Hydrogen Technologies

WINNING IMPERATIVES: UNLEASHING THE POWER OF HYDROGEN TECHNOLOGIES FOR A SUSTAINABLE FUTURE

- What are the winning imperatives for harnessing hydrogen technologies and propelling businesses to success?

- How can embracing hydrogen technologies fuel success and what are the winning imperatives associated with it?

- What are the crucial imperatives for leveraging hydrogen technologies and unleashing a competitive edge?

- What are the winning imperatives for companies embracing hydrogen technologies and empowering growth?

- What are the essential imperatives for adopting hydrogen technologies to unlock the future and achieve success in today's market?

Get deep dive analysis on each one of the above winning imperatives: ACCESS REPORT

Read More..

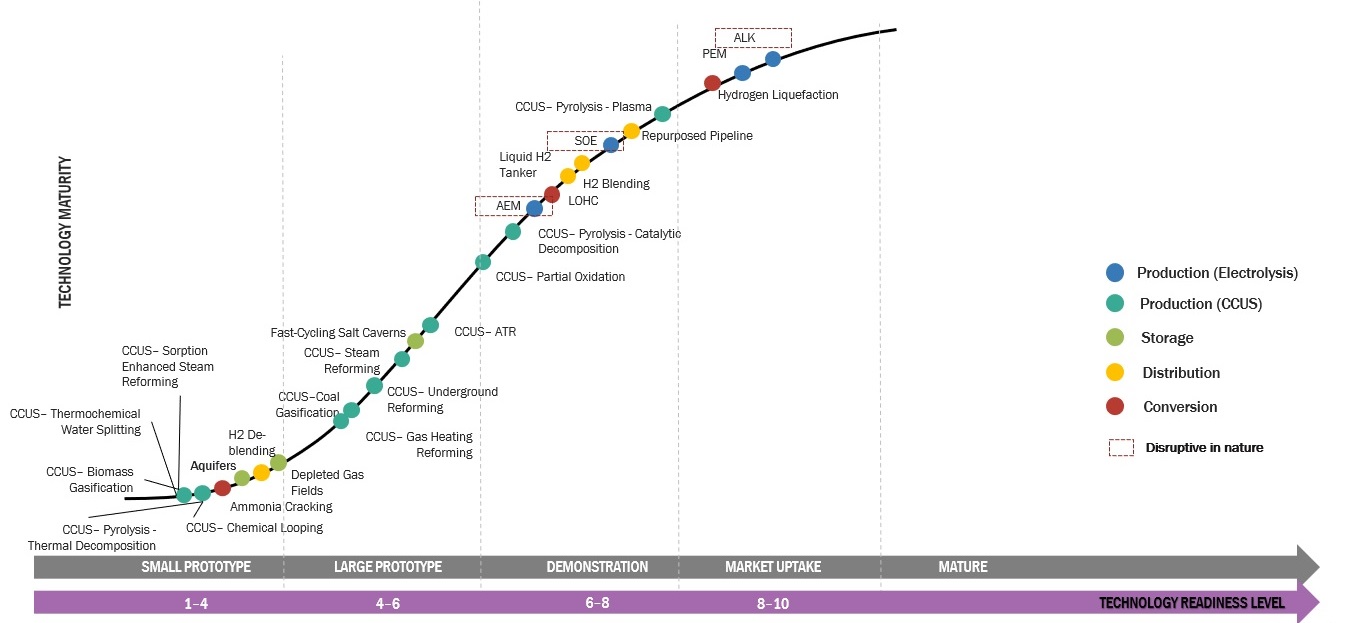

A flexible and clean energy source with many uses is hydrogen. The following list covers some of the most popular hydrogen technologies, along with a comparison of their benefits and drawbacks:

- Steam Methane Reforming (SMR): About 95% of the hydrogen produced worldwide is produced using SMR, which is the most widely used technique. In order to make hydrogen and carbon dioxide, methane and steam must react in the presence of a catalyst.

- Electrolysis: Water is split into hydrogen and oxygen by a process called electrolysis, which runs on electricity. Alkaline and proton exchange membrane (PEM) electrolysis are the two forms. A well-established technique, alkaline electrolysis is less effective than PEM electrolysis but is still reasonably priced.

- Biomass Gasification: The process of biomass gasification entails heating organic materials like wood or agricultural waste without the presence of oxygen in order to create a gas that can be refined into hydrogen.

- Nuclear: Water is divided using high-temperature nuclear reactors in the nuclear hydrogen generation process. Though costly and raising questions about the security and safety of nuclear reactors, this technology produces hydrogen without emitting carbon.

- Photobiological: The process of producing hydrogen by photosynthetic microorganisms, including algae, is known as photobiological hydrogen generation.

- Solid Oxide Electrolysis Cells (SOEC): Water is divided into hydrogen and oxygen using a ceramic electrolyte in SOECs. Although still in the research and development stage, this technology is effective.

- Thermochemical: Hydrogen can be produced from fossil fuels or other sources thermochemically, which uses heat and chemical reactions. Although it is currently in the research and development stage, this technique has the potential to be carbon neutral.

