Hydrogen Storage Solutions

TOP 10 OPPORTUNITIES IN HYDROGEN STORAGE SOLUTIONS

Explore the top high growth opportunities in Hydrogen Storage Solutions Industry Now!

- What are the top 10 high growth opportunities in hydrogen storage solutions economy?

- How to target companies, and what are their top use-cases?

- How can businesses capitalize on these top 10 high growth opportunities in hydrogen storage solutions to propel their growth?

- Who are the top players in the Hydrogen Storage Solutions Industry?

- How can businesses stay ahead of the curve in hydrogen storage solutions economy?

Get deep dive analysis on each one of the above points: ACCESS REPORT

Read More..

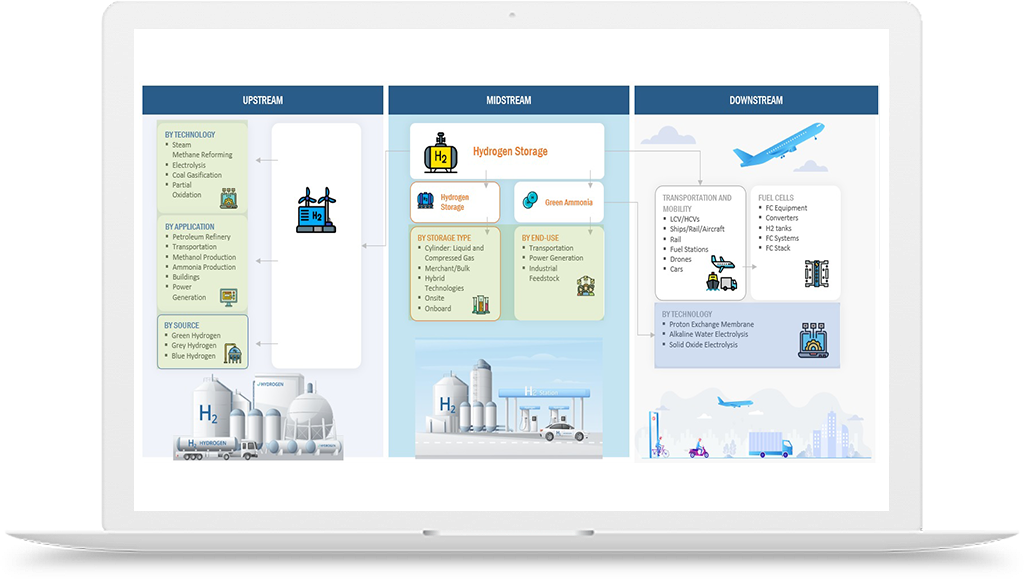

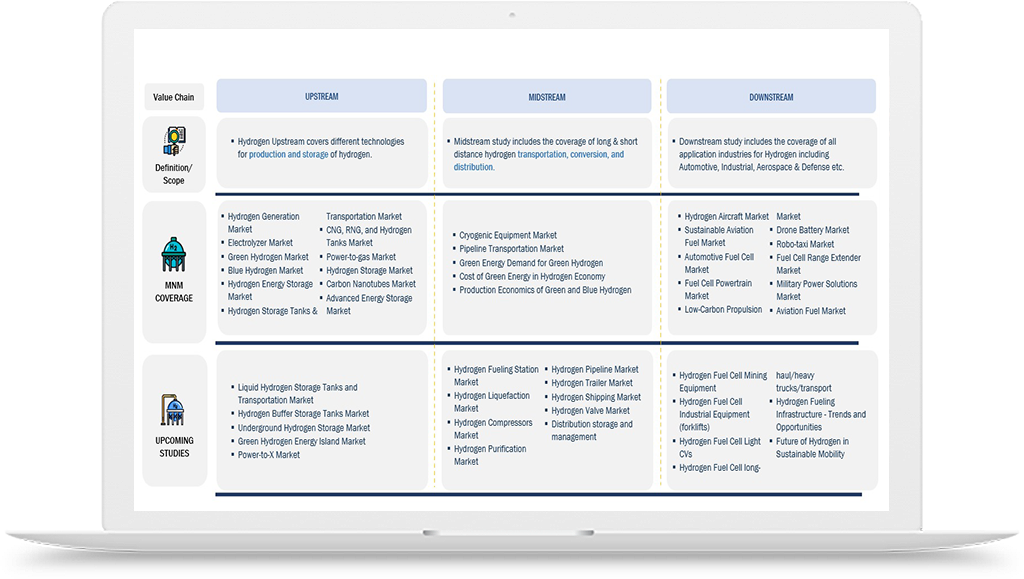

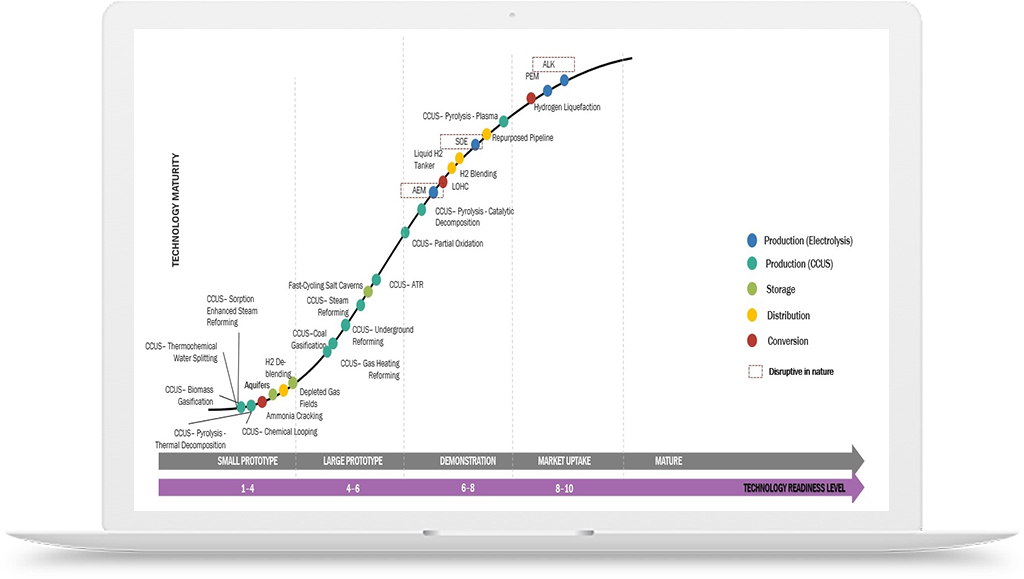

An essential element of the hydrogen economy is hydrogen storage. Hydrogen needs to be stored at high pressure, low temperature, or in a solid-state material because of its low density and high flammability.

There are various hydrogen storage solutions available, and each has its own set of advantages and disadvantages. In this response, we will discuss the different types of hydrogen storage solutions, their characteristics, and their applications.

-

Metal Hydride Storage

Metal alloys with the ability to absorb and release hydrogen gas are used in metal hydride storage. Aluminum, titanium, or magnesium are common lightweight metals used to make metal alloys. Metal hydride storage has several benefits, such as low operating pressure, safety, and large storage capacity. The alloys' high cost and requirement for high temperatures to release hydrogen are drawbacks. Backup power systems, tiny fuel cells, and portable electronics are good uses for metal hydride storage.

