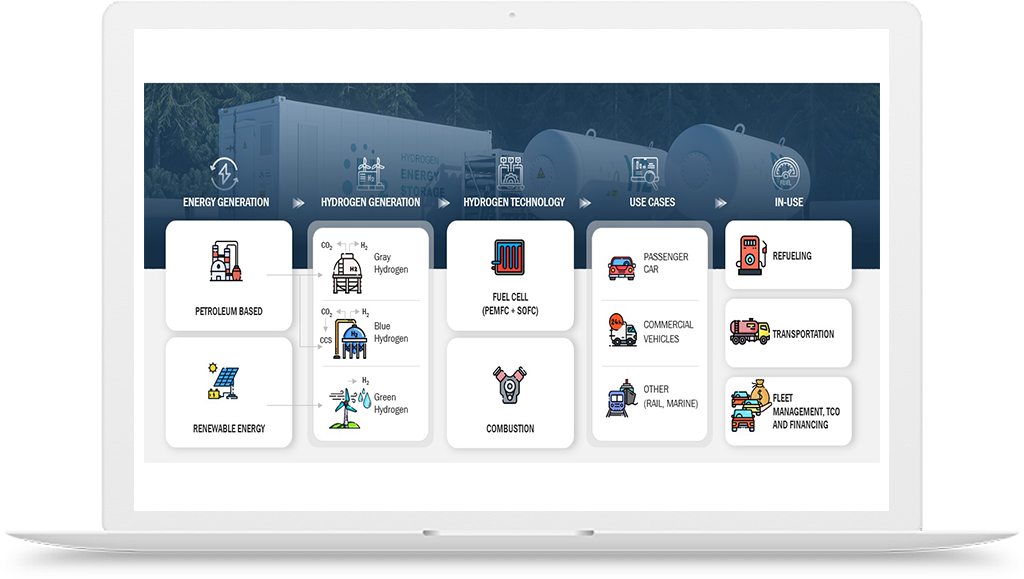

Hydrogen End Use Deployment, Supply Chain Model

The deployment of hydrogen in end-use applications is expected to involve a combination of on-site clusters, co-production, and dedicated supply chain models. The specific approach will depend on factors such as the scale of hydrogen demand, industry requirements, infrastructure availability, and regional considerations.

Here's an overview of potential deployment scenarios and end-use industries:

-

On-site Clusters and Co-production:

On-site Clusters: In some cases, industries with significant hydrogen demand may establish on-site clusters where hydrogen is produced and consumed within the same industrial complex. This approach reduces transportation costs and enables efficient utilization of waste or byproduct streams from the industrial processes for hydrogen production.

Co-production: Co-production refers to the simultaneous production of hydrogen and other products, such as chemicals or fertilizers, from the same feedstock. By integrating hydrogen production with existing industrial processes, co-production can enhance process efficiency and reduce costs.

-

End-use Industries:

Transportation: The transportation sector, including passenger vehicles, trucks, buses, trains, and maritime vessels, is a significant potential adopter of hydrogen fuel cells and hydrogen-powered vehicles.

Industry and Manufacturing: Industries such as refineries, petrochemicals, steel production, and cement manufacturing have high-temperature and high-purity hydrogen requirements. These industries can adopt on-site clusters or co-production models to meet their hydrogen needs.

Power Generation: Hydrogen can be used in fuel cells for distributed power generation, providing clean and reliable electricity in off-grid or remote areas. It can also support grid balancing and integration of renewable energy sources.

Buildings and Heating: Hydrogen can be utilized for heating purposes in buildings, either through direct combustion or by blending it with natural gas in existing gas networks.