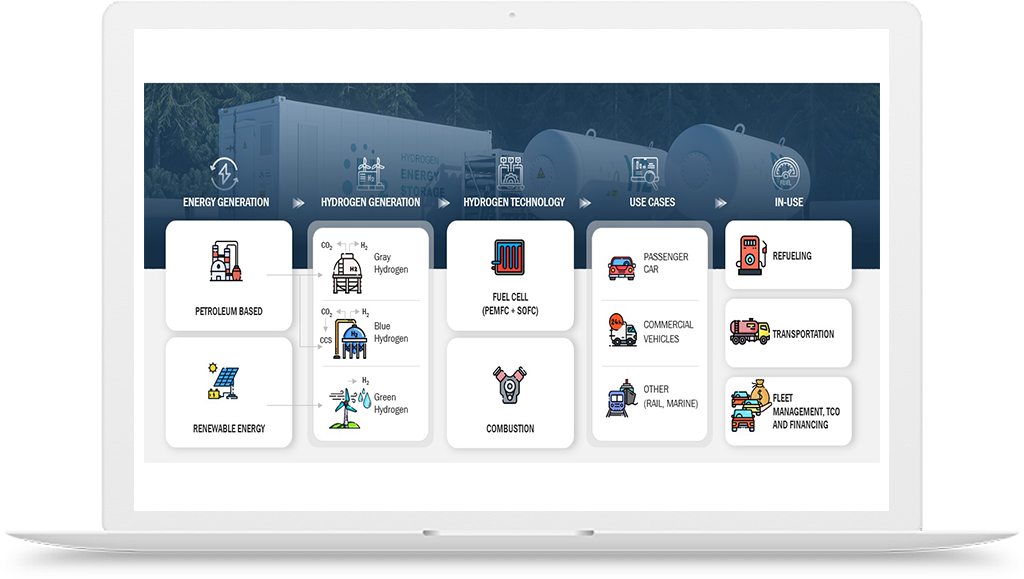

Explanation of Hydrogen Technologies

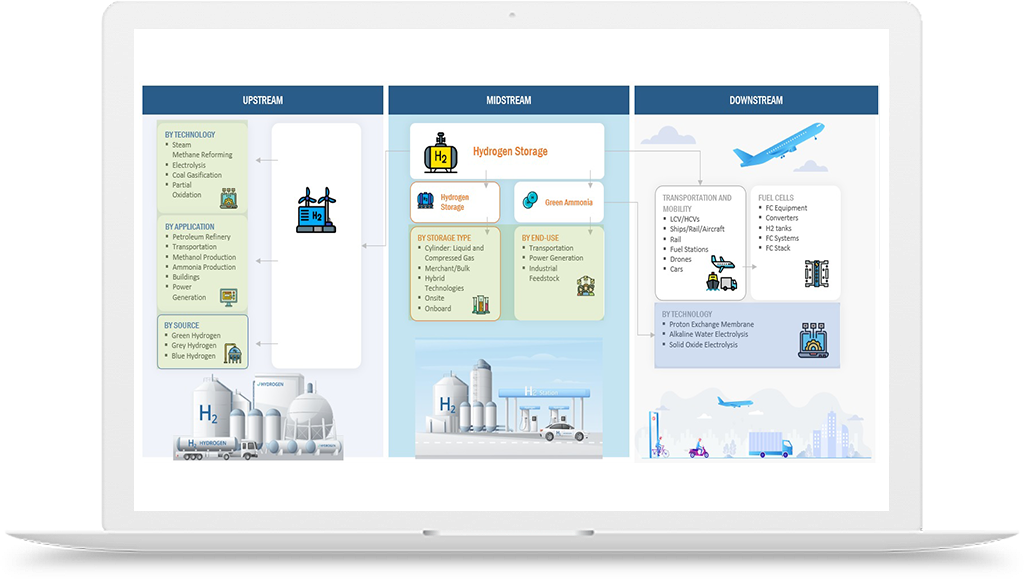

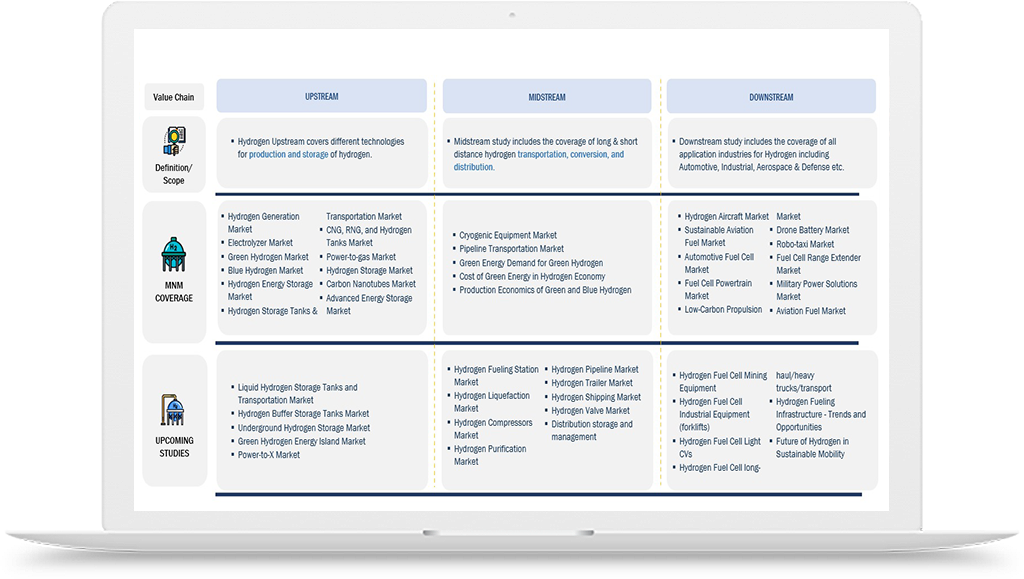

Technology and procedures related to the creation, distribution, storage, and use of hydrogen as an energy source are collectively referred to as hydrogen technologies. Energy needs can be met while reducing environmental impact by utilizing hydrogen, the most plentiful element in the universe, in a variety of forms.