An essential link in the hydrogen supply chain is hydrogen storage. It makes it possible to produce hydrogen during off-peak times and transport it to the consumption point. The application and the necessary energy density, safety, and cost factors determine which hydrogen storage solution is best. The goal of ongoing research and development is to lower the cost and increase the efficiency of hydrogen storage.

Hydrogen energy storageHydrogen energy storage has come to light as a viable way to deal with the intermittent nature of renewable energy sources in the quickly changing field of renewable energy. The promise of hydrogen energy storage is examined in this article, as is its potential to influence the development of sustainable energy systems in the future.

The capacity of hydrogen energy storage to store excess energy produced during periods of peak production is one of its main benefits. Hydrogen can be stored for long periods of time without experiencing a significant loss of energy, unlike traditional batteries. Because of this property, hydrogen energy storage is a practical solution for reducing the oscillations in the production of renewable energy. Furthermore, hydrogen's adaptability makes it useful in a variety of applications, including industrial processes and transportation, underscoring its potential as a flexible and scalable energy storage technology.

Hydrogen transportation methodsThe quest for cleaner and sustainable transportation has led to a growing interest in hydrogen as a fuel. This article explores the diverse landscape of hydrogen transportation methods, delving into the innovative technologies and solutions that are shaping the future of eco-friendly mobility.

