the digital twin market

- To offer a detailed overview of the process flow of the digital twin market

- To strategically analyze micromarkets1 with respect to individual growth trends, prospects, and contributions to the overall market size

- To study the complete value chain of the digital twin market

- To understand opportunities for stakeholders by identifying high-growth segments of the digital twin market

- To strategically profile the key players and comprehensively analyze their market positions in terms of their ranking and core competencies2

- To analyze competitive developments, such as product launches, deals (mergers, acquisitions, partnerships, cooperation, alliances, collaborations, agreements, contracts, and investments), and others (expansions) in the digital twin market

Available customizations:

With the given market data, MarketsandMarkets offers customizations according to the specific requirements of companies. The following customization options are available for the report:

- Detailed analysis and profiling of additional market players based on various blocks of the supply chain

Key Questions Addressed by the Report

What is a digital twin?

A digital twin is a virtual representation of a physical asset, system, or process that replicates its behavior and characteristics in real time. It integrates data from sensors, control systems, and operational sources to simulate, monitor, and optimize performance throughout the asset's lifecycle. By leveraging technologies such as the Internet of Things (IoT), artificial intelligence (AI), and advanced analytics, digital twins enable predictive maintenance, enhance decision-making, and support process optimization.

What is the total CAGR expected for the digital twin market during the forecast period?

The global digital twin market is expected to record a CAGR of 47.9% during the forecast period.

What are the driving factors for the digital twin market size?

The growing demand for predictive maintenance and asset management, and increased focus on smart manufacturing & urban planning are some factors driving the digital twin market.

Which are the significant players operating in the digital twin market size?

Siemens (Germany), GE Vernova (US), Dassault Systèmes (France), and PTC (US)are some of the major companies operating in the digital twin market.

Which region will lead the digital market in the future?

North America is expected to lead the hydraulics market during the forecast period

Need a Tailored Report?

Customize this report to your needs

Get 10% FREE Customization

Customize This ReportPersonalize This Research

- Triangulate with your Own Data

- Get Data as per your Format and Definition

- Gain a Deeper Dive on a Specific Application, Geography, Customer or Competitor

- Any level of Personalization

Let Us Help You

- What are the Known and Unknown Adjacencies Impacting the Digital Twin Market

- What will your New Revenue Sources be?

- Who will be your Top Customer; what will make them switch?

- Defend your Market Share or Win Competitors

- Get a Scorecard for Target Partners

Custom Market Research Services

We Will Customise The Research For You, In Case The Report Listed Above Does Not Meet With Your Requirements

Get 10% Free CustomisationGrowth opportunities and latent adjacency in Digital Twin Market

Federico

Dec, 2022

Understanding the potential of digital twins for creative industries and the environmental movement. .