Key components of hydrogen technologies:

Hydrogen Production:

Many techniques are available for producing hydrogen, such as:

- Steam Methane Reforming (SMR): This is the most used process, in which steam is chemically reacted to produce hydrogen from natural gas.

- Electrolysis: Utilizing electricity, water (H2O) is split into hydrogen (H2) and oxygen (O2). Solar or wind energy can be used to power electrolysis, which produces "green hydrogen" that emits no greenhouse gases.

- Thermochemical Processes: Gasification and pyrolysis are two examples of high-temperature processes that can produce hydrogen from a variety of feedstocks, including waste and biomass.

Hydrogen Storage:

Though its low density makes storage difficult, hydrogen is an incredibly adaptable energy carrier. Various techniques for storing data include:

- Compressed Hydrogen Gas: For industrial and transit purposes, hydrogen is compressed and kept in high-pressure tanks, usually at 350–700 bar.

- Liquid Hydrogen: Hydrogen is mostly employed in space exploration and certain industrial uses. It may be liquefied at extremely low temperatures (-253°C) and kept in insulated tanks.

- Hydrogen Carriers: Certain materials have the ability to absorb and release hydrogen, such as metal hydrides and chemical compounds, which makes them useful for hydrogen storage and transportation.

Hydrogen Distribution:

With the right adjustments, hydrogen can be supplied via pipelines and other existing infrastructure. Alternatively, tankers or specialized transport methods can be used to move it in liquid or compressed gas form.

Hydrogen Utilization:

There are several uses for hydrogen, such as:

- Fuel Cells: The only consequence of the electrochemical process that uses hydrogen to create energy in fuel cells is water. Vehicles such as vehicles, buses, and trains, as well as permanent power generating and portable electricity, all employ fuel cells.

- Combustion: In order to make hydrogen compatible with traditional internal combustion engines, hydrogen can be utilized as fuel in those engines or directly burned to produce heat.

- Industrial Processes: In many industrial processes, such as metallurgy, chemical synthesis, and refining, hydrogen is employed as a reducing agent or feedstock.

- Hydrogen Blending: It is possible to gradually move towards a hydrogen-based energy system without requiring major infrastructure upgrades by blending hydrogen with natural gas in already-existing gas pipes.

Importance of Hydrogen Technologies

As a flexible and clean energy source, hydrogen has shown great promise in addressing major global issues like energy security, climate change, and energy transition.

Decarbonization and Climate Change Mitigation:

Hydrogen technologies provide a way to decarbonize a number of industries, including heavy manufacturing, shipping, aviation, and long-distance transportation, which would otherwise be challenging to directly electrify.

Energy Storage and Grid Balancing:

The intermittent nature of renewable energy sources, such as wind and solar power, is one of their main problems.

Energy Transition and Sector Integration:

Moving away from fossil fuels and toward a greener energy mix is made easier by hydrogen technologies. An efficient and linked energy ecosystem is created by allowing the integration of several energy sectors, including power, transportation, and heating.

Energy Security and Independence:

Energy security is increased by utilizing hydrogen technology to diversify the energy mix and lessen reliance on imported fossil fuels. Nations can lessen their need on imported energy by producing hydrogen domestically from a variety of sources, including nuclear power, renewable energy, and natural gas.

Technological Innovation and Job Creation

Technology innovation and economic progress are promoted by investments in hydrogen technologies. Jobs are being created along the value chain by the development and implementation of hydrogen infrastructure, which includes facilities for production, storage, and delivery.

Significance and Potential Benefits of Hydrogen as an Energy Carrier

Regarding a sustainable and low-carbon future, hydrogen is an energy carrier with great importance and potential advantages.

Let's examine the main justifications for why hydrogen is seen as a significant participant in the energy scene:

Versatility and Energy Storage:

Utilized in a wide range of industries and applications, hydrogen is an extremely adaptable energy source.Hydrogen is a desirable alternative to fossil fuels in a number of industries, including power generation, transportation, and industrial.

Carbon Neutrality and Climate Change Mitigation:

Green hydrogen is produced by electrolyzing hydrogen that comes from renewable energy sources like sun, wind, or hydropower.

Energy Efficiency and Resource Optimization:

When compared to conventional combustion engines, hydrogen-based devices, such fuel cells, have better energy conversion efficiency.

Energy Security and Independence:

By combining different energy sources, hydrogen presents chances to improve energy security. It may be made locally, which lessens reliance on imported fossil fuels. Countries can increase their energy independence, lower the geopolitical risks related to energy supply, and promote a more secure and resilient energy system by building a strong infrastructure for the production and delivery of hydrogen.

Air Quality and Health Benefits:

Air quality can be greatly improved by switching to hydrogen-based systems, especially in urban areas. Fuel cells and combustion processes driven by hydrogen generate no particulate matter or toxic pollutants like sulfur dioxide (SO2) and nitrogen oxides (NOx).