Hydrogen transportation methods encompass a range of technologies, each with its own set of advantages and challenges. One prominent method involves the use of fuel cell vehicles, where hydrogen is converted into electricity to power electric motors. This method has gained traction for its zero-emission profile and potential for long-range travel. Additionally, hydrogen can be stored and transported in liquid or gaseous form, providing flexibility in distribution and fueling infrastructure. The versatility of hydrogen transportation methods makes them a compelling solution for reducing carbon emissions in the transportation sector.

Liquid hydrogen storageIn order to store liquid hydrogen, the gas must first be cooled to its boiling point (-253?°C), at which point it is placed in insulated tanks. The energy density of liquid hydrogen storage is higher than that of compressed hydrogen storage. Cryogenic temperatures are necessary, though, so the tanks must be well insulated to prevent boil-off and venting. Although liquid hydrogen storage is frequently utilized in space applications and certain specialized applications, like high-performance automobiles, it is not appropriate for widespread use because of its complexity and high cost.

Solid state hydrogen storageWith the goal of improving the effectiveness and safety of hydrogen fuel cell technologies, researchers are looking into novel materials for solid state hydrogen storage.

A major advancement in resolving the issues with conventional gas-based storage techniques is the creation of solid state hydrogen storage systems.

Recent advances in engineering have shown that lightweight, compact solid state hydrogen storage solutions are feasible, opening the door for further developments in portable energy storage applications.

High pressure hydrogen storageHigh pressure hydrogen storage systems, which provide a small and useful solution for a range of applications, are essential to the effective use of hydrogen as a clean energy source.

Strong containers made for high pressure hydrogen storage have been developed as a result of recent developments in materials science, guaranteeing the efficient and secure storage of this essential energy source.

With an eye toward realizing the full potential of hydrogen as a sustainable fuel source, engineers are actively investigating new technologies to enhance the efficiency and dependability of high pressure hydrogen storage.

hydrogen storage materialsResearchers in materials science are studying a wide range of compounds and structures to improve hydrogen storage capabilities, all in an effort to find effective and useful hydrogen storage materials.

In order to safely and effectively store hydrogen and pave the way for the development of clean energy technologies, innovations in hydrogen storage materials are essential.

The creation of innovative materials for hydrogen storage is at the forefront of our search for sustainable energy solutions; these materials have the potential to completely change the way we store and use hydrogen as a clean, renewable energy source.

Hydrogen fuel storageScientists and engineers are working hard to improve the efficiency and safety of hydrogen fuel storage technologies because they are critical to the future of sustainable energy.

Modern research is concentrated on creating cutting-edge materials and technologies for hydrogen fuel storage with the goal of producing storage options that are both environmentally and financially sustainable.

The design and optimization of hydrogen fuel storage systems are critical components in the search for sustainable energy sources, as they have the potential to revolutionize the way we store and use hydrogen.

Hydrogen fuel cell storageAt the forefront of clean energy innovations, hydrogen fuel cell storage technologies offer a dependable and sustainable way to store and use hydrogen in a variety of ways.

Scholars are making noteworthy progress toward the integration of hydrogen as a feasible energy source, tackling major obstacles, and creating economical and effective hydrogen fuel cell storage systems.

Hydrogen fuel cell storage holds great potential for transforming the renewable energy sector by providing an eco-friendly and scalable means of storing excess energy and promoting the wider use of hydrogen-based technologies.

Hydrogen storage and transportationTo fully realize hydrogen's potential as a clean energy source and ensure its smooth integration into a variety of industries, advancements in hydrogen storage and transportation technologies are essential.

Scientists are investigating novel approaches to hydrogen storage and transportation with the goal of creating effective and secure systems that can support the broad adoption of hydrogen as an environmentally friendly fuel source.

In order to create a strong hydrogen economy and support the shift to a more sustainable and environmentally friendly energy landscape, it is imperative that transportation infrastructure be integrated with dependable and reasonably priced hydrogen storage.

Underground hydrogen storageIn order to handle the difficulties caused by seasonal variations in the production of renewable energy, underground hydrogen storage offers a dependable and expandable method of storing excess hydrogen.

Using geological formations like salt caverns or depleted gas fields, underground hydrogen storage provides an economical and space-efficient way to store large amounts of hydrogen for future energy needs.

A crucial technology in our pursuit of sustainable energy solutions is underground hydrogen storage, which uses the earth's subsurface to store hydrogen safely and permanently while fostering the growth of an environmentally friendly and resilient energy infrastructure.

