Hydrogen Storage and Transportation Technologies

Hydrogen Storage and Transportation Technologies - Cost and Supply Chain Analysis

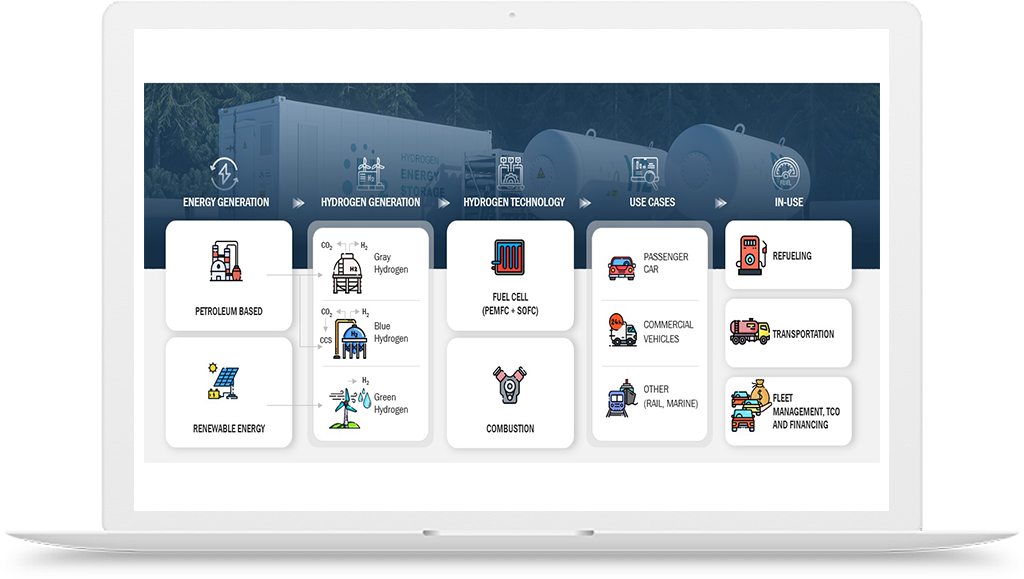

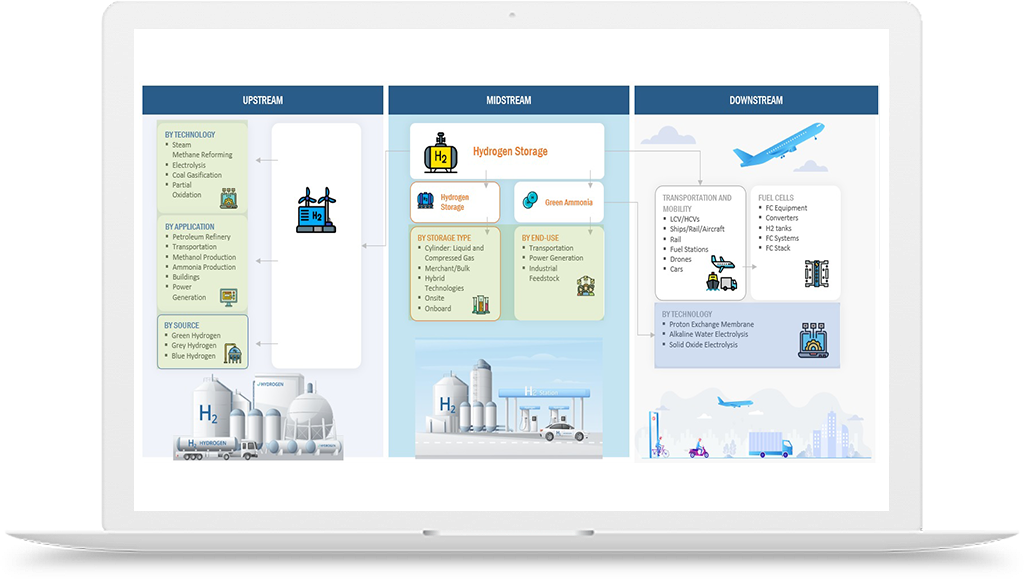