Technological Innovation and Job Creation:

Research and technological innovation are propelled forward by investments in hydrogen technologies. This advancement draws funding from the private sector, encourages the development of a hydrogen industry, and generates employment possibilities in infrastructure construction, production, research and development and maintenance.

Applications of Hydrogen Technologies

There are many uses for hydrogen technologies in many different industries. Let's examine a few of the major uses for hydrogen that are of great interest:

Transportation:

Transportation is one of the main areas where hydrogen technologies are being used, as they provide efficient and clean substitutes for traditional fossil fuel-powered cars.

- Fuel Cell Vehicles (FCVs): The only consequence of hydrogen fuel cells' process of turning hydrogen and oxygen into energy is water vapor, which powers fuel cell vehicles. Fuel cell vehicles (FCVs) present a viable approach to decarbonizing the transportation sector because to its extended driving range, rapid refueling periods, and zero emissions.

- Hydrogen Internal Combustion Engine Vehicles (HICEVs): A temporary way to use hydrogen in current car fleets while lowering emissions is to use it as fuel in internal combustion engines that have been upgraded.

Energy Storage and Grid Balancing:

Energy storage and grid balancing, especially for intermittent renewable energy sources like solar and wind, can greatly benefit from hydrogen technologies.

- Power-to-Gas: Hydrogen can be produced through electrolysis using surplus electricity generated during peak hours. Hydrogen can be utilized as a feedstock for industrial processes or stored and subsequently transformed back into energy.

- Hydrogen Fuel Cells for Backup Power: Telecommunications, off-grid applications, and essential infrastructure can all benefit from the clean, dependable backup power that hydrogen fuel cells can offer.

Industrial Applications:

Hydrogen technologies provide low-carbon alternatives and improve process efficiency, with numerous applications across diverse industrial sectors.

- Hydrogen as a Feedstock: Several industrial processes, like the synthesis of methanol and the manufacturing of ammonia, require the utilization of hydrogen.

- Hydrogen for Refining: In order to purge crude oil of contaminants and create cleaner fuels, refining techniques like hydrocracking and hydrotreating require hydrogen.

- Steel and Metal Production: In the manufacturing of iron and steel, hydrogen can be employed as a reducing agent to help these energy-intensive industries become more carbon-efficient.

Power Generation:

Hydrogen technologies present a clean and efficient option to conventional fossil fuel-based power plants for the production of electricity.

- Distributed Generation: Distributed power generation using fuel cells can supply heat and energy to commercial, industrial, and residential structures.

- Hybrid Power Plants: Reliable and dispatchable power can be produced by hybrid power plants that combine hydrogen with renewable energy sources, guaranteeing a steady supply of energy.

Residential and Commercial Heating:

Hydrogen presents a low-carbon substitute for natural gas in heating applications.

- Hydrogen Blending: Buildings, both residential and commercial, can use hydrogen for heating by blending it with natural gas in the current pipeline system.

- Hydrogen Boilers: Carbon emissions from heating systems can be decreased by switching to hydrogen-fueled boilers from conventional natural gas boilers.

Futuristic opportunities for hydrogen technologies

Future hydrogen technologies have a lot of promise and will be essential in establishing a low-carbon, sustainable society. The following futuristic prospects demonstrate the revolutionary potential of hydrogen technologies:

Renewable Hydrogen at Scale:

The production of renewable hydrogen needs to be scaled substantially if hydrogen technologies are to survive. The creation of "green hydrogen" has the potential to grow in popularity and profitability with improvements in electrolysis technology and growing use of renewable energy sources.

Hydrogen as an Energy Storage Solution:

The requirement for effective energy storage technologies grows as the share of renewable energy sources rises. Future advancements in hydrogen storage technologies, such as novel materials and creative storing techniques, may improve the hydrogen storage systems' capacity, efficiency, and affordability, allowing for a larger integration of renewable energy sources into the grid.

Hydrogen-Based Synthetic Fuels:

Methanation and methanol synthesis are two techniques that can use hydrogen and collected carbon dioxide to create synthetic fuels. These fuels offer carbon-neutral replacements for fossil fuels in the infrastructure and applications now in use, such as industrial processes, heating, and transportation.

Hydrogen Infrastructure Development:

Establishing a strong infrastructure for hydrogen is essential to achieving the full potential of hydrogen technology. Prospective avenues for growth entail the construction of a vast hydrogen distribution infrastructure, including pipelines, filling stations, and storage facilities, in order to facilitate the broad acceptance of hydrogen-powered automobiles and facilitate the effective conveyance and application of hydrogen in diverse industries.

Hydrogen for Grid Flexibility and Sector Coupling:

Sector coupling and grid flexibility may be improved by incorporating hydrogen technology into the electrical system. Moreover, by utilizing hydrogen as a common energy carrier to connect several energy sectors, including industrial, transportation, and power, hydrogen can facilitate sector coupling and enhance system flexibility and optimization.

Hydrogen for Space Exploration:

Because of its excellent propulsion qualities and high energy density, hydrogen has long been employed in space travel. Prospective avenues for hydrogen technology development encompass progressions in hydrogen-dependent propulsion mechanisms, including liquid hydrogen engines, for space exploration expeditions, encompassing crewed trips to Mars and beyond.