Hydrogen energy storage systemIn order to address the intermittent nature of renewable energy sources and provide a sustainable means of storing and utilizing excess energy, it is imperative that a reliable and effective hydrogen energy storage system be developed.

Systems for storing and integrating hydrogen energy are becoming more and more popular. They enable the storage of renewable energy and the smooth integration of hydrogen into a variety of industries, including transportation and industrial applications.

The performance of hydrogen energy storage systems is being actively optimized by engineers and researchers with the goal of developing dependable and affordable solutions that can be essential in the shift to a greener and more sustainable energy future.

Hydrogen production and storageIn order to create a comprehensive and effective hydrogen economy and accelerate the shift to cleaner and more sustainable energy systems, cutting-edge technologies for hydrogen production and storage must be integrated.

Current research endeavors are directed towards augmenting the cooperative relationship between hydrogen production and storage, investigating novel approaches to maximize effectiveness, and tackling the obstacles linked with extensive implementation.

To achieve carbon neutrality and realize the full potential of hydrogen as a clean energy carrier, renewable energy sources must be seamlessly integrated with state-of-the-art hydrogen production and storage solutions.

Solid hydrogen storageSolid hydrogen storage technologies are becoming more and more popular because they have the ability to solve problems with conventional gaseous storage techniques and provide a portable and secure hydrogen storage option.

Researchers are working to improve the efficiency and dependability of solid-state storage systems by investigating new compounds and structures in the development of novel materials for solid hydrogen storage.

The investigation of solid hydrogen storage, which offers a flexible and high-density storage option for a variety of applications, from transportation to stationary energy storage, represents a promising avenue as the market for clean energy solutions expands.

Hydrogen power storageWhen it comes to renewable energy, hydrogen power storage is revolutionary because it provides a flexible and effective way to store excess energy produced by variable sources.

In order to create resilient and sustainable energy grids and enable the seamless integration of hydrogen as a key player in the transition to clean energy, advanced hydrogen power storage technologies must be integrated.

The performance of hydrogen power storage systems is being meticulously improved by researchers, opening the door for scalable and reasonably priced solutions that could be essential to the development of renewable energy infrastructure in the future.

Hydrogen storage companiesIn order to meet the increasing demand for effective and sustainable storage solutions, a number of hydrogen storage companies are leading the way in innovation and creating cutting-edge technologies.

Research institutes and hydrogen storage companies working together is propelling storage technology forward and creating a competitive environment that speeds up the creation of scalable and dependable hydrogen storage solutions.

Hydrogen storage companies, which provide a wide range of solutions tailored to the specific storage requirements of different sectors, are playing a crucial role in shaping the future of the industry as the hydrogen economy grows.

- Hexagon Purus

- McPhy Energy

- NEL Hydrogen

- Linde plc

- Air Liquide

- Hydrogenious LOHC Technologies

- Advent Technologies

- Cella Energy

By offering cutting-edge methods for storing and using hydrogen as a clean, sustainable energy source, companies that specialize in hydrogen energy storage are fostering innovation in the renewable energy market.

Research organizations and hydrogen energy storage companies must work together to push technological boundaries and create reliable and effective storage systems that support the expansion of the hydrogen economy.

The advent of hydrogen energy storage companies marks a paradigm shift in the energy sector, as a range of innovative solutions are being developed to address the increasing need for adaptable and dependable energy storage alternatives.

- Hydrogenics (a Cummins Company)

- ITM Power

- Siemens Energy

- Nel Hydrogen

- Green Hydrogen Systems

- McPhy Energy

- Enapter

- Plug Power

- Advent Technologies

The advancement of sustainable energy practices depends on the development of green hydrogen storage solutions, with an emphasis on the storage and utilization of hydrogen produced using ecologically friendly processes.

In order to achieve carbon neutrality, green hydrogen storage technologies are essential because they provide a means of storing renewable energy and encourage the widespread use of green hydrogen as a clean fuel source.

Investments in green hydrogen storage research and development are increasing in response to the growing demand for environmentally friendly energy storage, which helps to build a more sustainable and environmentally friendly energy infrastructure.

