Emerging Hydrogen Business Models

Emerging Techno-Commercially attractive Hydrogen Business Models - Hydrogen Generation, Hydrogen Storage, and Hydrogen Distribution

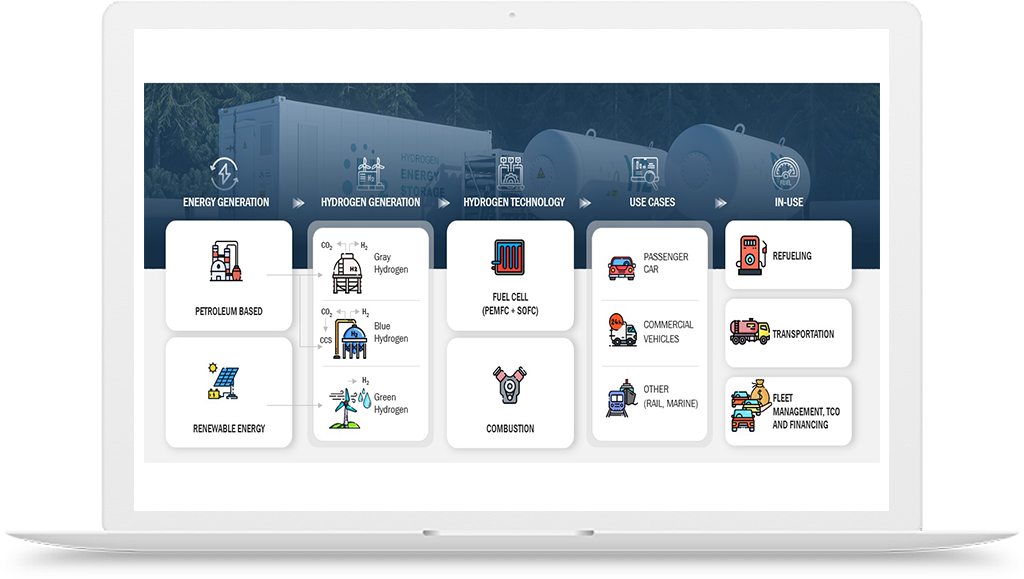

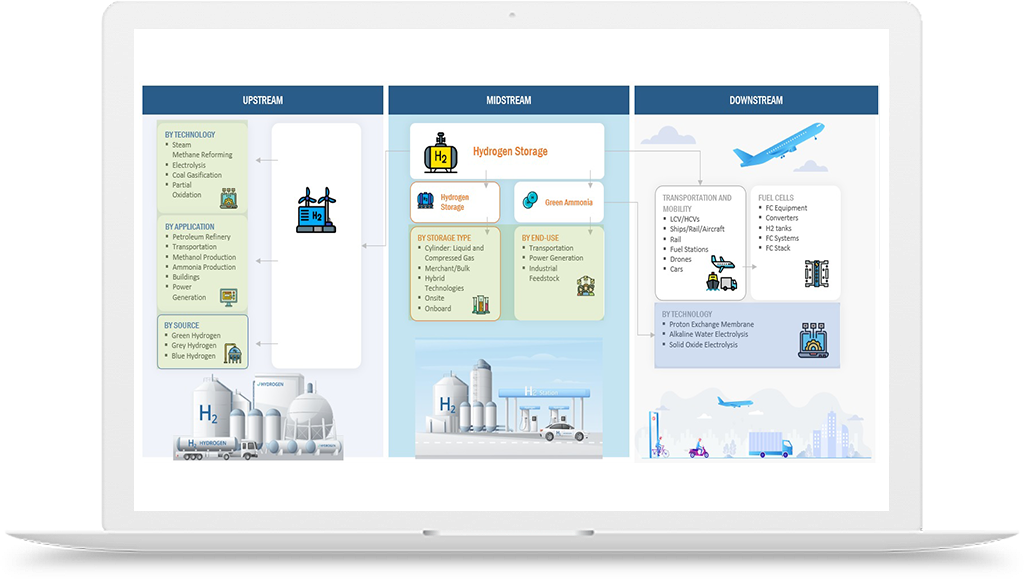

Hydrogen Generation:

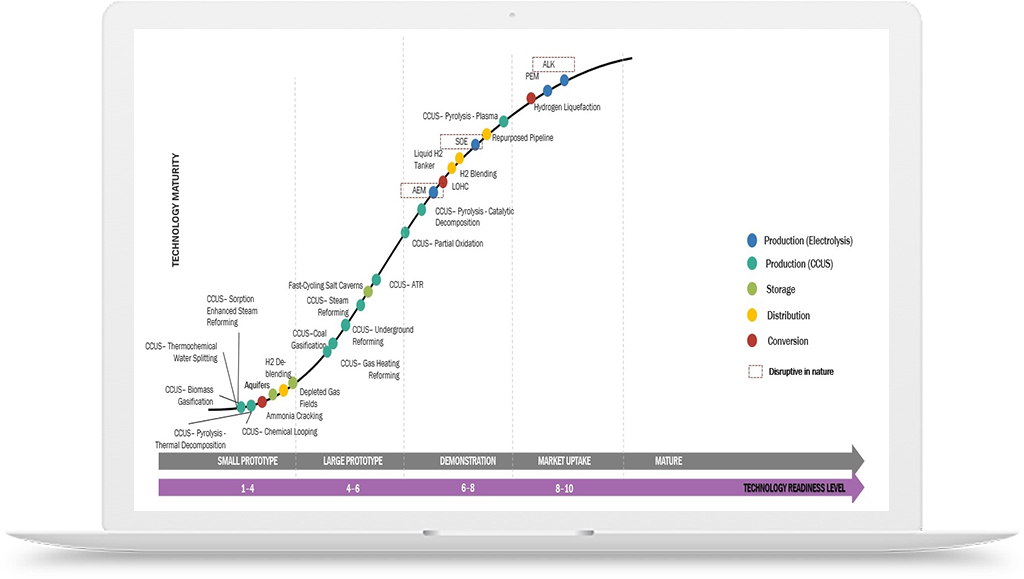

- Steam Methane Reforming (SMR): SMR is currently the most common method for large-scale hydrogen production, accounting for the majority of global hydrogen supply. It involves reacting natural gas (methane) with steam to produce hydrogen and carbon dioxide. SMR is a mature technology and has well-established infrastructure. However, it is associated with greenhouse gas emissions unless carbon capture and storage (CCS) technologies are employed.

- Electrolysis: Electrolysis is a promising method for hydrogen generation, particularly when powered by renewable energy sources. It involves using electricity to split water into hydrogen and oxygen. There are different types of electrolyzers, including alkaline, polymer electrolyte membrane (PEM), and solid oxide electrolysis cells (SOEC). Electrolysis offers the advantage of producing hydrogen without carbon emissions, making it suitable for clean hydrogen production. The costs of electrolyzers are gradually decreasing, making electrolysis more commercially attractive.

- Biomass Gasification: Biomass gasification is a thermochemical process that converts biomass feedstocks into hydrogen-rich gas. This method involves heating the biomass in a controlled environment to produce a mixture of hydrogen, carbon monoxide, carbon dioxide, and other gases. Biomass gasification offers a renewable pathway for hydrogen production, utilizing organic waste materials and agricultural residues. However, it currently represents a smaller portion of the hydrogen production landscape compared to SMR and electrolysis.

Hydrogen Storage:

- Compressed Hydrogen Storage: Compressing hydrogen gas and storing it in high-pressure tanks is a common method for hydrogen storage. Hydrogen can be compressed to pressures ranging from 350 to 700 bar. Compressed hydrogen storage is well-suited for stationary applications and some vehicle refueling stations. The technology is mature, and the infrastructure for compressed hydrogen storage already exists in certain regions.

- Liquid Hydrogen Storage: Hydrogen can be cooled to extremely low temperatures (-253°C) and stored as a liquid in cryogenic tanks. Liquid hydrogen offers higher storage density compared to compressed hydrogen, enabling more efficient use of storage space. However, liquid hydrogen storage requires specialized insulation and handling due to the extremely low temperatures involved. Cryogenic storage is commonly used for space exploration and some niche applications, but the infrastructure for widespread deployment is limited.

- Hydrogen Carriers: Another approach to hydrogen storage is using chemical carriers or materials that can absorb and release hydrogen. One example is ammonia, which can act as a hydrogen carrier and be converted back to hydrogen when needed. Metal hydrides are another option, where hydrogen is chemically bound within metallic materials. Hydrogen carriers can provide a means for safe and compact hydrogen storage and transportation. However, there are challenges related to the efficiency of hydrogen release and the cost-effectiveness of the carrier materials.

Hydrogen Distribution:

- Pipelines: Existing natural gas pipelines can be repurposed to transport hydrogen. However, hydrogen has different material compatibility requirements and can cause embrittlement in some pipeline materials. Thus, modifications or dedicated hydrogen pipelines may be necessary to ensure safe transportation. Hydrogen pipelines are well-suited for continuous and large-scale distribution, particularly for industrial applications.

- Tube Trailers: Hydrogen can be transported in high-pressure tube trailers, similar to compressed gas transportation. These trailers are typically used for shorter distances, such as delivering hydrogen to refueling stations. Tube trailers offer flexibility and can be easily transported between locations, providing a mobile solution for hydrogen distribution.

- Liquid Hydrogen Tankers: For long-distance transportation, liquid hydrogen tankers can be used to transport hydrogen in cryogenic form. Liquid hydrogen tankers are well-suited for large-scale distribution and can carry larger quantities of hydrogen over longer distances. However, the infrastructure for liquid hydrogen transportation is limited compared to traditional oil or gas tankers.

- On-Site Generation: In some cases, hydrogen can be generated directly at the point of use, eliminating the need for long-distance distribution. This approach is particularly beneficial for applications where hydrogen is needed in close proximity to the generation source, such as fueling stations or industrial facilities. On-site generation can reduce the costs and challenges associated with hydrogen transportation and storage.

It's important to note that the attractiveness and viability of these business models depend on various factors, including local energy prices, government policies and incentives, availability of renewable resources, infrastructure development, and technological advancements. The hydrogen sector is rapidly evolving, and the techno-commercial attractiveness of these models may vary depending on specific regional contexts and market conditions. For the latest statistics and insights, it is advisable to consult up-to-date reports and market analyses from reputable sources.