Key Components and Processes Involved in Hydrogen Technologies

Hydrogen technologies encompass a range of parts and procedures that make it possible to produce, store, distribute, and use hydrogen as a source of energy. Let's examine the essential elements and procedures of hydrogen technologies:

Hydrogen Production:

There are numerous ways to create hydrogen, including:

- Steam Methane Reforming (SMR): The most popular technique of producing hydrogen involves reacting natural gas with steam to create carbon dioxide and hydrogen.

- Electrolysis: Electrolysis is the process of employing an electrical current to divide water (H2O) into hydrogen (H2) and oxygen (O2).

- Thermochemical Processes: Using high-temperature chemical reactions, thermochemical processes like gasification and pyrolysis can transform a variety of feedstocks, including waste or biomass, into hydrogen.

Hydrogen Storage:

Storage of hydrogen is essential to its effective use and transportation. There are several ways to store hydrogen, including:

- Compressed Gas: At pressures between 350 and 700 bar, high-pressure tanks can be used to compress and store hydrogen. Applications related to transportation frequently use this technique.

- Liquid Hydrogen: In insulated tanks, hydrogen can be stored after being liquefied at a very low temperature of -253°C.

- Hydrogen Carriers: Compact and secure hydrogen storage is made possible by hydrogen transporters, which include metal hydrides and chemical compounds.

Hydrogen Distribution:

Depending on the amount and goal of the distribution, there are several ways to spread hydrogen:

- Pipelines: It is possible to adapt or repurpose existing natural gas pipelines for the distribution of hydrogen. But there are issues with hydrogen embrittlement and permeability that call either special hydrogen pipelines or improvements to existing pipelines.

- Hydrogen Trucks and Tankers: Transporting hydrogen in liquid or compressed gas form requires the use of specialist trucks and tankers.

- On-Site Generation: On-site hydrogen production is possible with the use of specialized systems like reformers or electrolyzers. For confined hydrogen supply, this method works well.

Hydrogen Utilization:

Depending on the needs and application, there are several ways to use hydrogen:

- Fuel Cells: The sole byproduct of fuel cells, which are electrochemical devices that transform hydrogen and oxygen into energy, is water vapor. They are used as stationary power sources, backup power, and vehicle power.

- Combustion: In engines or burners, hydrogen can be used directly to produce heat and mechanical power, just like traditional fuels.

- Industrial Processes: Metallurgy, refining, and chemical manufacture are just a few of the industrial uses for hydrogen. It serves these operations as a heat source, reducing agent, or feedstock.

- Hydrogen Blending: It is possible to gradually move towards a hydrogen-based energy system without requiring major infrastructure upgrades by blending hydrogen with natural gas in already-existing gas pipelines or distribution networks.

Key Challenges for Hydrogen Technologies in The Future

Hydrogen technologies have great potential, but before they can be successfully implemented and widely used in the future, a number of important issues must be resolved:

Cost Competitiveness:

Compared to traditional fossil fuel-based alternatives, the cost of producing hydrogen, especially green hydrogen from renewable sources, is now greater. Hydrogen production, storage, and infrastructure development come with significant capital and operating expenses, which makes it difficult for hydrogen technologies to become widely used.

Infrastructure Development:

A strong hydrogen infrastructure must be established before hydrogen technologies may be widely used. The construction of pipelines or other alternate distribution systems, refueling stations, storage facilities, and hydrogen generating facilities are all included in this.

Energy Storage and Conversion Efficiency:

Energy storage problems can be solved with hydrogen technology, although efficiency and storage capacity are not without problems. Because of its low energy density, hydrogen requires high pressure storage methods or enormous storage volumes.

Safety Considerations:

In order to avoid mishaps, hydrogen must be handled and stored carefully because it differs from conventional fuels in terms of safety. Strict safety precautions and laws are required for the storage, transportation, and use of hydrogen due to its extreme flammability.

Scalability and Supply Chain:

Ensuring a sustainable and dependable hydrogen supply becomes imperative as hydrogen technologies expand.

Policy and Regulatory Framework:

The regulatory and policy environments must be favorable for the successful implementation of hydrogen technologies. The adoption of hydrogen technology can be sped up by implementing policies that encourage funding, R&D, and the creation of suitable safety norms and regulations.