Compressed hydrogen storageOne of the most popular and extensively used methods for storing hydrogen is compressed hydrogen storage. Hydrogen gas is compressed and kept in high-pressure tanks using this method. Metal or composite materials can be used to make the tanks. Higher pressures result in more storage capacity; the storage pressure ranges from 350 to 700 bar. Refueling stations, industrial processes, and backup power sources are examples of stationary applications that can benefit from compressed hydrogen storage. Unfortunately, the tanks' large size and weight prevent them from being used in mobile applications.

Hydrogen battery storageSystems for storing and effectively using hydrogen as a clean, renewable energy source are starting to take shape. These systems are known as hydrogen battery storage systems.

Researchers are looking into how hydrogen battery storage, which provides a portable and adaptable way to store and release hydrogen, might transform portable energy solutions.

Innovative hydrogen battery storage technologies are changing the renewable energy scene by offering a scalable and sustainable way to store excess energy produced from different sources.

Cryogenic hydrogen storageBy storing hydrogen at extremely low temperatures, a novel technique known as cryogenic hydrogen storage opens up new possibilities for dense and effective hydrogen storage.

In order to overcome the difficulties associated with volumetric density, engineers are investigating the possibilities of cryogenic hydrogen storage systems, which provide a high-density storage option that can aid in the creation of a reliable hydrogen infrastructure.

Advances in the use of hydrogen as a clean and sustainable energy carrier are made possible by the application of cryogenic hydrogen storage technologies, which are gaining attention for their capacity to offer a compact and energy-dense storage solution.

Low pressure hydrogen storageLow pressure hydrogen storage systems are becoming more and more popular as a sensible and secure option that offers an affordable substitute for storing hydrogen in a variety of applications.

In order to maximize the efficiency and dependability of low pressure hydrogen storage and make it a feasible alternative for decentralized energy storage, novel materials and engineering solutions must be developed.

The benefits of low pressure hydrogen storage become clear as we examine various methods of storing hydrogen; it provides an adaptable and affordable way to incorporate hydrogen into a variety of energy systems.

ahydrogen compression and storageTechnologies for compressing and storing hydrogen are essential to maximizing its use and transportation, providing economical and practical solutions for a range of sectors.

In order to solve the issues related to hydrogen transportation, it is imperative that state-of-the-art hydrogen compression and storage systems be integrated. This will allow for safe and compact storage at various stages of the supply chain.

Advances in hydrogen compression and storage are being actively pursued by researchers in an effort to improve the efficiency and economics of systems that may aid in the general use of hydrogen as a clean energy source.

Hydrogen storage methodsIn order to meet the increasing demand for clean energy solutions, it is imperative to investigate a variety of hydrogen storage methods. Researchers are currently looking into creative and efficient ways to store hydrogen.

At the forefront of clean energy research is the optimization of hydrogen storage methods, with the goal of creating adaptable and affordable solutions that can meet the particular needs of various industries.

The development of reliable hydrogen storage methods is essential as the hydrogen landscape changes because it will open the door to a sustainable energy future and the widespread use of hydrogen as a clean fuel source.

Chemical hydrogen storageUtilizing chemical substances that, when activated, can release hydrogen gas is known as chemical hydrogen storage. The substances include sodium borohydride, ammonia borane, and formic acid. They can be inorganic or organic. Chemical hydrogen storage has several benefits, such as a large storage capacity, low operating pressure, and portability. The compounds' drawbacks include their high cost, the need for a catalyst to release hydrogen, and the production of byproducts. Small fuel cells, backup power systems, and portable electronics can all benefit from chemical hydrogen storage.

Hydrogen storage systemFor hydrogen to be widely used as a clean energy carrier, a dependable and effective hydrogen storage system must be developed.

In order to meet the various needs of various industries, engineers are actively designing and optimizing hydrogen storage systems, providing scalable and affordable solutions for the storage and utilization of hydrogen.

Green hydrogen energy storageGreen hydrogen energy storage provides a flexible and environmentally responsible way to capture and use green hydrogen, making it a sustainable option for storing renewable energy.

Advanced technology must be incorporated into green hydrogen energy storage systems in order to build a robust, carbon-neutral energy infrastructure that can store excess energy produced by renewable sources.

In an effort to position green hydrogen energy storage as a major player in the shift to a cleaner and more environmentally friendly energy landscape, researchers and engineers are working together to maximize the efficiency and scalability of this technology.

Fuel cell based energy storageFuel cell based energy storage systems are a dependable way to collect and use extra electricity from renewable sources since they provide an efficient and sustainable way to store and retrieve energy.