-

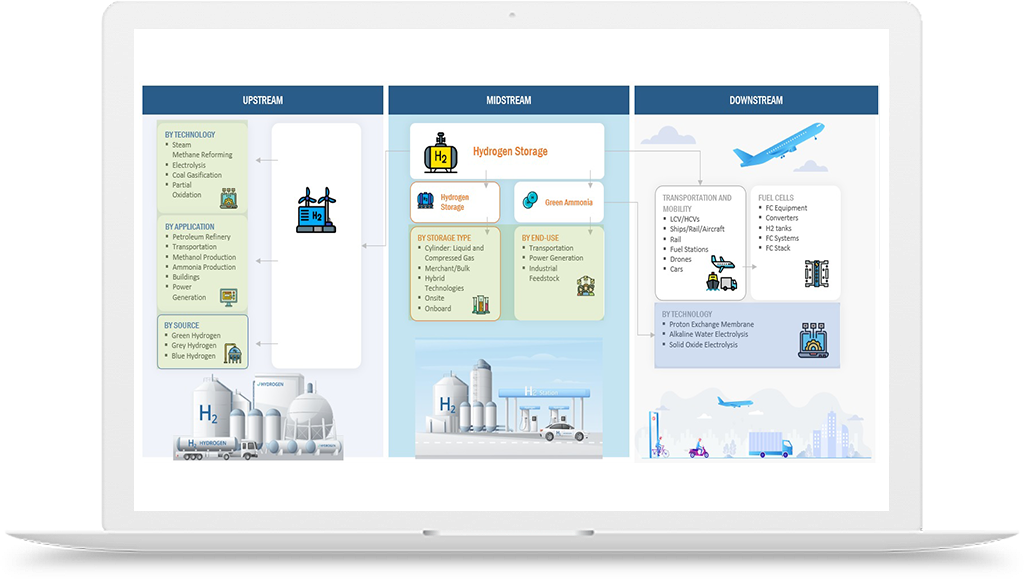

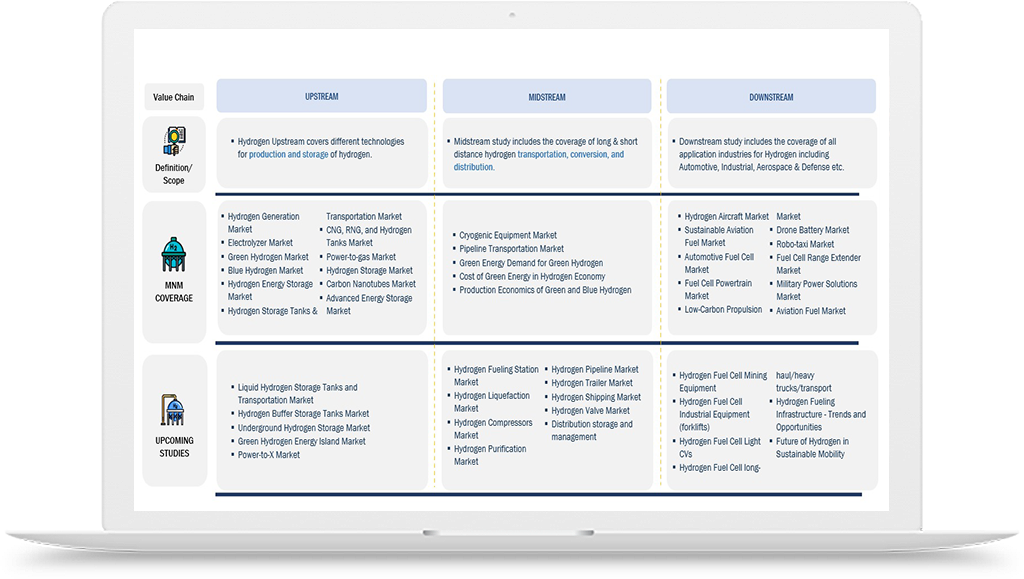

Supply Chain Model:

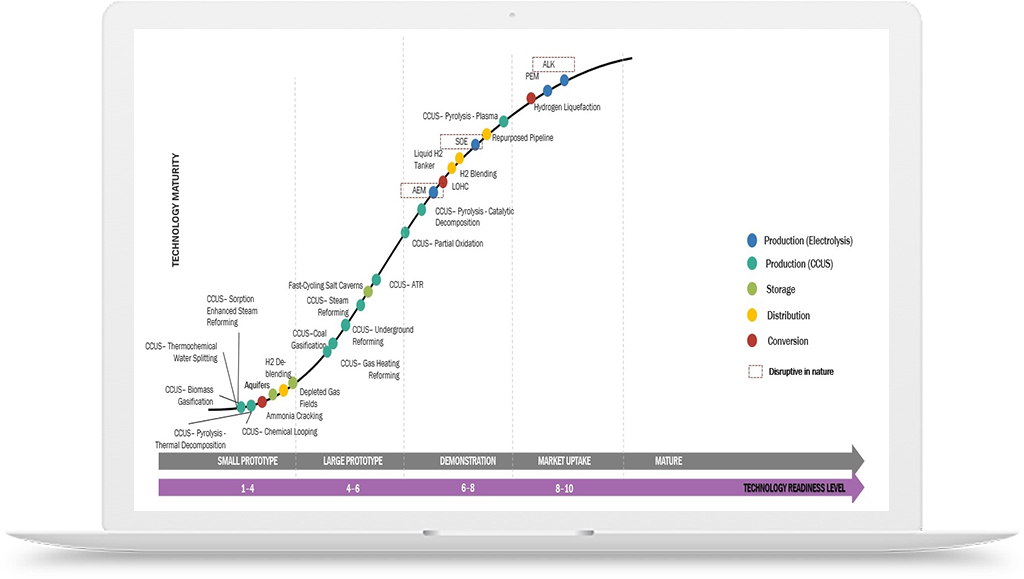

Hydrogen Production: Hydrogen can be produced through various methods, including electrolysis, steam methane reforming (SMR), biomass gasification, or other emerging technologies. The supply chain model will depend on the hydrogen production method and the availability of feedstocks and infrastructure.

Hydrogen Distribution: The distribution of hydrogen will require an infrastructure network comprising pipelines, trucking, or shipping. Existing natural gas pipelines can be repurposed for hydrogen transportation, and dedicated hydrogen pipelines may be established in regions with high demand.

Hydrogen Storage: Hydrogen can be stored in various forms, including compressed gas, liquid hydrogen, or solid-state storage materials. Storage infrastructure will be needed to ensure a reliable supply of hydrogen to end-users.

Integration with Renewables: Regions with abundant renewable energy resources may focus on integrating hydrogen production facilities with renewable energy projects. This can involve co-location of electrolyzers with wind or solar farms, facilitating direct utilization of renewable energy for hydrogen production.

It's important to note that the deployment of hydrogen in end-use industries will require collaborative efforts between industry stakeholders, policymakers, and infrastructure developers to establish supportive regulatory frameworks, incentivize investment, and ensure the development of a robust and efficient supply chain.

Some real-world examples of hydrogen end-use deployment and supply chain models:

-

On-site Clusters and Co-production:

Shell Rhineland Refinery, Germany: Shell's Rhineland Refinery in Germany operates an on-site hydrogen production plant that uses both natural gas reforming and co-production with other refinery processes. The hydrogen produced is primarily used for desulfurization and fuel upgrading within the refinery complex.

Air Liquide Hydrogen Hub, California: Air Liquide operates a hydrogen hub in Wilmington, California, where hydrogen is produced on-site through steam methane reforming. The hydrogen is supplied to various industries, including the transportation sector, for fuel cell vehicle refueling and other applications.

-

End-use Industries:

Toyota Mirai Fuel Cell Vehicle: Toyota's Mirai is an example of hydrogen adoption in the transportation sector. The Mirai is a hydrogen fuel cell electric vehicle (FCEV) that uses hydrogen to generate electricity and power the vehicle, emitting only water vapor as a byproduct.

EDF's HYFLEXPOWER Project, France: EDF, a French energy company, is implementing the HYFLEXPOWER project, which integrates hydrogen in the power generation sector. The project combines a 12 MW hydrogen electrolyzer with a 25 MW gas turbine to produce low-carbon electricity and support grid stability.

ENGIE's Hydrogen-Powered Residential Complex, Netherlands: ENGIE, in collaboration with housing association Nijestee, is developing a residential complex in the Netherlands that utilizes hydrogen for heating. The project involves converting renewable energy into hydrogen through electrolysis and supplying the hydrogen to the buildings for heating purposes.

-

Supply Chain Models:

H2H Saltend, United Kingdom: H2H Saltend is a hydrogen hub located in the Saltend Chemicals Park in the UK. The hub aims to produce low-carbon hydrogen using natural gas reforming with carbon capture and storage (CCS). The hydrogen is planned to be transported via pipelines to various industries in the region, including refineries and chemical manufacturers.

HyNet North West Project, United Kingdom: The HyNet North West project is a collaboration between various stakeholders, including industrial companies, government bodies, and infrastructure developers. It aims to establish a low-carbon hydrogen supply chain in the North West of England, integrating hydrogen production from natural gas with CCS and creating a distribution network for hydrogen transportation and utilization in different sectors.

These examples highlight the diverse applications of hydrogen in various industries and the different approaches taken for on-site production, co-production, and supply chain development. They demonstrate the potential and ongoing efforts to deploy hydrogen as a decarbonization solution in real-world scenarios.