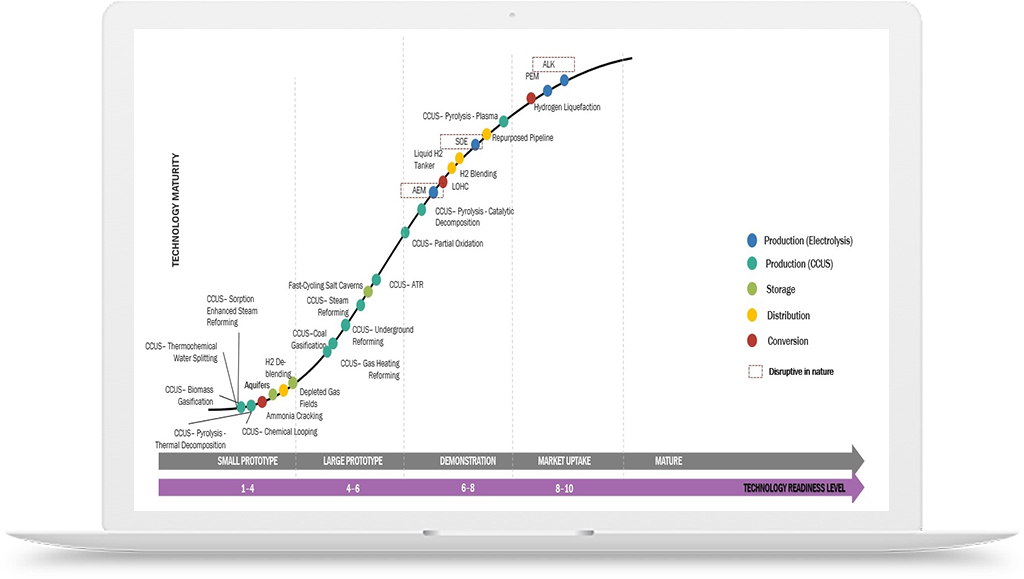

Deep dive in specific hydrogen technologies and their significance in the context of hydrogen production

Steam Methane Reforming (SMR):

For industrial hydrogen production, steam methane reforming is the most popular technique. Carbon dioxide and hydrogen gas are created when high-temperature reactions between steam and methane, which is usually obtained from natural gas, occur.

Electrolysis:

The process of electrolysis divides water (H2O) into hydrogen (H2) and oxygen (O2) using an electrical current. It provides a means to create "green hydrogen" while using renewable energy. There are two primary approaches for performing electrolysis:

- Proton Exchange Membrane (PEM) Electrolysis: Solid polymer electrolyte is used in PEM electrolysis to separate the oxygen and hydrogen gasses. It can produce hydrogen locally and decentralized, as at hydrogen fueling stations, and operates at relatively low temperatures.

- Alkaline Water Electrolysis (AWE): Alkaline electrolyte solutions are used by AWE to speed up the electrolysis process. Because of its great durability and efficiency, it has been frequently employed for large-scale hydrogen production.

Gasification of biomass entails using a thermochemical process to transform biomass feedstock such as wood chips, energy crops, or agricultural residues into a gas that is high in hydrogen.

Nuclear:

Hydrogen can be produced using nuclear power by thermochemical reactions or high-temperature electrolysis. Utilizing the surplus heat produced by nuclear reactors, high-temperature electrolysis increases the electrolysis's effectiveness.

Photobiological:

Hydrogen is produced by photosynthesis by photosynthetic microorganisms, such as algae or cyanobacteria, in a process known as photobiological hydrogen production. Even though research on photobiological hydrogen production is very promising, there are still many obstacles to overcome in terms of efficiency, scalability, and cost-effectiveness.

Solid Oxide Electrolysis Cells (SOEC):

Utilizing a solid oxide ceramic electrolyte, Solid Oxide Electrolysis Cells (SOEC) allow for the direct conversion of steam into hydrogen and oxygen at high temperatures.

Thermochemical:

A variety of chemical reactions involving high temperatures and certain catalysts are included in the thermochemical techniques used to produce hydrogen. Water splitting via metal oxide cycles, such as those based on iron or cerium, can be one of these processes.

Recent technological developments and innovations in each of the hydrogen production technologies:

Steam Methane Reforming (SMR):

Carbon Capture and Utilization (CCU): Efforts are being made to capture and use the carbon dioxide produced during SMR, a process known as carbon capture and utilization (CCU). The environmental impact of SMR can be lessened by carbon capture technologies, such as carbon capture and storage (CCS) or carbon capture and utilization (CCU), which capture CO2 and use it for storage or other industrial activities.

SMR with Carbon Capture and Storage (CCS): By combining CCS technology with SMR, carbon dioxide emissions can be captured and then stored, lowering the total carbon footprint of producing hydrogen.

Electrolysis:

Proton Exchange Membrane (PEM) Electrolysis Advancements: The goals of recent developments in PEM electrolysis technology have been to increase cell cost-effectiveness, durability, and efficiency. The increased efficiency and extended longevity of PEM electrolyzers can be attributed to the use of novel materials, enhanced catalysts, and sophisticated cell designs.

Alkaline Water Electrolysis (AWE) Innovations: The goal of research and development is to increase AWE systems' scalability and efficiency. In order to improve the efficiency and reduce the costs of AWE, innovations include the creation of new electrode materials, improved electrolyte compositions, and optimized cell designs.

Biomass Gasification:

Optimization of the Gasification Process: In order to increase hydrogen yields and decrease unwanted byproducts, researchers are looking into ways to optimize the gasification process.

Integration with Bioenergy Systems:

To improve overall sustainability, biomass gasification for hydrogen production might be combined with bioenergy systems.

Nuclear:

High-Temperature Electrolysis (HTE): Research is being done to better utilize the extra heat produced by nuclear reactors for the efficient synthesis of hydrogen.

Hybrid Systems:

High-temperature nuclear reactors combined with hydrogen production technologies are the subject of research into hybrid nuclear-hydrogen systems.

Photobiological:

Genetic Engineering:

Enhancing photosynthetic microorganism productivity and efficiency for photobiological hydrogen production is being done by researchers through genetic engineering.

The potential for photobiological systems to produce hydrogen is being maximized by exploring advancements in culture strategies, such as photobioreactor design, light management techniques, and nutrition optimization.

Solid Oxide Electrolysis Cells (SOEC):

Better Electrolyte Materials: Advanced electrolyte materials with improved stability, durability, and ionic conductivity are the subject of research.