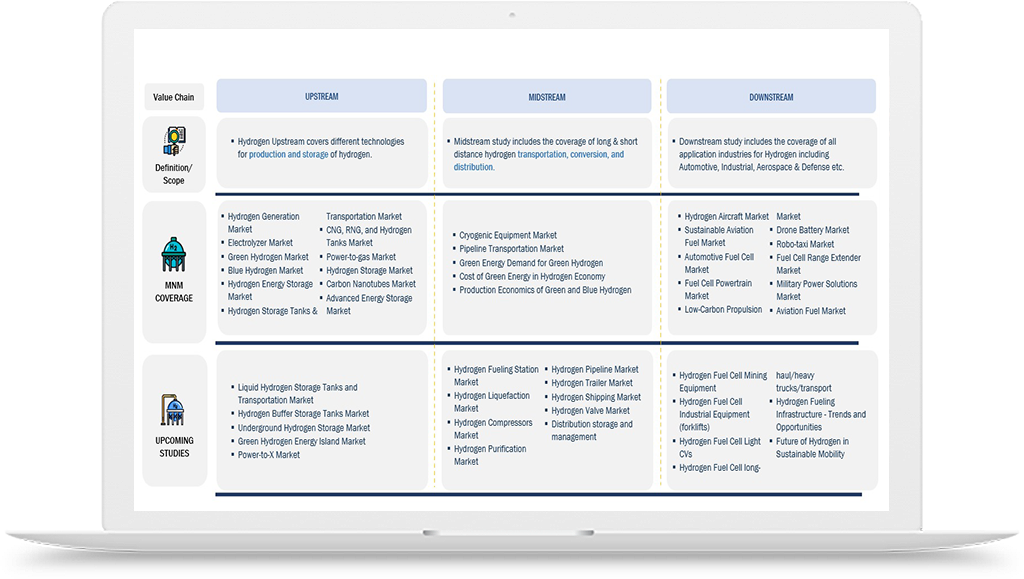

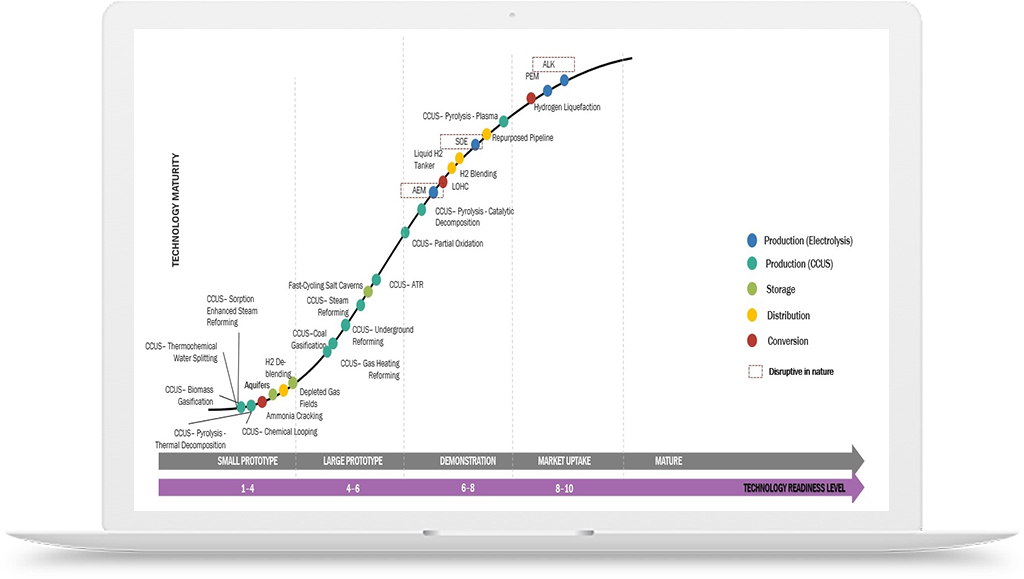

Current and evolving hydrogen storage and transportation technologies aim to address the challenges of storing and transporting hydrogen efficiently and safely.

