Hydrogen Application in Semiconductors Industry

The semiconductor industry is a critical sector in the global economy, with a wide range of applications across various industries. The use of hydrogen in the semiconductor industry has the potential to revolutionize the manufacturing process, leading to increased efficiency, reduced costs, and improved product quality.

Here are some of the key applications of hydrogen in the semiconductor industry:

- Cleaning: Hydrogen is commonly used as a cleaning agent in the semiconductor manufacturing process. It is used to remove contaminants from the surface of wafers, ensuring that they are free from impurities that could affect their performance.

- Annealing: Hydrogen can also be used in the annealing process, which involves heating the wafers to a specific temperature and then cooling them slowly to reduce internal stress and improve product quality. By using hydrogen in the annealing process, the energy required to heat and cool the wafers can be reduced, leading to improved energy efficiency and reduced costs.

- Etching: Hydrogen can be used in the etching process, which involves removing layers of material from the surface of the wafers. Hydrogen can be used as a selective etchant, which means that it only removes specific materials from the surface of the wafers. This can help improve product quality and reduce the amount of waste generated during the manufacturing process.

- Doping: Hydrogen can also be used in the doping process, which involves introducing impurities into the semiconductor material to modify its electrical properties. Hydrogen can be used as a carrier gas to introduce the impurities into the semiconductor material, leading to improved performance and efficiency.

Frequently Asked Questions (FAQ):

How is hydrogen used in the semiconductor industry?

Hydrogen is used in the semiconductor industry for various purposes, such as plasma cleaning and etching processes to remove contaminants and create precise patterns on semiconductor surfaces. It is also used in annealing processes to activate dopants and repair crystal lattice defects, enhancing the electrical properties of semiconductor materials.

Which gases are used in semiconductor industry?

The semiconductor industry uses several gases, including hydrogen, nitrogen, oxygen, argon, helium, and fluorine-based gases. These gases are employed for various processes such as cleaning, etching, deposition, and doping in the fabrication of semiconductor devices.

How is hydrogen used in semiconductor manufacturing?

Hydrogen is used in semiconductor manufacturing for processes like plasma cleaning and etching, surface passivation, and reducing oxide layers. It plays a critical role in maintaining clean and controlled environments during semiconductor fabrication, ensuring high-quality device performance.

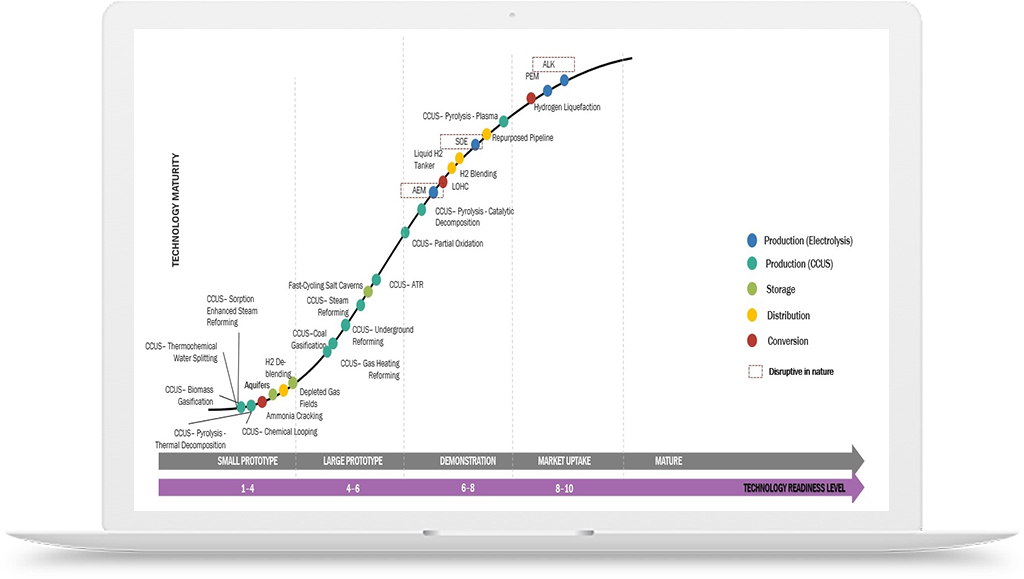

What is the most mature technology available for hydrogen storage?

Compressed gas storage is currently the most mature technology available for hydrogen storage, with well-established infrastructure and a long history of industrial use. It involves storing hydrogen gas in high-pressure tanks, making it a widely adopted and practical method for various applications.