System Integration: By combining SOECs with other renewable energy sources, including solar or wind power, or by utilizing waste heat from industrial processes to increase the electrolysis process's energy efficiency, system integration innovations seek to maximize the overall performance of SOECs.

Practical applications for all hydrogen-related technologies

Steam Methane Reforming (SMR):

Practical Use Case: Manufacturing Hydrogen

For the large-scale industrial production of hydrogen, SMR is now the leading technique.

Electrolysis:

Transport-Related Use Case: Renewable Hydrogen

"Green hydrogen" can be produced via electrolysis using renewable energy sources for use in transportation.

Biomass Gasification:

A Practical Application: Carbon Capture and Storage Combined with Sustainable Bioenergy (BECCS).

Carbon capture and storage (CCS) in conjunction with biomass gasification has the potential to remove CO2 from the environment and produce low-carbon hydrogen.

This technology is a component of the BECCS (Bioenergy with Carbon Capture and Storage) concept, which uses gasified biomass feedstock to produce hydrogen, captures and stores the resulting CO2 emissions, and uses hydrogen for a variety of purposes, including power generation and transportation.

Nuclear:

Practical Use Case: Production of Nuclear Hydrogen

Efficient hydrogen production can be achieved by thermochemical processes driven by nuclear energy or high-temperature electrolysis.

Nuclear power facilities can supply the high-temperature heat required for thermochemical or electrolysis processes, which can produce hydrogen with low or no carbon emissions.

Photobiological:

A Practical Application: Producing Hydrogen Using Algae

A sustainable method for producing hydrogen can be found in photobiological hydrogen production, which uses cyanobacteria or microalgae.

Algae growth and hydrogen generation can be supported by the organic nutrients found in wastewater, which can be utilized by integrating algae culture systems with wastewater treatment facilities.

Solid Oxide Electrolysis Cells (SOEC):

Practical Use Case: Combining Renewable Energy Sources

Clean hydrogen can be produced by combining SOEC technology with renewable energy sources, such solar or wind power.

Key players in each of the Hydrogen Technologies:

Steam Methane Reforming (SMR):

- Air Liquide

- Linde

- Air Products and Chemicals, Inc.

- Shell

- BP

- Chevron

- TotalEnergies

- ExxonMobil

Electrolysis:

- Nel Hydrogen

- ITM Power

- Siemens Energy

- McPhy Energy

- Ballard Power Systems

- Hydrogenics

- Enapter

- Proton OnSite

Biomass Gasification:

- Mitsubishi Power

- Valmet

- Nexterra Systems Corp.

- DP CleanTech

- Biomass Engineering Ltd.

- Choren Industries

- PRM Energy Systems Inc.

- Zilkha Biomass Energy

Nuclear:

- X-energy

- Framatome

- General Atomics

- Idaho National Laboratory

- TerraPower

- Westinghouse Electric Company

- NuScale Power

- Lightbridge Corporation

Photobiological:

- Synthetic Genomics

- Algenol

- HyperSolar

- Cyanotech Corporation

- Aurora Algae

- Sapphire Energy

- Heliae Development, LLC

- Algenuity

Solid Oxide Electrolysis Cells (SOEC):

- Sunfire

- SolidPower

- Elcogen

- Ceres Power

- Nexceris

- Haldor Topsoe

- Cummins

- Fraunhofer IKTS

Finally, hydrogen technologies are extremely promising for a low-carbon, sustainable energy future. Cooperation and additional research are necessary to realize their full potential.

- Multi-Stakeholder Collaboration: To promote innovation, exchange knowledge, and develop laws and regulations that are helpful, governments, business leaders, academic institutions, and international organizations should work together.

- Research and Development: To solve technical problems, increase productivity, and cut expenses, research must continue. Programs for system integration, innovative materials, catalysts, and hydrogen generation technology optimization should receive funding for research and development.

- Pilot Projects and Demonstration Plants: Pilot projects and demonstration facilities should be established in order to demonstrate the feasibility and scalability of hydrogen technologies, with cooperation from governments and industry stakeholders.

- Infrastructure Development: The development of hydrogen infrastructure, such as manufacturing plants, storage options, transportation systems, and refueling stations, requires teamwork. Governments and business should collaborate to establish incentives and a regulatory environment that will encourage the construction of hydrogen infrastructure.

- International Cooperation: Reaching the full potential of hydrogen technologies requires international cooperation. To solve shared issues, standardize requirements, and hasten the worldwide use of hydrogen as an energy carrier, nations should promote cross-border collaboration, knowledge exchange, and cooperative research projects.

- Public Awareness and Education: It is essential to raise public knowledge of and educate them about the advantages of hydrogen technologies. To educate and involve the public on hydrogen's role in a sustainable energy transition, governments, businesses, and academic institutions should fund public outreach campaigns, educational initiatives, and knowledge-dissemination platforms.

We can unleash the transformational power of hydrogen technology and build a cleaner, more sustainable future for future generations by embracing collaboration, funding research and development, and cultivating a supporting ecosystem.

- Green Hydrogen Systems: For the purpose of producing, storing, and consuming hydrogen gas, renewable energy sources like solar, wind, or hydropower are used in "green hydrogen systems," which are the mechanisms and procedures involved.

- Hydrogen Fuel Technology: Transportation, industry, and power generation are just a few of the uses for hydrogen fuel technology, which is the creation, implementation, and exploitation of technologies that use hydrogen as a clean and effective energy source.