In this field, the following are some noteworthy technologies:

- Compressed Gas Storage:Compressed gas hydrogen can be kept in high-pressure tanks or cylinders. Normally, the gas is compressed to 350–700 bar of pressure. For small-scale uses, such industrial and hydrogen refueling stations, compressed gas storage is a well-established technique.

- Liquid Hydrogen Storage: At very low temperatures (-253°C or 20 K), hydrogen can be liquefied. One may store more hydrogen in a given container by using liquid hydrogen since it has a higher energy density than compressed gas storage. Both large-scale storage at hydrogen production and distribution facilities and aeronautical applications frequently use it.

- Metal Hydride Storage: Hydrogen can be absorbed by metal hydrides, which then release it when heated. The benefit of safe and reversible hydrogen storage is provided by this method. However, compared to compressed gas or liquid hydrogen storage, metal hydrides usually have a lesser hydrogen storage capacity, which restricts their applicability to particular uses.

- Chemical Hydride Storage: Through chemical processes, hydrogen can be stored in chemical hydrides like ammonia (NH3) or organic hydrides. They could provide simpler handling and transportation as well as high-density hydrogen storage. When necessary, chemical hydrides can be transformed back into hydrogen by means of a catalyst or thermal energy.

- Hydrogen Carriers: Chemical substances that have the ability to release hydrogen on demand are known as hydrogen carriers. One illustration is the use of reversible hydrogenation and dehydrogenation to store hydrogen in liquid form using liquid organic hydrogen carriers (LOHC). Hydrogen carriers can make use of the current infrastructure, such as tanker ships and pipelines, and provide the benefit of simpler and safer transportation.

Cost effectiveness is dependent on a number of variables, including the size of the transportation or storage system, the maturity of the technology, and the demands of the particular application. Currently, liquid hydrogen storage is frequently used in larger-scale storage facilities due to its higher energy density, whereas compressed gas storage is more economical for smaller-scale applications. Ongoing developments and economies of scale, however, should result in lower costs for cutting-edge technologies like hydrogen carriers and chemical hydrides.

Transport and storage technologies for hydrogen relate to the systems and procedures used to move and store hydrogen gas, which is a flexible and clean energy source. Because of its high energy content and the fact that its combustion or reaction with oxygen produces only water vapor as a byproduct, hydrogen is seen as a promising energy source for a variety of uses, including fuel cells for power production, industrial processes, and transportation.

For hydrogen to be widely used as a clean and sustainable energy source, these storage and transportation technologies must be developed and improved. Scientists and engineers are still investigating novel materials and techniques to improve the economic viability, safety, and efficiency of hydrogen storage and transportation systems.

To incorporate these technologies into the existing hydrogen supply chain, a number of factors need to be taken into account:

- Infrastructure Development: Pipelines, storage tanks, and refueling stations are examples of storage and transportation infrastructure that needs to be built or modified to support the particular storage and transportation strategies selected.

- Safety and Regulatory Compliance: To guarantee the safe handling, storage, and transit of hydrogen in its many forms, strict safety protocols and laws must be in place.

- System Integration: It is imperative that the storage and transportation technologies are smoothly incorporated into the current supply chain, taking into account aspects such as equipment and infrastructure compatibility.

- Logistics and Distribution Planning: To transfer hydrogen from production facilities to end-use applications efficiently, optimal logistics and distribution networks must be established, taking into account considerations such as distance, demand, and storage requirements.

In order to overcome the technological, financial, and legal obstacles, infrastructure developers, legislators, and industry players must work together to integrate these technologies into the present supply chain.