Fuel cell based energy storage technology integration is essential for maintaining grid balance, enabling on-demand power generation, and bolstering the stability of renewable energy sources.

In order to fully realize the potential of fuel cell based energy storage as a flexible and clean energy storage option, engineers and researchers are working hard to improve the efficiency and affordability of these systems.

Hydrogen storage is a critical component of the hydrogen supply chain. It enables the production of hydrogen at off-peak hours and its transportation to the point of use. The choice of hydrogen storage solutions depends on the application and the required energy density, safety, and cost. Ongoing research and development efforts are focused on improving the efficiency and reducing the costs of hydrogen storage.

Some of the leading companies that specialize in hydrogen storage solutions, includes:

- Air Liquide: Air Liquide offers a range of hydrogen storage solutions, including compressed gas cylinders, bulk storage tanks, and tube trailers.

- Linde: Linde offers a variety of hydrogen storage options, including high-pressure gas cylinders, tube trailers, and cryogenic storage tanks.

- Hexagon Purus: Hexagon Purus specializes in composite high-pressure storage tanks for hydrogen, including Type 4 tanks which are lightweight and durable.

- McPhy Energy: McPhy Energy offers hydrogen storage solutions that include solid-state hydrogen storage and hydrogen refueling stations.

- Plug Power: Plug Power offers hydrogen storage solutions for fuel cells, including metal hydride-based storage solutions.

- Worthington Industries: Worthington Industries offers a range of hydrogen storage options, including compressed gas cylinders and bulk storage tanks.

- Chart Industries: Chart Industries specializes in cryogenic storage tanks for hydrogen, which can store large amounts of hydrogen at low temperatures.

- Hydrogenics: Hydrogenics offers hydrogen storage solutions that include compressed gas cylinders and hydrogen refueling stations.

Hydrogen storage has been one of the major technical challenges in the widespread adoption of hydrogen as a fuel source. Some of the key hydrogen storage problems include:

- Low energy density: Hydrogen has a low energy density per unit volume compared to conventional fuels such as gasoline and diesel. This means that a larger volume of hydrogen is required to store the same amount of energy as conventional fuels.

- Storage at high pressures: Hydrogen needs to be compressed to extremely high pressures in order to achieve the required energy density for practical use. This presents a safety concern, as the high pressure can lead to leaks and explosions.

- Cryogenic storage: Another method of hydrogen storage is to cool it to very low temperatures to achieve a liquid state. However, this requires very low temperatures (-253°C) which makes the storage process complex and costly.

- Material compatibility: Hydrogen can cause embrittlement and corrosion in some materials, so storage tanks and pipelines must be made from materials that are compatible with hydrogen.

- Cost: The cost of hydrogen storage is still relatively high compared to other fuels. The cost of high-pressure tanks, cryogenic storage, and materials that are compatible with hydrogen can add to the overall cost of hydrogen storage.

Addressing these hydrogen storage solutions problems is critical for the widespread adoption of hydrogen as a fuel source. Ongoing research and development efforts are focused on developing new hydrogen storage technologies that are safe, cost-effective, and have high energy density.

Frequently Asked Questions (FAQ):

What are the solutions for hydrogen storage?

Hydrogen can be stored through various methods including compressed hydrogen gas storage, liquid hydrogen storage, and solid-state hydrogen storage using materials like metal hydrides or carbon-based materials. Each method has its advantages and challenges, and the choice depends on factors such as storage duration, space requirements, and safety considerations.

What are 4 ways to store hydrogen?

Four common methods for hydrogen storage are compressed gas storage (high-pressure tanks), liquid hydrogen storage (cryogenic tanks), solid-state storage using metal hydrides, and hydrogen storage in carbon-based materials like graphene or carbon nanotubes. Each method has its own characteristics and considerations for practical implementation.

What is the best material to store hydrogen?

The best material for hydrogen storage depends on factors such as storage capacity, weight, safety, and ease of use. Metal hydrides, such as complex metal hydrides or metal-organic frameworks (MOFs), are promising candidates due to their high hydrogen storage capacity and potential for reversible hydrogen uptake and release.

How much energy is in 1kg of hydrogen?

The energy content of 1 kilogram (kg) of hydrogen is approximately 33.6 kilowatt-hours (kWh) or 120,000 British thermal units (BTU). It has a high energy density, making it an efficient fuel source for various applications.