- Hydrogen Power Systems: When hydrogen is employed as a major energy carrier, hydrogen power systems are the infrastructure and integrated technologies used to produce electricity.

- Hydrogen Vehicle Technology: The term "hydrogen vehicle technology" describes the planning, creation, and use of automobiles that run on hydrogen as a fuel source.

- New Hydrogen Technology: Innovations and recent developments in the realm of hydrogen-related technologies are referred to as "New Hydrogen Technology".

- Hydrogen Fuel Cell Generator: A hydrogen fuel cell generator is a device that uses the electrochemical reaction that takes place inside a fuel cell to directly convert hydrogen fuel into power.

- Hydrogen Fuel Cell Technology Companies: Companies and organizations that actively work on the development, production, and marketing of hydrogen fuel cell technologies are known as hydrogen fuel cell technology companies.

- Hydrogen Storage Technologies: Technologies for storing hydrogen safely and effectively for later use are referred to as hydrogen storage technologies.

- Hydrogen Power Plant: An industrial facility used primarily as a fuel source for the production of electricity is called a hydrogen power plant, sometimes referred to as a hydrogen energy facility or hydrogen power station.

- Fuel Cell Technology: The term "fuel cell technology" describes the research, development, and use of devices known as "fuel cells," which produce electricity by reacting electrochemically with hydrogen and oxygen.

- Hydrogen Production Technologies: The techniques and procedures used to produce hydrogen gas from various feedstocks are referred to as hydrogen production technologies. Hydrogen is an energy carrier with multiple applications that can be created through different ways, each with its own set of benefits, drawbacks, and environmental considerations.

- Hydrogen Energy Technology: The generation, storage, distribution, and use of hydrogen as a clean and adaptable energy source are all included in the wide category of technologies and systems known as hydrogen energy technology.

- Hydrogen Technology Companies: Businesses and organizations that focus on the development, manufacture, and commercialization of hydrogen-related technologies across a range of industries, including production, storage, distribution, and consumption, are known as hydrogen technology firms.

- Green Hydrogen Technology: The techniques and procedures used to produce hydrogen gas from renewable energy sources, such as solar, wind, or hydropower, are referred to as "Green Hydrogen Technology."

- Hydrogen Cell Technology: Using an electrochemical process, hydrogen gas (H2) is used as fuel in hydrogen fuel cell technology to produce electricity.

- Applications of Hydrogen Energy: Hydrogen energy's adaptability and potential as a clean and efficient energy carrier make it suitable for use in a wide range of sectors.

- Hydrogen Fuel Cell Technology: Utilizing an electrochemical reaction between hydrogen and oxygen to generate electricity, hydrogen fuel cell technology is a clean and effective energy conversion method.

- Fuel Cell Manufacturing: Fuel cell manufacturing is the process of creating fuel cells, which are devices that use an electrochemical reaction to directly transform chemical energy into electrical energy.

- Hydrogen Car Technology: The use of hydrogen fuel cells to power automobiles is known as hydrogen car technology. Fuel cell vehicles, or hydrogen cars, are a cutting-edge and sustainable substitute for conventional gasoline-powered automobiles.

- Blue Hydrogen Technology: With the use of carbon capture and storage (CCS), blue hydrogen technology produces hydrogen gas while reducing emissions of carbon dioxide (CO2).

- Hydrogen Power Companies: The production, distribution, and use of hydrogen as a clean and effective energy source are the main areas of concentration for enterprises engaged in the hydrogen energy sector.

- Hydrogen Engine Technology: Hydrogen engine technology pertains to the utilization of hydrogen as a fuel in internal combustion engines or other engine types intended to burn hydrogen to produce electricity.

- Hydrogen Generation Technology: Technology related to producing hydrogen gas, a flexible and clean energy source with a wide range of uses, is known as Hydrogen Generation Technology.

- Fuel Cell Technology Cars: Technology using fuel cells Automobiles that use hydrogen fuel cells to produce electricity to run an electric motor are referred to as fuel cell vehicles, or FCVs for short.

-

Together, let's make the transition to a world powered by hydrogen.

HYDROGEN GENERATION MARKET

Frequently Asked Questions (FAQ):

What are the technologies for hydrogen?

The main technologies for hydrogen include electrolysis, which splits water into hydrogen and oxygen using electricity, and steam methane reforming, which extracts hydrogen from natural gas. Other emerging technologies include biomass gasification and high-temperature electrolysis, offering alternative pathways for hydrogen production.

What are the main three 3 hydrogen production technologies?

The three main hydrogen production technologies are steam methane reforming (SMR), electrolysis (both alkaline and proton exchange membrane), and coal gasification. These methods are currently the most widely used for large-scale hydrogen production.

Where is hydrogen technology used?

Hydrogen technology is used in various sectors, including transportation (fuel cell vehicles), industrial processes (refineries, chemical production), energy storage, power generation (fuel cells), and heating applications. Its versatility makes it applicable across a range of industries, offering potential for decarbonization and energy diversification.

What is the new technology to store hydrogen?

One new technology for hydrogen storage is solid-state hydrogen storage, which involves using materials such as metal hydrides or chemical compounds to store hydrogen safely and efficiently. Another emerging approach is hydrogen storage in liquid organic hydrogen carriers (LOHC), where hydrogen is chemically bound to a liquid carrier, enabling easier transportation and release of hydrogen when needed.